Asymmetric Aeration Method for Curved Spillways

A spillway, asymmetrical technology, applied in sea area engineering, construction, barrage/weir, etc., to save engineering cost, improve the effect of excessive water surface gradient in bends, and simple construction structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

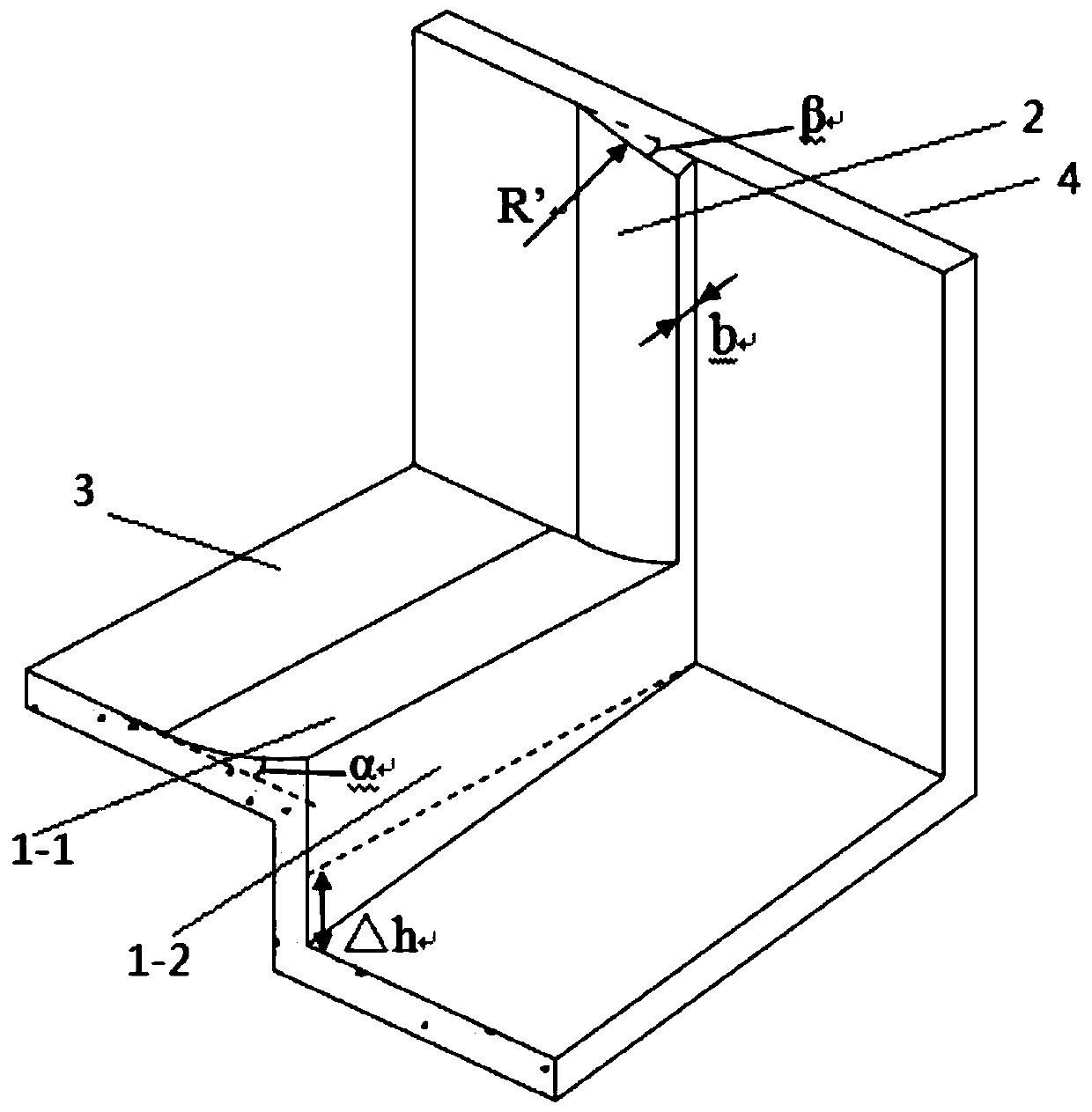

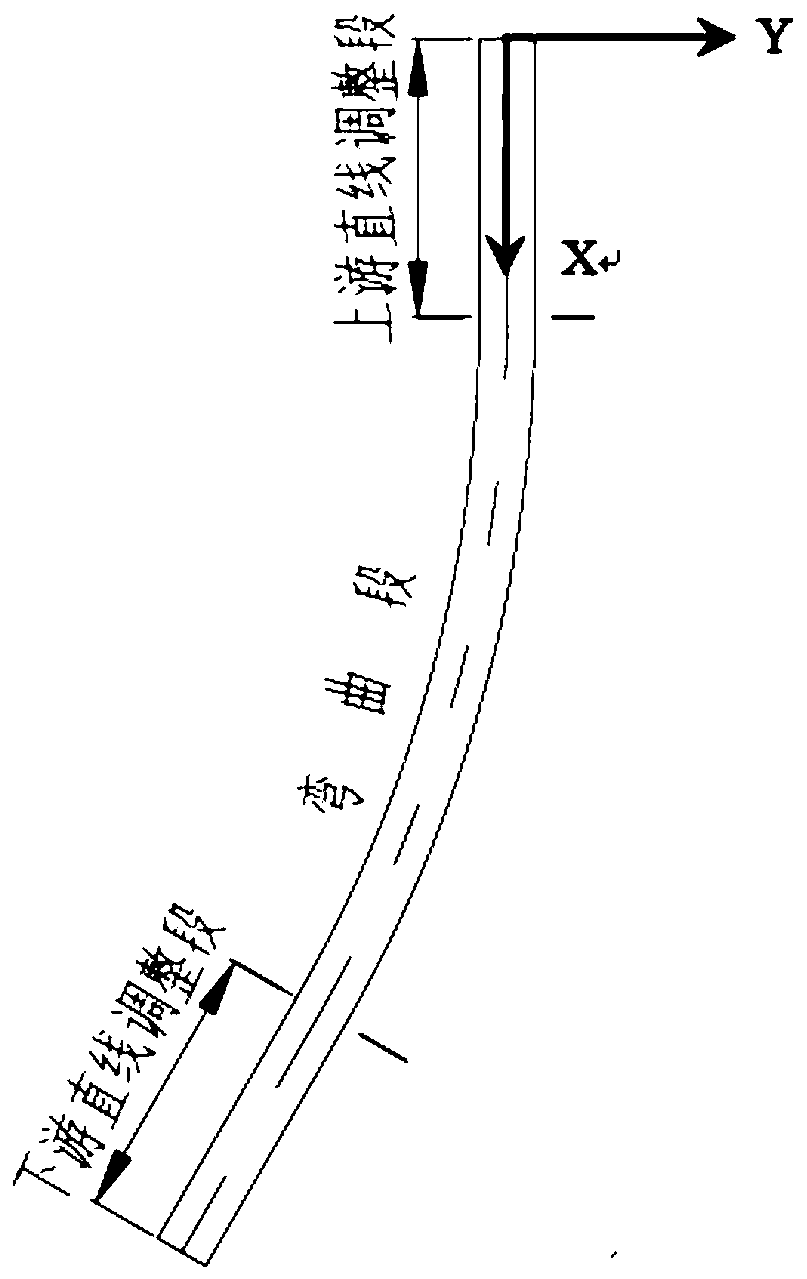

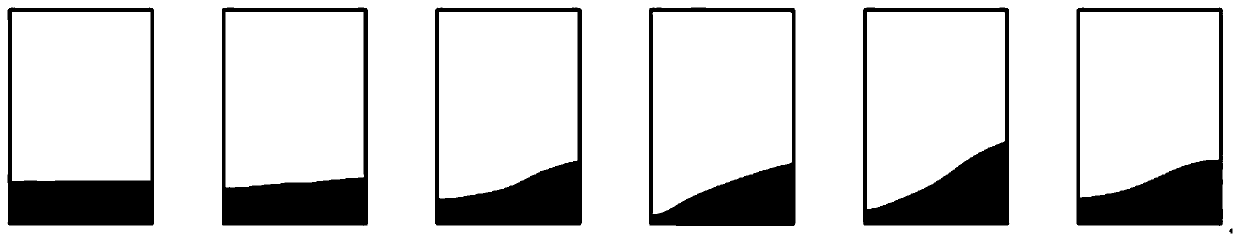

[0029] A spillway is open layout, the turning radius of the curved section is 250m, and the turning angle θ=30°. The spillway has the same width throughout, the width is 10m, and the height of the left and right side walls is about 14m. A 50m straight line adjustment section tangent to the curved section is set upstream of the curved section, and the slope of the bottom plate is i=12°. Using the asymmetric aeration method, the aeration facilities formed are as follows: figure 1 shown. Specifically, an aeration sill 1 is set on the upstream square floor of the curved initial section of the curved spillway, and the aeration sill is connected to the downstream end of the sill by an arc-shaped sill 1-1 that is tangent to the bottom plate 3 of the spillway along the flow direction. The falling sill 1-2 constitutes, and the arc-shaped lateral foot 2 is set on the spillway concave bank wall 4 corresponding to the aeration sill, so that the cross-sectional width of the water flow ch...

Embodiment 2

[0035] The spillway is an open layout, the turning radius of the curved section is 280m, the turning angle θ=30°, there is a 50m straight line adjustment section tangent to the curved section upstream of the curved section, and the slope of the bottom plate is i=9°. The spillway has the same width throughout, the width is 10m, and the height of the left and right side walls is about 15m. Adopt the method with embodiment 1, the aeration facility structure of design is identical, and difference is that each parameter is as follows:

[0036] The aerated sill has an angled bend of α=8°, the height of the concave bank aerated sill from the bottom plate is 2.5m, and the height of the convex bank aerated sill from the bottom plate is 4m. The curved section adopts an inclined floor, and the height difference △h between the edge of the concave bank of the floor and the edge of the convex bank is 1.5m. The angle between the lateral foot of the concave bank and the wall of the concave b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com