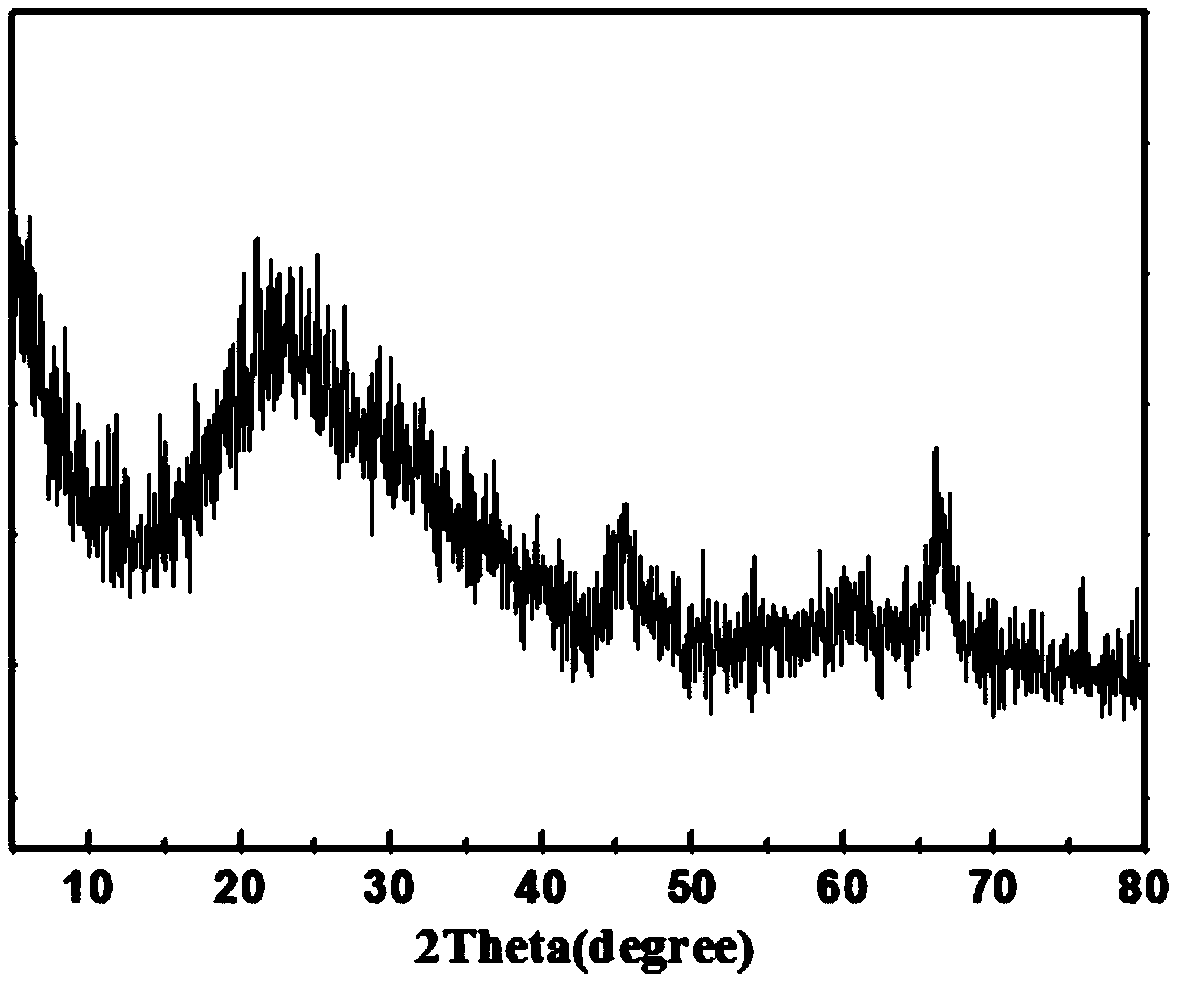

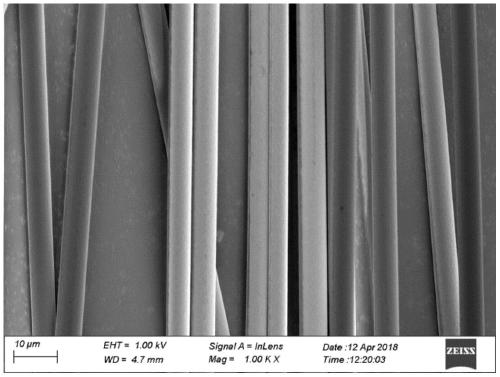

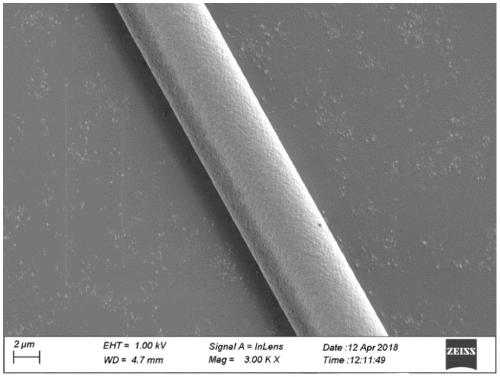

A containing 1 ~ 5wt% b 2 o 3 Preparation method of alumina-based ceramic continuous fiber

A continuous fiber, 5wt.o3 technology, applied in the field of preparation of alumina-based ceramic continuous fibers, can solve problems such as low tensile strength, and achieve the effects of reducing calcination temperature, excellent mechanical properties, good stability and stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A containing 1 ~ 5wt% B 2 o 3 A method for preparing alumina-based ceramic continuous fibers, comprising the following steps:

[0046] (1) Preparation of spinnable precursor sol

[0047] Contains Al in 1361.6g 13 Colloidal aluminum sol (in the form of A1 2 o 3 meter, A1 2 o 3 content of 12.91wt%), add 137.87g pseudo-boehmite nano-dispersion (A1 2 o 3 The mass content is 5wt%), stir at room temperature, and mix well; add 208.73g silica sol (SiO 2 content is 35wt%), stir at room temperature, then add 667.7g boric acid aqueous solution (H 3 BO 3 Content is 3.45wt%) and 173.33g polymer spinning aid polyvinyl alcohol aqueous solution (polyvinyl alcohol content is 15wt%), stirs evenly under room temperature, obtains mixed liquor; Then mixed liquor is in 40 ℃ of water baths, vacuum Under the condition of 0.095MPa, the aging concentration is carried out until the viscosity of the sol is 580Pa.s, and the spinnable precursor sol is obtained.

[0048] Among them, with ...

Embodiment 2

[0056] A containing 1 ~ 5wt% B 2 o 3 A method for preparing alumina-based ceramic continuous fibers, comprising the following steps:

[0057] (1) Preparation of spinnable precursor sol

[0058] Contains Al in 1072.4g 13 Colloidal aluminum sol (in the form of A1 2 o 3 Meter, Al 2 o 3 content is 13.5wt%), add 78.5g pseudo-boehmite nano-dispersion (Al 2 o 3 The mass content is 5%), stir evenly at room temperature, then add 162g silica sol (SiO 2 Content is 35wt%) and 190.5g boric acid aqueous solution (H 3 BO 3 Content is 3.45wt%), then add 132.3g polyvinylpyrrolidone aqueous solution (mass content of polyvinylpyrrolidone is 12.5wt%) as spinning aid, stir at room temperature to obtain mixed solution; then mixed solution in 40 ℃ water bath, Under the condition of vacuum degree of 0.098MPa, the aging concentration is carried out until the viscosity of the sol is 795Pa.s, and the spinnable precursor sol is obtained.

[0059] Among them, with A1 2 o 3 meter, Al in the m...

Embodiment 3

[0067] A containing 1 ~ 5wt% B 2 o 3 A method for preparing alumina-based ceramic continuous fibers, comprising the following steps:

[0068] (1) Preparation of spinnable precursor sol

[0069] Contains Al in 1182.5g 13 Colloidal aluminum sol (in the form of A1 2 o 3 Meter, Al 2 o 3 content of 13.5wt%), add 81.6g pseudo-boehmite dispersion (Al 2 o 3 The mass content is 5wt%), stir evenly at room temperature, then add 155.66g silica sol (SiO 2 Mass content is 35%) and 198.76g boric acid aqueous solution (H 3 BO 3 Mass content is 3.45wt%), then add 127.52g polyoxyethylene aqueous solution (mass content of polyoxyethylene is 17.8wt%) as spinning aid, stir at room temperature, obtain mixed liquor; Then mixed liquor is in 40 ℃ In a water bath, aging concentration is carried out under the condition of a vacuum of 0.096 MPa until the viscosity of the sol is 894 Pa.s to obtain a spinnable precursor sol.

[0070] Among them, with A1 2 o 3 meter, Al in the mixture 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com