Mould device for producing U-shaped heating body blank

A heating element and green body technology, applied in the direction of molds, etc., can solve the problems of long production process cycle of heating element, unstable size and shape, low green body density, etc., and achieve simple structure, convenient operation and high green body density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

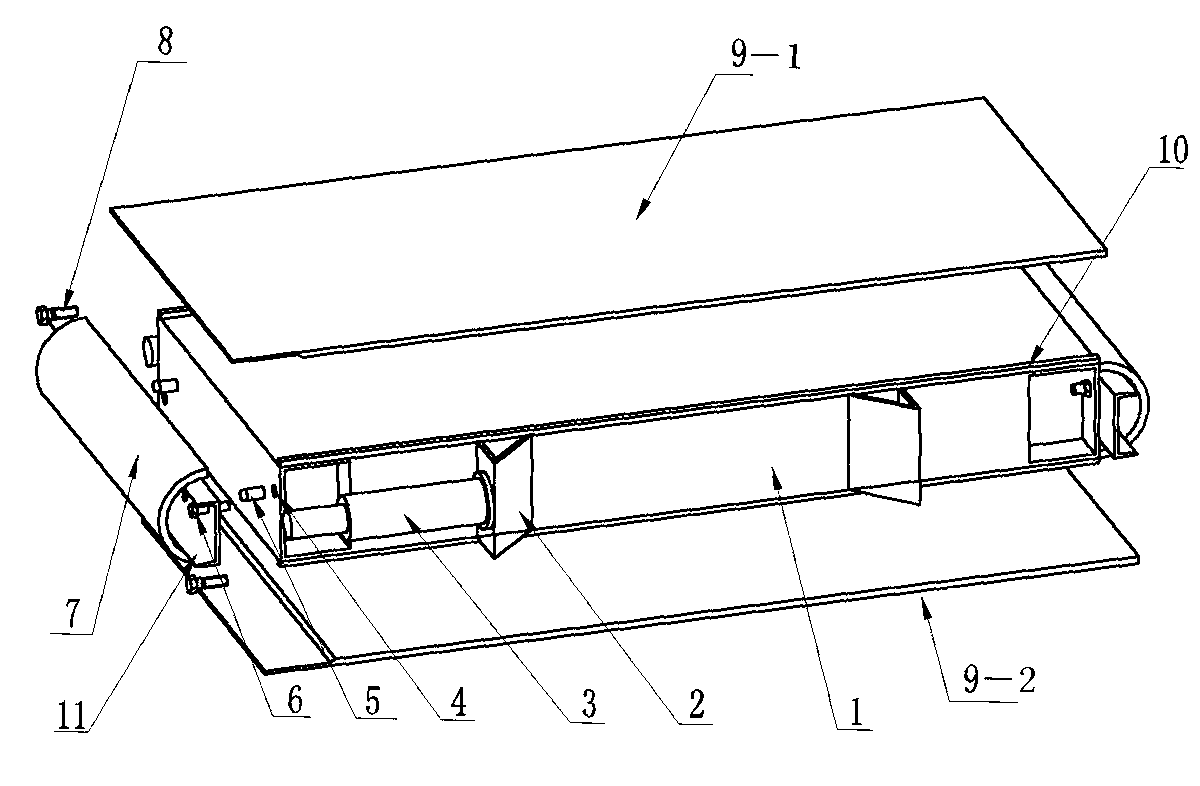

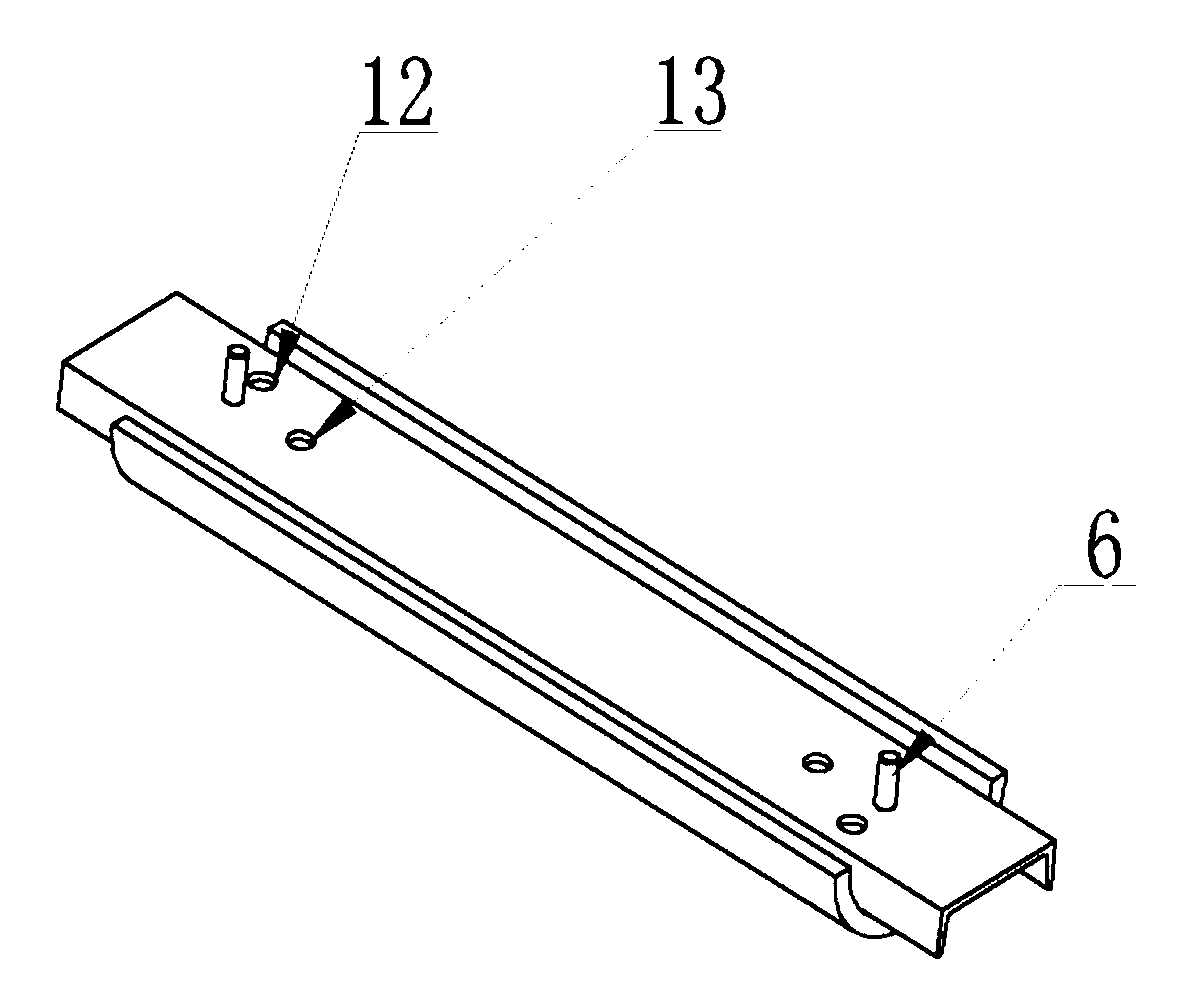

[0014] As shown in the figure, this embodiment includes a mold body 1, a movable arc mold 7, a hydraulic device 3, and a cover plate. The two sides of the mold body 1 are respectively welded with lugs 2, and the end surface of the mold body 1 is provided with two guiding positioning Pin 5, two locking holes I4, and the two sides of the upper and lower surfaces of the mold body 1 are respectively provided with limit bars 10; There are two locking holes II12, two guiding and positioning holes 13, two jacking screws 6, the length of the channel steel 11 protruding from the two ends of the movable arc mold 7 corresponds to the width of the lugs 2 on both sides of the mold body 1, In order to install the hydraulic device 3; the position and size of the guide positioning pin 5 on the end face of the mold body 1 and the guide positioning hole 13 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com