concrete mud inhibitor

A mud-repelling agent and concrete technology, which is applied in the field of concrete mud-repelling agent, can solve the problems of concrete quality control and control difficulties in concrete construction, and the discount of water-reducing effect of concrete water-reducing agent, etc., to achieve delayed hydration rate, low cost, and good flow The effect of sex and slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: A concrete mud-repelling agent, the proportion of each component is as follows: (by weight)

[0022] Waterborne Polymer: 70

[0023] Gallic acid: 10

[0024] Diethylene glycol: 20

[0025] In waterborne polymers:

[0026] thioglycolic acid

[0027] The polymer of allyl ether is 8

example 2

[0028] Example 2: A concrete mud-repelling agent, the proportion of each component is as follows: (by weight)

[0029] Waterborne Polymer: 80

[0030] Gallic acid: 10

[0031] Diethylene glycol: 10

[0032] In waterborne polymers:

[0033] thioglycolic acid

[0034] The polymer of allyl ether is 6

example 3

[0035] Example 3: A kind of concrete anti-sludging agent, the proportion of each component is as follows: (by weight)

[0036] Waterborne Polymer: 75

[0037] Gallic acid: 5

[0038] Diethylene glycol: 20

[0039] In waterborne polymers:

[0040] mercaptopropionic acid

[0041] The polymer of allyl ether is 6.

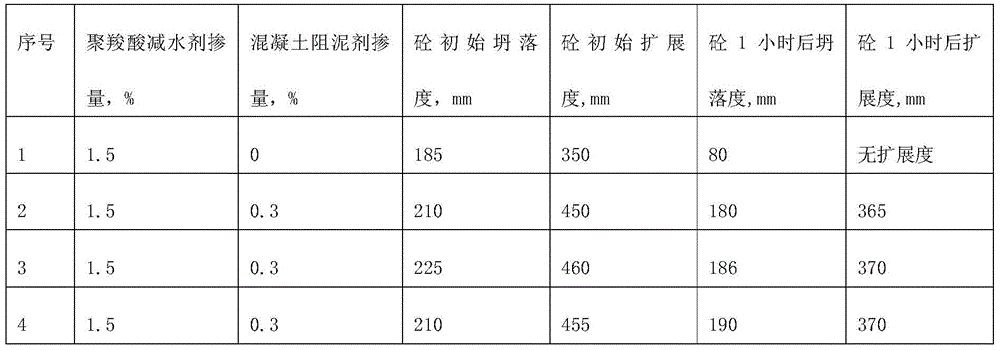

[0042] The effect of concrete mud inhibitor is shown in the table below:

[0043]

[0044] Note: (1) The output of polycarboxylate superplasticizer in the table is the weight ratio of polycarboxylate superplasticizer to cement, (2) The amount of concrete mud-repelling agent is the weight ratio of concrete mud-repelling agent to cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com