Technology for forming high-viscous material in mould

A forming technology and high-viscosity technology, applied in the field of forming in high-viscosity material molds, can solve the problems of complex production process, inability to meet requirements, poor production effect, etc., to achieve simple operation, meet the needs of quality of life, and good forming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

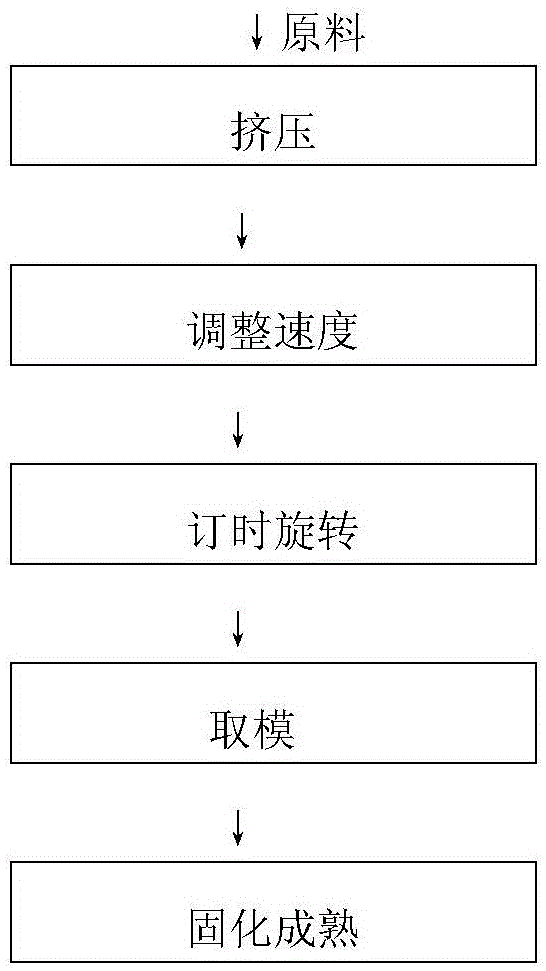

Image

Examples

Embodiment 1

[0019] Embodiment 1: Extrude the food raw materials into the mold according to the amount, then put the mold with the raw materials into the centrifuge, adjust the centrifuge speed at 1000 rpm to a suitable speed, and rotate the centrifuge at a predetermined time until the raw material Evenly distribute in the mold; take out the mold, and cure and mature according to the nature of the food material.

Embodiment 2

[0020] Embodiment 2: Squeeze the ceramic raw material into the mold according to the amount, then put the mold with the raw material into the centrifuge, adjust the centrifuge speed to a suitable speed of 1500 rpm, and rotate the centrifuge at a predetermined time until The raw materials are evenly distributed in the mold; the mold is taken out and solidified and matured according to the properties of ceramic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com