Concrete mud retarder

A mud inhibitor and concrete technology, which is applied in the field of concrete mud inhibitor, can solve the problems of water reducing effect of concrete water reducing agent, difficulty in quality control and control of concrete construction concrete, etc., and achieves delayed hydration rate, low cost, good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Waterborne polymer: 70

[0023] Gallic acid: 10

[0024] Diethylene glycol: 20

[0025] In water-based polymers:

[0026] Thioglycolic acid

[0027] The polymer of allyl ether is 8

example 2

[0028] Example 2: A concrete mud inhibitor, the distribution ratio of each group is as follows: (by weight)

[0029] Waterborne polymer: 80

[0030] Gallic acid: 10

[0031] Diethylene glycol: 10

[0032] In water-based polymers:

[0033] Thioglycolic acid

[0034] The polymer of allyl ether is 6

example 3

[0035] Example 3: A concrete mud inhibitor, the distribution ratio of each group is as follows: (by weight)

[0036] Waterborne polymer: 75

[0037] Gallic acid: 5

[0038] Diethylene glycol: 20

[0039] In water-based polymers:

[0040] Mercaptopropionic acid

[0041] The polymer of allyl ether is 6.

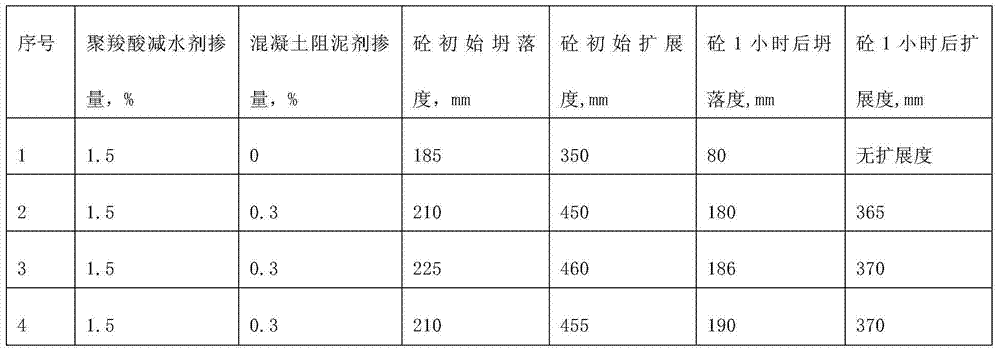

[0042] The effect of concrete mud inhibitor is shown in the table below:

[0043]

[0044] Note: (1) The output of polycarboxylate water-reducing agent in the table is the weight ratio of polycarboxylate water-reducing agent to cement, and (2) the content of concrete mud inhibitor is the weight ratio of concrete mud inhibitor to cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com