Landfill type bridge expansion device and construction method

A telescopic device and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor stability, and achieve the effects of easy construction, excellent stretching performance, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

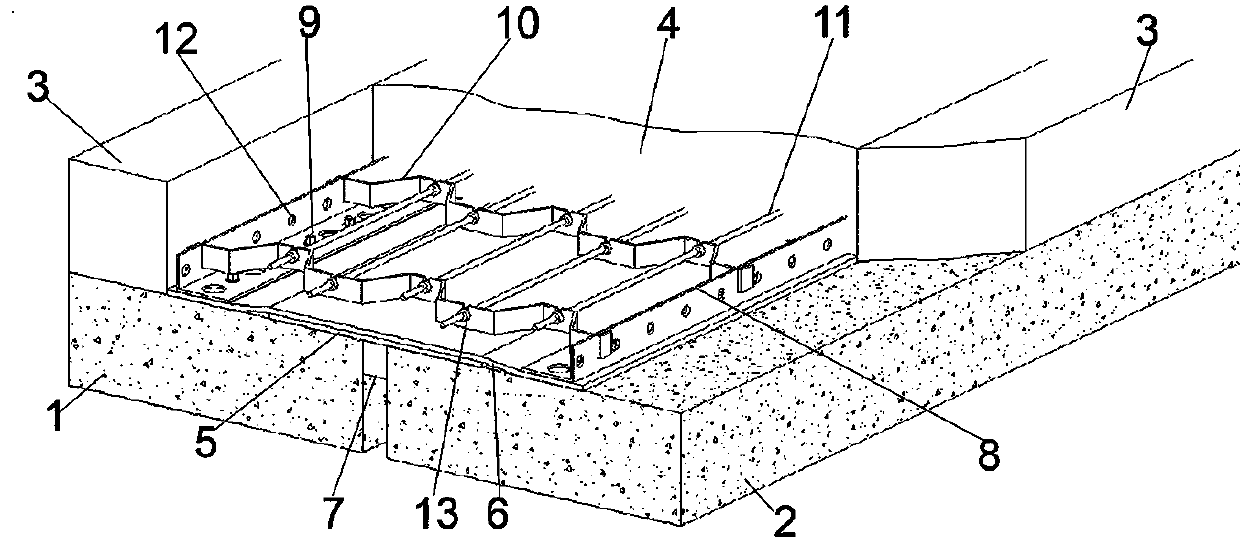

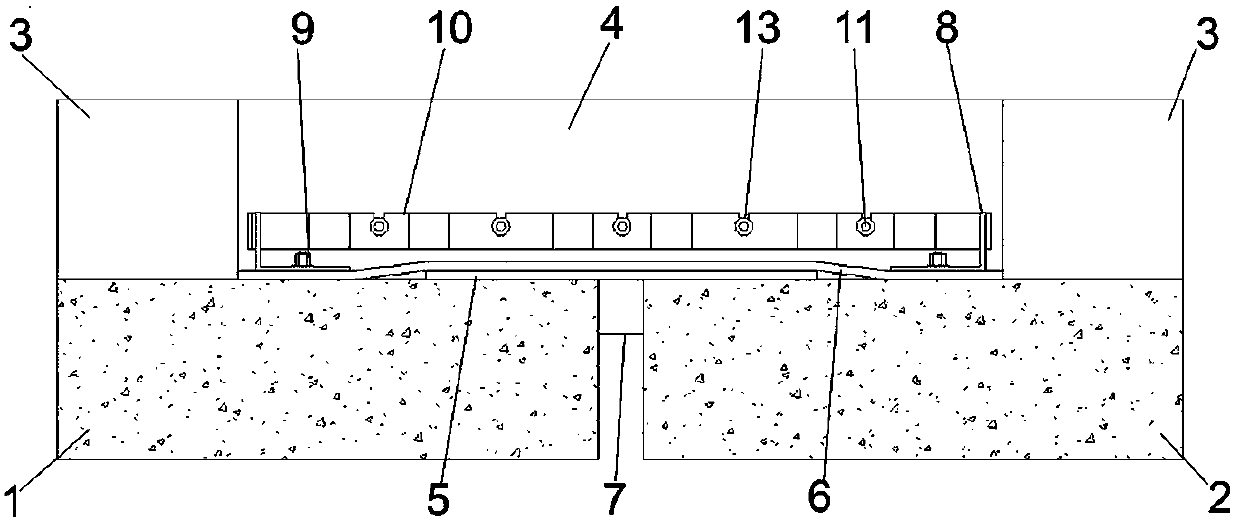

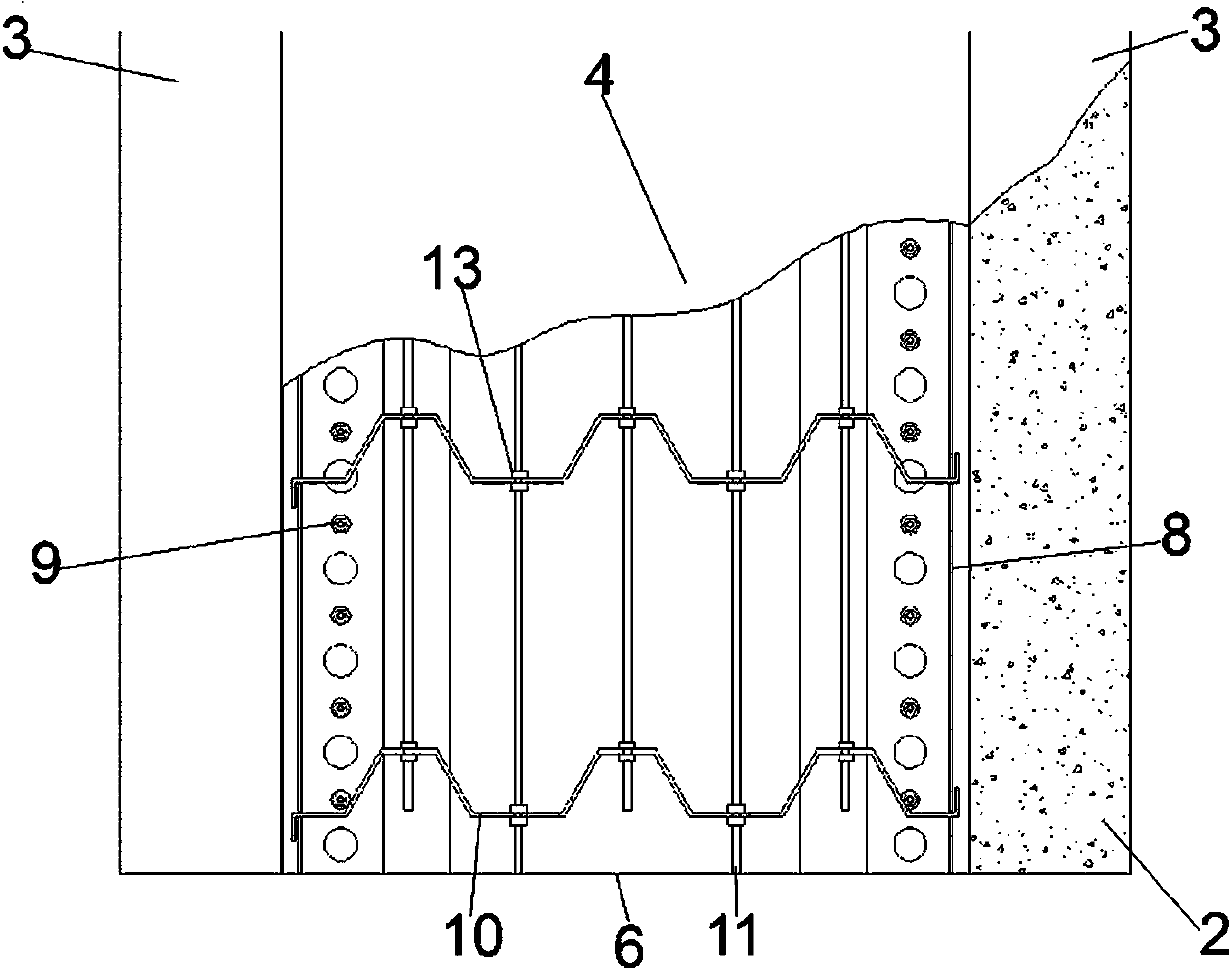

[0042] A kind of buried bridge expansion device, its structure is as follows Figure 1-Figure 6 As shown, it includes the stressed skeleton, which includes the tension and compression steel plate group matched with the expansion joint, and also includes the transverse steel bar group matched with the tension and compression steel plate group; one end of the tension and compression steel plate group is connected with the bridge 1, The other end is connected to the back wall 2; the stressed skeleton is filled with polymer concrete 4, and the polymer concrete 4 is aligned with the pavement; the expansion joint is provided with a composite plate group matched with the stressed skeleton. A sealing strip 7 is provided in the expansion joint between the bridge 1 and the back wall 2 .

[0043] The tensile and compression steel plate group includes a plurality of corrugated steel plates 10 perpendicular to the expansion joints, and the distance between adjacent corrugated steel plates ...

Embodiment 2

[0048] A buried bridge telescopic device, which is different from Embodiment 1 in that no grout hole 12 is provided on the side of the angle steel 8 .

[0049] (1) When newly installing the landfill bridge expansion device, (a) prefabricate; weave the force-bearing skeleton, fix the transverse reinforcement group on the tensile and compression steel plate group, and the transverse reinforcement passes through the corrugated steel plates with an average interval of 30cm-50cm U-shaped notch 101 on 10 utilizes a pair of fixing nuts 13 that are all provided with at the intersection of transverse reinforcing bar 11 and any U-shaped notch 101 to fix transverse reinforcing bar 11 and corrugated steel plate 10, and a pair of fixing nuts 13 moves to Both sides of U-shaped notch 101, make the both sides of U-shaped notch 101 respectively have a fixed nut 13, rotate fixed nut 13, fixed nut 13 realizes the clamping of U-shaped notch 101 by the screw thread on the transverse steel bar 11 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com