Test mould for preparation of shear thickening glue test piece and using method thereof

A technology of thickening glue and test pieces, which is applied in the field of rheology experiment molds, which can solve the problems of no test molds, slow shear rate, easy deformation, etc., and achieve simple and convenient production and maintenance processes, uniform and stable pressure, and internal structure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

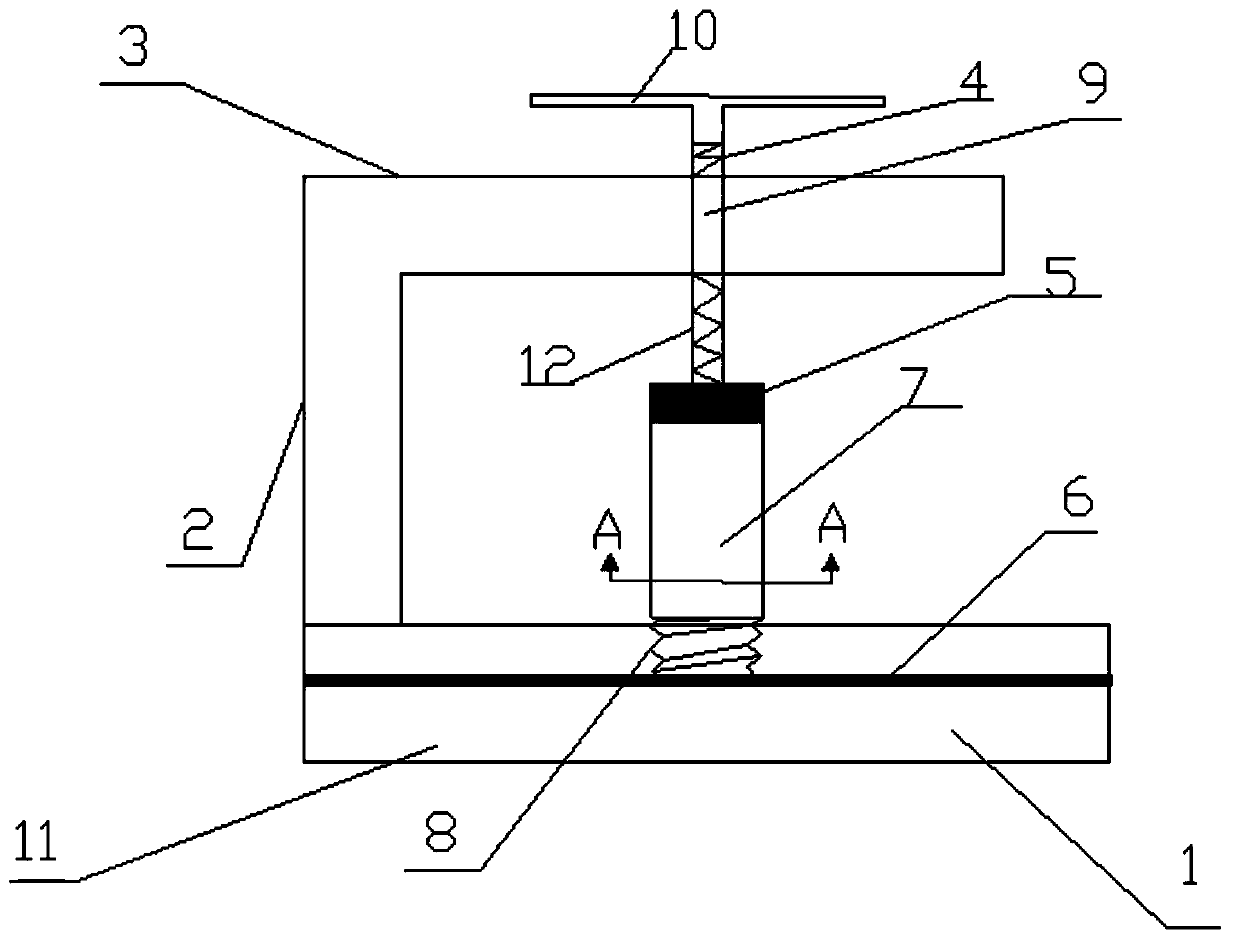

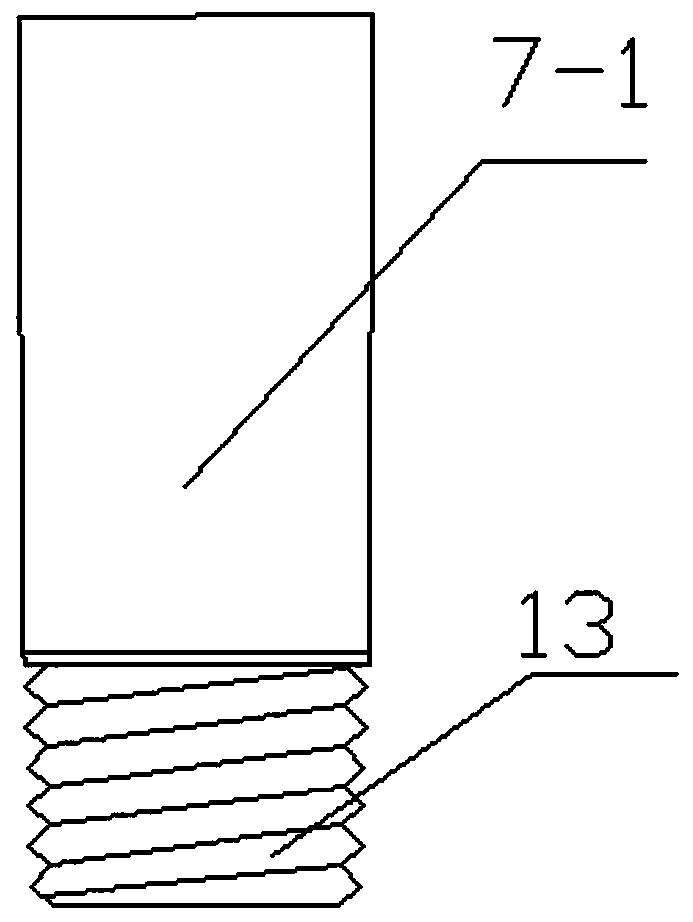

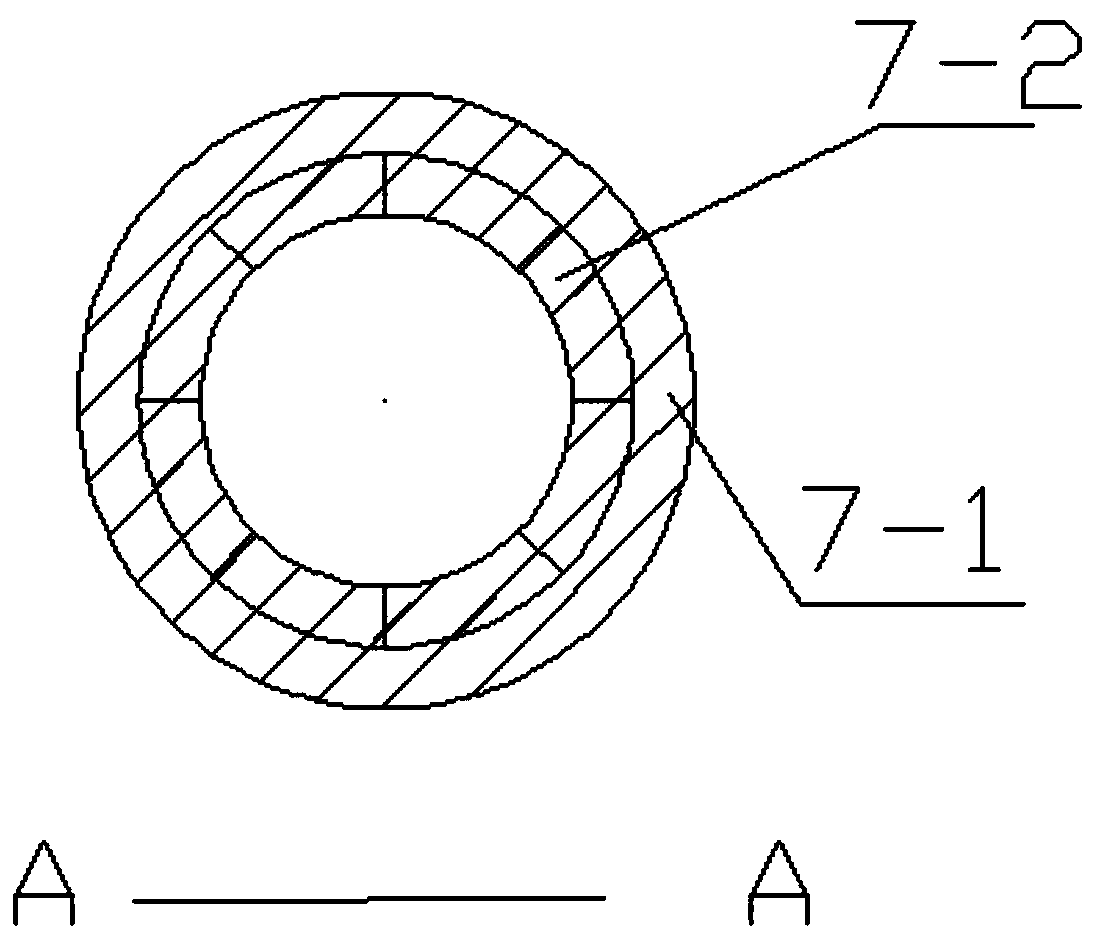

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an experimental mold for the preparation of a shear thickening glue specimen includes a base device 11, a specimen mold device 7, and a specimen compacting device 4, and the base device includes a base 1, a fixing groove 8, a buffer foam Layer 6, support frame 2, beam 3, threaded hole 9, said beam 3 has said threaded hole 9, said beam 3 is fixed by said support frame 2, and said support frame 2 is fixed on said base 1 On one side, the test piece mold device 7 includes an outer shaping cylinder 7-1, a sheet cylinder 7-2 that can be spliced, the lower end of the outer shaping cylinder 7-1 is provided with a thread 13, and the splicable sheet The outer diameter of the shaped cylinder 7-2 is equal to or slightly smaller than the inner diameter of the outer shaping cylinder 7-1, and the splicable sheet-shaped cylinder 7-2 is placed in the outer shaping cylinder 7-1, and the outer The lower end of the shaping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com