Reinforced magnesium phosphate cement composite material and preparation method thereof

A technology of magnesium phosphate cement and composite materials, applied in the field of new building materials, can solve the problems of low strength and inapplicability, and achieve the effects of high strength, sufficient reaction and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

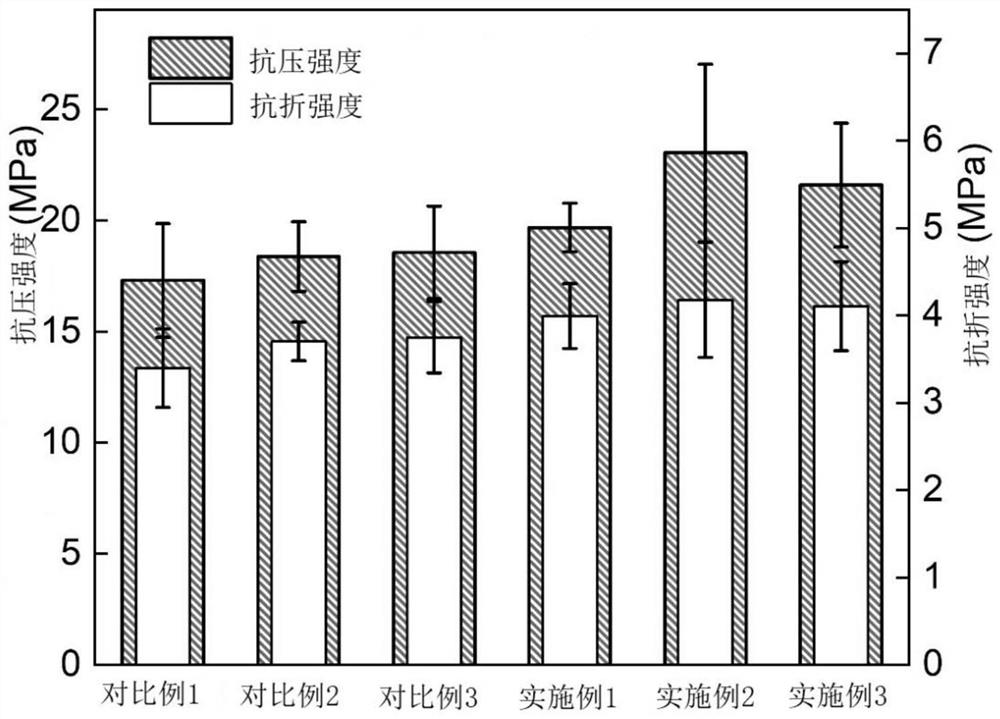

Examples

Embodiment 1

[0035] This embodiment provides oxidized graphene / carbon nanotube to improve the magnesium phosphate cement composite, including oxide / carbon nanotube composite modifier, magnesium phosphate cement dry material, wherein the oxide / carbon nanotube recombination The modifier is compounded by a small amount of oxide oxide and multi-walled carbon nanotubes, and the ratio of small carbon oxide and multi-walled carbon nanotubes is 1: 1. In the case of specific implementation, the number of monomeric oxide oxide or single-walled carbon nanotubes can also be selected from the form of the present invention. The ratio of the total dry weight of the merchandise of the product is 0.05: 100. Water and magnesium phosphate dry material mass ratio is 0.15. The magnesium phosphate cement dry material consists of a buffenagnesium oxide, boron sand and pelletine dihydrogen phosphate, and the phosphate cement dry material can be used in a commercially available group, and the present embodiment ...

Embodiment 2

[0043]This embodiment provides oxidized graphene / carbon nanotube to improve the magnesium phosphate cement composite, including oxide / carbon nanotube composite modifier, magnesium phosphate cement dry material, wherein the oxide / carbon nanotube recombination The modifier is compounded by a small amount of oxide oxide and multi-walled carbon nanotubes, and the ratio of small carbon oxide and multi-walled carbon nanotubes is 1: 1. The total dry weight of the dry material with the magnesium phosphate cement dry parts by weight of the product less than the mass of the graphene oxide layers and multi-walled carbon nanotubes is 0.1: 100. Water and magnesium phosphate dry material mass ratio is 0.15. Magnesium phosphate cement by the dry feed dead burned magnesium oxide, borax and potassium dihydrogen phosphate composition. The specific ratio of each component of the present embodiment is shown in Table 1.

[0044] The above-mentioned oxide-oxide / carbon nanotubes can be prepared ...

Embodiment 3

[0051] This embodiment provides the graphene oxide / nanotube synergistic magnesium phosphate cement composites, the present embodiment differs from embodiment 1 in that the polycarboxylate superplasticizer is added, the polycarboxylate superplasticizer dry matter of magnesium phosphate cement parts by weight ratio of 0.1: 100, other conditions are the same as in Example 1. The specific ratio of each component of the present embodiment is shown in Table 1.

[0052] Graphene oxide / nanotube synergistic magnesium phosphate cement composite materials can be prepared using the following procedure:

[0053] The oxide in grapiele solution having a concentration of 0.05 g / L was prepared.

[0054] The carbon nanotubes were added to the oxide oxide insertion solution After mixing in the beaker, stirred with a glass rod to a flovent visible visible to the coffee eye, add an ultrasonic dispersion to prepare an oxide oxide / carbon nanotube composite modifier, depending on the amount of so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com