Wheel-disc-type multi-material selective laser melting molding device and method

A laser selective melting and forming device technology, which is applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems that cannot meet the requirements of direct forming of multi-material integrated parts, limit the application range of laser selective melting technology, etc. , to achieve the effect of improving good metallurgical bonding performance, improving molding efficiency and quality, and small rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

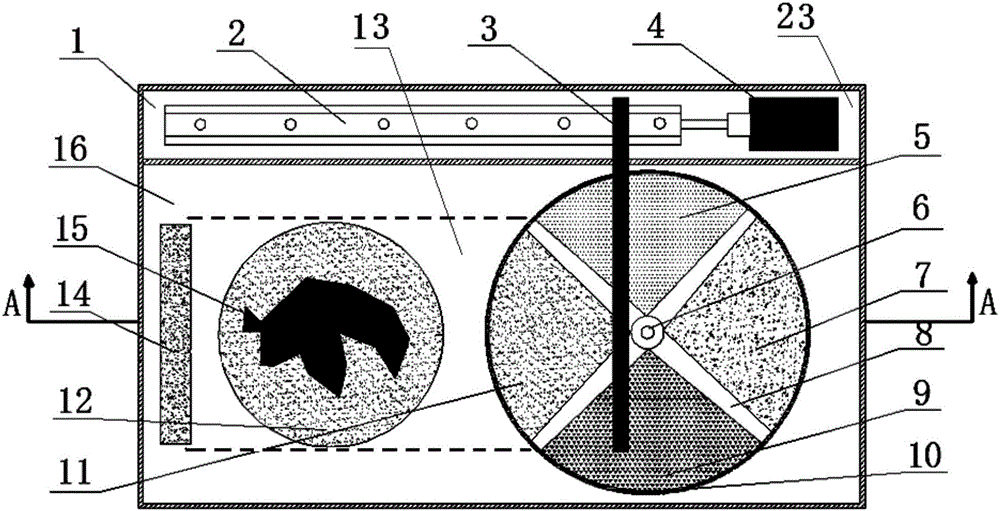

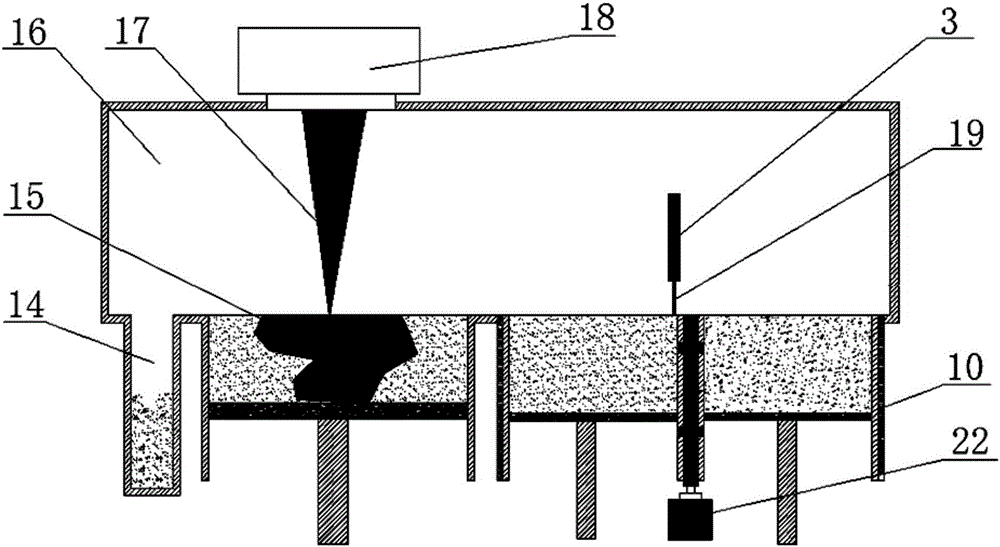

[0032] Such as figure 1 with 2 Shown. The invention discloses a roulette type multi-material laser selective melting and forming device, which comprises a forming chamber 16, a forming cylinder 12, a powder spreading mechanism, a powder supply device, a laser selective melting device, and a control system in the forming chamber 16; The forming cylinder 12 and the powder supply mechanism are arranged along the length of the forming chamber 16 below the plane of the substrate of the forming chamber 16;

[0033] The powder supply device is a rotatable roulette-type powder cylinder. The roulette-type powder cylinder has a cylindrical structure, and its interior is divided into four equally divided powder cylinders by a partition 8, namely: the first powder cylinder 11. The second powder material tank 5, the third powder material tank 7 and the fourth powder material tank 9; these four powder material tanks can be used to hold powder of different materials;

[0034] When the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com