Anti-cracking additive for concrete

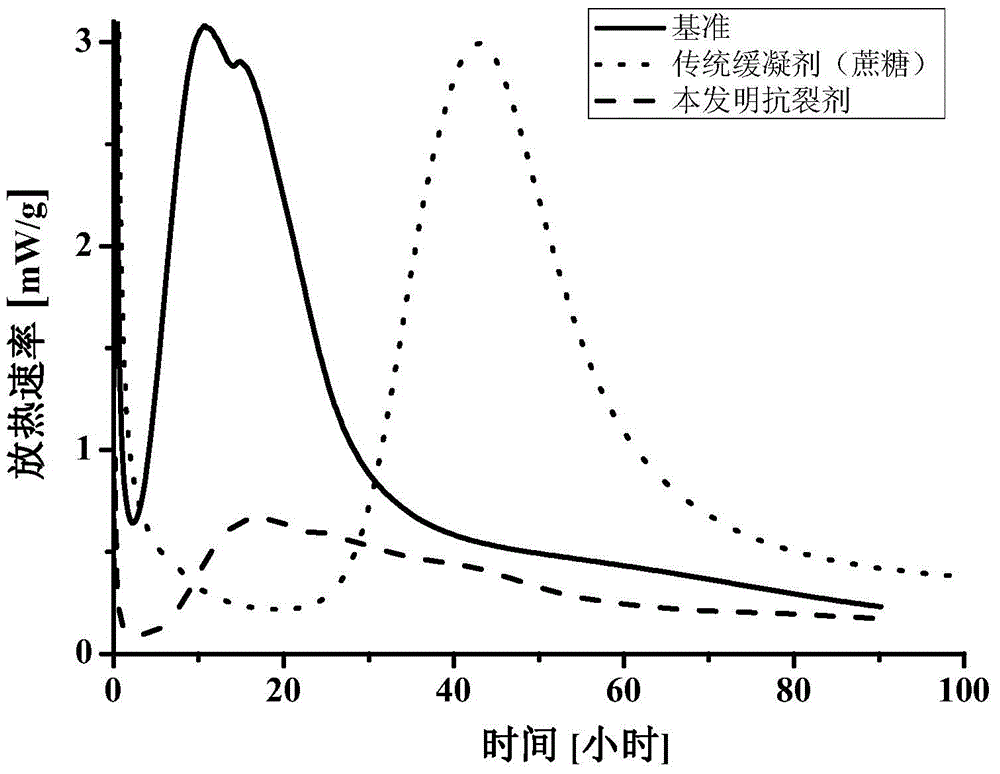

A technology for concrete and admixtures, applied in the field of concrete admixtures, can solve problems such as concentrated heat release during cement hydration, and achieve the effects of reduced heat release, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

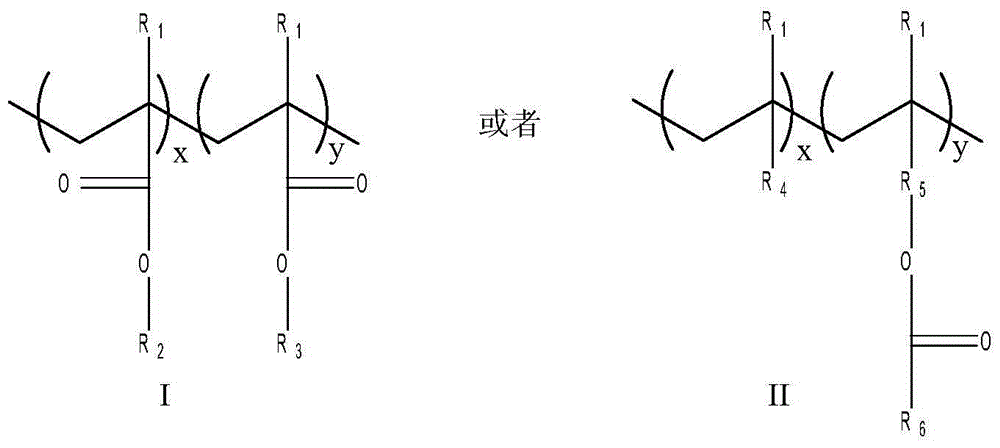

Method used

Image

Examples

Embodiment 1

[0039] 100g of polyacrylic acid with a degree of polymerization of 146, 8g of glucose, and 1g of p-toluenesulfonic acid were added to 500ml of toluene, and the temperature was raised to 130°C for 15 hours. During this period, the generated water was separated by a water separator, which was beneficial to improve the degree of esterification. After the reaction, the liquid was precipitated in ether, filtered and dried to obtain the desired product.

Embodiment 2

[0041] Except that the glucose quality is 27g, others are the same as Example 1.

Embodiment 3

[0043]Except that the glucose quality is 45g, others are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com