Pile foundation hole cleaning device and technology

A technology of hole cleaning device and pile foundation, which is applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of poor quality of pile foundation, poor quality of hole cleaning, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

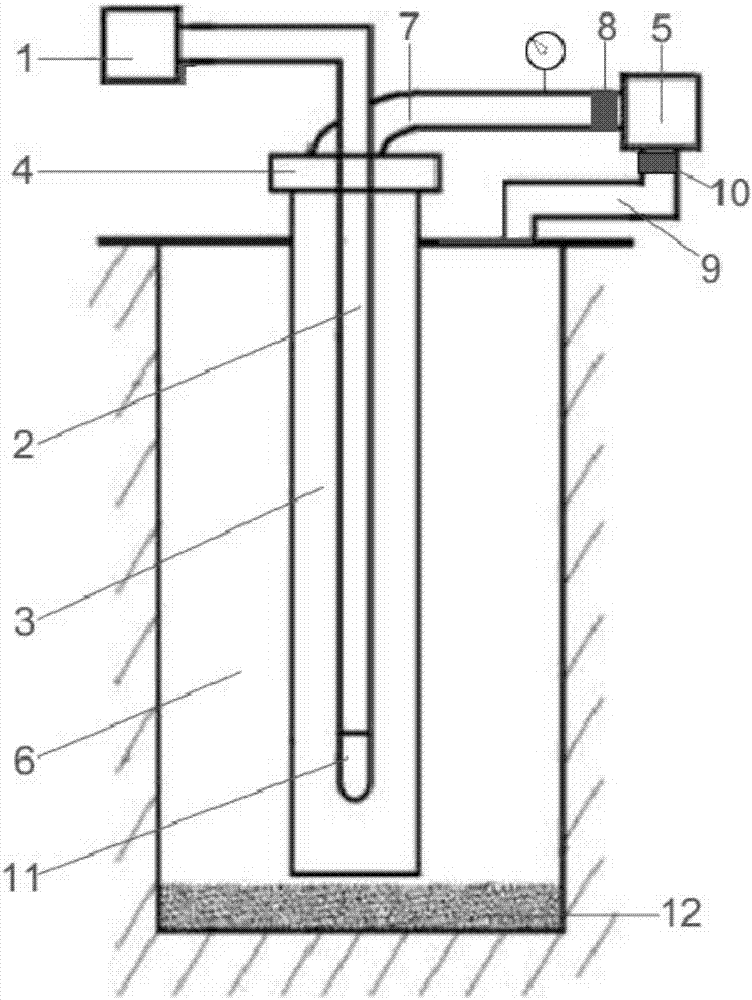

[0020] Such as figure 1 As shown, a pile foundation cleaning device includes an air compressor 1, an air supply pipe 2, a conduit 3, a gas lift reverse circulation shroud 4 and a sedimentation tank 5, and one end of the air supply pipe 2 is connected to the input port of the air compressor 1 , the other end is inserted into the conduit 3, the conduit 3 is set in the pile hole 6 to be cleaned, the pile hole 6 is provided with chemical slurry, the upper port of the conduit 3 is connected with the sedimentation tank 5 through the slag discharge pipe 7, and the slag discharge pipe 7 exits A pressure gauge is provided, a first filter screen 8 is provided between the slag discharge pipe 7 and the sedimentation tank 5, the sedimentation tank 5 is connected to the pile hole through a grout filling pipe 9, and a second The filter screen 10, the upper port of the conduit 3 is connected to the gas lift reverse circulation shroud 4, and the air supply pipe 2 and the slag discharge pipe 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com