Triphibian omnibearing moving mechanism

An omni-directional mobile, land, water and air technology, applied in motor vehicles, convertible vehicles, transportation and packaging, etc., can solve the problems of difficult design and processing, weak carrying capacity, etc., to achieve strong adaptability, smooth use, Wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

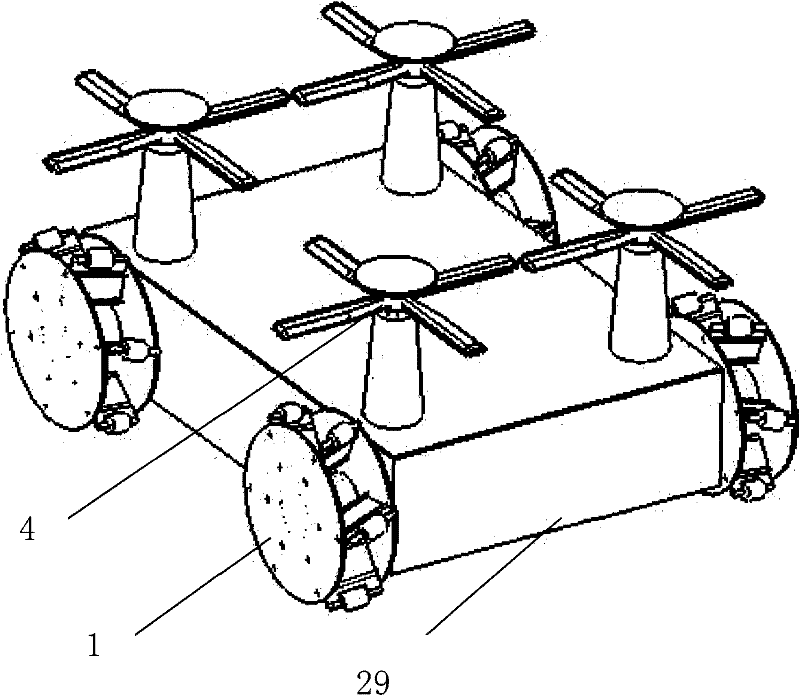

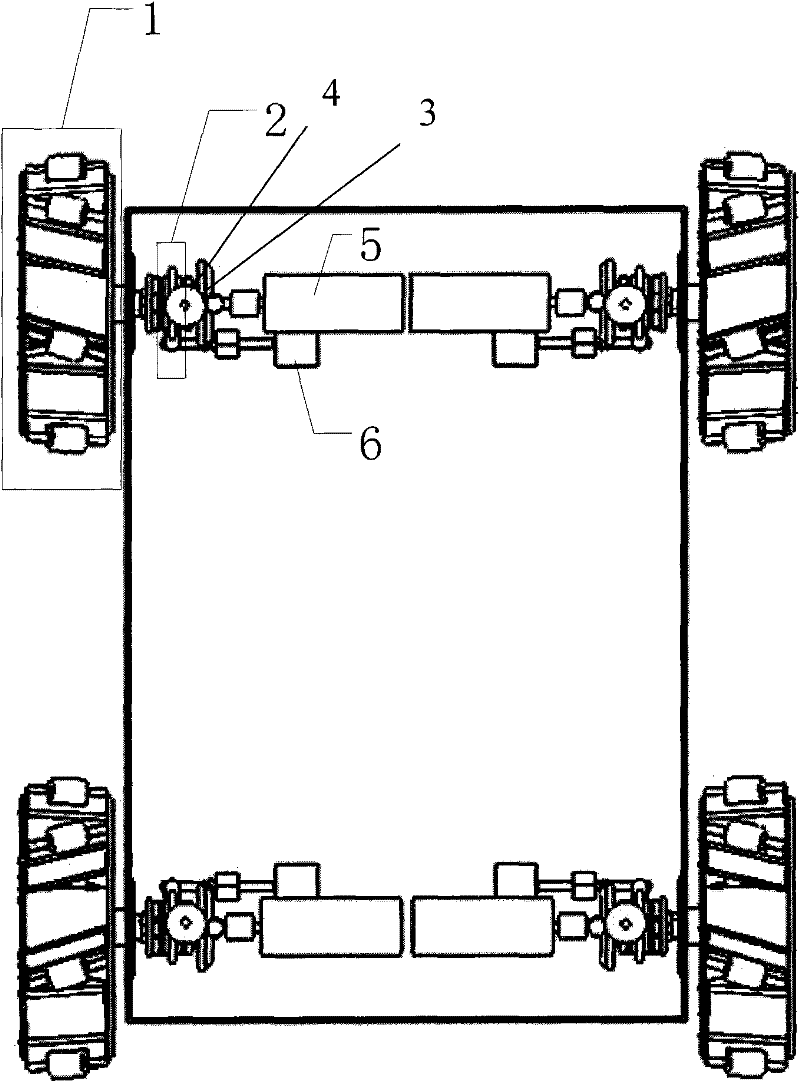

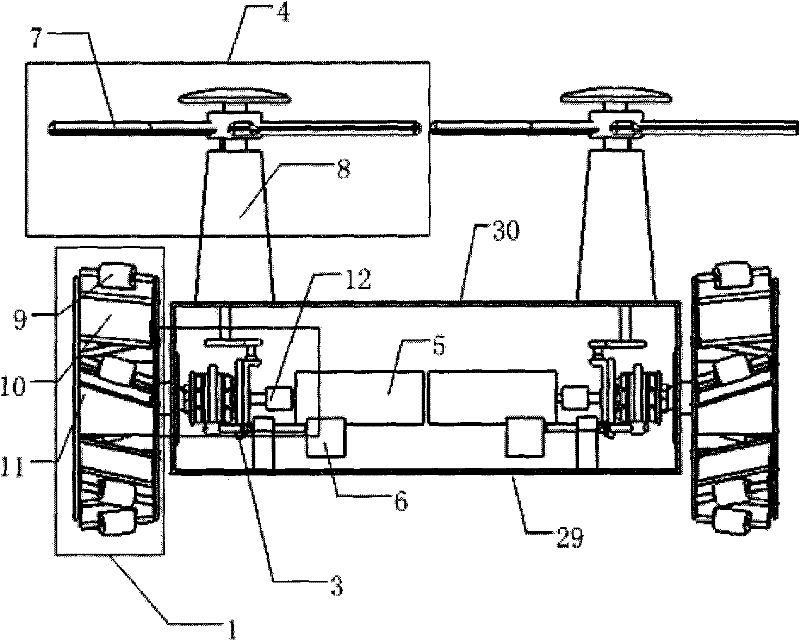

[0027] Embodiment 1: as figure 1 Shown, the present invention comprises box body 29, four groups of wheel trains 1 and the driving mechanism that is arranged with respect to each wheel train 1, and four groups of wheel trains 1 are symmetrically distributed on both sides of box body 29, as figure 2 As shown, the structures of the driving mechanisms of each group are the same, and all include a motor 5, a transmission mechanism 3, a clutch mechanism 2 and a helicopter rotor mechanism 4, wherein the motor 5, the transmission mechanism 3, and the clutch mechanism 2 are placed in the casing 29, The helicopter rotor mechanism 4 is placed on the top of the box body 29, the motor 5 is connected to the transmission mechanism 3, the output end of the transmission mechanism 3 is connected to the wheel train 1 and the helicopter rotor mechanism 4 respectively, and the clutch mechanism 2 connected with the electromagnet 6 is installed on the transmission mechanism 4. On the mechanism 3, ...

Embodiment 2

[0036] Embodiment 2: The structure of this example is the same as that of Embodiment 1. The difference is that two sides of the base body 24 of the clutch mechanism 2 are evenly provided with two springs, locking pins and locking pins along the circumference of the small wheel disc. The end cover installation hole 35 that the pin matches, and the flange 17 and the large bevel gear 16 of the transmission mechanism 3 connected to it are all provided with 4 holes. The propellers on the described helicopter rotor mechanism 4 are 4 pieces. The hub of the wheel train 1 is provided with 8 paddle-roller sets.

Embodiment 3

[0037] Embodiment 3: The structure of this example is the same as that of Embodiment 1, but the difference is that both sides of the base body 24 of the clutch mechanism 2 are evenly provided with 6 springs, locking pins and locking pins along the circumference of the small wheel disc. The end cover installation hole 35 that the pin matches, the flange 17 of the transmission mechanism 3 that is connected with it and the large bevel gear 16 are all provided with 2 holes. The propellers on the described helicopter rotor mechanism 4 are 6 pieces. The hub of the wheel train 1 is provided with 10 paddle-roller sets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com