A kind of protective tube device for forming holes in building foundation and construction method thereof

A construction method and casing technology, applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems affecting the construction quality and progress, difficult to form pile holes, etc., to improve the quality of holes, reduce air pressure, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

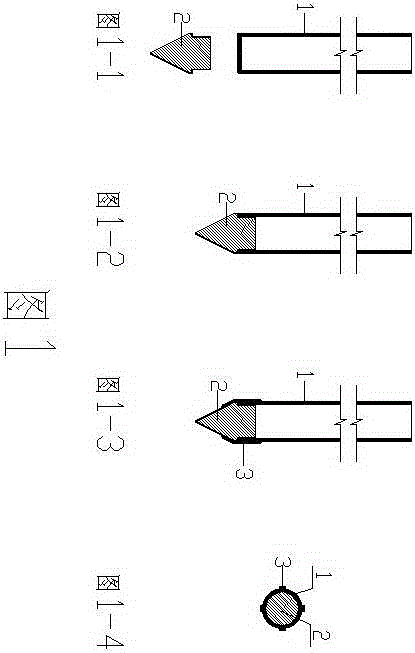

[0032] figure 1 is a schematic diagram of an embodiment of the parts and connections of the casing device of the present invention, the parts of the casing device being as figure 1 - Casing 1 and impact cone 2 shown in -1; figure 1 As shown in -2, at the bottom of the casing 1, insert the cylinder of the upper half of the impact cone 2 into the inside of the casing 1, and weld and fix it at the connection; figure 1 As shown in -3, the connection between the casing 1 and the impact cone 2 is welded and fixed with a strip steel plate 3; the top view sectional view of the connection between the casing 1 and the impact cone 2 is shown in figure 1 -4 shown.

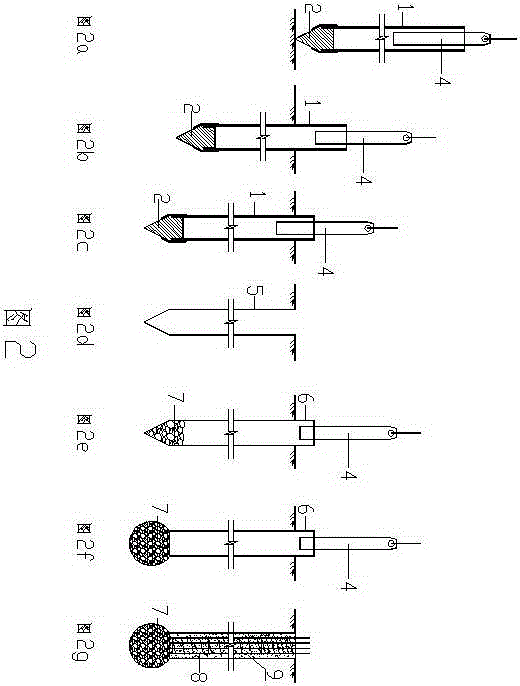

[0033] figure 2 It is the process diagram of the construction method of the building foundation of an embodiment of the present invention, and it comprises the following steps, at first, as figure 2 As shown in a, place a casing 1 with an impact cone 2 at the bottom end at the pile site, and put a slender weight 4 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com