Prefabricated reinforced concrete column template and making method thereof

A technology for reinforced concrete columns and manufacturing methods, which is applied to columns, pier columns, pillars, etc., can solve problems affecting the integrity of columns and mechanical performance, and achieve easy assurance of construction quality, improvement of integrity, and reduction of on-site workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The prefabricated reinforced concrete column formwork proposed by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings and embodiments.

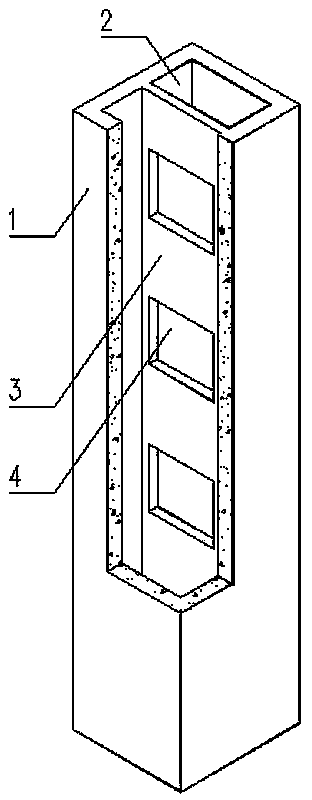

[0047] In an embodiment of the prefabricated reinforced concrete column formwork proposed by the present invention, as figure 1 , the prefabricated reinforced concrete column formwork includes a cylindrical outer wall 1 and a longitudinal inner partition 3, the inside of the column formwork is separated by the inner partition 3 into two hollow tunnels 2 running through the longitudinal direction, and at least one is opened on the inner partition Transverse holes 4 communicating with the hollow channels on both sides of the inner partition. The surface of the hollow channel 2 or the transverse hole 4 is a rough surface. figure 1 The middle shaded part is the cutting plane.

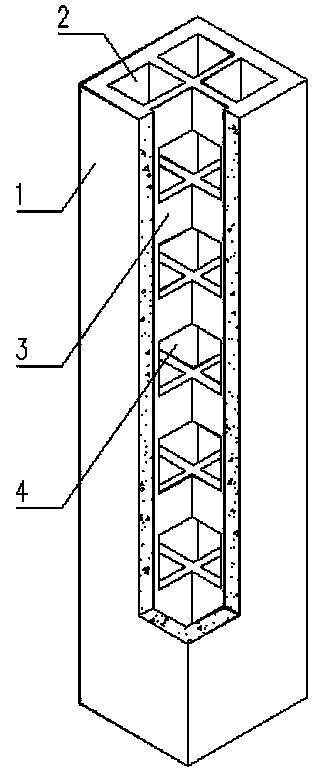

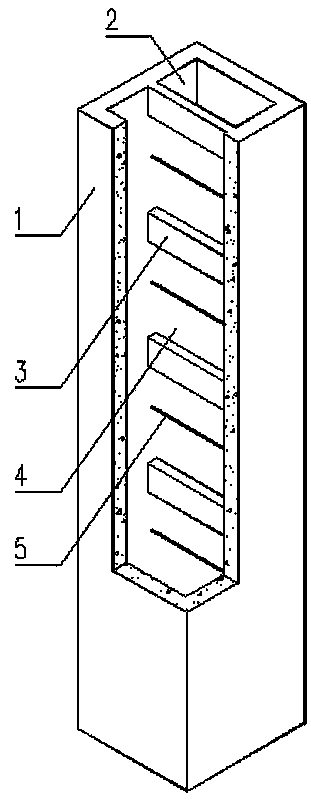

[0048] In another embodiment of the prefabricated reinforced concrete column template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com