Construction method and construction structure for preventing ground subsidence caused by backfill looseness under foundation straining beam

A ground subsidence and construction method technology, applied in the direction of infrastructure engineering, filling, construction, etc., can solve problems such as backfilling is not dense, achieve the effect of reasonable construction structure, ensure construction quality, improve economic performance and safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

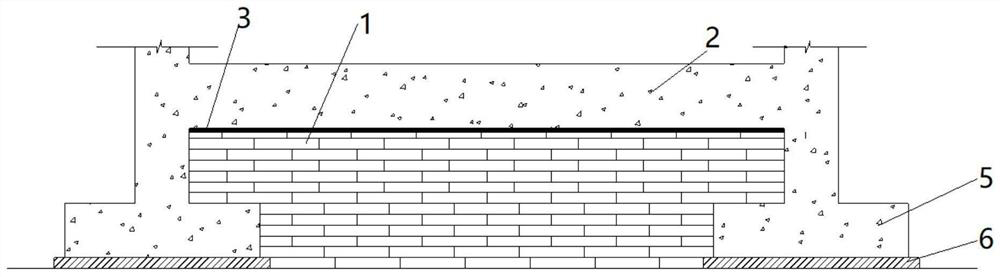

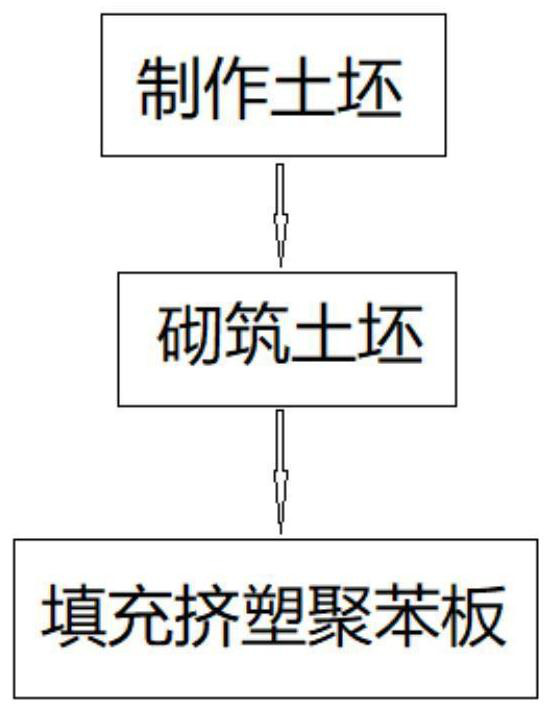

[0033] Construction methods to prevent ground subsidence caused by loose backfilling under foundation tension beams, such as figure 2 , including the following steps,

[0034] At the construction site, the adobe 1 is made by using a billet making machine;

[0035] Masonry the prepared adobe 1 under the foundation tension beam 2, and separate the space of the foundation tension beam 2;

[0036] Make the width of the adobe layer behind the masonry equal to the width of the foundation tension beam 2;

[0037] A gap of preset height is reserved between the bottom of the foundation tension beam 2 and the top of the adobe 1 , and the gap is filled with extruded polystyrene boards 3 .

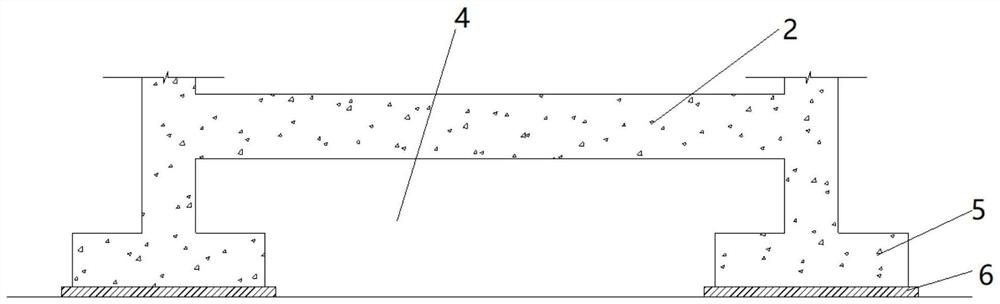

[0038] Construction structures that prevent ground subsidence due to loose backfill under foundation tension beams, such as image 3 , it is constructed by the construction method of the present embodiment that prevents ground subsidence due to loose backfilling under the foundation tension beam. ...

Embodiment 2

[0040] The construction method to prevent ground subsidence due to loose backfilling under the foundation tension beam is similar to that of Example 1, the difference is that when the prepared adobe 1 is laid under the foundation tension beam 2, it is built from bottom to top and from the foundation One side below the tension beam 2 is built by laying bricks or stones to the other side.

[0041] Furthermore, in the construction method of this embodiment to prevent ground subsidence due to loose backfilling under the foundation tension beam, the prepared adobe 1 is built under the foundation tension beam 2, and the upper and lower adjacent two-layer adobe 1 Interval staggered seam distribution.

[0042] At this time, the construction structure to prevent ground subsidence due to loose backfill under the foundation tension beam is constructed through the construction method of this embodiment to prevent ground subsidence due to loose backfill under the foundation tension beam. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com