Construction structure and construction method of anchor pile for large-tonnage test pile

A large-tonnage, anchor pile technology, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of conduit influence, complicated lowering process, and damage of prestressed steel strand structure, so as to ensure the quality of forming and structural structure Simplicity, the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

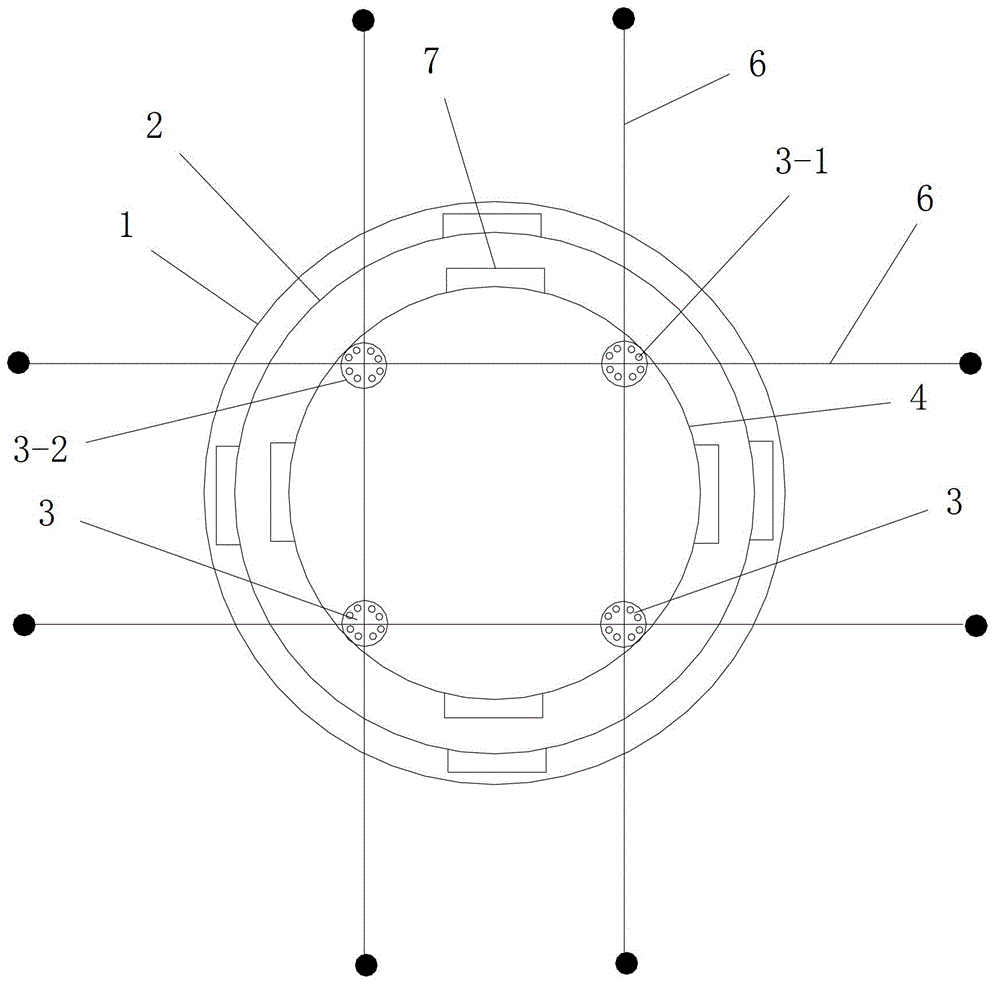

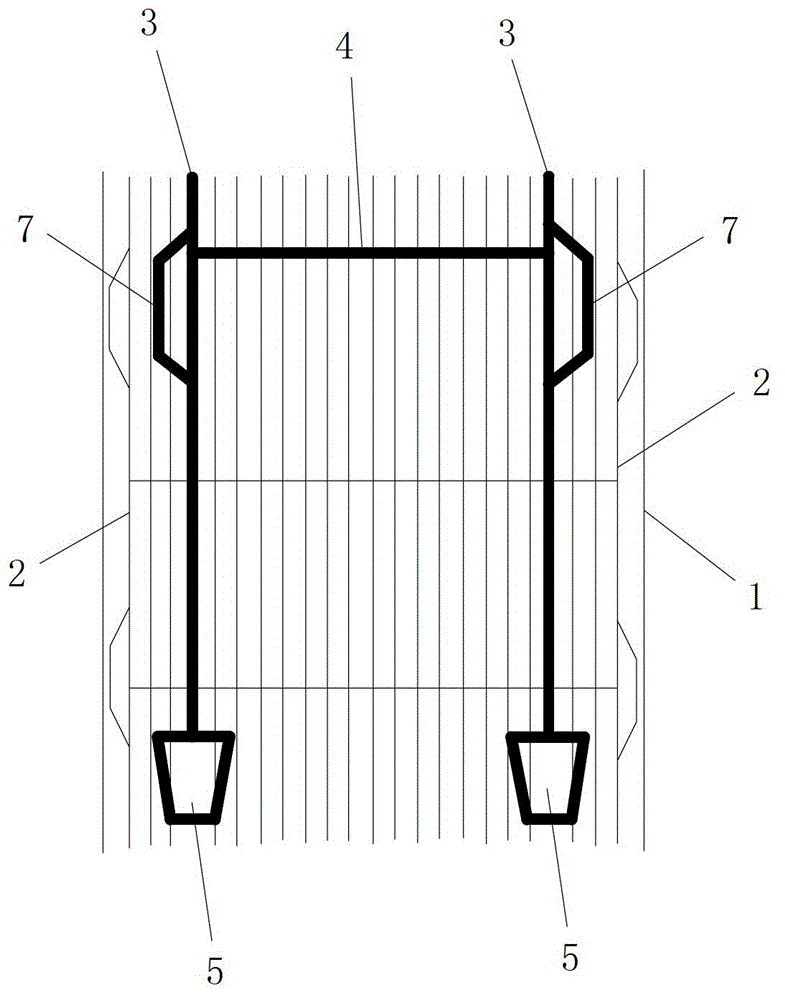

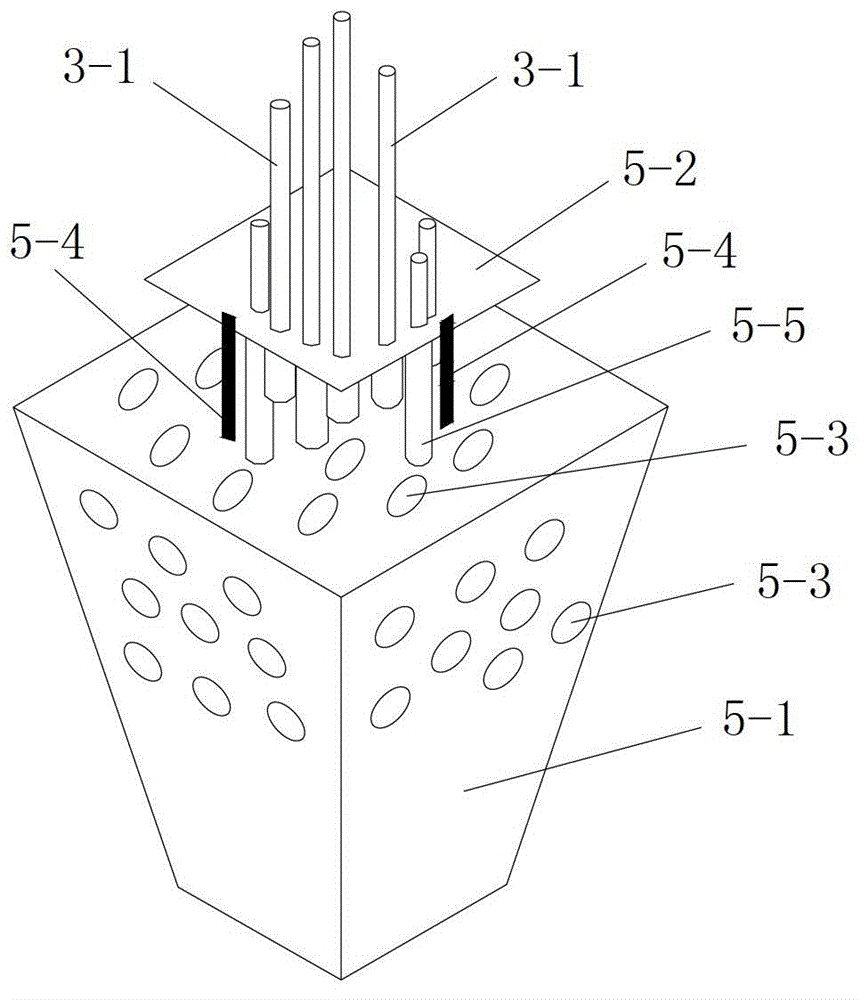

[0050] Such as figure 1 The construction structure of anchor piles for large-tonnage test piles shown includes a pile body reinforcement cage 2 lowered into the pile hole 1 of the constructed anchor pile, a prestressed structure lowered into the pile body reinforcement cage 2 and a The positioning frame on the pile hole 1 and for positioning the prestressed structure, the positioning frame is a horizontal support. The pile holes 1 are arranged vertically, and the cross section of the pile holes 1 is circular. Both the pile body reinforcement cage 2 and the prestressed structure are arranged coaxially with the pile hole 1 . combine figure 2 , the prestressed structure includes a cylindrical steel cage 4 and a plurality of prestressed steel tendons 3 uniformly arranged on the cylindrical reinforced cage 4 along the circumferential direction, and the structure and size of the plurality of prestressed steel tendons 3 are the same. Each of said prestressed steel strands 3 all c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com