High-strength microcrystalline foamed fireproof and thermal insulation board produced by attapulgite and Guanyin soil and its production process

A microcrystalline foaming and attapulgite technology, which is applied in the directions of heat preservation, fire prevention, and application, can solve the problems of compressive strength limit, limit the use range and safety of plates, and improve strength, safety and service life. , the effect of large application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

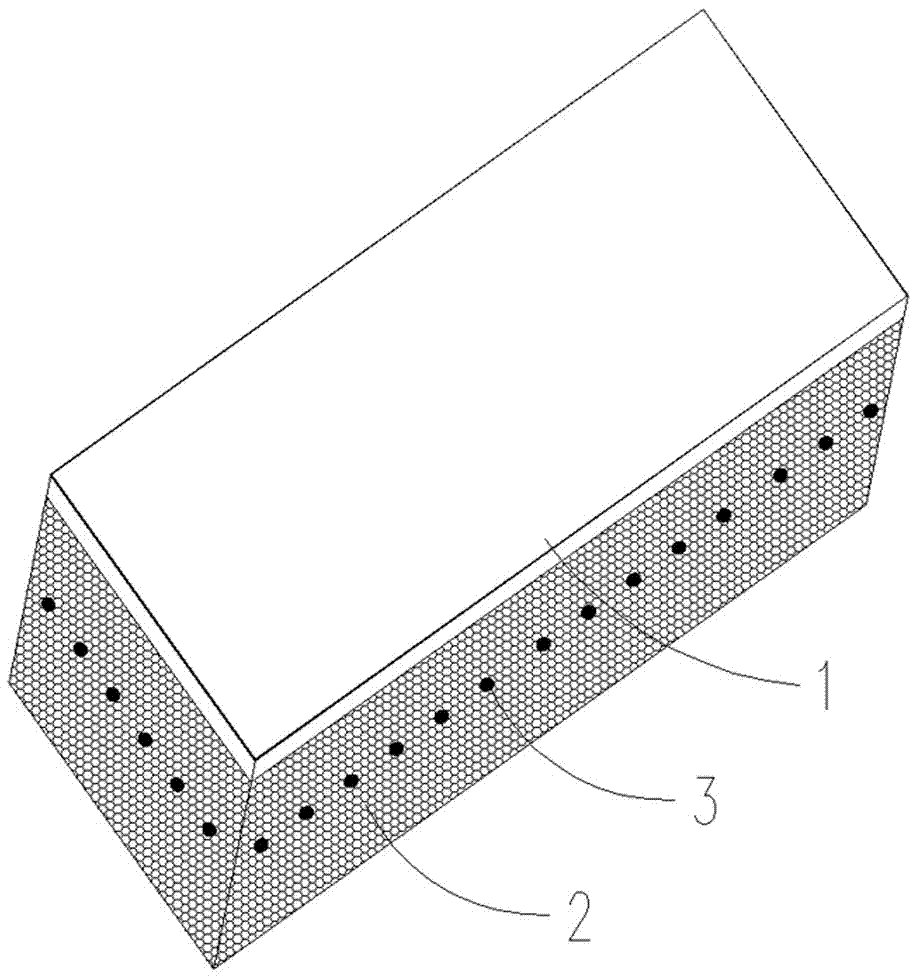

[0040] as attached figure 1 As shown, a high-strength microcrystalline foamed fireproof and thermal insulation panel with pure microcrystalline layer 1 is produced according to the production process of high-strength microcrystalline foamed fireproof and thermal insulation panels produced by using attapulgite and Guanyin clay. The crystal plate layer 1 and the microcrystalline foamed plate layer 2 are fired in one piece at one time; the pure microcrystalline plate layer 1 is made of fine powder mixed with attapulgite clay and Guanyin clay microcrystals, and the surface of the plate is rust red. The structure is dense; the microcrystalline foamed board layer 2 is made of attapulgite and Guanyin soil microcrystalline mixed fine powder, red clay fine powder and limestone fine powder mixed and evenly fired. The interior is honeycomb structure, and the middle is lined with The steel mesh 3 is sintered together with the plate body.

[0041] The microcrystalline foamed board layer 2...

Embodiment 2

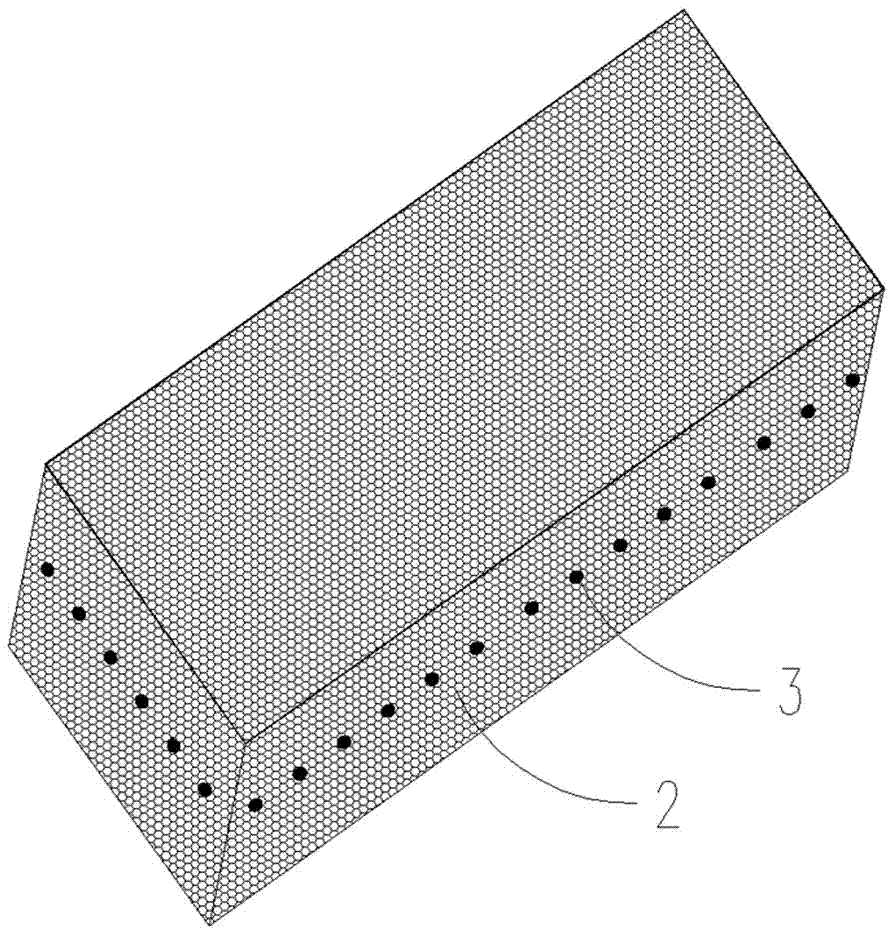

[0045] as attached figure 2 As shown, a high-strength microcrystalline foamed fireproof and thermal insulation board without pure microcrystalline layer 1 is produced according to the production process of high-strength microcrystalline foamed fireproof and thermal insulation panels produced by using attapulgite and Guanyin soil. The board body of the foam board layer 2 is made of mixed fine powder of attapulgite and Guanyin soil microcrystals, red clay fine powder and limestone fine powder, and is evenly fired. The interior is honeycomb structure, and the middle is lined with steel mesh 3 , the steel mesh 3 is sintered together with the plate body.

[0046] The microcrystalline foamed board layer 2 has the following ingredients by weight percentage: attapulgite 70-50%, Guanyin clay 20-10%, red clay 30-20%, limestone 20-10%.

[0047] The steel mesh 3 is made of high-temperature-resistant steel mesh made of iron-linked aluminum alloy, with a melting point greater than 1400°C an...

Embodiment 3

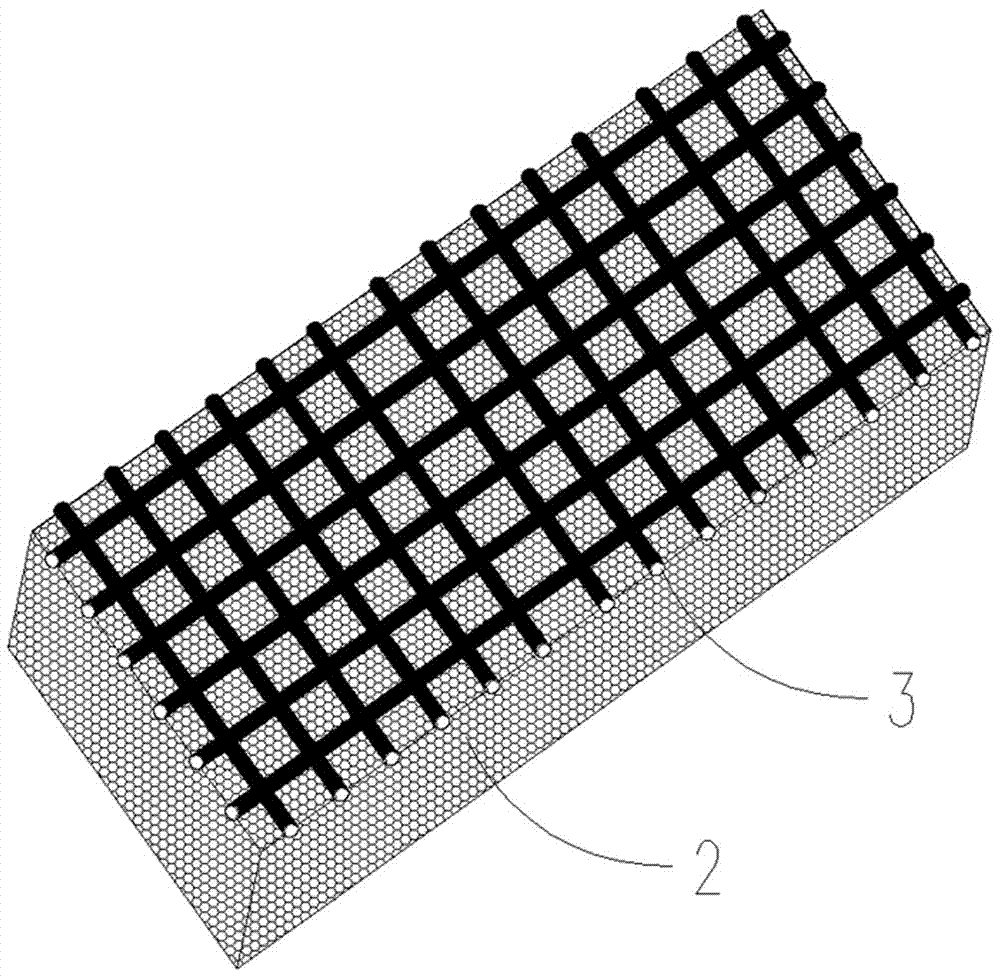

[0050] as attached image 3 As shown, the present invention utilizes attapulgite and Guanyin soil to produce high-strength microcrystalline foam fireproof and thermal insulation panels produced by the production process of high-strength microcrystalline foam fireproof and thermal insulation panels, and the steel mesh in the microcrystalline foam mixed material layer 2 3. Use iron-linked aluminum alloy high-temperature-resistant steel mesh with a melting point greater than 1400°C and a well-shaped shape. The reinforcement strength of steel mesh 3 is

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com