Connecting mechanism for improving tube-and-coupler scaffold

A connecting device and scaffolding technology, which is applied in the connection of scaffolding, building construction, construction, etc., can solve the problem of difficult arrangement of façade slanting bars and horizontal slanting bars, affecting the stability and safety of structural systems, and reducing structural safety and stability issues, to achieve the effects of improving mechanical properties, simple structural installation and use, and increasing stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

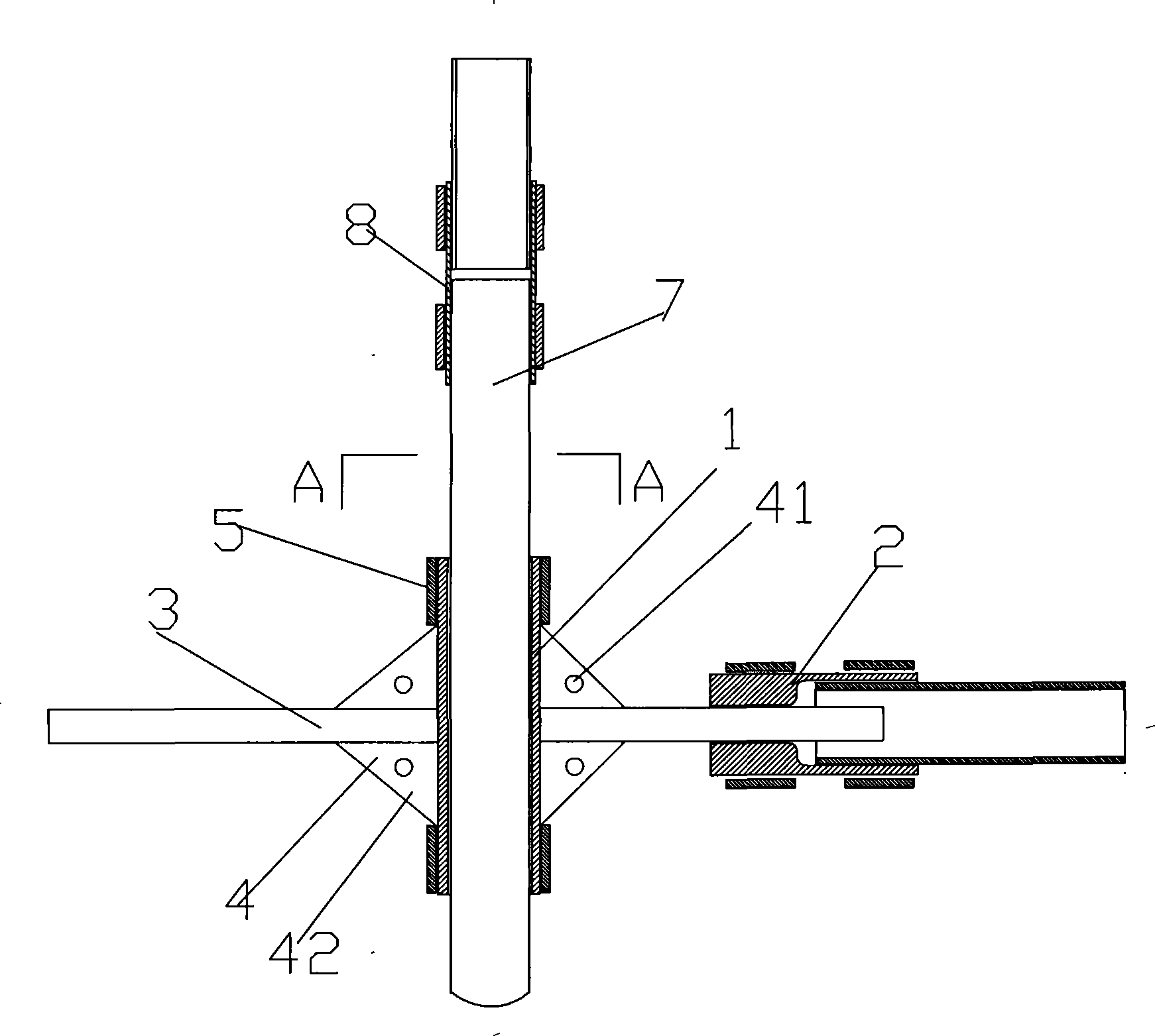

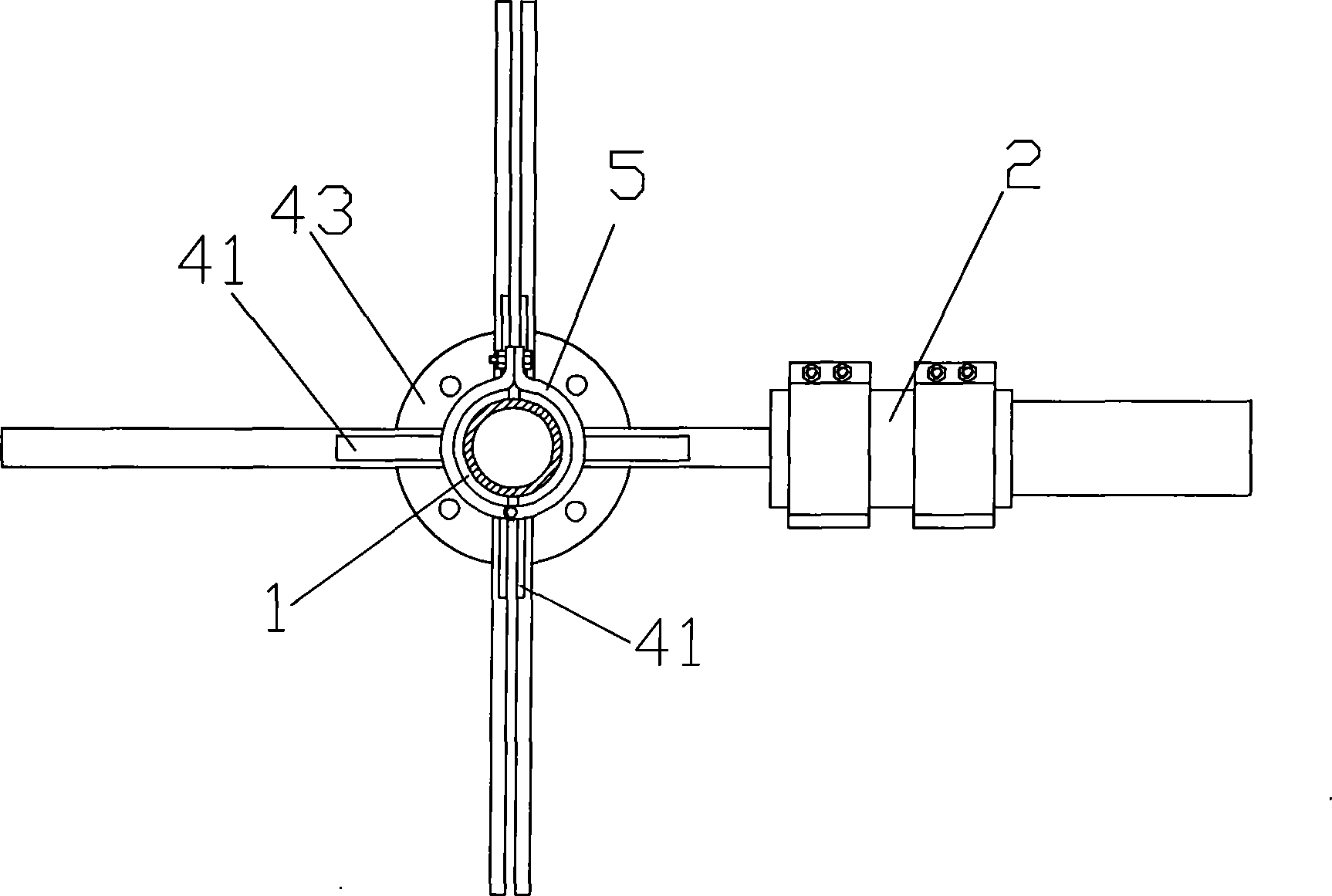

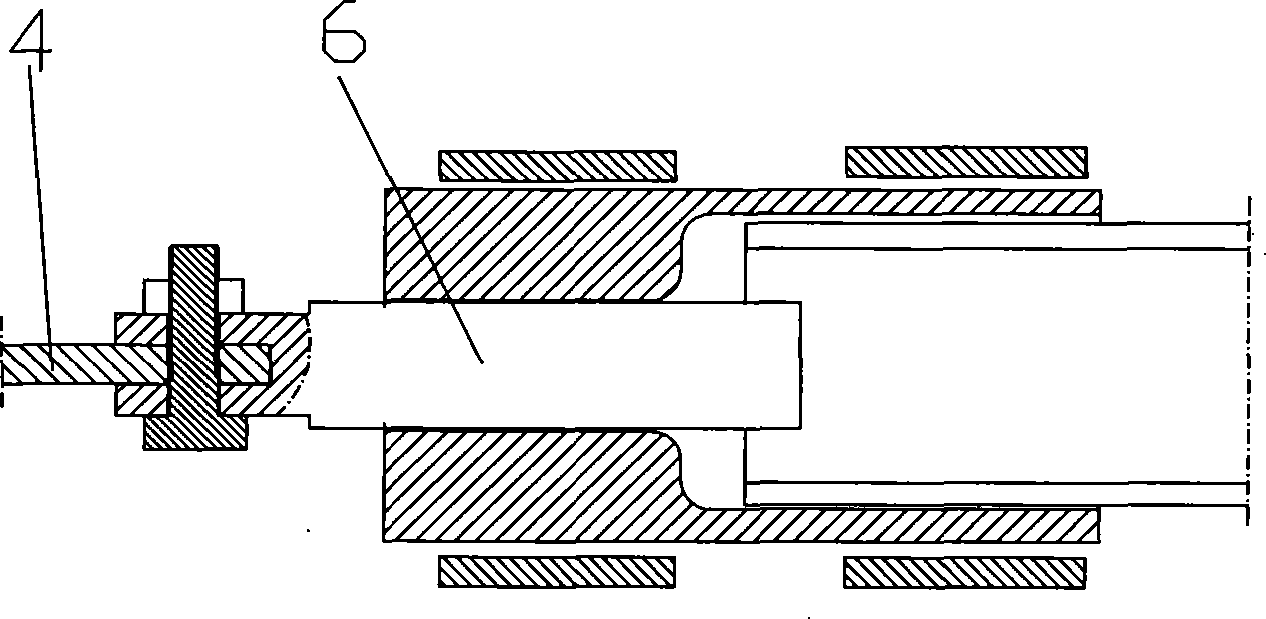

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A sectional view along A-A, as shown in the figure: the connecting device used to transform the fastener type steel pipe scaffolding in this embodiment includes the joint connecting sleeve 2, the node connecting sleeve 1 installed on the vertical pole 7 and the node connecting sleeve 1 fixedly arranged on the node The four cross-sections of the outer circumference of the connecting sleeve 1 are circular connecting rods 3, the connecting rods 3 are welded on the node connector 1 in a cross shape, the connecting rods 3 are perpendicular to the node connector 1 and the extension line passes through the node connecting sleeve 1 The center line of the inner circle; the node connection sleeve 1 and the joint connection sleeve 2 are respectively composed of two half-circle sleeves cut longitudinally. When in use, they are combined and fixed by the fastener 5 arranged on the outer ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com