Process for extracting phosphatidecholine from powdered soybean phosphatide

A technology of soybean powder phospholipid and phosphatidylcholine, which is applied in the direction of edible phospholipid composition, food science, protein food ingredients, etc., can solve the problem that the two indicators of phosphatidylcholine content and yield cannot be balanced, the product yield is low, Problems such as low product purity, to achieve the effect of less solvent consumption, less investment in equipment, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

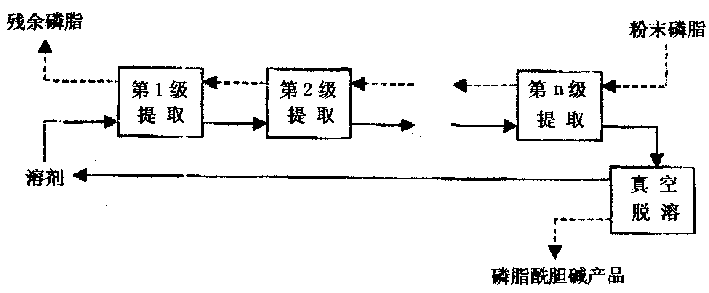

[0009] figure 1 Shown is the process flow chart of extracting phosphatidylcholine from soybean powder phospholipids. The technological process shown in it is to add fresh soybean powder phospholipids into the n-level leaching tank, and use the (n-1)-level leaching solution to extract for 0.5-3 hours at a temperature of 20-55°C, and then separate the solid and liquid. Finally, the solid enters the (n~1) stage, and is leached with the (n~2) stage leach solution under the same conditions, and so on until the first stage. The first stage is leached with a fresh mixed solvent. Its solvent is acetonitrile: lower carbon alcohol = 1: 10~10: 1 (by volume), the solid obtained after the first-stage leaching is residual phospholipids, which can be used to extract other types of phospholipids such as phosphatidylethanolamine. The extract solution of the nth stage undergoes vacuum precipitation to remove the solvent to obtain the phosphatidylcholine product. After the solvent is recovered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com