Convenient combined mounting equipment for jack

A combined installation and jack technology, used in mechanical equipment, metal processing equipment, lifting devices, etc., can solve the problems of scratched piston rod, assembly failure, piston rod misalignment, etc., to reduce friction, avoid being scratched, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

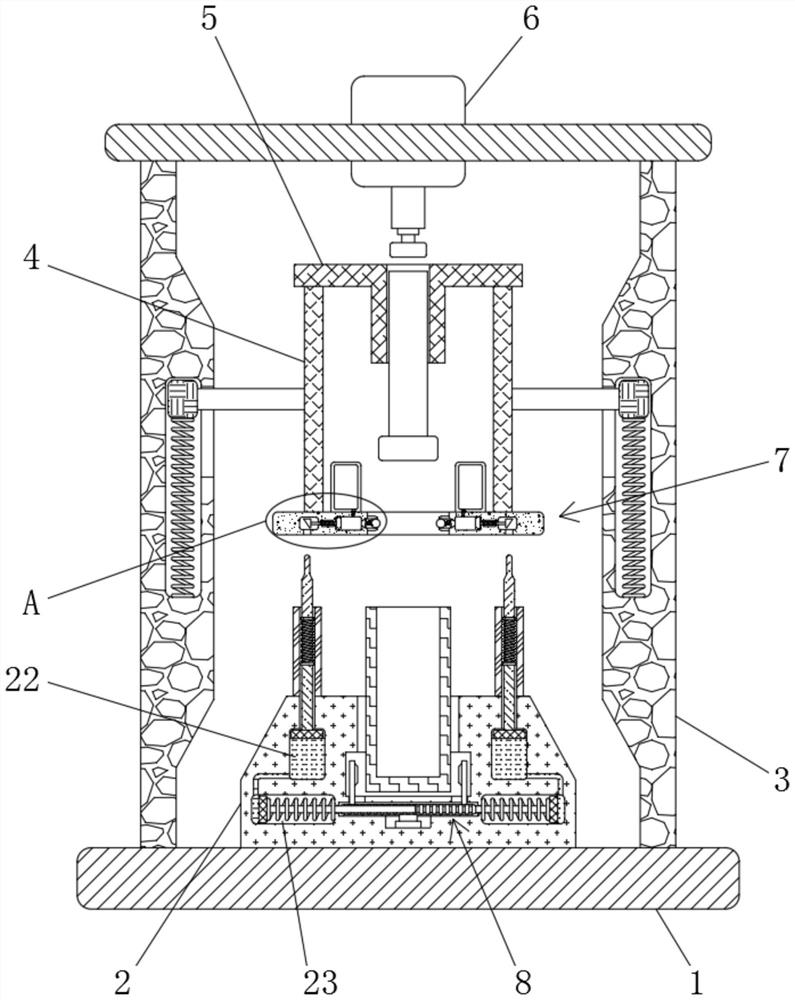

[0022] see Figure 1-2 , a jack convenient combined installation equipment, including a base 1, the top of the base 1 is welded with a fixed table 2 two support rods 3, between the two support rods 3 are slidably connected with a fixed plate 4, the top of the two fixed plates 4 A splint 5 is welded, a cylinder 6 is always above the splint 5, a lubricating mechanism 7 is welded on the bottoms of the two fixing plates 4, and a shaft fixing mechanism 8 is opened inside the fixing table 2.

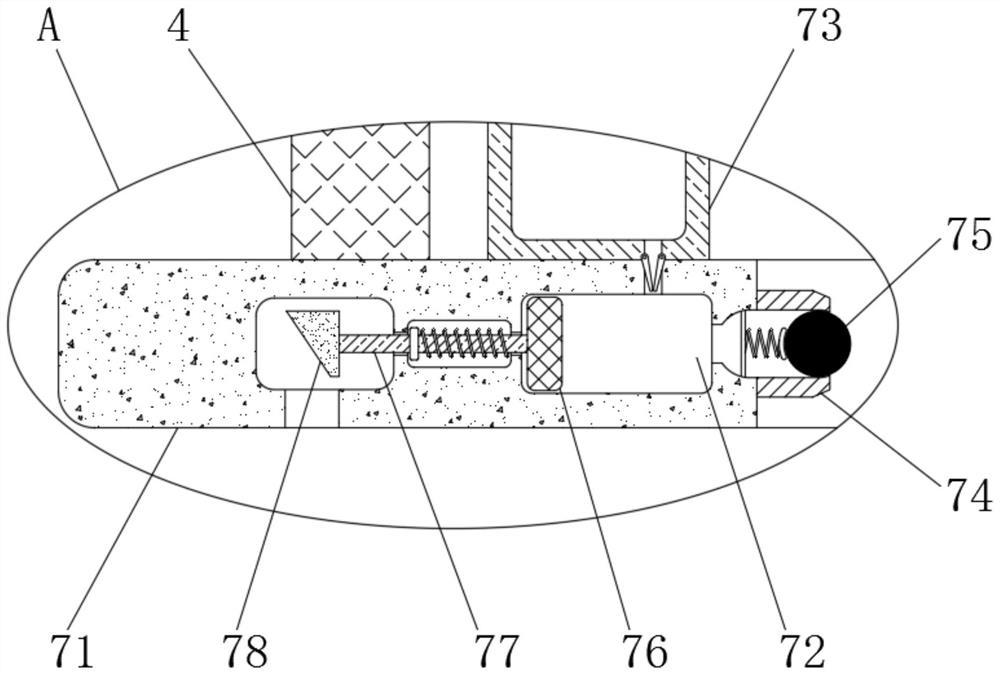

[0023] The top of the fixed table 2 is provided with a placement slot 21, and the top of the fixed table 2 is inserted with two ejector rods 26. The lubricating mechanism 7 includes a movable plate 71, and the inside of the movable plate 71 is provided with two feeding cavities 72. The movable plate 71 There are two storage boxes 73 welded on the top of the movable plate 71, and six oil outlet pipes 74 arranged in a ring are arranged on the inner side wall of the movable plate 71. The opposite...

Embodiment 2

[0026] see Figure 3-4, a jack convenient combined installation equipment, including a base 1, the top of the base 1 is welded with a fixed table 2 two support rods 3, between the two support rods 3 are slidably connected with a fixed plate 4, the top of the two fixed plates 4 A splint 5 is welded, a cylinder 6 is always above the splint 5, a lubricating mechanism 7 is welded on the bottoms of the two fixing plates 4, and a shaft fixing mechanism 8 is opened inside the fixing table 2.

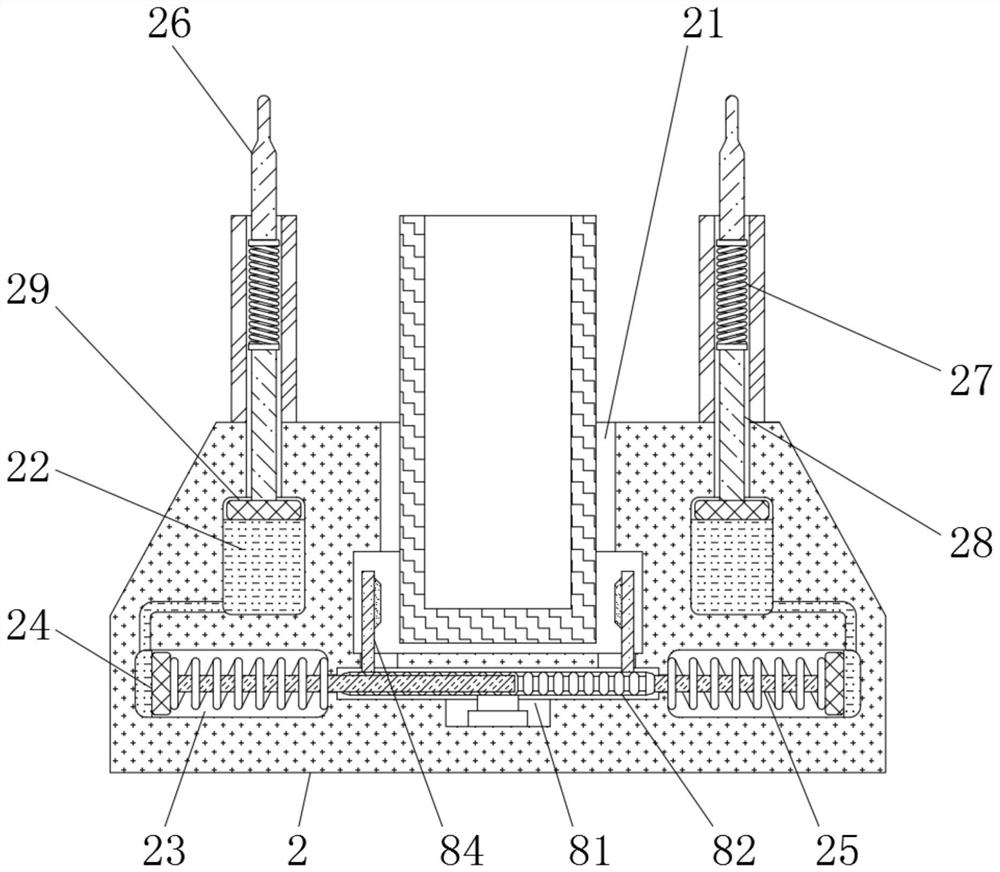

[0027] The top of the fixed table 2 is provided with a placement groove 21 , and the inside of the fixed table 2 is provided with two oil chambers 22 and a sealing chamber 23 . The interiors of the two sealing chambers 23 are slidably connected with a pressurized piston 24 , and the two pressurized pistons 24 A movable rack 25 is welded on the opposite side, two ejector rods 26 are inserted on the top of the fixing table 2, a buffer spring 27 is welded on the bottom of the two ejector rods 26, ...

Embodiment 3

[0031] see Figure 1-4 , a jack convenient combined installation equipment, including a base 1, the top of the base 1 is welded with a fixed table 2 two support rods 3, between the two support rods 3 are slidably connected with a fixed plate 4, the top of the two fixed plates 4 A splint 5 is welded, a cylinder 6 is always above the splint 5, a lubricating mechanism 7 is welded on the bottoms of the two fixing plates 4, and a shaft fixing mechanism 8 is opened inside the fixing table 2.

[0032] The top of the fixed table 2 is provided with a placement groove 21 , and the inside of the fixed table 2 is provided with two oil chambers 22 and a sealing chamber 23 . The interiors of the two sealing chambers 23 are slidably connected with a pressurized piston 24 , and the two pressurized pistons 24 A movable rack 25 is welded on the opposite side, two ejector rods 26 are inserted on the top of the fixing table 2, a buffer spring 27 is welded on the bottom of the two ejector rods 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com