A steel pipe lining expansion device

A technology for expanding and tightening steel pipes, applied in the field of plastic-lined steel pipe processing equipment, can solve the problems of reduced installation and use reliability, unstable deformation and loosening of plastic-lined pipes, and achieves uniform expansion speed, simple structure, and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

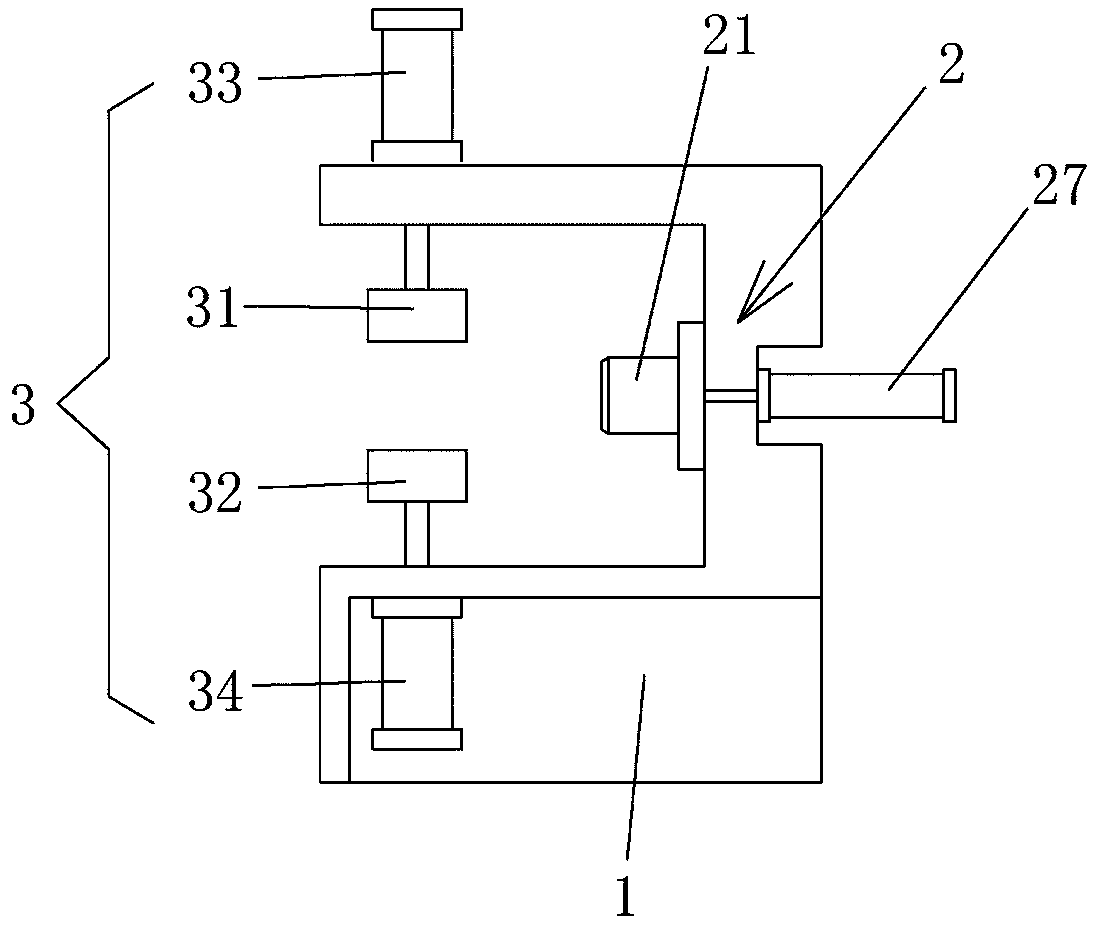

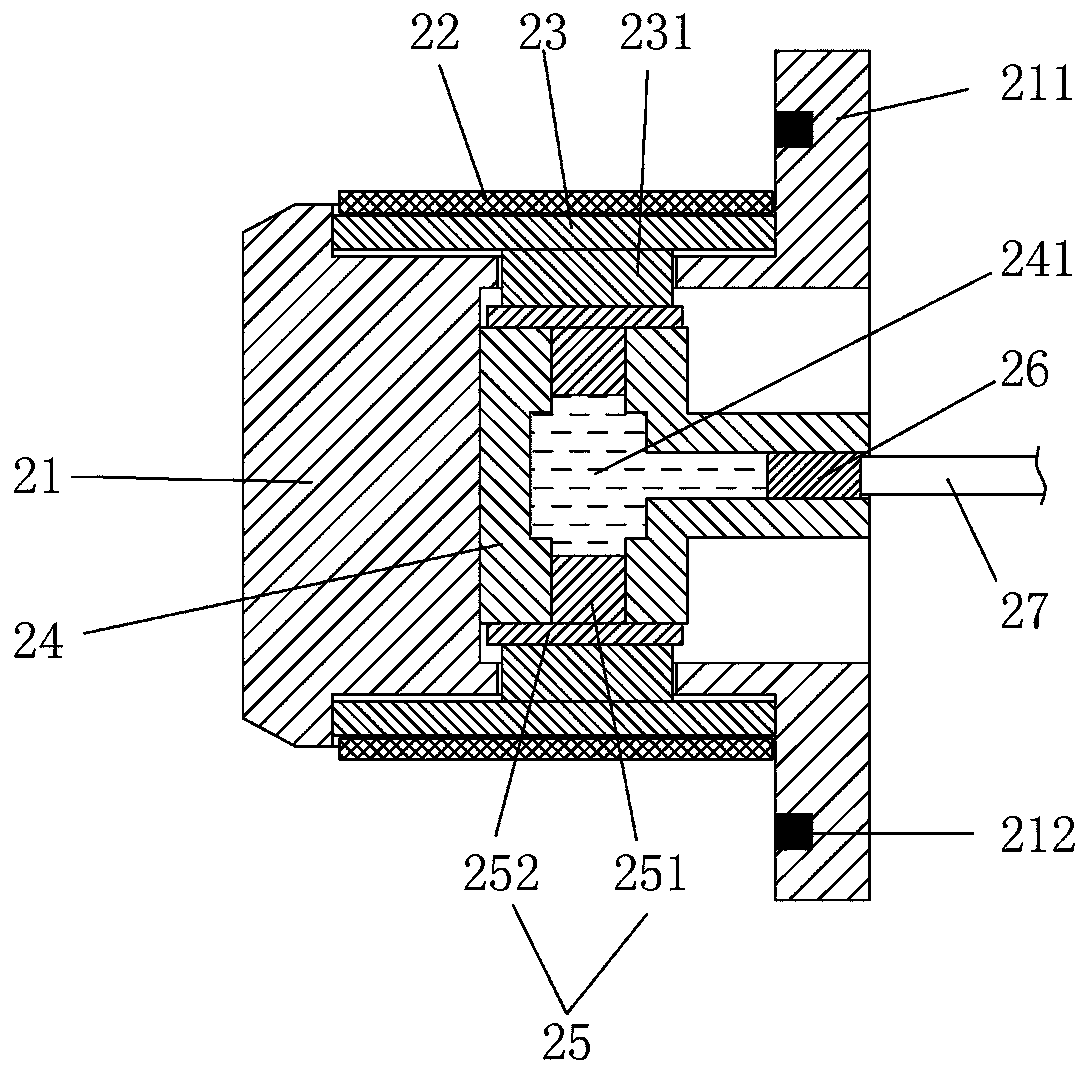

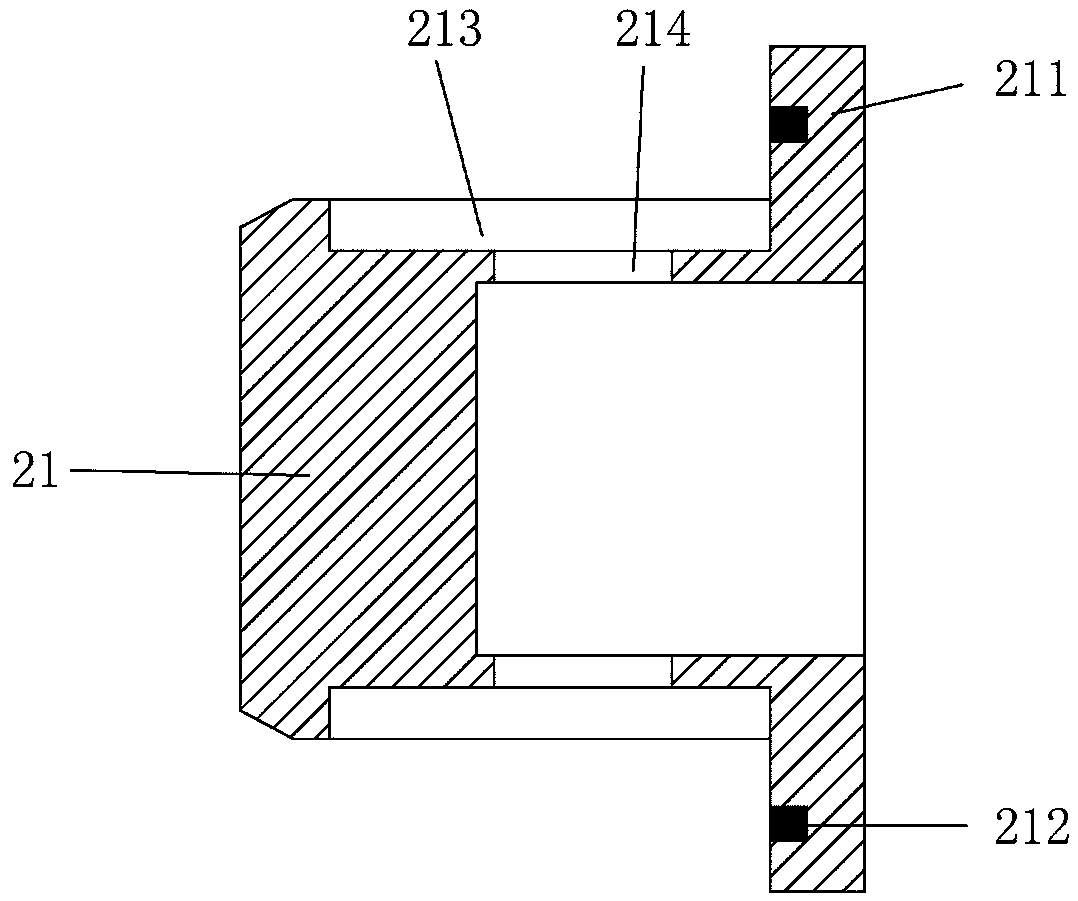

[0020] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a steel pipe lining expansion device includes a frame 1, an expansion mechanism 2 and a clamping mechanism 3 arranged on the frame 1, the expansion mechanism 2 includes an expansion seat 21, and a The tension block 21 is evenly distributed on the expansion block 21 on the circumference of the expansion block 21 and the expansion sleeve 22 sleeved on the outside of the expansion block 23 and drives the expansion block 23 along the expansion seat. 21 A drive assembly 27 that moves in the radial direction, and the drive assembly 27 is a hydraulic cylinder. The expansion seat 21 is fixedly connected to the frame 1, and the expansion seat 21 is provided with a hydraulic seat 24, and the hydraulic seat 24 is provided with an expansion piston 25 and a jacking piston 26. The tight piston 25 is connected to the expansion block 23, the jacking piston 26 is connected to the driving assembly 27, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com