A cornmeal production and processing mechanism based on multi-directional feeding

A technology of processing mechanism and cornmeal, which is applied to mixers, mixers, conveyors and other directions with rotating stirring devices, which can solve the problems of poor work continuity and difficulty in ensuring the accuracy of feeding amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

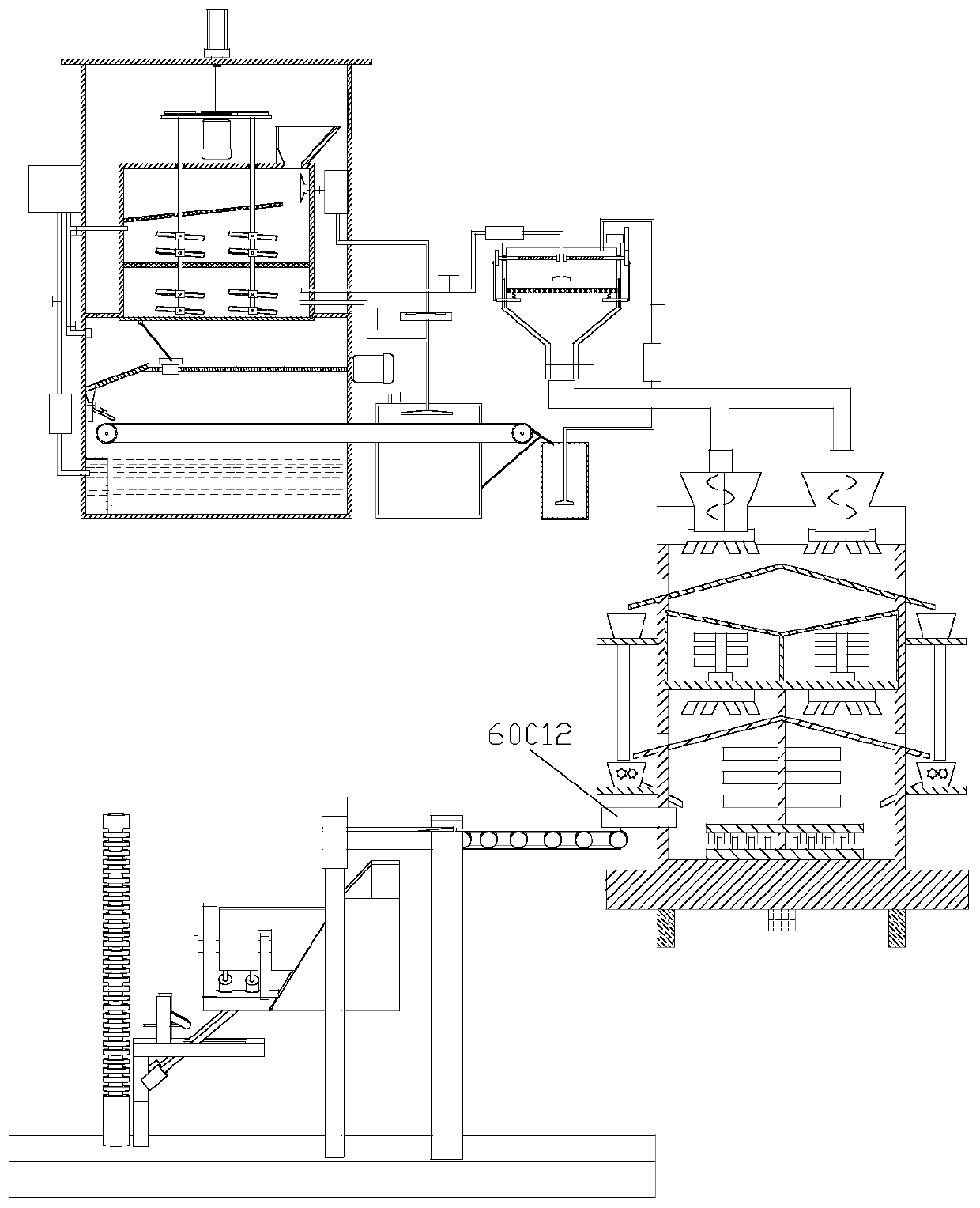

[0057] Such as figure 1 As shown, this embodiment discloses a cornmeal production and processing mechanism based on multi-directional feeding, which includes a corn grain crushing device, a powder mixing device, and a powder running device in sequence from front to back according to the technological process.

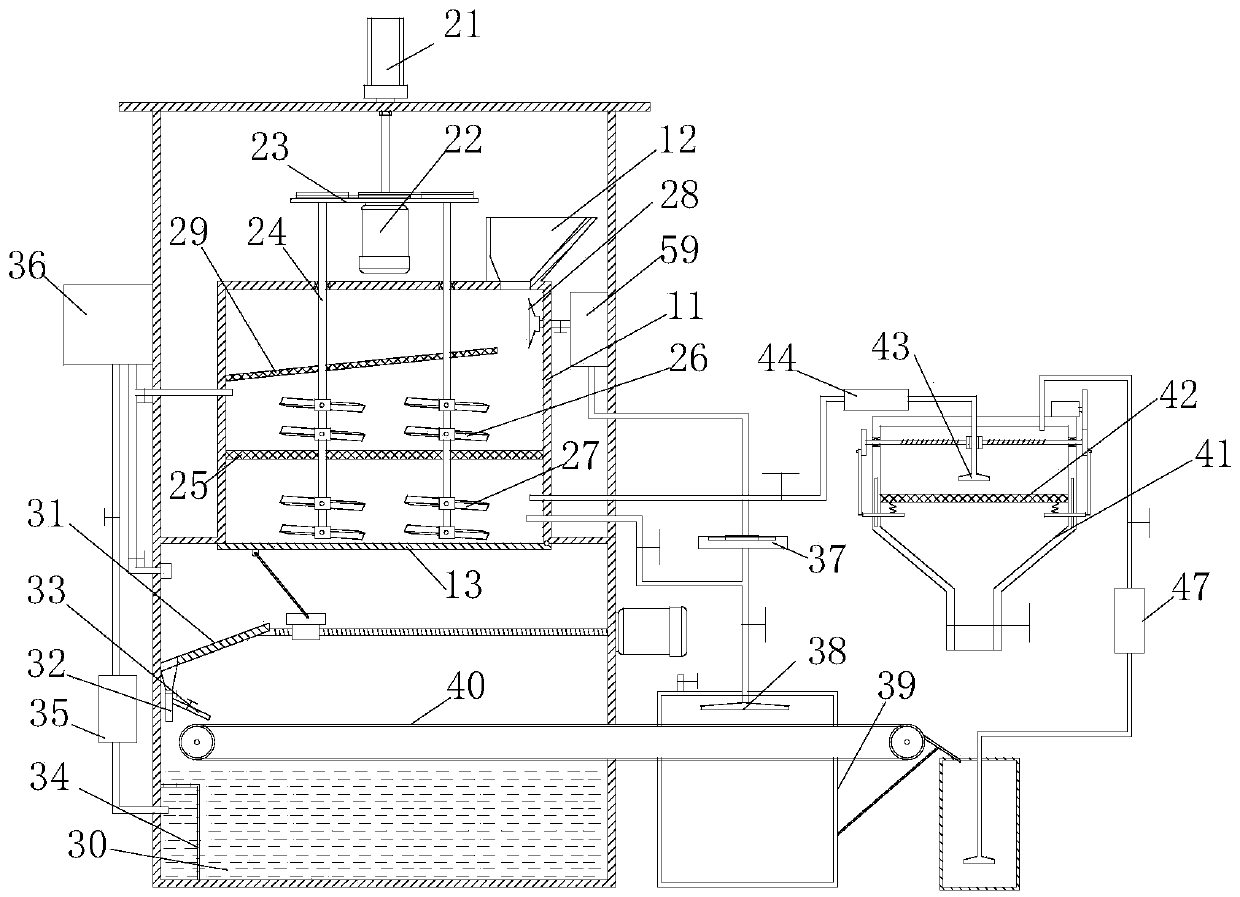

[0058] Such as figure 2 As shown, the corn crushing device sequentially includes a crushing unit, a drying unit and a recycling unit in the order of the process flow. The crushing unit includes a crushing box 11, a rotating shaft 24, an impurity removal mechanism arranged in the crushing box 11, an upper crushing mechanism and a lower crushing mechanism. The top of the scrap box 11 has a feed inlet and an upper insertion opening for vertically inserting the rotating shaft 24 , and the bottom of the scrap box 11 has a discharge opening. The discharge port is hinged with a material door 13, which is used to close the discharge port of the scrap bin 11. The material doo...

Embodiment 2

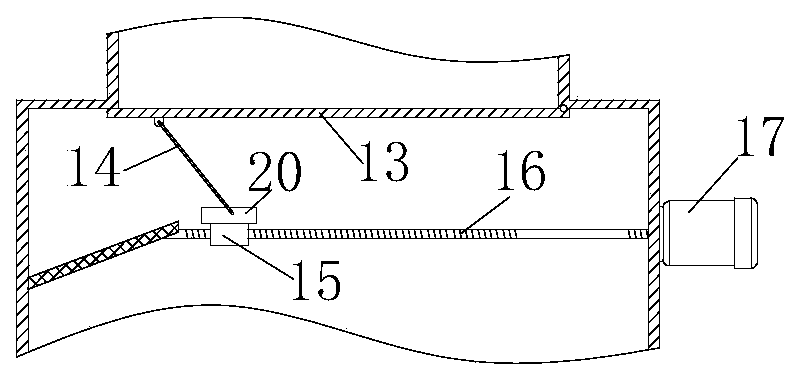

[0071] Such as image 3 , 4 As shown, the difference between the present embodiment and the above-mentioned embodiments is that the feeding power mechanism includes a feeding rod 14 and a movable block 20, and the two ends of the feeding rod 14 are respectively hinged on the material door 13 and the movable block 20, and the movable block 20 Located below the material door 13, the movable block 20 is connected with the first power mechanism or the second power mechanism for horizontal movement.

[0072] Such as image 3 , 5 As shown, the first power mechanism includes telescopic rod 18 and blanking cylinder 19, movable block 20 is connected on the telescopic end of telescopic rod 18, and the telescopic end of telescopic rod 18 is connected with the piston end of blanking cylinder 19.

[0073] On the premise that the movable block 20 is connected to the first power mechanism, when it is necessary to open or close the discharge port of the crushed material box 11, the telesco...

Embodiment 3

[0092] Such as Figure 11-13 As shown, the difference between this embodiment and the above-mentioned embodiments is that the mixing device also includes a base 68 on which a rotating motor 681 is installed, the rotating motor 681 is connected to the mixing shaft 67, and several supporting legs 682 are installed on the base 68. Around the base 68 are also provided with some accommodation grooves 683, and a vertically arranged mixing cylinder 684 is installed in the accommodation groove 683. The upper end of the mixing cylinder 684 is fixedly connected with the base 68, and the lower end of the mixing cylinder 684 is equipped with universal wheels. 685.

[0093] Traditional powder mixing devices generally have a fixed base, which makes it cumbersome and time-consuming to move the entire device. There are also some powder mixing devices for the convenience of moving to install moving wheels on the lower part of the base, but they vibrate greatly when they are in motion, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com