A cavitation facility for a stepped overflow dam

An overflow dam and ladder technology, which is applied in sea area engineering, construction, barrage/weir, etc., to achieve the effects of simple construction, accelerated dissipation, and reduced possibility of cavitation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

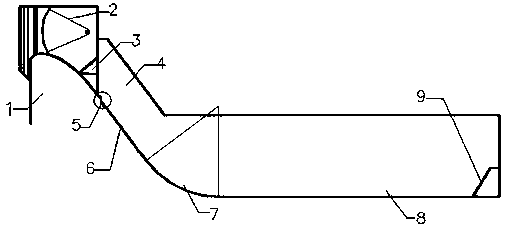

[0026] Example 1: A cavitation facility 5 for a stepped overflow dam is applied to a key water conservancy and hydropower project. The length of the dam crest of the power station is 482 m, the maximum dam height is 132 m, and the single-width flow rate is 150-200 m 3 / s·m in flood discharge and energy dissipation buildings. The flood discharge and energy dissipation structure is composed of the overflow surface hole on the left bank and the flood discharge sand bottom hole. The number of overflow surface holes is 5 holes, and the size of the hole is 13m×20m. It adopts "wide tail pier + ladder + stilling pool" The integrated flood discharge and energy dissipation method adopts the WES weir type, followed by a slope section of 1:0.75, with a total of 29 steps on the dam surface, the steps are 1 m high and 0.75 m wide, and the slope of the dam surface is 53°. and stilling pool.

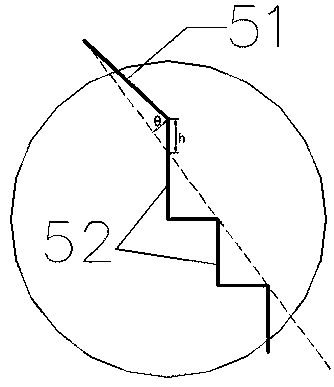

[0027] Its structure is as Figure 6 Shown: including the sill 51 set behind the wide tail pier 3 ...

Embodiment 2

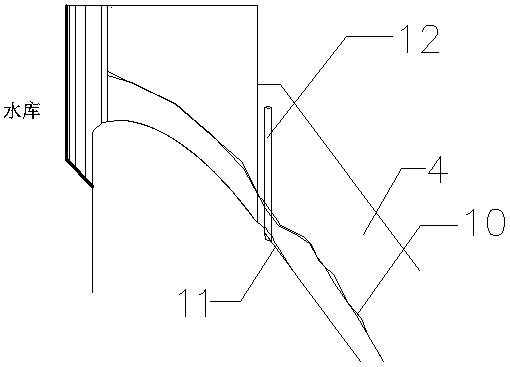

[0030] Example 2: A cavitation facility 5 for a stepped overflow dam is applied to a key water conservancy and hydropower project. The length of the dam crest of the power station is 482 m, the maximum dam height is 132 m, and the single-width flow rate is 100-150 m 3 / s·m in flood discharge and energy dissipation buildings. The flood discharge and energy dissipation structure is composed of the overflow surface hole on the left bank and the flood discharge sand bottom hole. The number of overflow surface holes is 5 holes, and the size of the hole is 13m×20m. It adopts "wide tail pier + ladder + stilling pool" The integrated flood discharge and energy dissipation method adopts the WES weir type, followed by a slope section of 1:0.75, with a total of 29 steps on the dam surface, the steps are 1 m high and 0.75 m wide, and the slope of the dam surface is 53°. and stilling pool.

[0031] Its structure is as Figure 7 , Figure 8 Shown: include the pick-up 51 and the novel tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com