Front-end air distribution device of discharging valve of ice cream machine

An ice cream machine and discharge valve technology, which is used in frozen desserts, food science, applications, etc., can solve the problems of unstable gas distribution, inconsistent gas distribution, and the lack of consistent quality ice cream, etc., to achieve stable product puffing rate, reduce The cost of a single machine and the effect of reducing the power consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

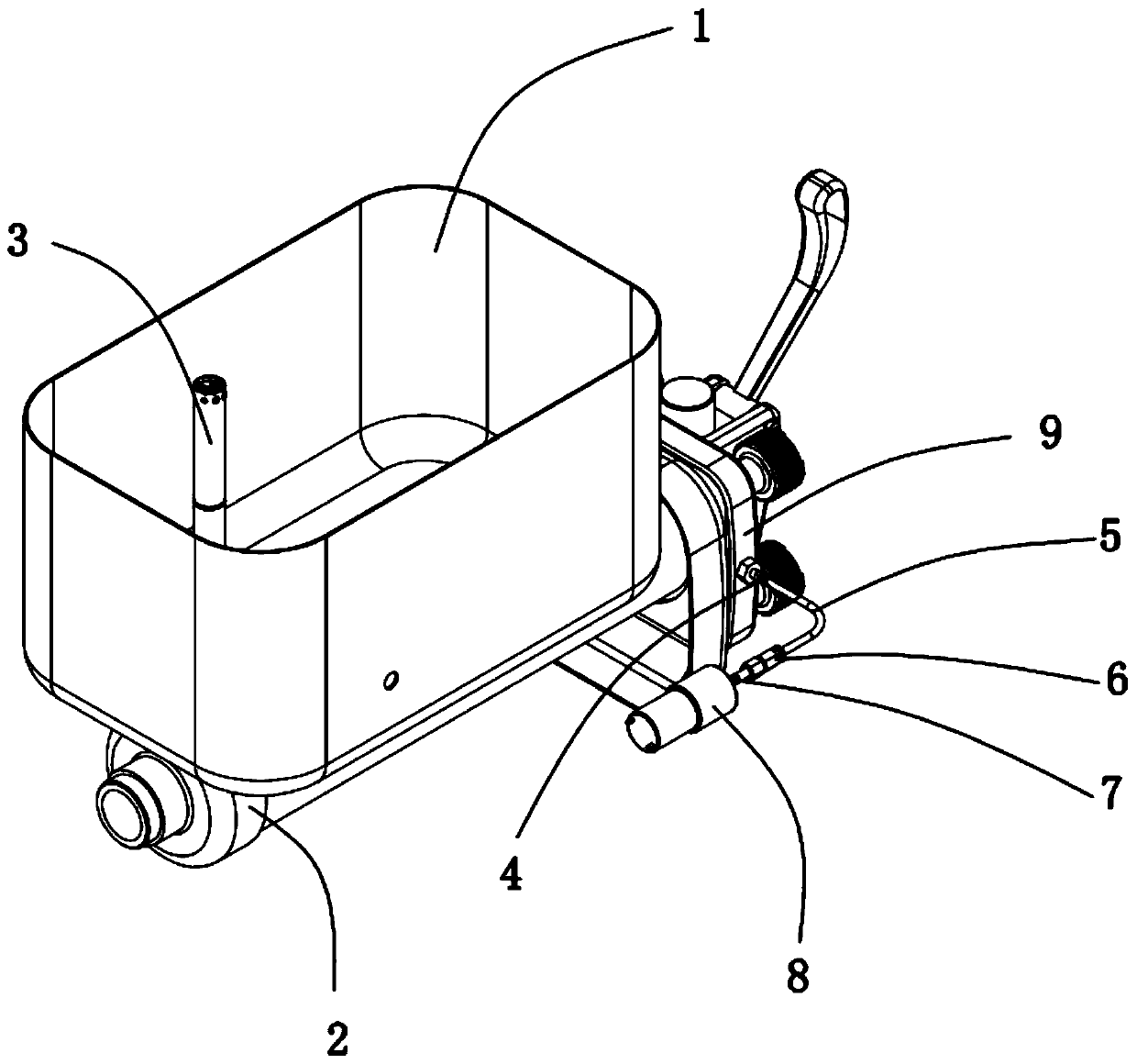

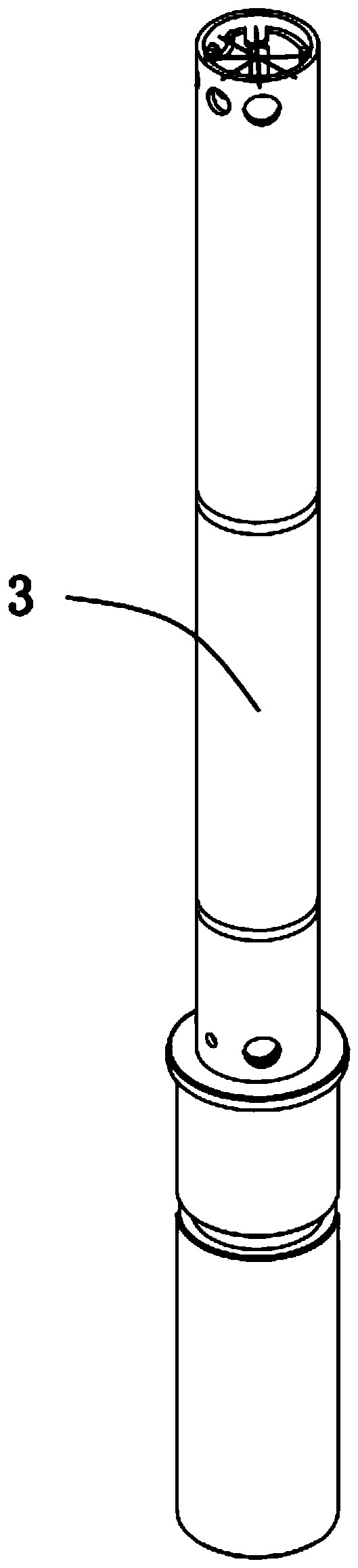

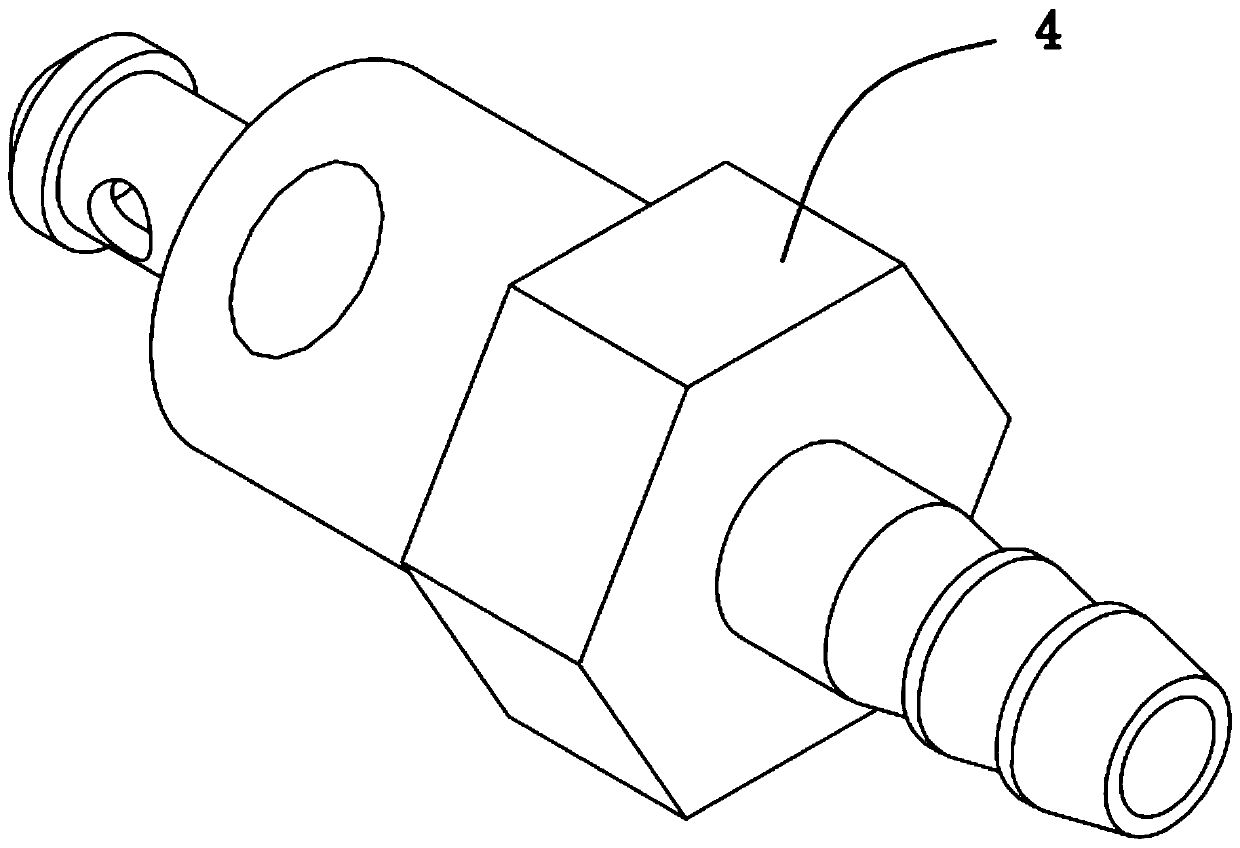

[0024] Please refer to Figure 1-Figure 9 , The pre-air distribution device for the discharge valve of the ice cream machine includes a puffing rod assembly 3, the puffing rod transfer part 3 is installed in the trough 1, and the bottom end of the puffing rod assembly 3 extends into the evaporation cylinder 2 , The evaporation cylinder 2 is fixedly installed at the bottom of the material tank 1, and the evaporation cylinder 2 is connected to the material tank 1, and a discharge valve 9 is provided on one side of the evaporation cylinder 2. A discharge valve 9 is connected to the evaporation cylinder 2; a gas check valve 4, the gas outlet end of the gas check valve 4 is connected to the discharge valve 9; an inlet pipe 5, one end of the inlet pipe 5 Connected to the gas inlet end of the gas one-way valve 4; gas pipe quick-change connector 6, one end of the gas pipe quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com