Low-thermal-expansion concrete and admixture

A low-heat, micro-expansion technology, applied in the field of low-heat micro-expansion concrete, cement/concrete (concrete), can solve the problems of concrete cracking and insufficient compensation

Active Publication Date: 2020-07-28

ZHEJIANG CHENGYU ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] Based on the researches on expansion and low-heat cement concrete in the above-mentioned theoretical and engineering circles, there is still the problem of insufficient compensation in the early and mid-term, especially in the early stage, resulting in concrete cracking

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

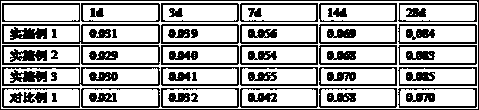

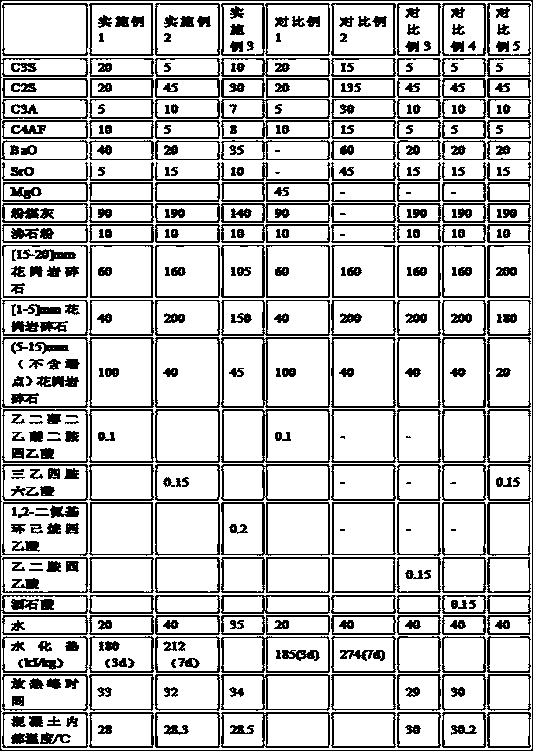

[0027] Examples 1-3 and Comparative Examples 1-5 were prepared according to the mix ratio in Table 1, and according to the general concrete technology and maintenance. See Table 1-3 for specific experimental results.

[0028] Table 1

[0029]

[0030] Note 1: The raw materials in the table are measured by weight, and the selected unit is kg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a low-thermal-expansion concrete and an admixture. The concrete comprises cement clinker, fly ash, zeolite powder, granite gravel and the balance being water. The cement clinker comprises the following components in percentage by weight: 5-20% of C3S, 20-45% of C2S, 5-10% of C3A and 5-10% of C4AF, and is characterized by further comprising 20-40% of barium oxide and 5-15%of strontium oxide. The ratio of the cement clinker to (fly ash and zeolite powder) to granite gravel is 1: (1-2): (2-4), and water to cement clinker is 0.2-0.4. Barium oxide and strontium oxide are used as expansion admixtures for the first time to replace fly ash in particular zeolite powder under the assistance of a newly developed retarder; and granite gravels with different sizes are matchedto realize a low-heat micro-expansion effect of concrete.

Description

technical field [0001] The application relates to the field of construction engineering, in particular to cement / concrete (concrete), in particular to a low-heat micro-expansion concrete. Background technique [0002] Cement concrete is by far the largest man-made material in the world, and this situation will continue for a long time in the future. Concrete has two inherent material characteristics, one is the volume deformation-shrinkage accompanied by strength growth during the hydration hardening process, and the other is the low tensile-compressive strength ratio of concrete materials. Concrete fractures (cracks) when the tensile stress inside the concrete caused by shrinkage exceeds the tensile strength of the concrete. It is generally considered that cracks are the biggest defect of concrete structures, which will lead to the intrusion of harmful media such as moisture, CO2, Cl-, etc., accelerate the corrosion of steel bars and reduce durability, and cause the reduct...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/06C04B20/00C04B22/06C04B18/08C04B14/04C04B24/12

CPCC04B20/0076C04B28/06C04B7/02C04B22/064C04B18/08C04B14/047C04B14/048C04B22/002C04B24/123Y02W30/91

Inventor 楼晓刚郭亮丁盛

Owner ZHEJIANG CHENGYU ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com