Workability keeping agent for ballastless track self-compacting concrete and preparation method of workability keeping agent

A technology of self-compacting concrete and ballastless track, applied in the field of concrete admixtures, can solve the problems of decreased dispersion and dispersion retention performance, difficult to realize industrialization, large scope, etc. effect of loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

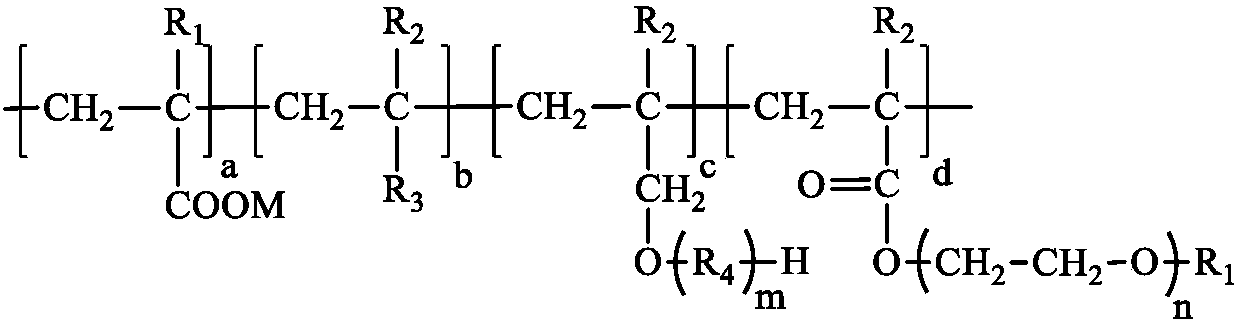

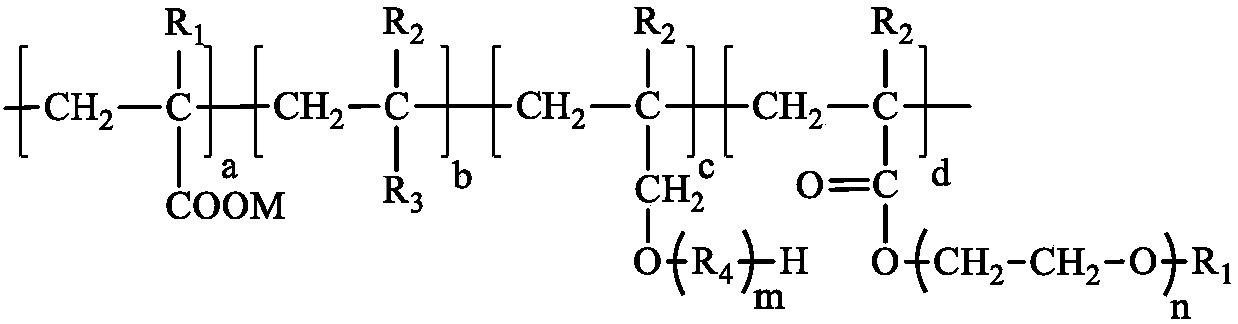

Method used

Image

Examples

specific Embodiment 1

[0040]Add 76.06 kg of deionized water to the stirring tank, add 22 kg of SP-1 and 20 g of organosilicon defoamer, stir for 10 min, mix 25 g of sodium lauryl sulfate, 10 g of polyethylene glycol monolaurate, 10 g of hydroxyethylidene Phosphonic acid, 1.5kg chitosan, and 0.4kg sodium alginate were added therein, stirred and dissolved to obtain the workability retaining agent product TKSP-1 for ballastless track self-compacting concrete.

specific Embodiment 2

[0042] Add 78.09kg of deionized water to the stirred tank, add 20kgSP-2 and 35g polyether defoamer, stir for 10min, mix 25g sodium lauryl sulfate, 10g polyethylene glycol monolaurate, 20g potassium oleate, 25g of aminotrimethylene phosphonic acid and 1.8kg of chitosan were added therein, stirred and dissolved to obtain the workability retention agent product TKSP-2 for ballastless track self-compacting concrete.

specific Embodiment 3

[0044] Add 72.58kg of deionized water to the stirring tank, add 25kgSP-1 and 30g of organosilicon defoamer, stir for 10min, mix 35g of sodium lauryl sulfate, 15g of sorbitan monostearate, 40g of polyamino poly Ether-based methylene phosphonic acid, 2.0kg chitosan, and 0.3kg hyaluronic acid were added thereto, stirred and dissolved, and TKSP-3, a workability retaining agent product for ballastless track self-compacting concrete, was obtained.

[0045] Implementation Effect:

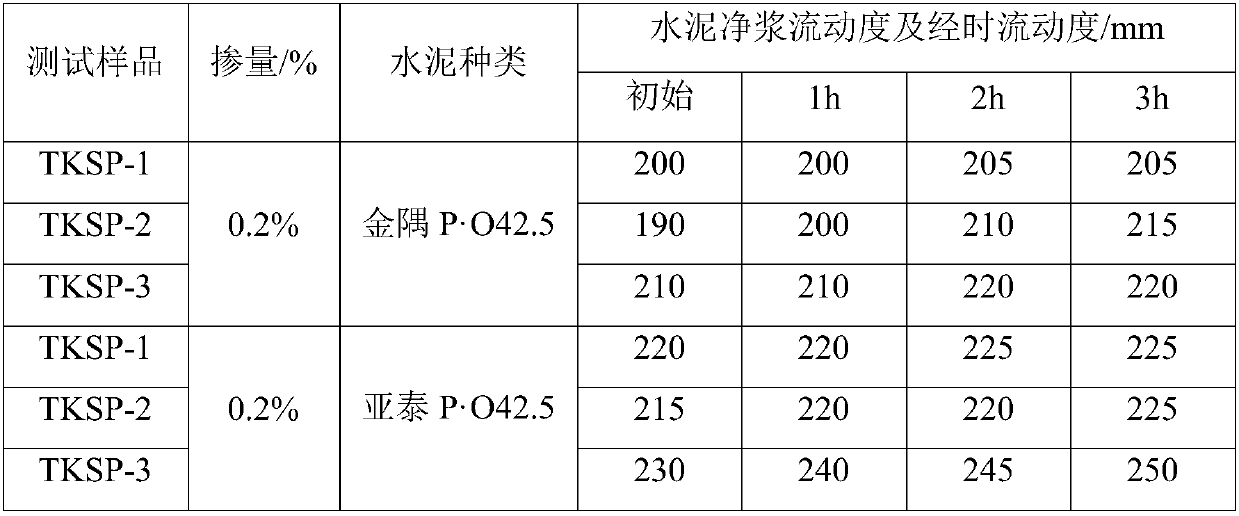

[0046] Clean slurry test: test has measured the fluidity of cement slurry of each embodiment under the same dosage. The test is carried out in accordance with GB / T8077-2012 "Test Method for Homogeneity of Concrete Admixtures", where W / C=0.29 and the dosage is the reduced-solid dosage. The specific test results are shown in Table 1.

[0047] Table 1 The fluidity of cement paste of different test samples and the test results of fluidity over time

[0048]

[0049] From the data in Table 1, it can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com