Ultrahigh-strength red mud light material and preparation method thereof

A light-weight material and ultra-high-strength technology, applied in the field of ultra-high-strength red mud lightweight materials and preparation, can solve the problems of air environment and groundwater pollution, occupying large land, consuming large manpower and material resources, etc., to reduce preparation costs, Effect of avoiding pollution and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

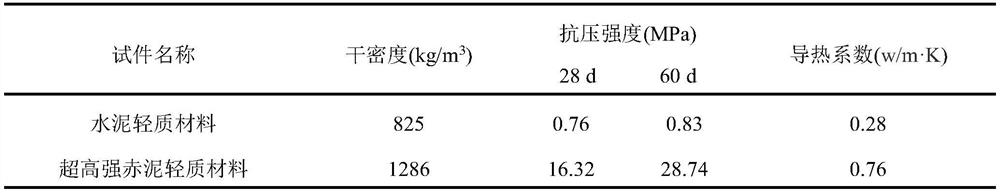

Examples

Embodiment 1

[0016] Example 1: A super-high-strength red mud lightweight material and its preparation method, including: mixing process, preparation process, curing and drying process, the specific method is as follows:

[0017] (1) The total mass of the cementitious material is 20,000g, including 12,000g of red mud, 4,000g of fly ash, 3,000g of slag, and 1,000g of slaked lime powder. The total mass of the activator is 20,000g, including 600g of sodium hydroxide, 13,000g of water, and 6,400g of liquid sodium silicate.

[0018] (2) Preparation process: First, dissolve sodium hydroxide into water according to the composition of raw materials and their mass percentages and let it stand for cooling, then mix red mud, fly ash, slag and slaked lime powder evenly, add sodium hydroxide solution, and slowly Stir at high speed for 15s, add liquid sodium silicate solution, stir quickly for 30s, and finally pour into a mold of 600mm×200mm×200mm.

[0019] (3) Curing and drying process: After the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com