Multi-component composite reinforced anti-cracking agent for concrete and preparation method of multi-component composite reinforced anti-cracking agent

A technology of strengthening anti-cracking agent and multi-component compounding, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. Obvious problems, to achieve the effect of improving long-term mechanical properties, reducing too fast reaction rate, and long duration of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

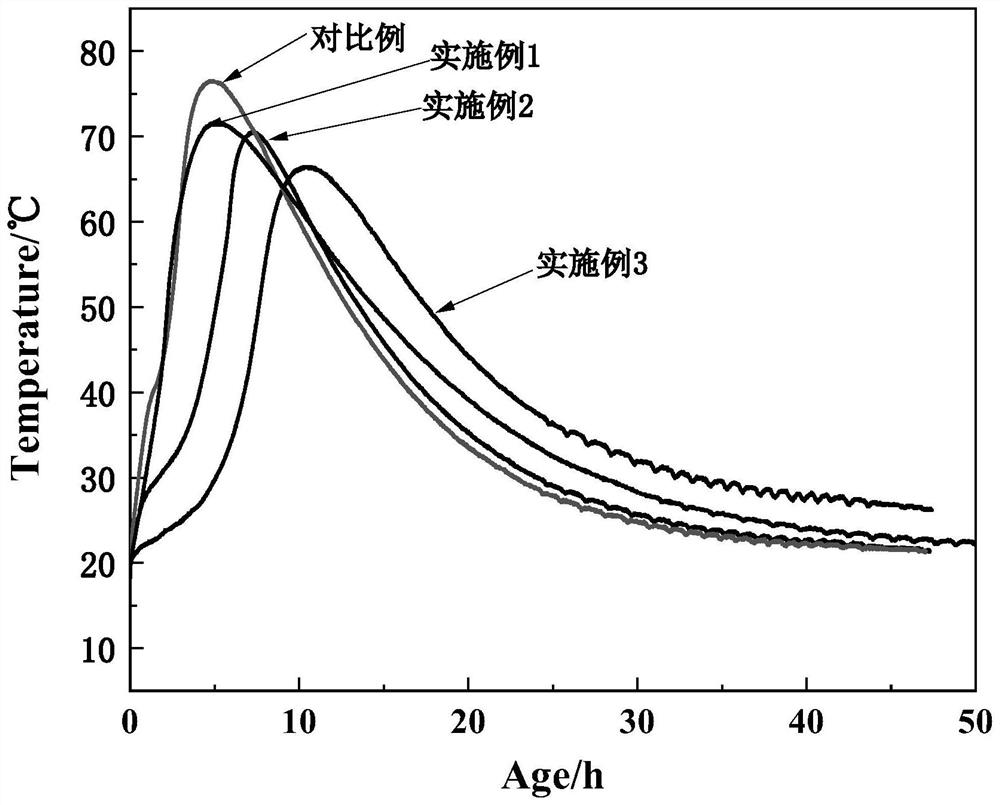

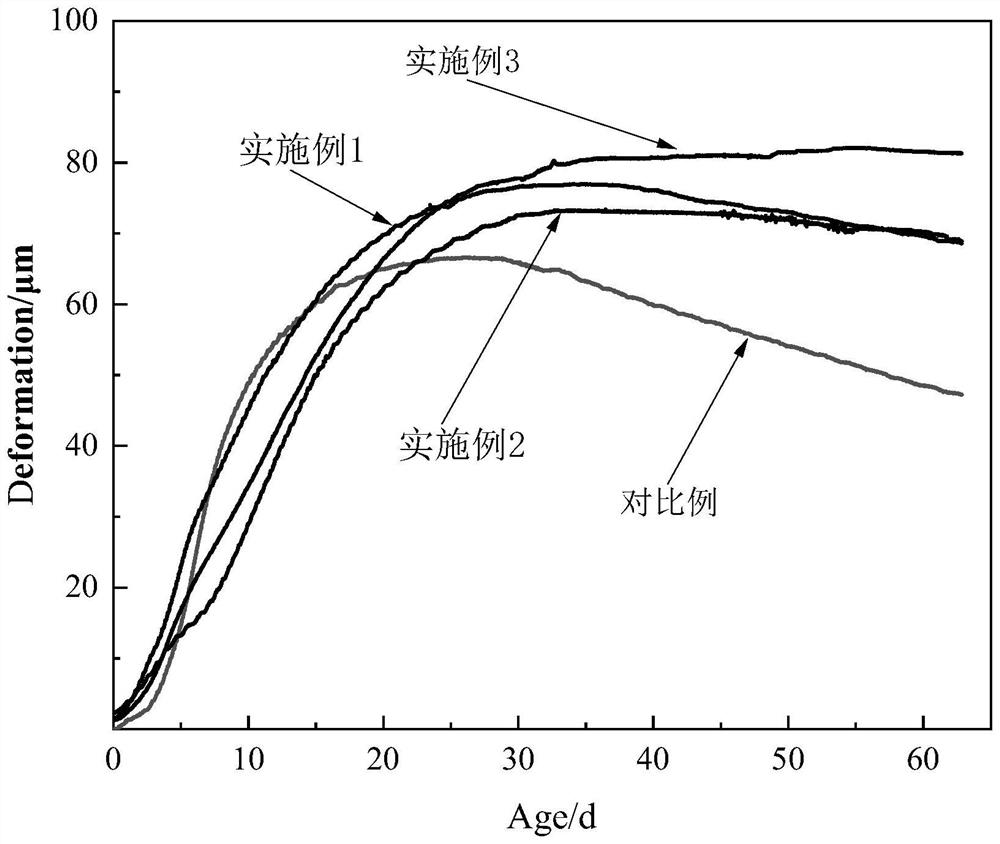

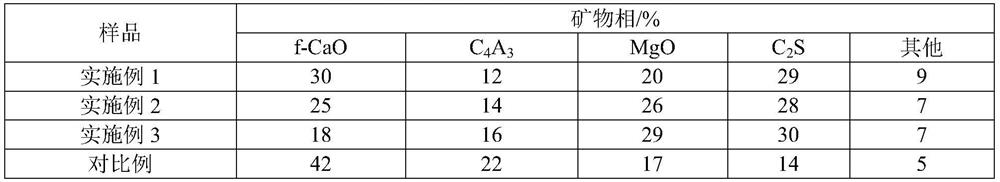

Embodiment 1

[0032] Crushing and grinding the dolomite, drying the original phosphogypsum and phosphorus slag through a drum dryer until the free water content is less than 3%; weigh 55 parts of dolomite, 2 parts of phosphogypsum, and 2 parts of phosphorus slag in parts by weight. 1 part, 14 parts of fly ash, 25 parts of limestone, 1 part of strontium oxide, and 1 part of sodium tungsten, mix them evenly to get raw meal; place the raw meal in a rotary kiln for calcination at 1250°C for 60 minutes, and then quench the temperature with a grate cooler , lowered to below 400°C within 30 minutes, and finally ground by a ball mill to 80 μm sieve ≤ 10%, that is, the finished multi-component composite reinforced anti-cracking agent for concrete is obtained.

Embodiment 2

[0034] Crushing and grinding the dolomite, drying the original phosphogypsum and phosphorus slag through a drum dryer until the free water content is less than 3%; weigh 73 parts of dolomite, 3 parts of phosphogypsum, and 1 12 parts of fly ash, 10 parts of limestone, 1 part of molybdenum oxide, and 1 part of calcium fluoride, and mix them evenly to obtain raw meal; place the raw meal in a rotary kiln for calcination at 1300°C for 60 minutes, and then cool it rapidly with a grate cooler , lowered to below 400°C within 30 minutes, and finally ground by a ball mill to 80 μm sieve ≤ 10%, that is, the finished multi-component composite reinforced anti-cracking agent for concrete is obtained.

Embodiment 3

[0036]Crushing and grinding the dolomite, drying the original phosphogypsum and phosphorus slag through a drum dryer until the free water content is less than 3%; weigh 80 parts of dolomite, 3 parts of phosphogypsum, and 1 1 part, 11 parts of fly ash, 3 parts of limestone, 1 part of molybdenum oxide, 0.5 part of sodium tungstate, and 0.5 part of zinc oxide, and mix them evenly to obtain raw meal; place the raw meal in a rotary kiln for 90 minutes at 1300 °C, and then The grate cooler is used for rapid cooling, and the temperature is lowered to below 400°C within 30 minutes. Finally, it is ground by a ball mill until the sieve residue of 80 μm is ≤10%, and the multi-component composite reinforced anti-cracking agent for concrete is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com