Novel winter cement based grouting agent for railway concrete beam support

A grouting material and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as not suitable for negative temperature construction in winter, achieve the effects of eliminating adverse effects, fast heat dissipation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

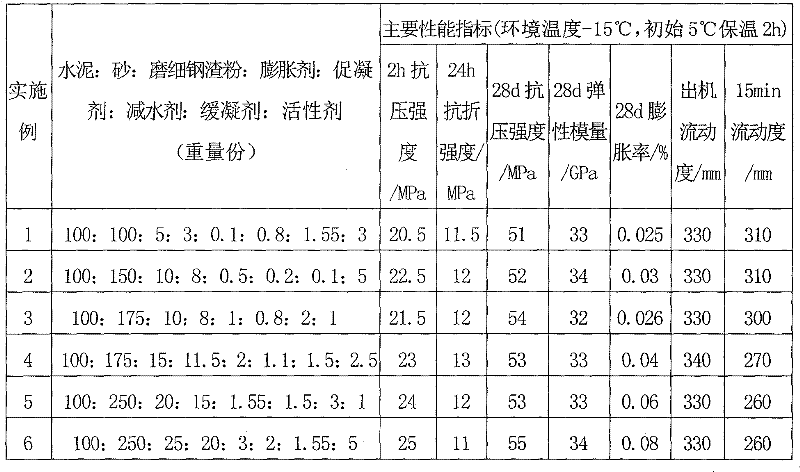

Examples

Embodiment 7

[0021] A winter cement-based grouting material for railway concrete beam bearings (use temperature is -25°C), which is mainly composed of cement, sand, finely ground steel slag powder, expansion agent, coagulant accelerator, retarder, water reducer, active It is made by mixing and stirring the agent and water. The parts by weight of each raw material are: cement: 100 parts, sand: 200 parts, finely ground steel slag powder: 25 parts, expansion agent: 14 parts, coagulant: 2 parts, water reducer : 1.8 parts, retarder: 1.3 parts, active agent: 4 parts. The expansion agent is selected from alunite expansion agent; the cement is early strength 52.5 portland cement; the coagulation accelerator is calcium nitrite; the active agent is lithium carbonate; the water reducer is a melamine water reducer; The retarder is sodium gluconate; the sand is ordinary fine river sand with a fineness of 30-100 mesh.

[0022] After all the raw materials are weighed according to the proportion, they ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com