Patents

Literature

59results about How to "Guarantee the final quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

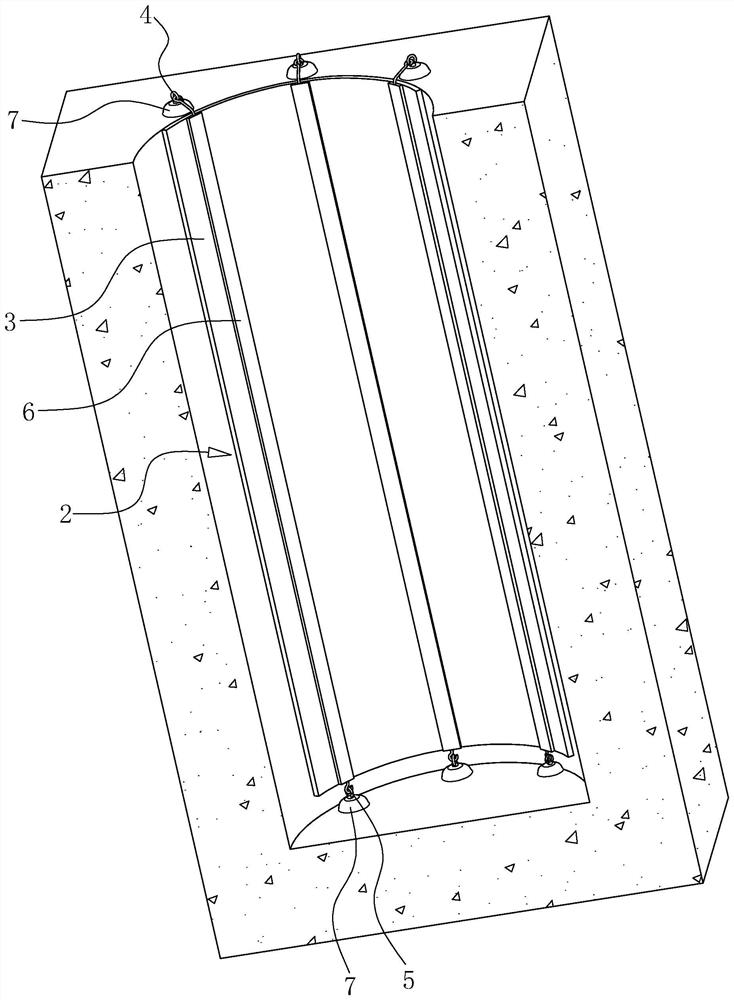

Construction method for subway contact passage

The invention provides a construction method for a subway contact passage suitable for a very thick Cenozoic stratum region with low heat conductivity and strong heat insulation effect. The method comprises five stages, namely construction preparation, construction of freezing holes, freezing, digging and supporting of the passage and a water collecting well and slurry filling in the back of a wall. The method specifically comprises the following steps of: performing the construction preparation, then forming the freezing holes under the condition that the thickness of a frozen soil curtain is ensured, adding short-range freezing holes on the upper parts of the bell mouths of the freezing holes, and detaching reserved steel pipe sheets at the opening of the passage by adopting a secondary hole forming technology; performing positive freezing after a freezing system runs normally, and making the freezing system perform maintenance freezing after the frozen soil curtain meets the design requirement; after the procedures are finished, performing the digging and supporting stage of the passage and the water collecting well; and pre-burying slurry pipes and filling slurry. By the construction method, the construction difficulty is reduced, the safety and the reliability of engineering are improved, the construction period is shortened, the construction efficiency is improved, and the quality of the engineering is ensured.

Owner:TIANJIN URBAN CONSTR TUNNEL

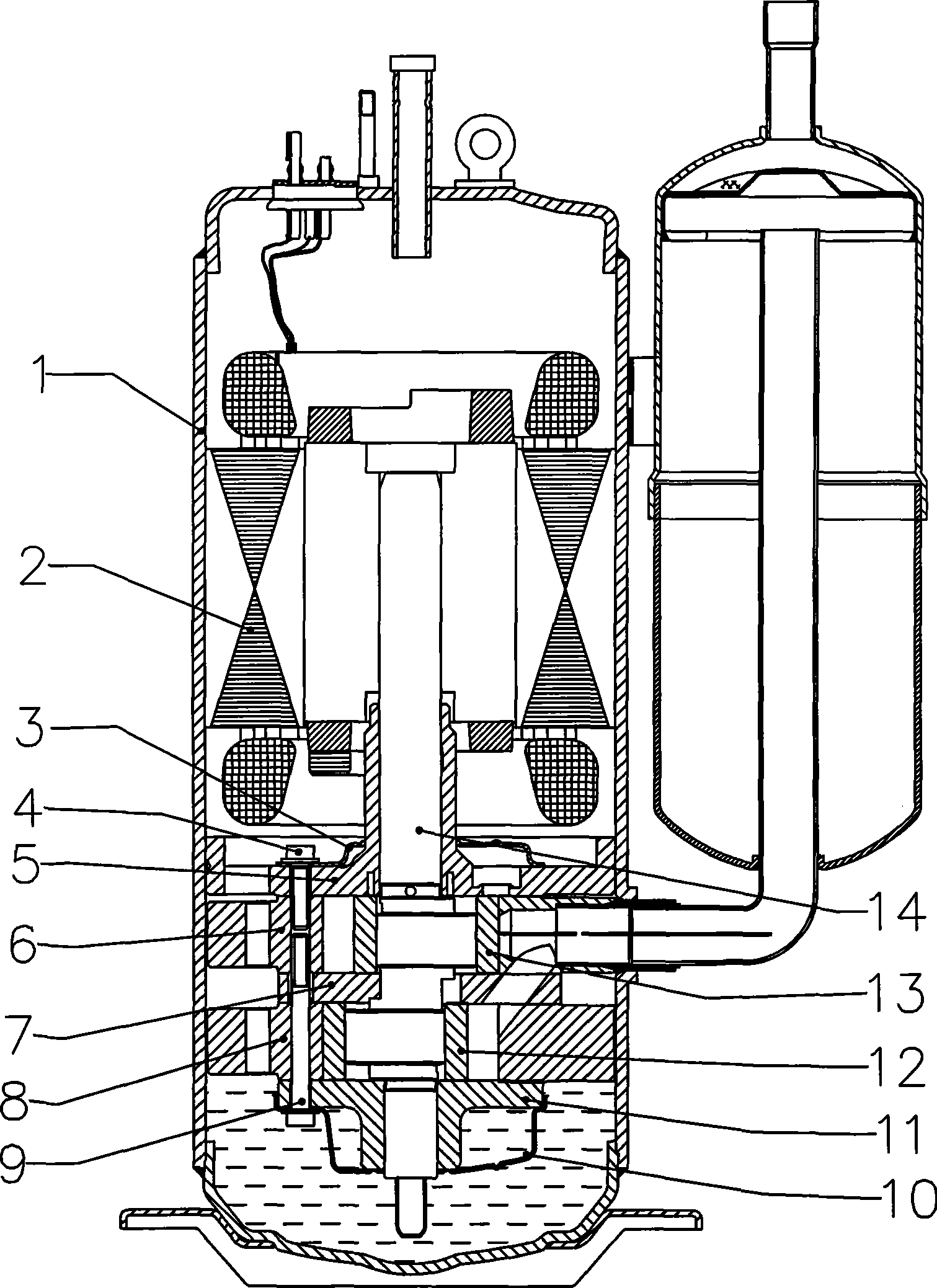

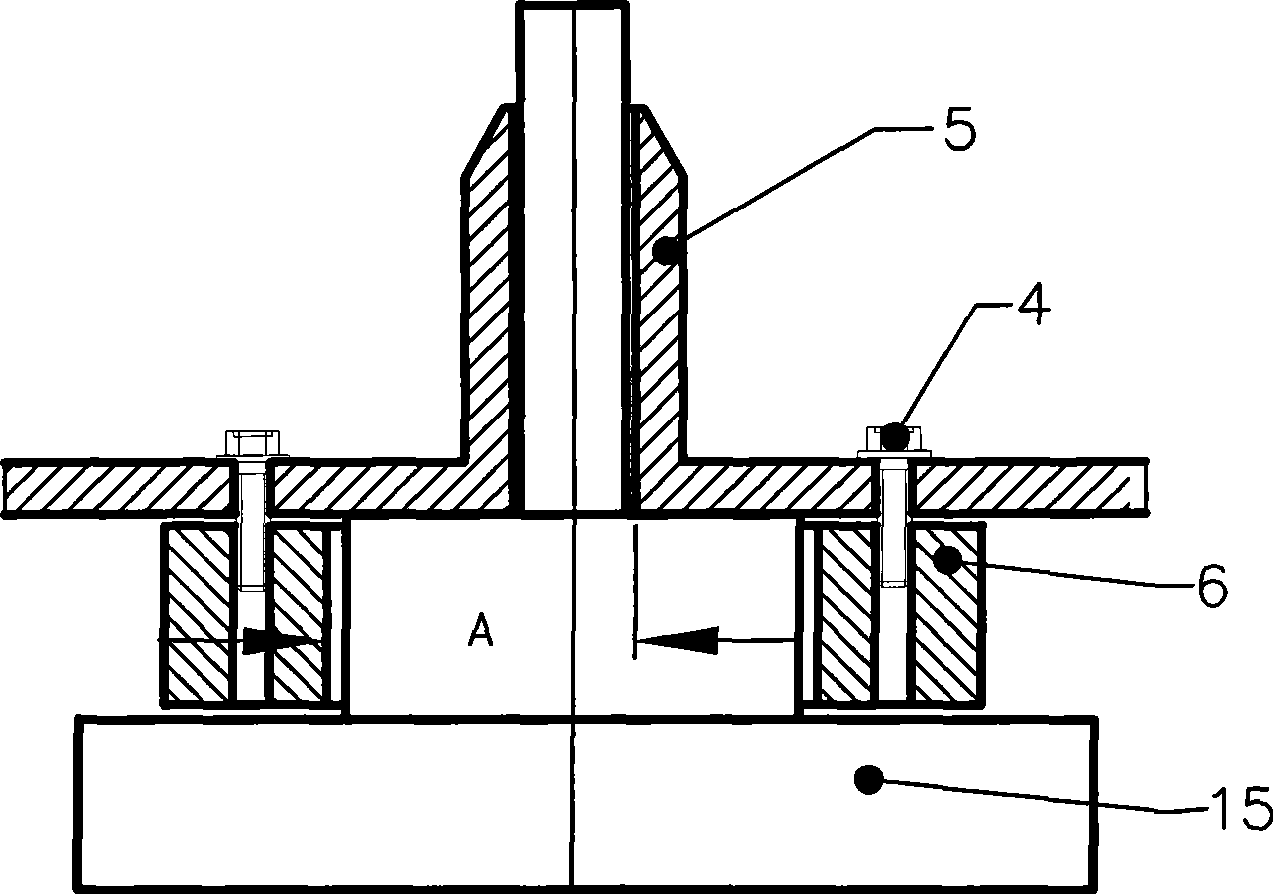

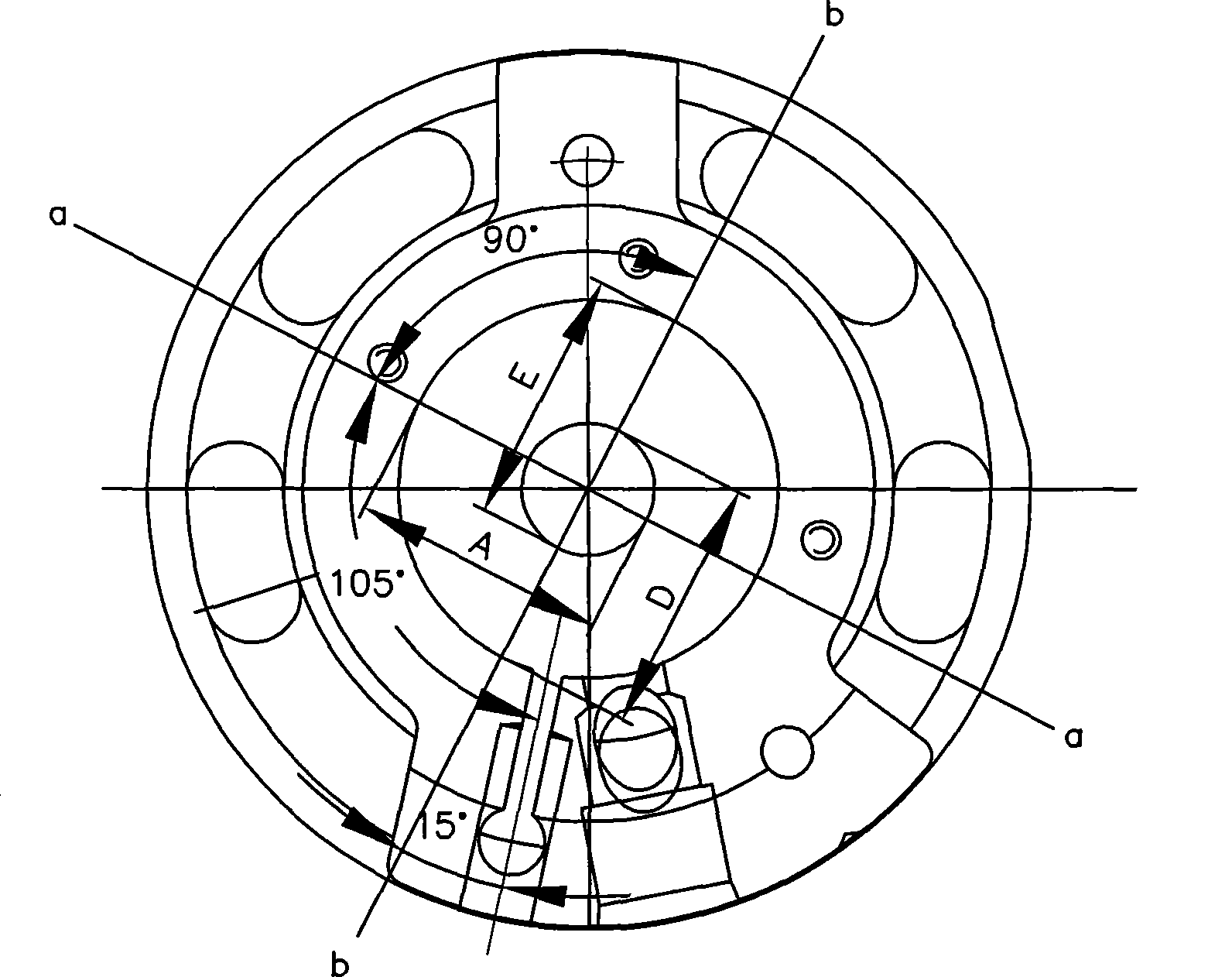

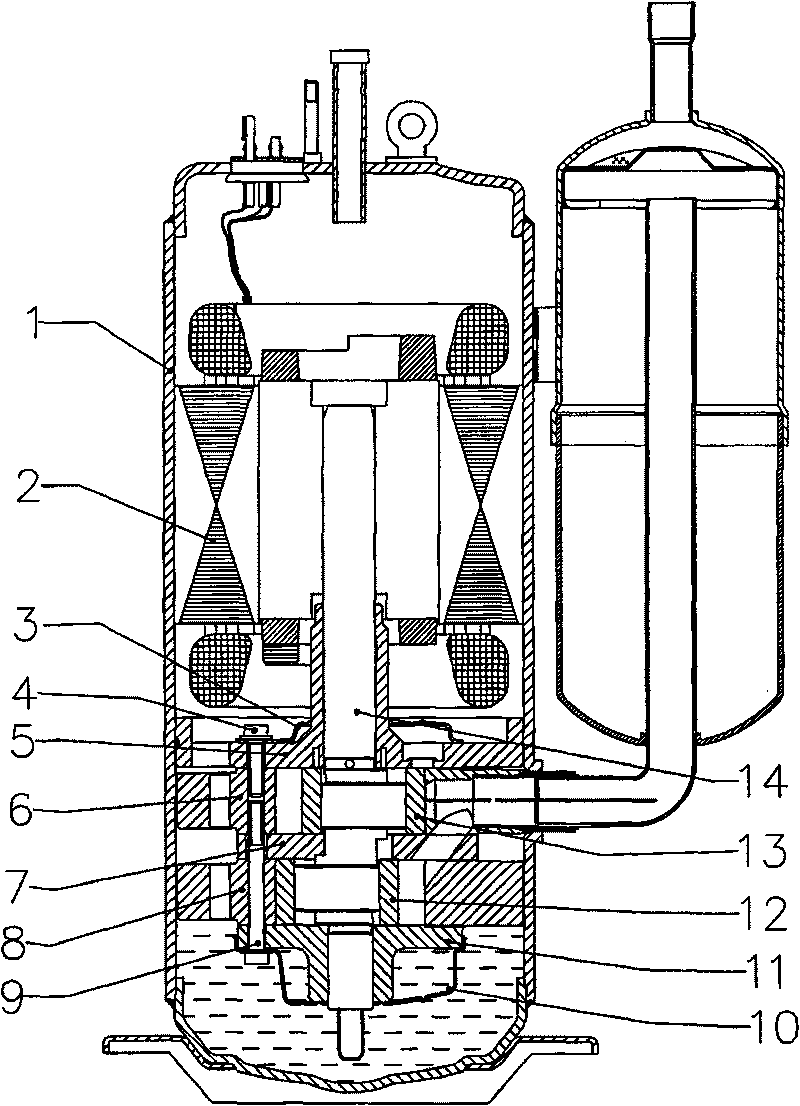

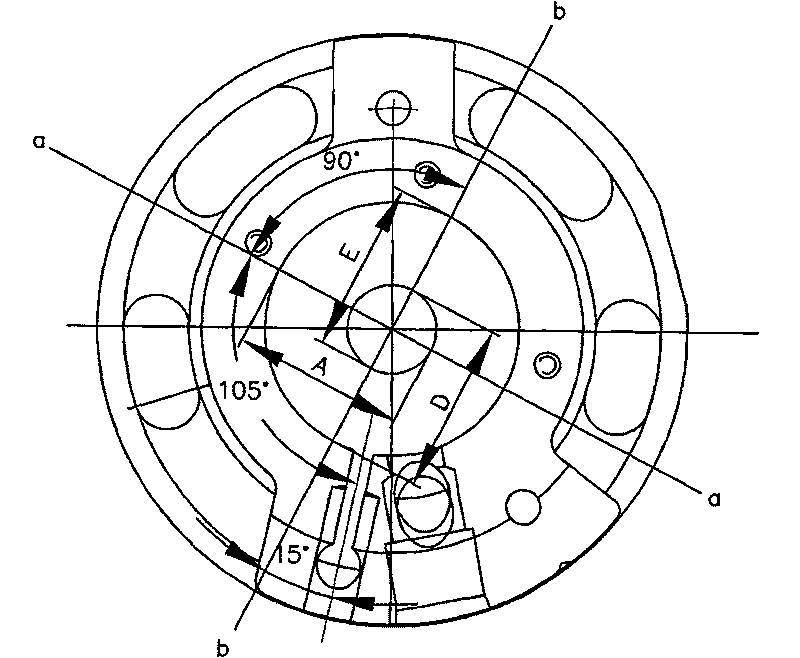

Assembling method of rotary double cylinder compressor pump body

ActiveCN101397997AReduce leakageIncrease cooling capacityCompression machines with non-reversible cycleRotary piston pumpsEngineeringCrankshaft

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

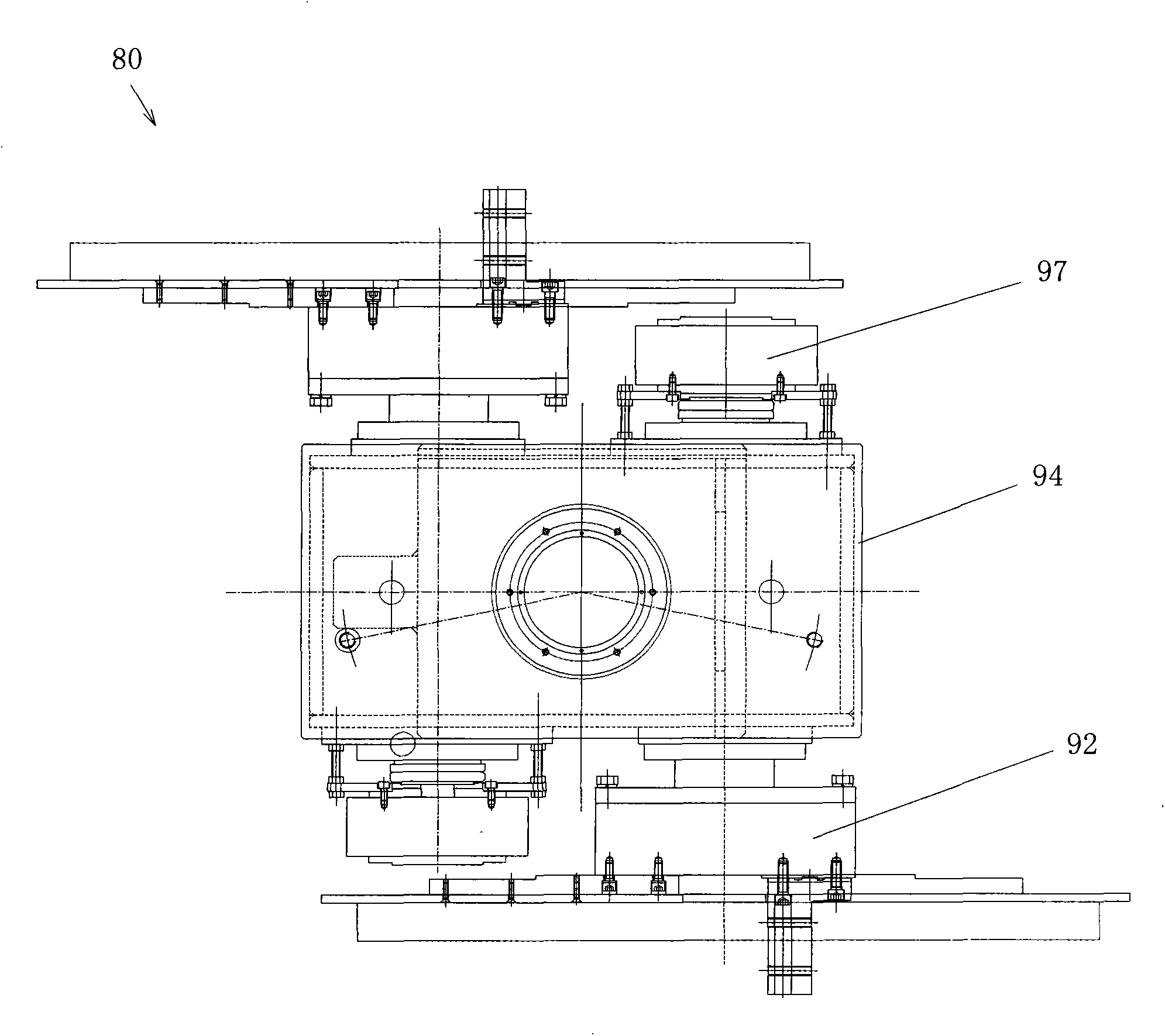

Ring crane corbel for nuclear power station and manufacturing method thereof

ActiveCN101875475AReasonable structureMeet support requirementsLoad-engaging girdersBuilding constructionsNuclear powerArchitectural engineering

The invention relates to a ring crane corbel for a nuclear power station and a manufacturing method thereof, belonging to the technical field of building construction facilities. In the ring crane corbel, a box-type frame main body comprises a rectangular main body plate, wherein an upper cover plate and a lower cover plate are respectively soldered and fixed on one side of the main body plate; a left lateral plate, a right lateral plate and a middle stiffened plate are soldered between the upper cover plate and the lower cover plate; the left lateral plate, the right lateral plate and the middle stiffened plate are soldered with the main body plate; the two ends of one side of the lower cover plate are soldered with the two bottom edges of an external baffle; the upper part of the external baffle extends between the left lateral plate and the right lateral plate after the upper part of the external baffle is bent; the two lateral edges of the upper part of the external baffle are respectively soldered with the inner surfaces of the left lateral plate and the right lateral plate; the other side of the main body plate is soldered with a bent bar; and horizontal and vertical stiffened plates are respectively soldered on corresponding positions on the main body plate, which are soldered with the upper cover plate, the lower cover plate, the left lateral plate, the right lateral plate and the middle stiffened plate. After the ring crane corbel is adopted, the use requirement can be met, and reasonable assembly and soldering sequence are adopted, so the final quality of the ring crane corbel component can be ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

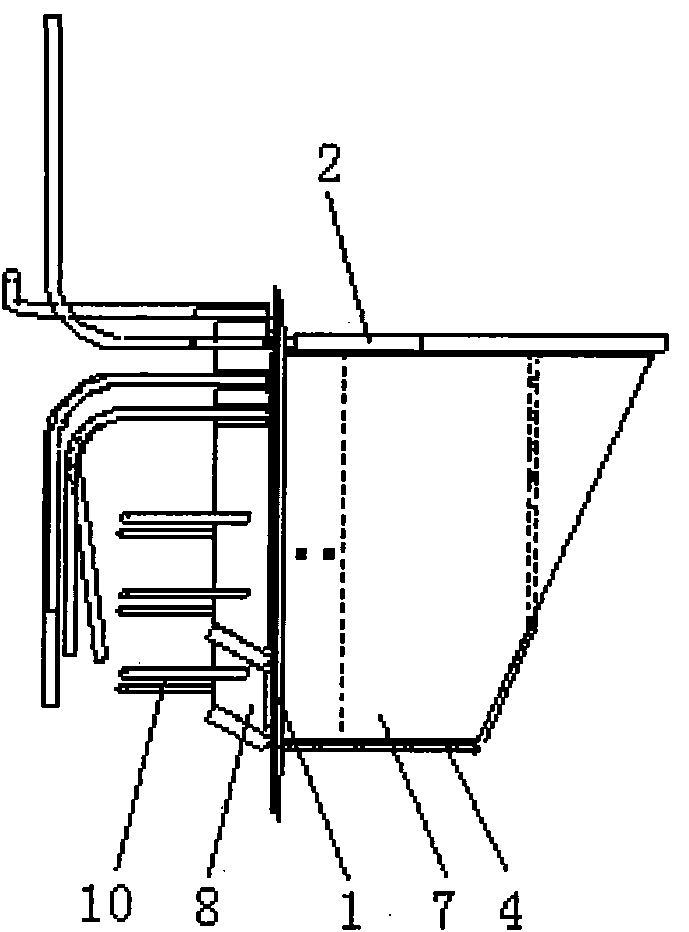

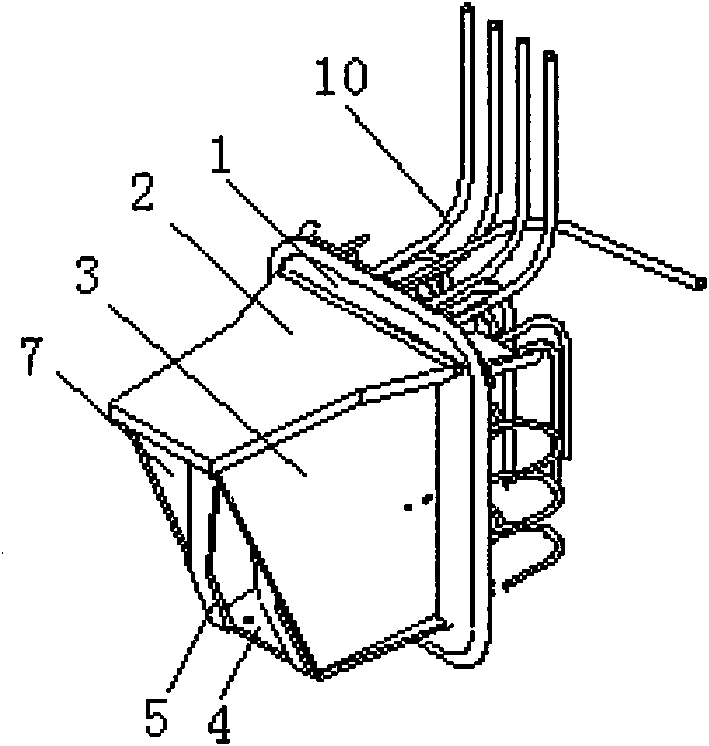

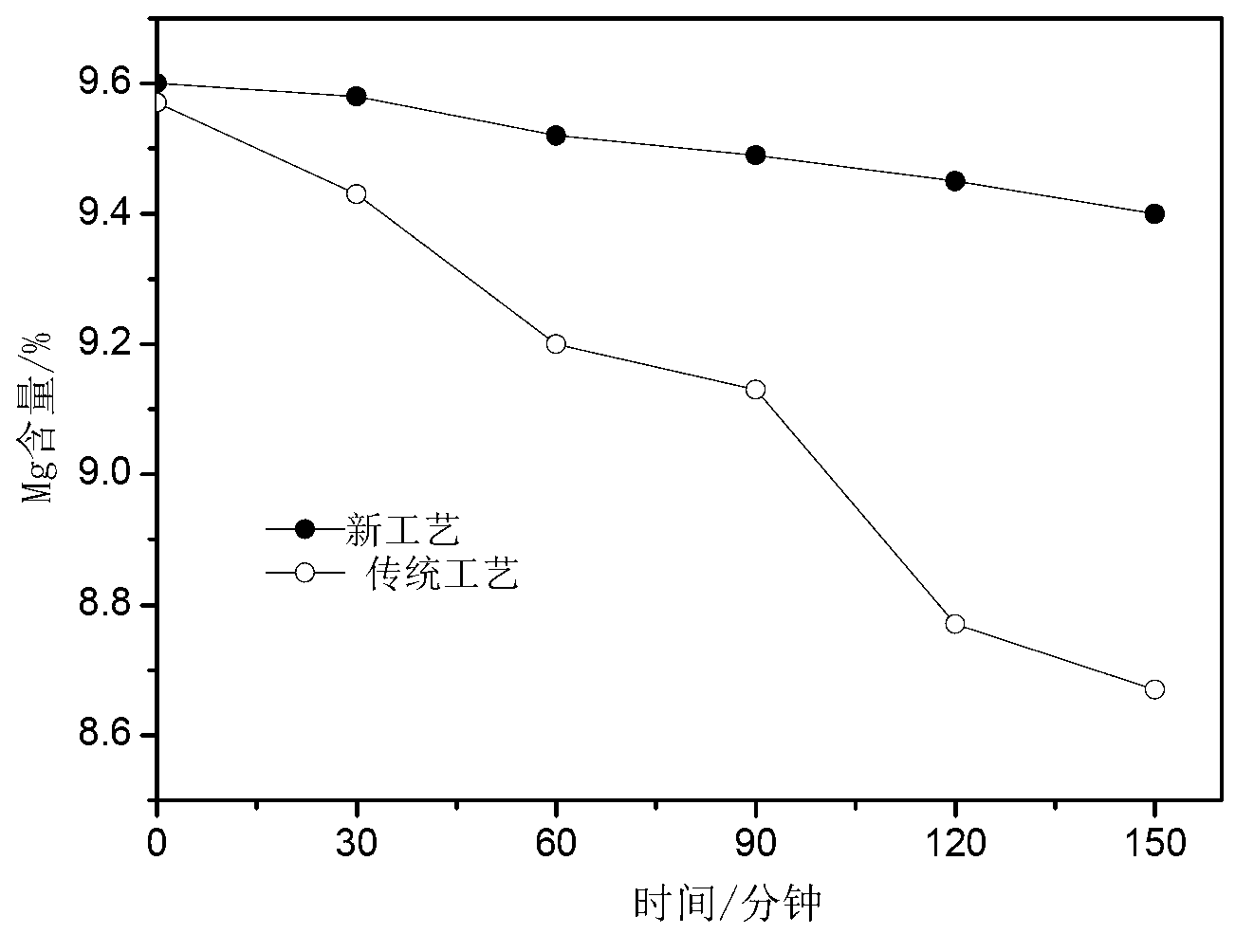

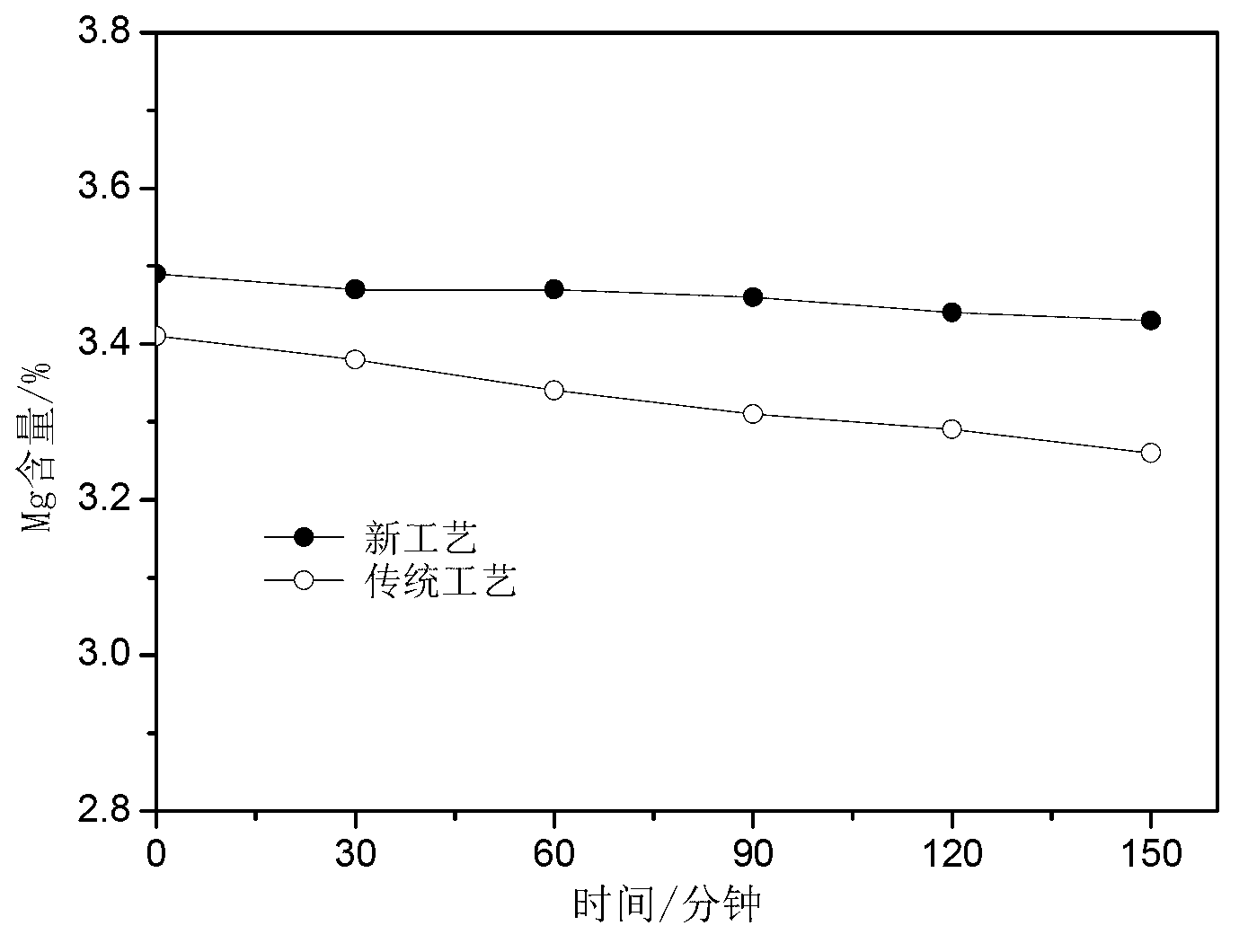

Refining method of aluminum-magnesium-series cast aluminum alloy material

The invention relates to a refining method of an aluminum-magnesium-series cast aluminum alloy material. In the method, a novel covering agent is selected for performing surface protection on an aluminum-magnesium-series alloy in a smelting process, a refining agent special for a magnesium-aluminum alloy is prepared simultaneously for refining a melt, and the smelting temperature and the pouring temperature are controlled, so that an aluminum-magnesium-series cast aluminum alloy with higher performance and a low magnesium burnout rate is obtained. According to the method, the novel covering agent and the special refining agent are applied for smelting an Al-Mg-series alloy (the content of Mg is 3-10 percent) under the control of a specific production process, so that the burnout of magnesium is controlled effectively, the production cost is saved, the cleanliness of the alloy is enhanced, and the porosity of the alloy is lowered.

Owner:天津新立中合金集团有限公司

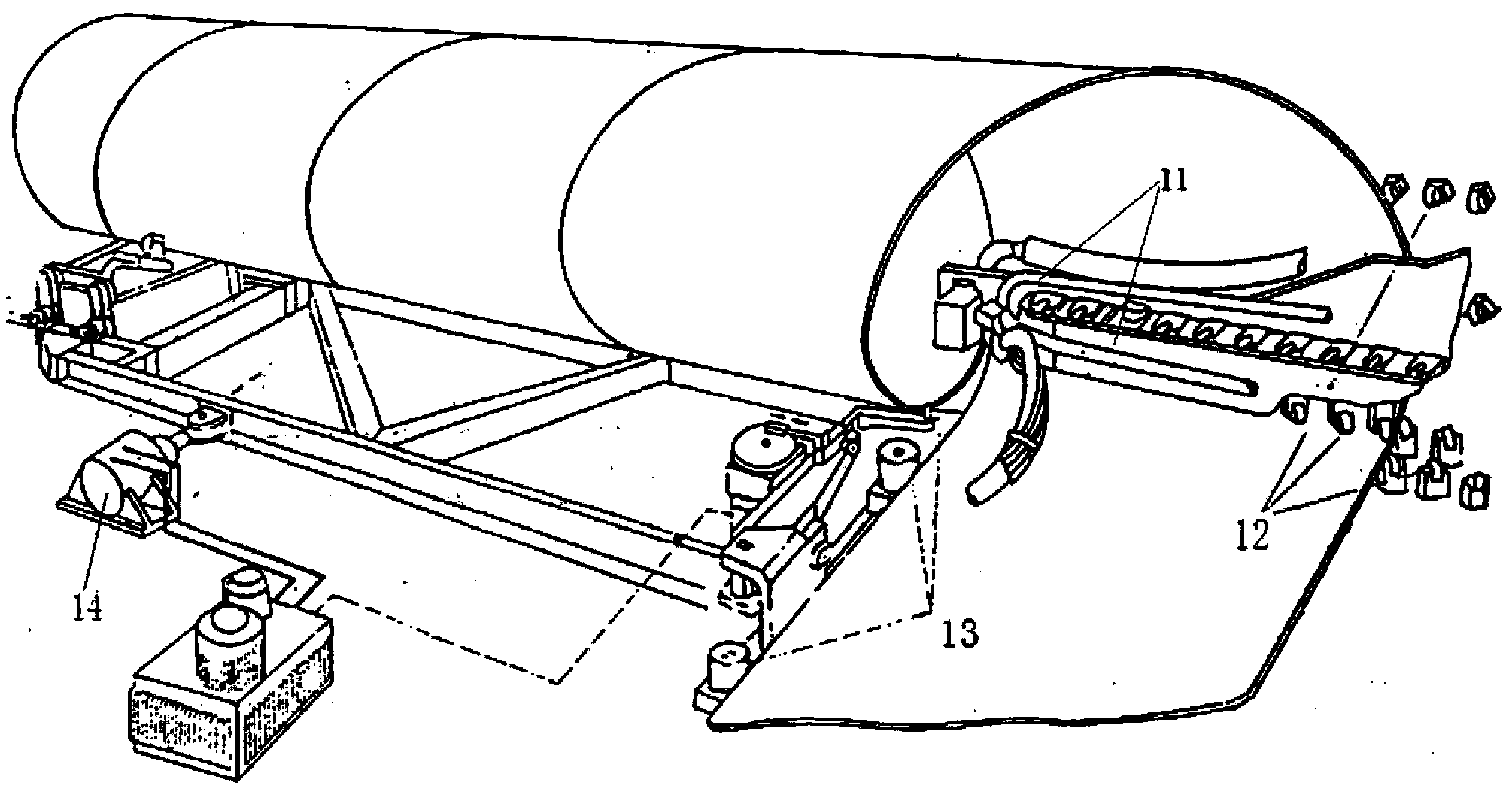

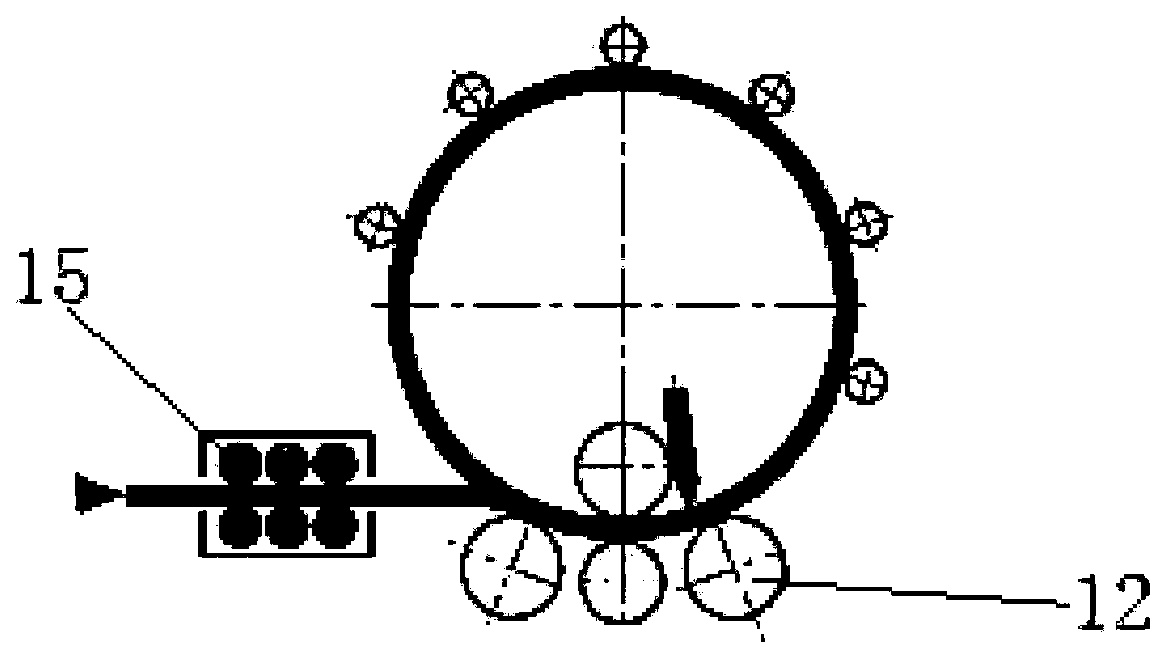

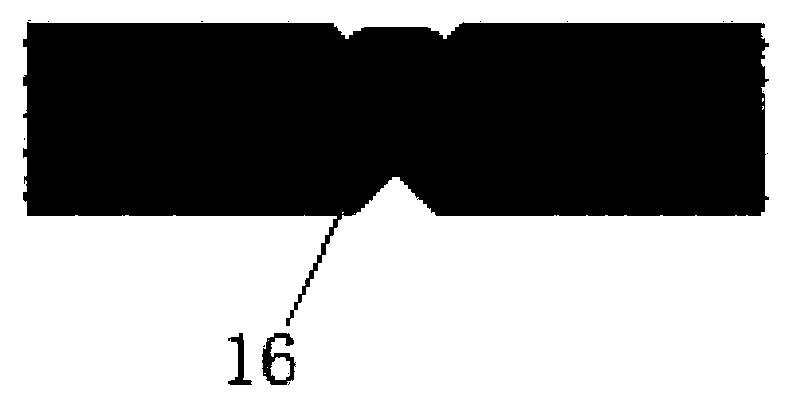

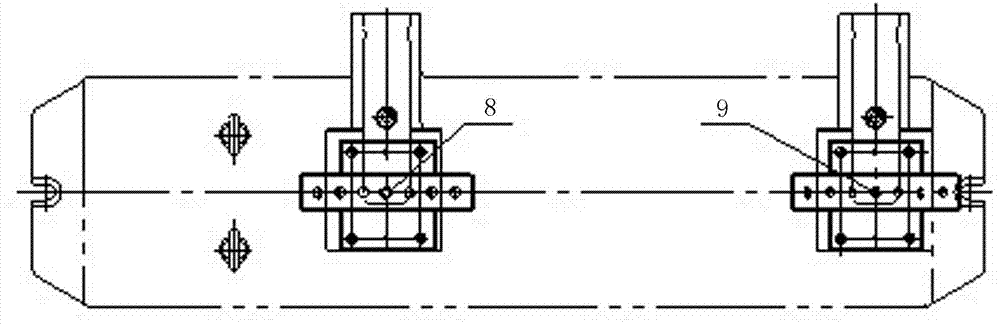

Welding production method for spiral seam submerged-arc welding steel pipes

InactiveCN103567707AReduce mutual interferenceImprove layout freedomArc welding apparatusMetal working apparatusDegrees of freedomEngineering

The invention discloses a welding production method for spiral seam submerged-arc welding steel pipes. In the traditional one-step spiral seam submerged-arc welding production device, welding is performed on the steel pipes when a welding position of an inner welding bead is pushed back by at least one screw pitch from a welding position of a traditional inner welding bead or welding is performed on the steel pipes when the welding positions of the traditional inner welding bead and a traditional outer welding bead are pushed back by at least one screw pitch. According to the welding production method for the spiral seam submerged-arc welding steel pipes, inner welding bead welding and steel pipe forming which are separated are performed in a relatively independent mode; mutual interference between the forming and welding is small; degree of freedom of welding position arrangement is large, namely, uphill welding, downward welding or downhill welding can be performed; final quality of welding can be guaranteed due to selection of most appropriate welding parameter assemblies.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

Nuclear power plant ring crane corbel and manufacturing method thereof

ActiveCN102815603AStrong enoughRigid enoughBase supporting structuresBraking devices for hoisting equipmentsWorkloadUltimate tensile strength

The invention relates to a nuclear power plant ring crane corbel, and relates to a manufacturing method thereof simultaneously, belonging to the technical field of building construction facilities. The corbel consists of a back rib plate, a bearing box body, a reinforcing plate and a sealing plate. The manufacturing method comprises the following steps of: performing full penetration weld; blanking, and prefabricating the back rib plate and the bearing box body; and performing field assembly welding. Sufficient strength and rigidity of the nuclear power plant ring crane corbel can be ensured, major members can be prefabricated, and only simple field assembly welding is required, so that the workload of field construction is reduced greatly, and the construction progress is accelerated; and meanwhile, due to the adoption of a structural design, welding deformation can be reduced or compensated to the maximum extent, and the construction quality is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

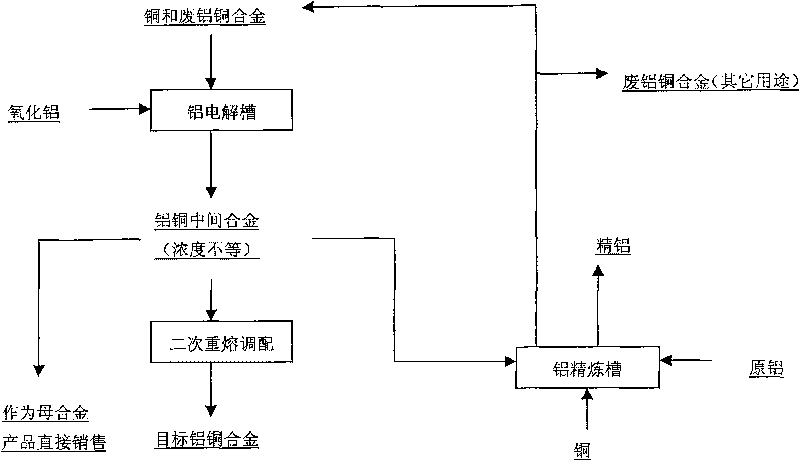

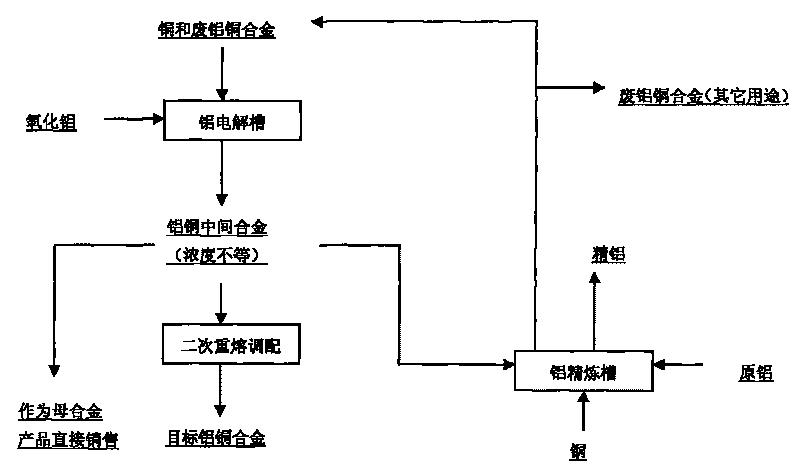

Joint production method of electrolytic copper-aluminium alloy and refined aluminium

The invention provides a joint production method of electrolytic copper-aluminium alloy and refined aluminium and relates to a production process with jointed production process of copper-aluminium alloy and refined aluminium which are produced with an electrolytic method; the joint production method is characterized in that: the method comprises the following steps: (1) copper or copper-aluminium alloy is added in an aluminium electrolytic tank for electrolysis, so as to obtain the copper-aluminium alloy; (2) the copper-aluminium alloy obtained by electrolysis is used as refining flux to carry out virgin aluminum refining process, so as to obtain the refined aluminium; (3) the waste copper-aluminium alloy produced in the virgin aluminum refining process is returned to the step (1) to carry out copper-aluminium alloy electrolysis. The method can reduce copper-aluminium alloy production energy consumption, improve the recovery rate of finished products, reduce the material flow rate in the production and reduce the financial cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

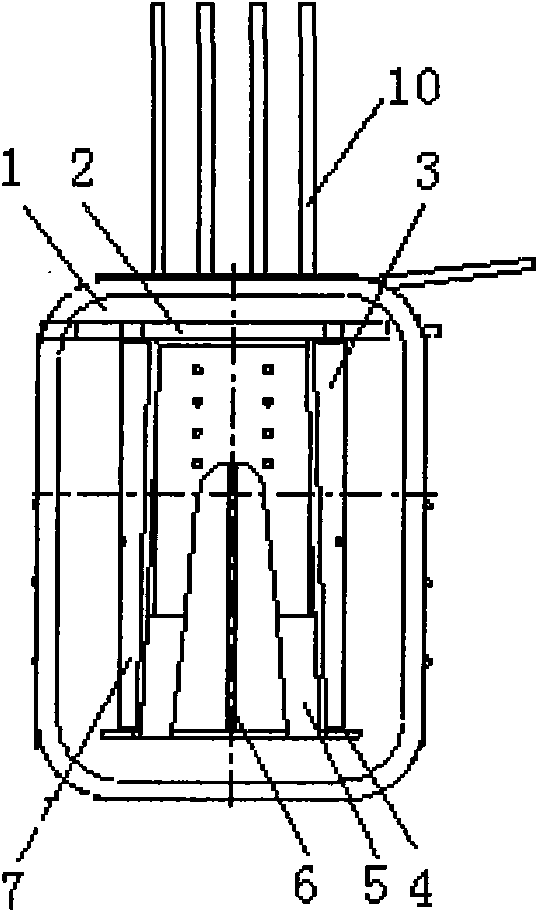

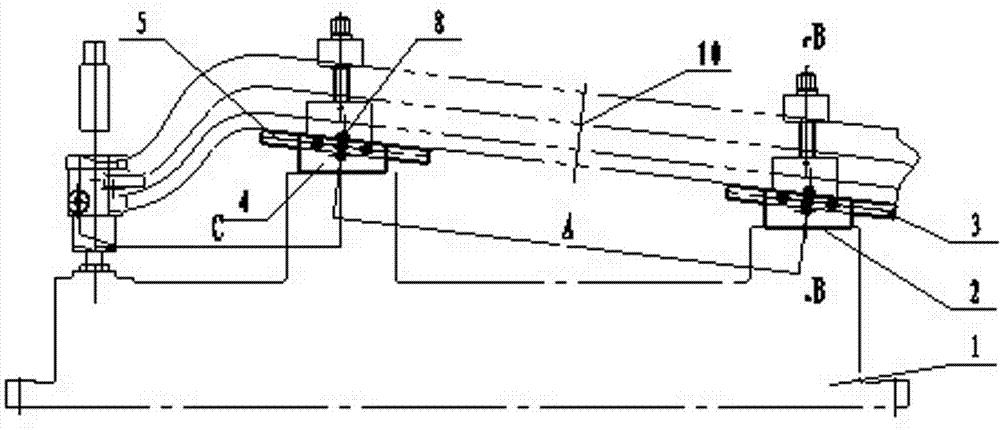

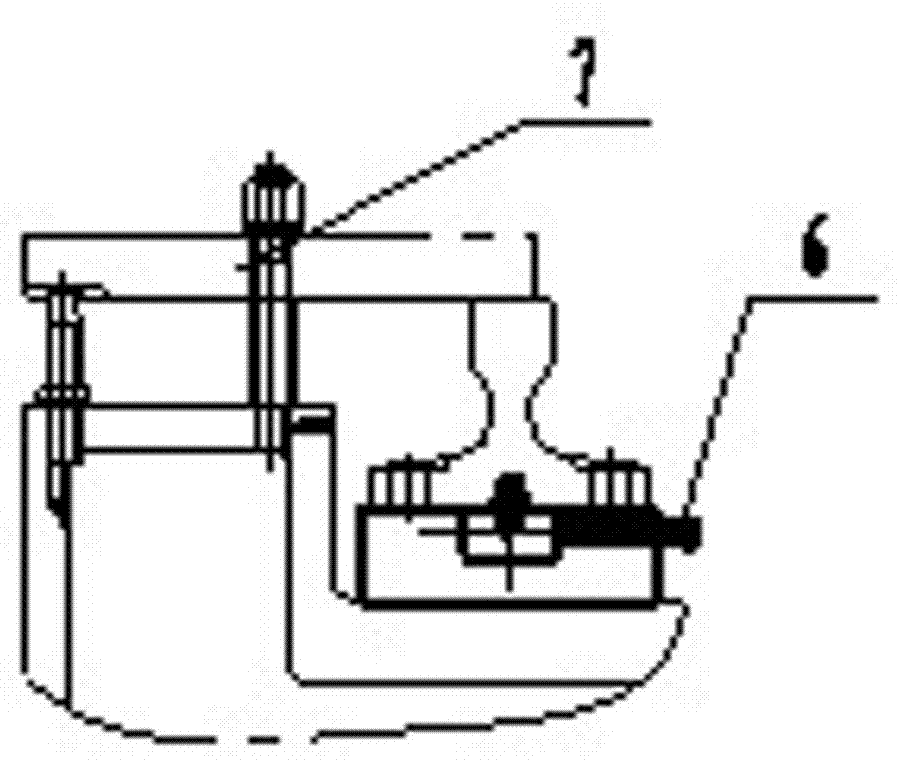

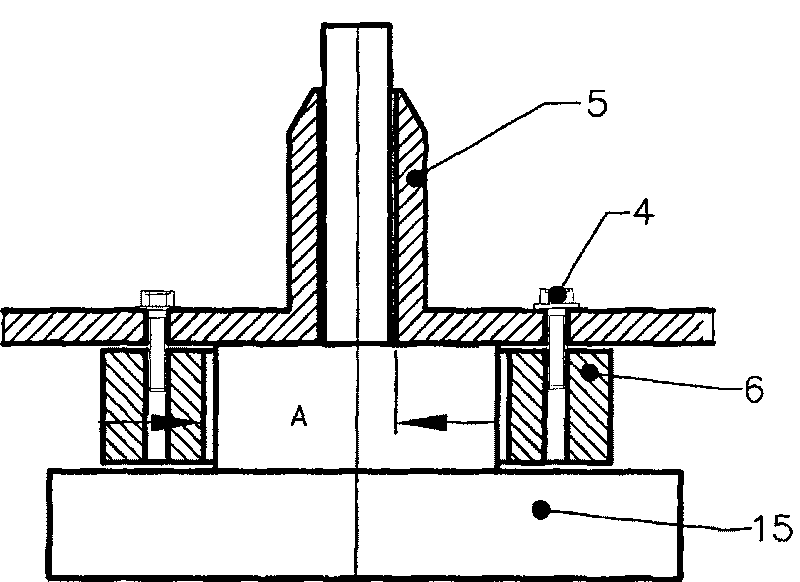

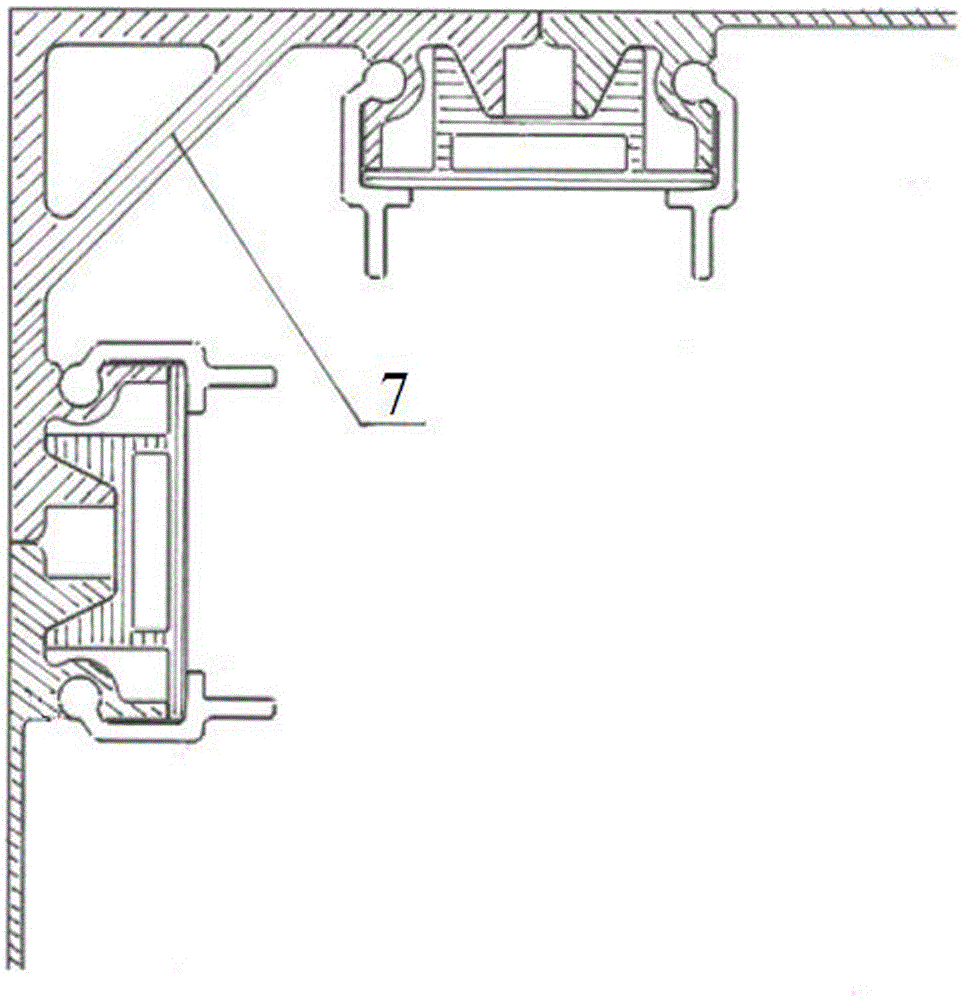

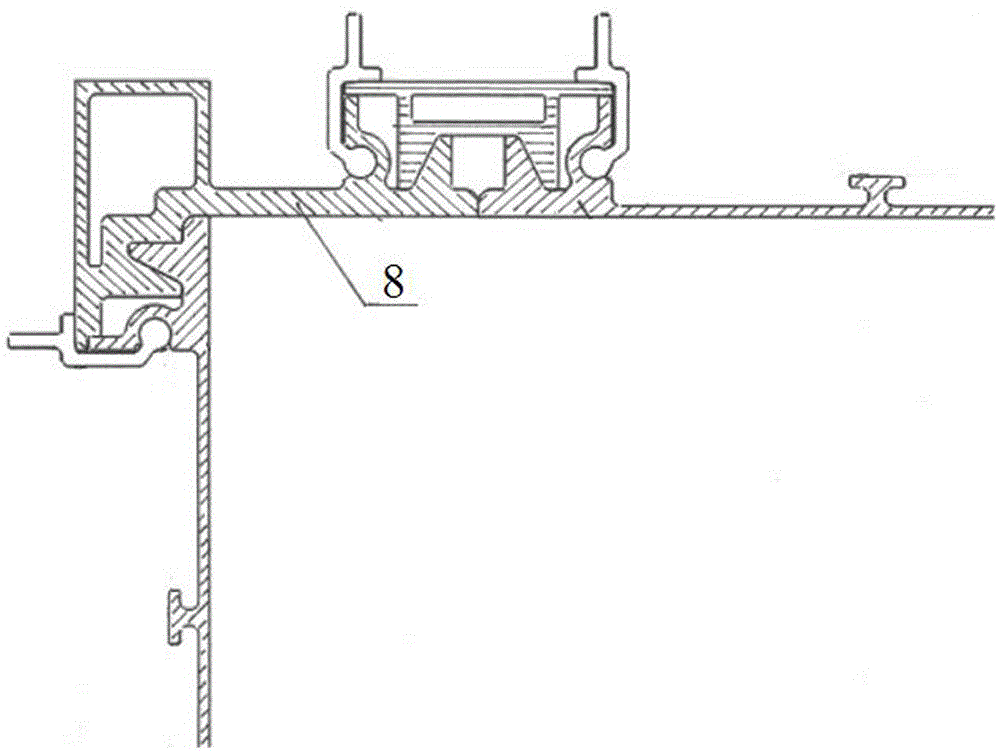

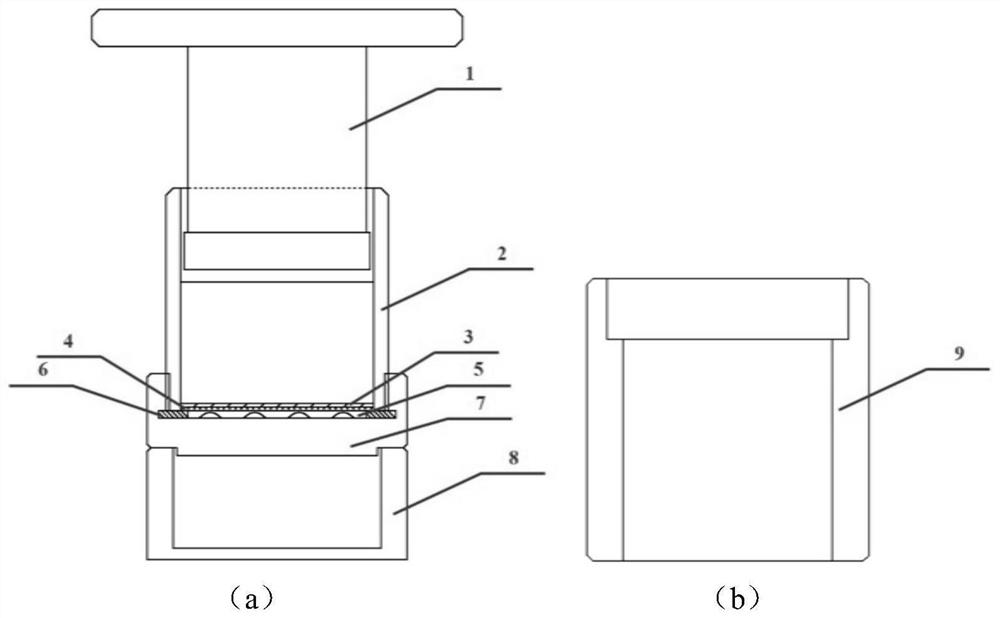

Device of drill front shaft master pin hole

InactiveCN102773728AAccurate and fast sizeReduce labor intensityPositioning apparatusMetal-working holdersPin distanceSlide plate

The invention relates to a device of a drill front shaft master pin hole. The device comprises a fixture body (1), a rear backing board (2), a rear sliding plate (3), a front backing board (4), a front sliding plate (5), compression screws (6), a chucking device (7), a cylindrical pin (8) and a rhombus pin (9), the rear backing board (2), the front backing board (4) and the chucking device (7) are arranged on the fixture body (1), the rear sliding plate (3) is disposed on the rear backing board (2), the rhombus pin (9) is arranged on the rear sliding plate (3), the front sliding plate (5) is mounted on the front backing board (4), the cylindrical pin (8) is disposed on the front sliding plate (5), and the compression screws (6) are arranged on the rear backing board (2) and the front backing board (4) respectively. The device has the advantages that a plate spring distance and a master pin distance can be accurately and rapidly adjusted, the device is multipurpose, the labor intensity of workers can be effectively reduced, time and effort are saved, and the work efficiency is increased.

Owner:王庆

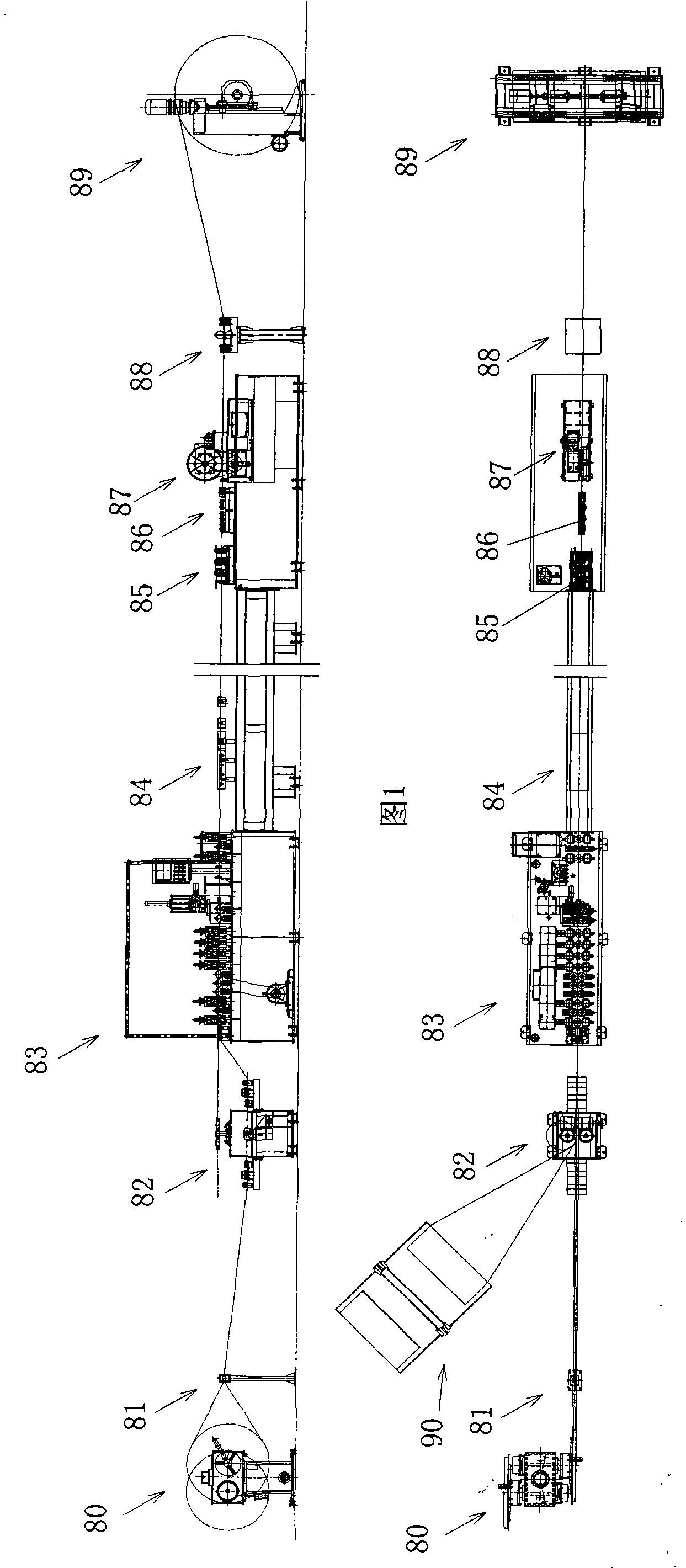

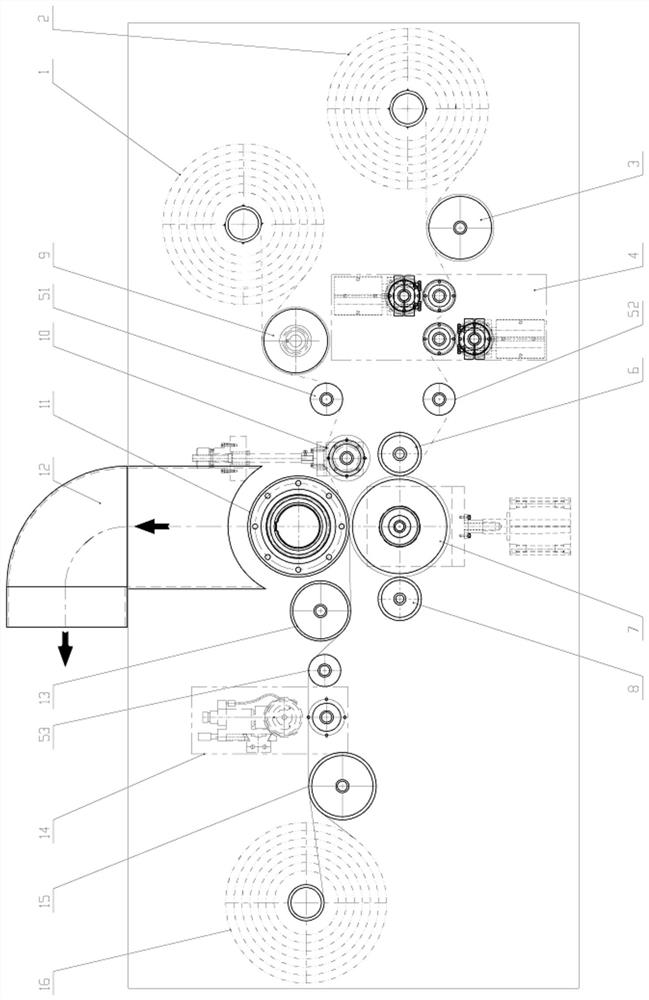

Consecutive wrapping welding drawing production line for railway subgrade through ground wires

A consecutive wrapping welding drawing production line for railway subgrade through ground wires sequentially comprises a belt releasing machine, a copper belt edge grinding washing machine, a consecutive wrapping welding device, a cooling tank, a drawing die seat device, a tractor, a wire-rewinding machine and a core wire pay-off machine. The production line is good in effect of washing copper belts, ensures that the upper face, the lower face and two side faces wrapping a front copper belt are processed and washed, and improves wrapping welding quality and the appearance quality of products. Due to the fact that a cooling component is arranged in a drawing oil cavity, reduction of the viscosity of drawing oil is effectively prevented, drawing quality is remarkably improved, the requirements of the quality of present railway subgrade through ground wires are met, production consecutiveness is good, and the failure rate in middle links is reduced. A line arranging roller is arranged on the tractor, so that wire rods wound on traction wheels can be arrayed evenly, and extrusion phenomena do not exist. Consequently, the final quality of products is further ensured.

Owner:王玉凯

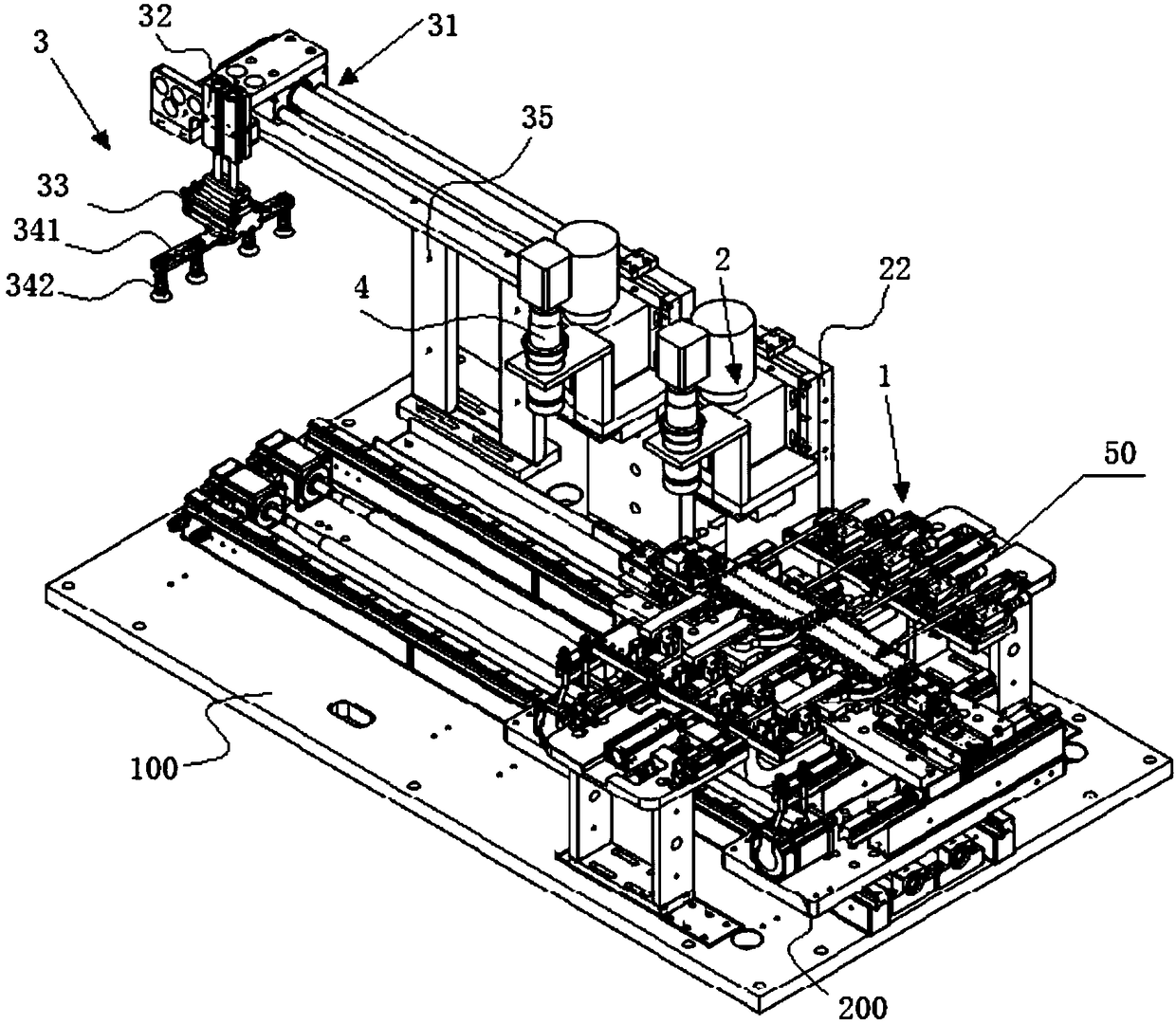

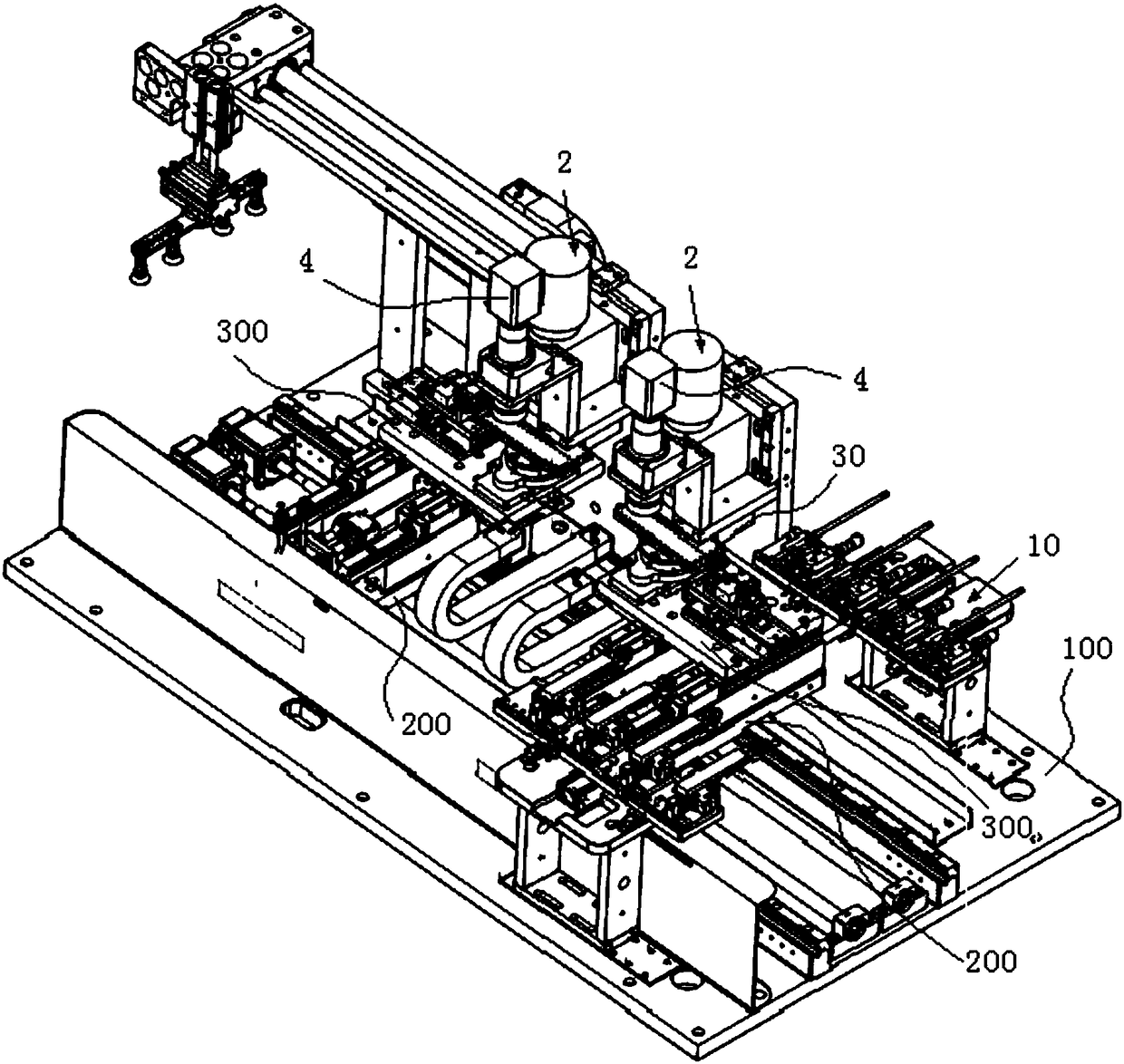

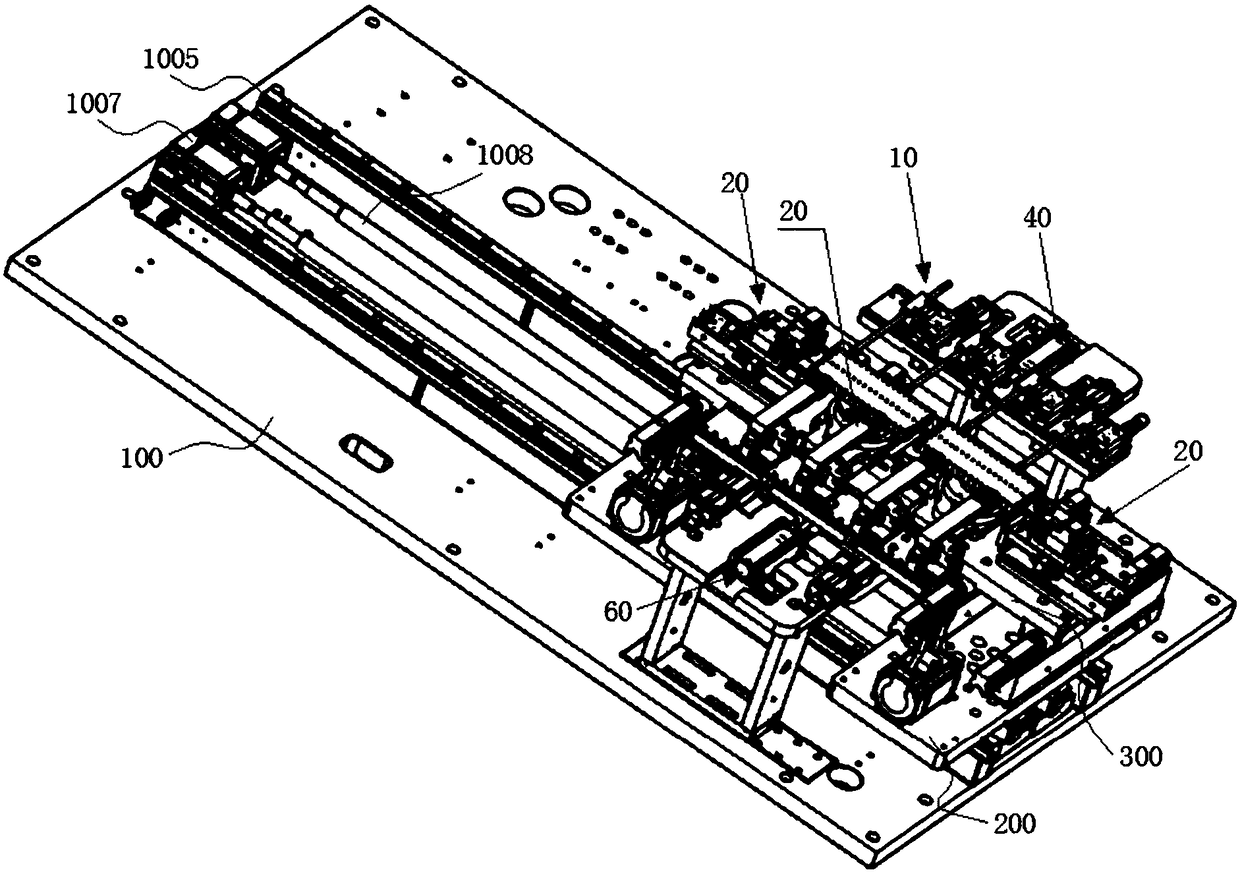

Light guide plate full-automatic numerical control polishing apparatus

PendingCN108527126APrecise positioningNot easy to scratchGrinding carriagesPolishing machinesNumerical controlLight guide

The invention discloses a light guide plate full-automatic numerical control polishing apparatus. The light guide plate full-automatic numerical control polishing apparatus comprises a workbench, a positioning device, a polishing device, a material taking device and a dust collection cover. The positioning device, the polishing device, the material taking device and the dust collection cover are arranged on the workbench. The workbench is provided with at least one rotary platform for fixing a light guide plate. The rotary platform is connected with a rotation driving mechanism for driving therotary platform to rotate horizontally. The workbench is further provided with an X-axis-direction driving mechanism and a Y-axis-direction driving mechanism, wherein the X-axis-direction driving mechanism can drive the rotary platform to horizontally move in the X-axis direction back and forth, and the Y-axis-direction driving mechanism can drive the rotary platform to horizontally move in the Y-axis direction back and forth. The light guide plate full-automatic numerical control polishing apparatus is further provided with a control system. A full-automatic operation mode is adopted by thelight guide plate full-automatic numerical control polishing apparatus, all the mechanisms can automatically return, and therefore, the efficiency is improved; and additionally, by using a first positioning mechanism and a second positioning mechanism in cooperation, datum positioning is formed by the side face, positioned by adopting the first positioning mechanism or a positioning plate, of thetwo opposite side faces of the light guide plate, buffer compensation type positioning is formed by the other side face positioned by adopting the second positioning mechanism, and then, accurate positioning is achieved; and the dust collection efficiency is as high as 99.5%.

Owner:KUNSHAN HENGDA PRECISION MACHINERY IND CO LTD

Method of sticking coloured glass on colourless glass

InactiveCN1903758AFirmly connectedImprove yieldGlass reforming apparatusMonochromatic colorColor glass

The present invention relates to a method for sticking color glass on colorless glass, in particular, it relates to a processing method of various glasses. It is characterized by that the designed pattern can be divided into several monochromatic units according to its monochromatic zone, every monochromatic zone is divided into at least one monochromatic unit, then the unit glass units with identical form can be made according to the form of monochromatic color unit, and the self-body and all the monochromatic glass units are heated, all the monochromatic glass units can be thermowelded on the self-body, cooled so as to obtain the invented product.

Owner:张建民

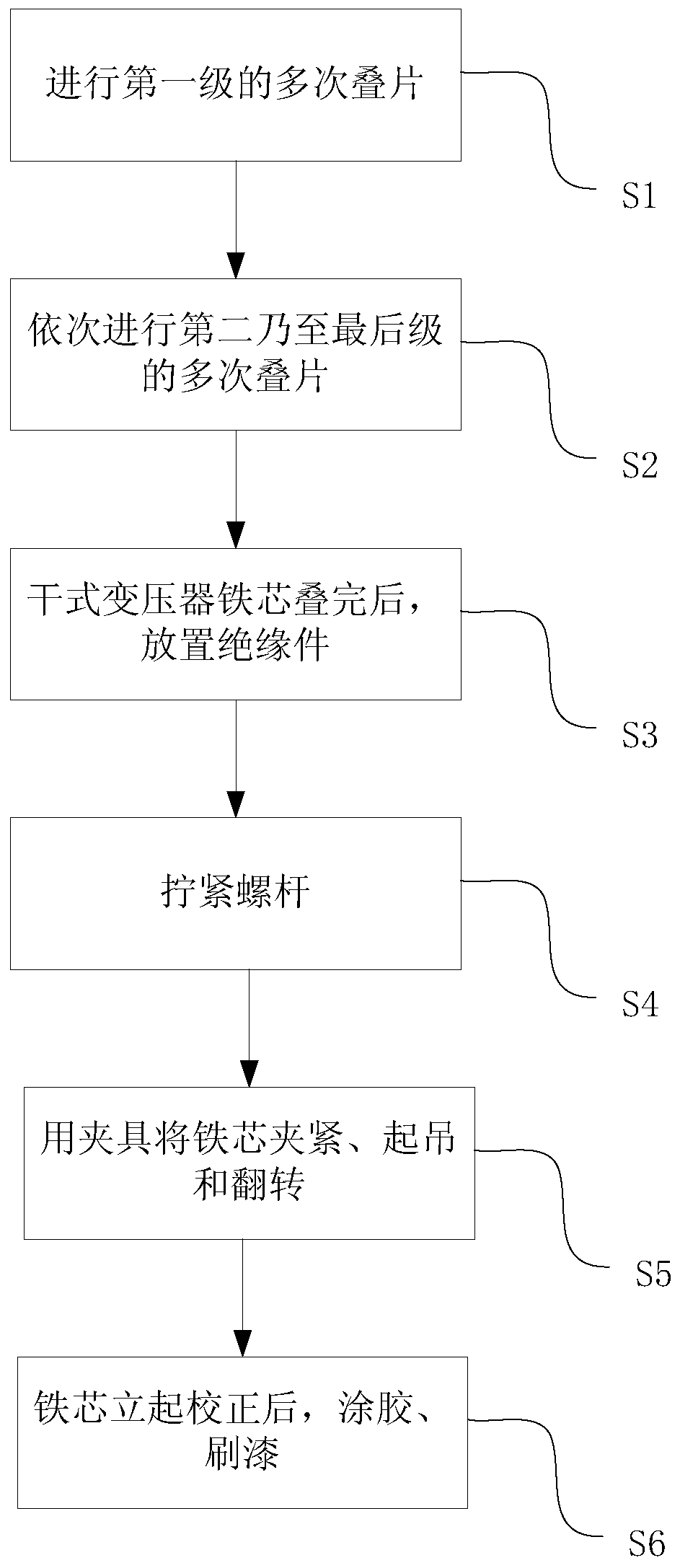

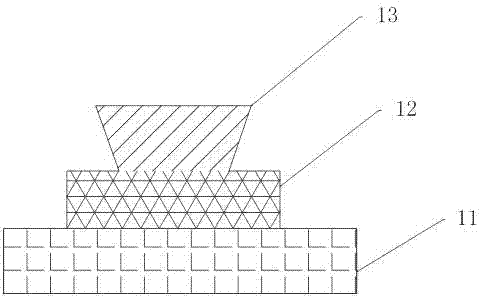

Method for completely mitering and stacking dry type transformer core

InactiveCN109887738AGuarantee the final qualityImprove final qualityInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses a method for completely mitering and stacking a dry type transformer core. The method comprises the following steps: carrying out repeated stacking in the first stage, whereintwo pieces are stacked once, after the first stacking, flatness is measured and adjusted, and the joints of next stacking and previous stacking are placed in a staggered mode; carrying out repeated stacking in the second to the last stage; and carrying out correction once after stacking once, wherein the joints and laps are checked, and whether the core column of the dry type transformer core is vertical to a yoke piece is checked. The stacking quality can be improved effectively.

Owner:ZHONGBIAN GRP SHANGHAI TRANSFORMER CO LTD

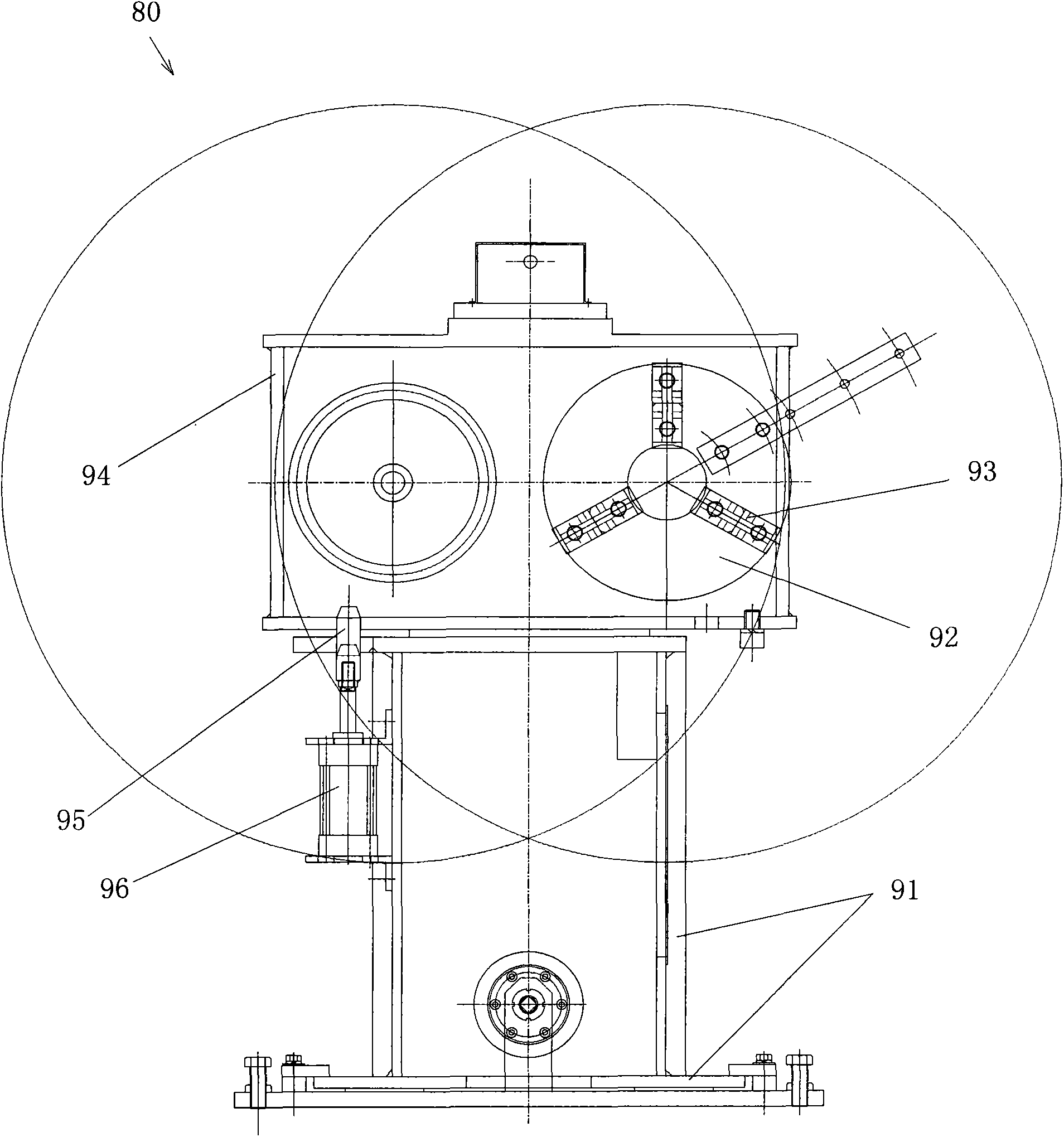

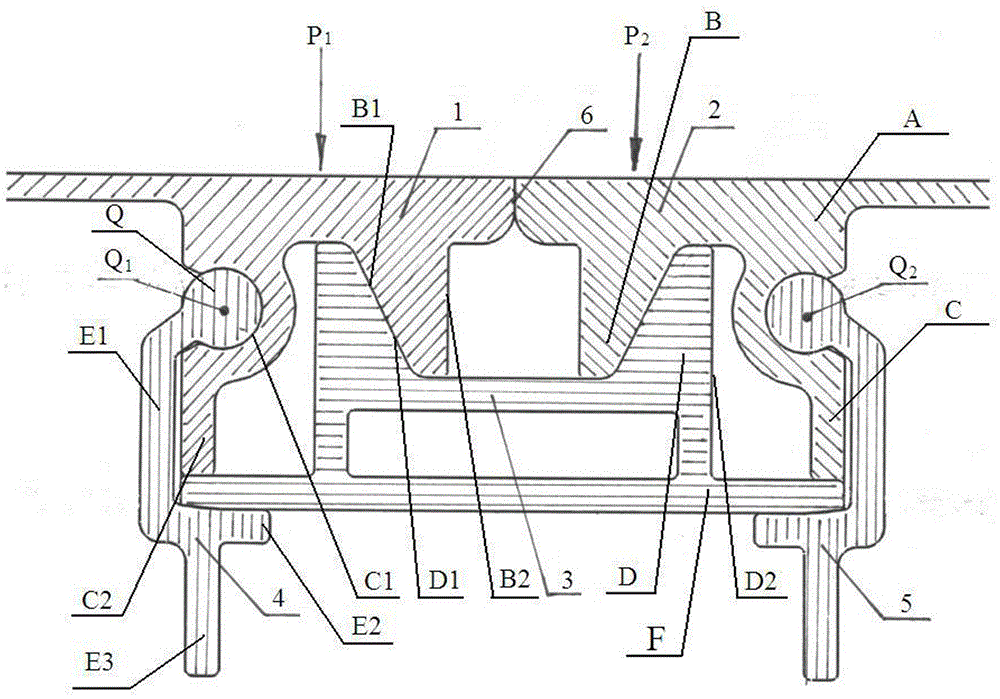

Assembling method of rotary double cylinder compressor pump body

InactiveCN101397997BGuaranteed minimum clearanceReduce leakageCompression machines with non-reversible cycleRotary piston pumpsEngineeringCrankshaft

The invention discloses a method for assembling a pump body of a rotary duplex cylinder compressor, which comprises the steps: (1) after the centers of an upper cylinder and an upper flange are regulated, the upper cylinder and the upper flange are fixed into a component (M) with a short screw; (2) the center of a lower cylinder is regulated corresponding to the component (M), and the upper cylinder is separated from the component (M) after the corresponding position of the lower cylinder to the component (M); (3) after the centers of the lower cylinder and a lower flange are regulated, the lower cylinder and the lower flange are fixed into a component (N) with a short screw; (4) an upper roller, a lower roller, a sliding vane and a crank shaft are put in the component (M) and the component (N); a baffle is put between the component (M) and the component (N); according to step (2), the corresponding position of the lower cylinder to the component (M) is recorded; the component (M) is matched with the component (N) and fixed together with the component by long screws to form a whole pump body. The method can reduce spillage to the highest extent, maximizes the universal use of existing devices and has detectable clearance.

Owner:GREE ELECTRIC APPLIANCES INC +1

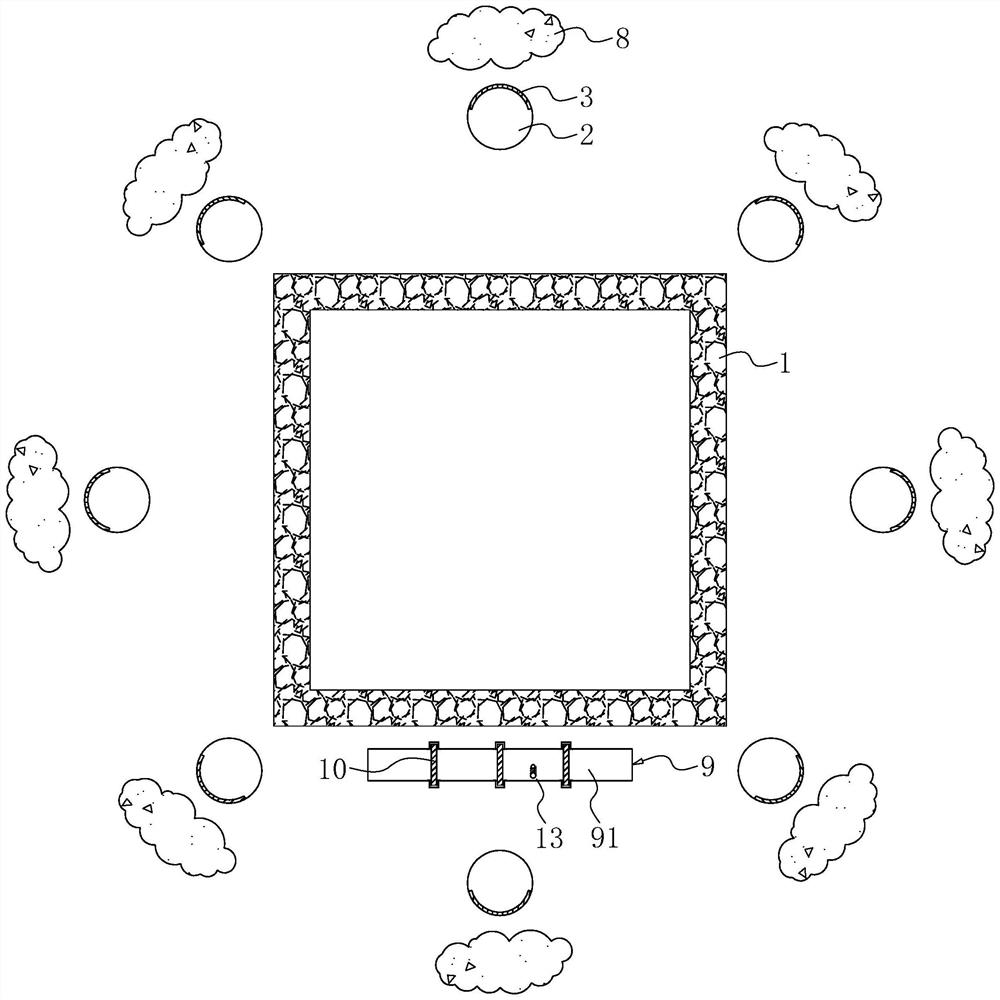

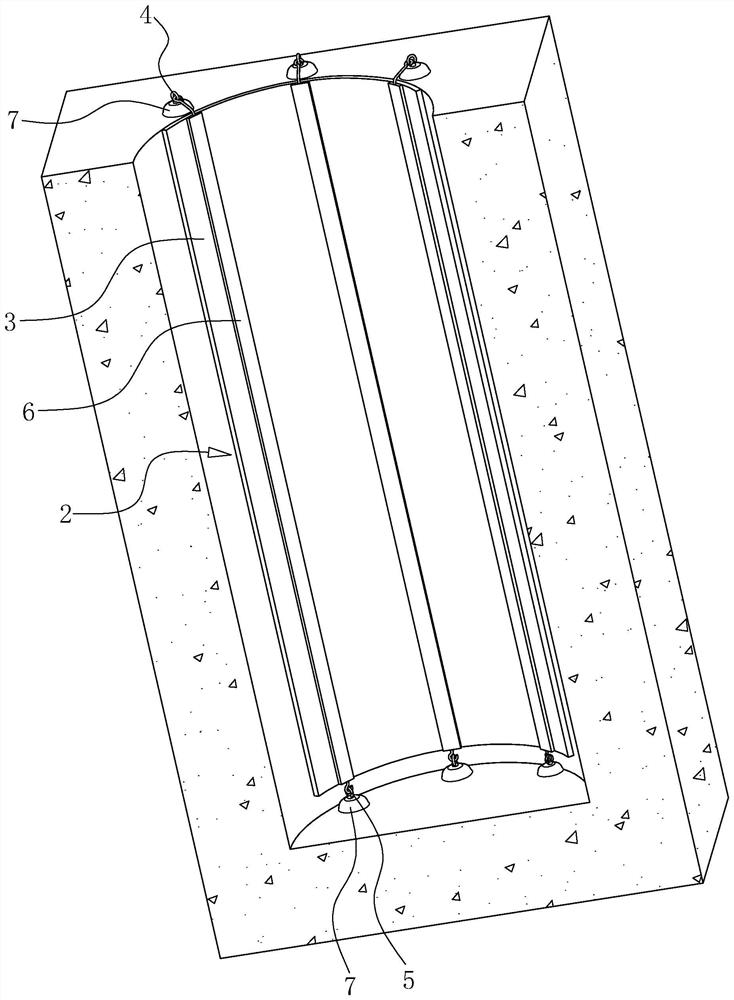

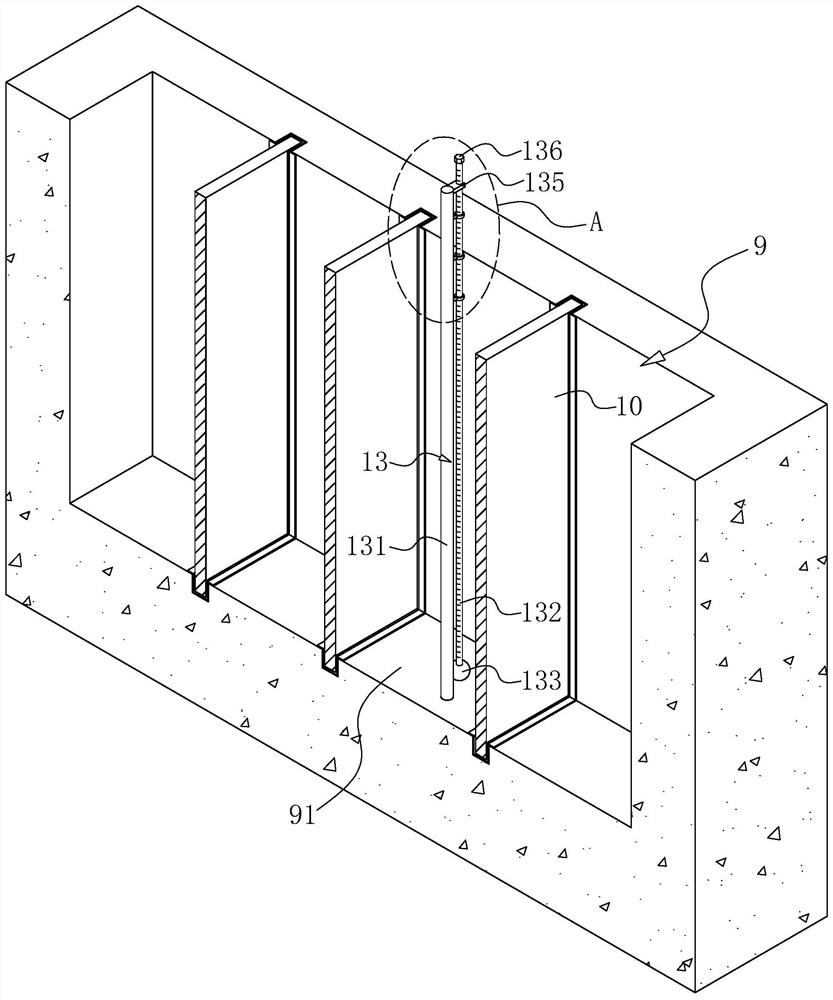

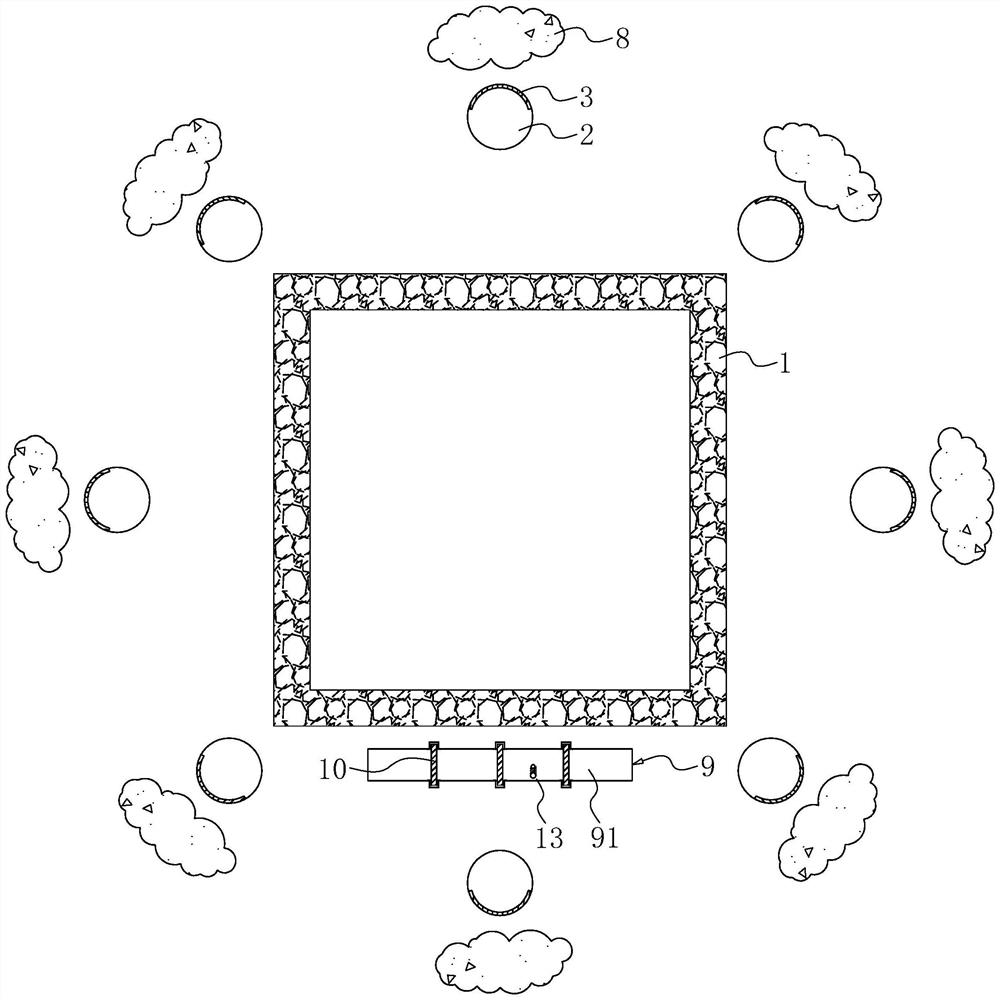

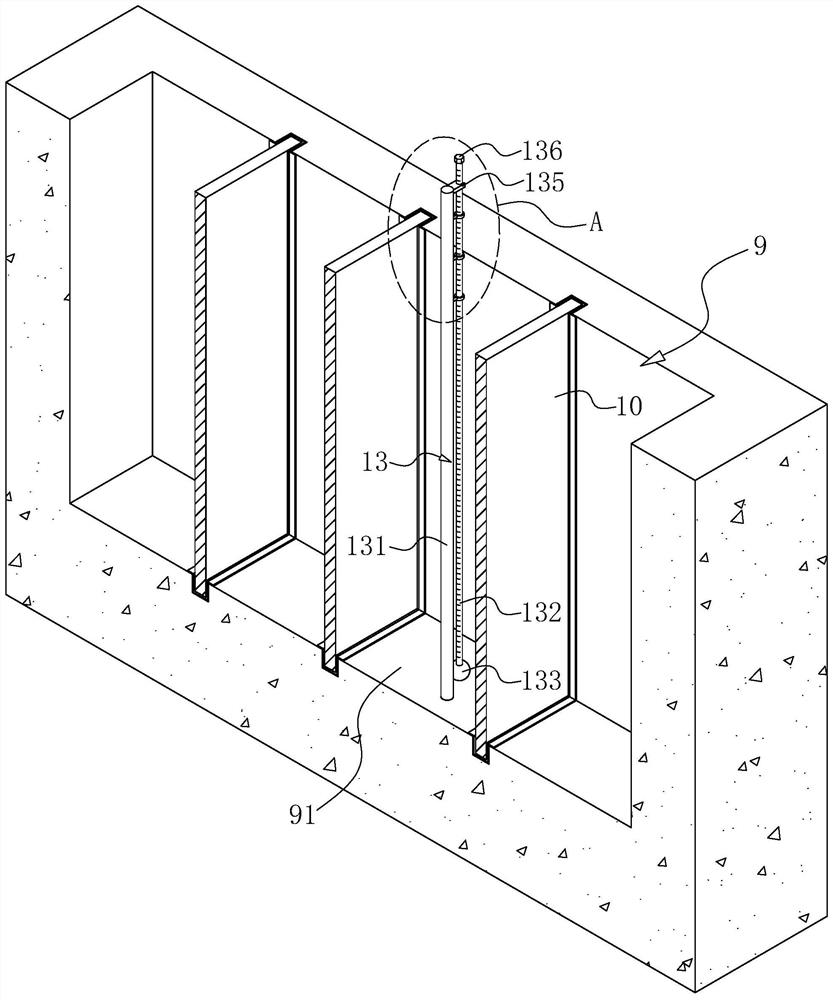

Method for detecting position of leakage point of underground concrete continuous wall

ActiveCN113203527AGuarantee the final qualityDiversity guaranteedDetection of fluid at leakage pointProtective foundationStructural engineeringWater level

The invention relates to a method for detecting the position of a leakage point of an underground concrete continuous wall. The method comprises the steps of S1, digging a preliminary exploration well out of the continuous wall; S2, extracting underground water in the continuous wall; S3, observing the water level of the preliminary exploration well, and determining that the continuous wall corresponding to the preliminary exploration well with the reduced water level is the orientation of a leakage point; S4, digging a detection groove outside the leakage point area of the continuous wall, and dividing the detection groove into a plurality of detection intervals by using partition plates; S5, filling water into the detection groove, observing the water level of each detection interval, and if the water level of a certain detection interval drops, determining that the continuous wall corresponding to the detection interval is the position of the leakage point; S6, pumping out water in the detection groove, taking out the partition plates, reserving the two partition plates on the two sides of the detection interval, and backfilling the other detection intervals; and S7, irrigating the detection interval step by step, conducting standing for a period of time after each time of irrigation, observing the water level change, and if the water level drops at a certain time, determining the position corresponding to the water level height as the final position of the leakage point. The method has the effect of improving the comprehensiveness of leakage point position detection of the continuous wall.

Owner:JIANGSU TESTING CENT FOR QUALITY OF CONSTR ENG

Release film compounding equipment and release film compounding production line

PendingCN113979170AControl compound temperatureReduce heat lossLaminationLamination apparatusProduction lineThin membrane

The invention discloses release film compounding equipment and a release film compounding production line. The release film compounding equipment comprises a rack; a first unwinding device, a second unwinding device, an infrared preheating roller, a high-temperature water preheating roller, a composite roller device, a heat supply system, a cooling roller, a third flattening roller, an edge cutting mechanism and a winding device are arranged on the rack; a thin film on the first unwinding device is preheated through an infrared preheating roller, a base film on the second unwinding device is preheated through a high-temperature water preheating roller, the preheated thin film and the base film are composited through the composite roller device to obtain a composite film, and the composite film bypasses the cooling roller and the third flattening roller, is subjected to edge cutting through an edge cutting mechanism and then is fed into the winding device to be wound. Aiming at the characteristics of the polyester composite release film, the production requirements of the novel polyester composite release film can be met, the release effect of the polyester composite release film is ensured, and meanwhile, the large-scale production of the novel composite release film is realized.

Owner:江苏金由新材料有限公司

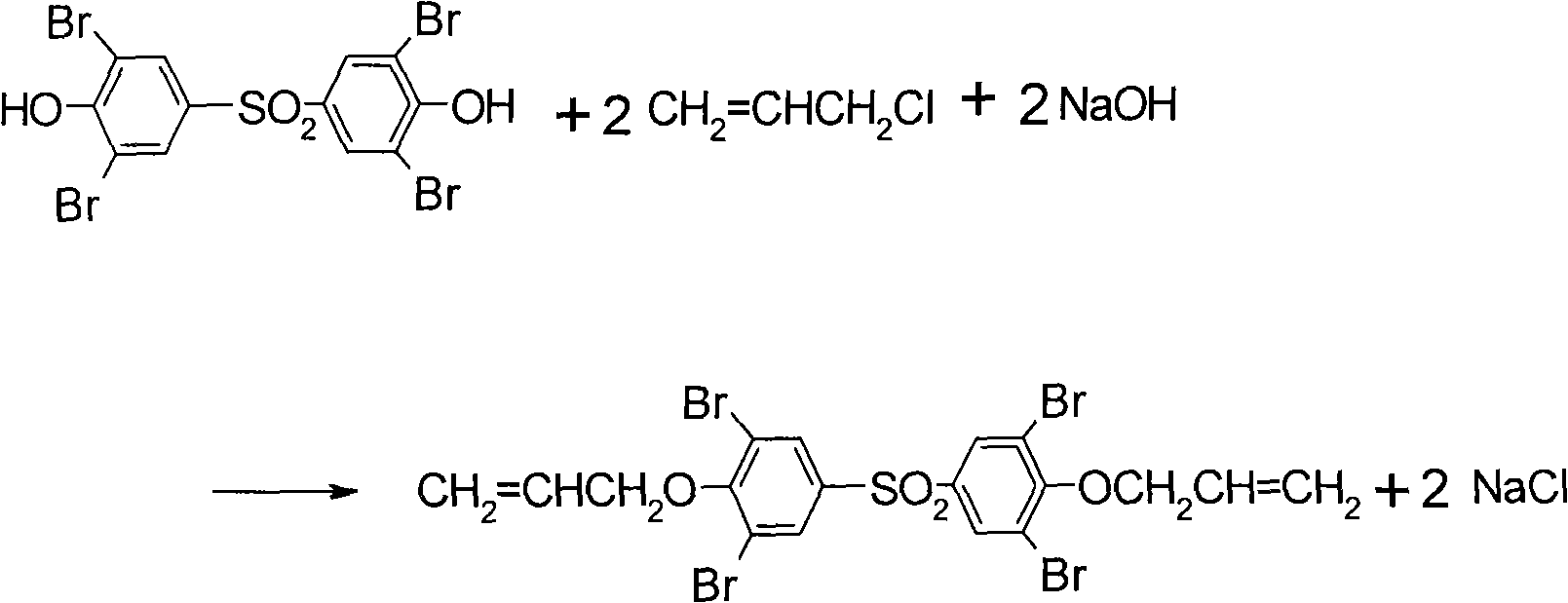

Method of preparing bromobisphenol S diene propyl ether

InactiveCN101343246AReduce manufacturing costReduce pollutionOrganic chemistryOrganic compound preparationChlorobenzenePropyl ether

The invention discloses a preparation method of tetrabromobisphenol S diallyl oxide, which is characterized in that: tetrabromobisphenol S is reacted with chloropropene at a temperature of between 40 and 100 DEG C to generate the tetrabromobisphenol S diallyl oxide in an isopropyl alcohol-water-chlorobenzene mixed solvent in the presence of sodium hydroxide and tetraethyl ammonium bromide, wherein, the function of sodium hydroxide is to transform tetrabromobisphenol S into sodium salt, and the tetraethyl ammonium bromide is a catalyst. After the complete reaction, the tetrabromobisphenol S diallyl oxide is obtained through centrifugal separation, and the mother liquor can be used repeatedly. The method has advantages of good purity of prepared products, low energy consumption and high production efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

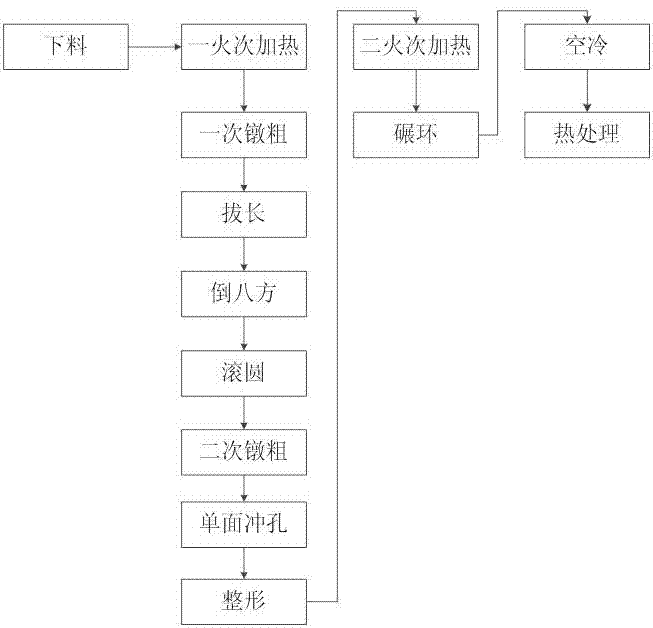

A method for forging the inner and outer rings of fan variable speed bearings

ActiveCN105537863BImprove efficiencyInfluence of internal organizational structureBearing componentsForging/hammering/pressing machinesEngineering

Owner:四川民盛特钢锻造有限公司

Application of a kind of adhesion promoter for rubber

The invention discloses an adhesion promoter for rubber as well as a preparation method and application thereof, belonging to the technical field of rubber preparation. The adhesion promoter comprises the following components in parts by weight: 60-85 parts of liquid cis-butadiene rubber, 13-25 parts of maleic anhydride, 1-4 parts of an initiator and 0.1-0.8 part of a dispersant, wherein the sum of the components is 100. The prepared adhesion promoter is applied to a rubber preparation formula, so that a mixing process of rubber materials is simplified, matching requirements of various types of rubber can be widely met, and meanwhile, the adhesive strength between the rubber and fabrics can be remarkably improved.

Owner:SHENYANG ECONOMIC ZONE ZHANGWU SHENHUA RUBBER ANDPLASTICS AUX

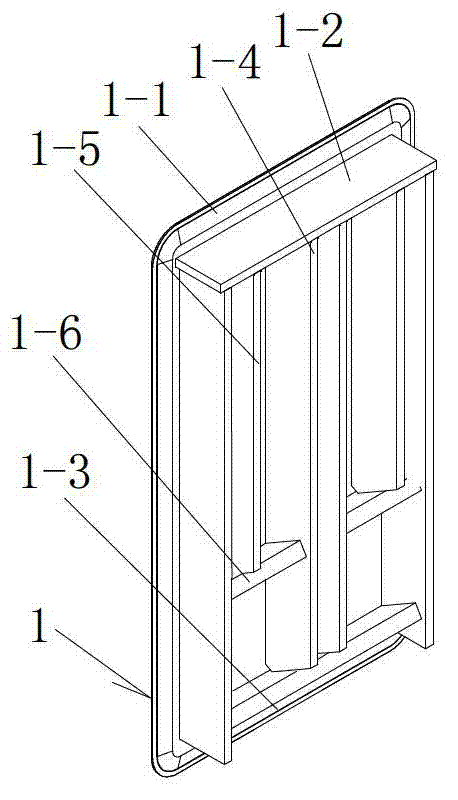

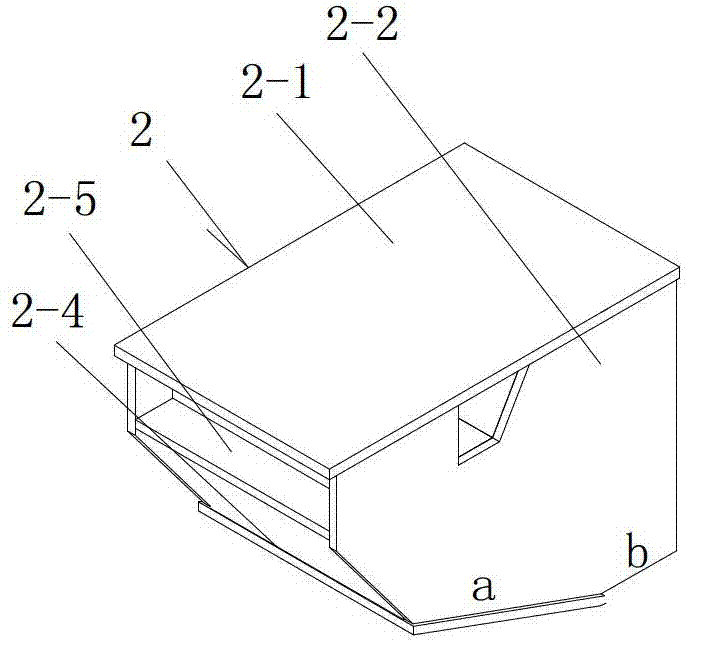

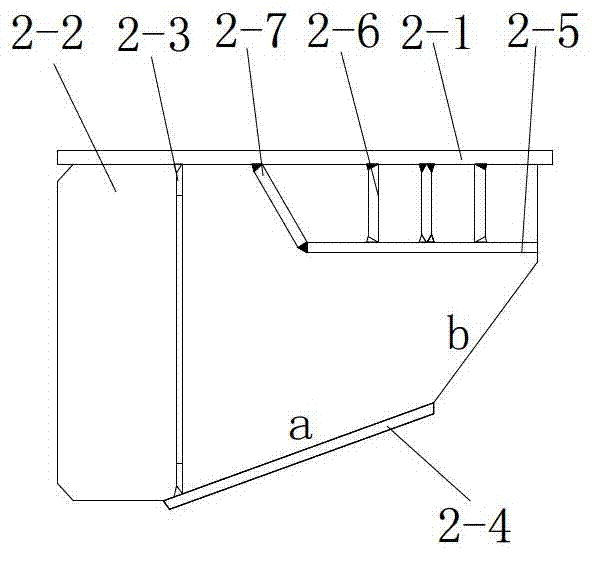

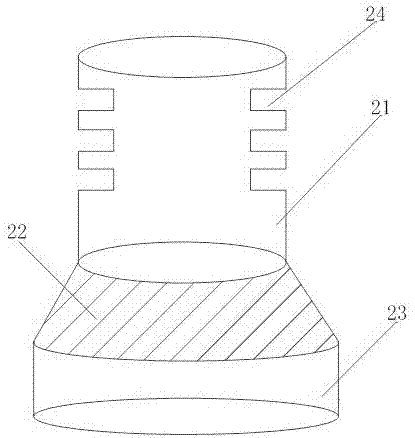

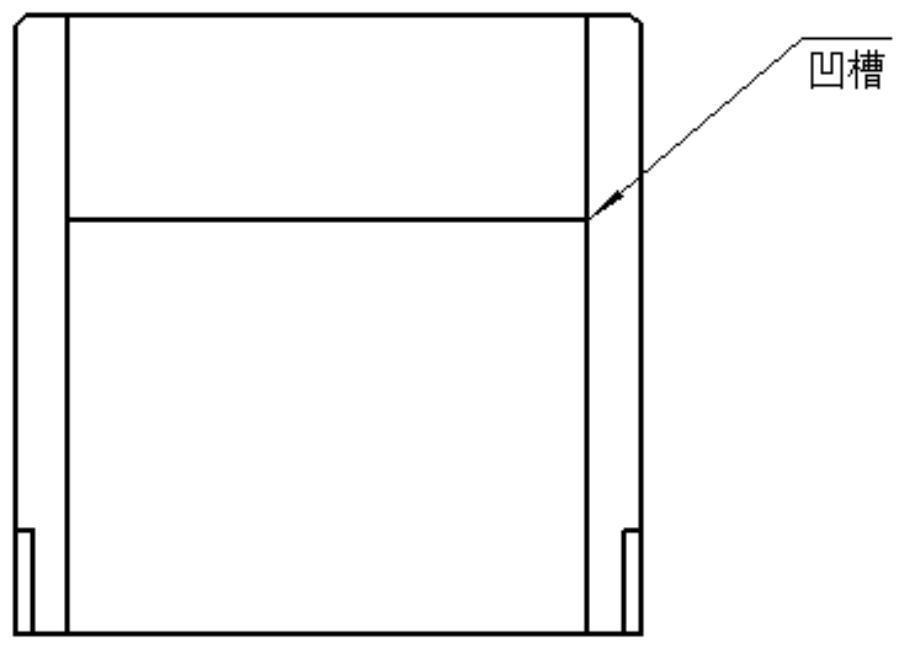

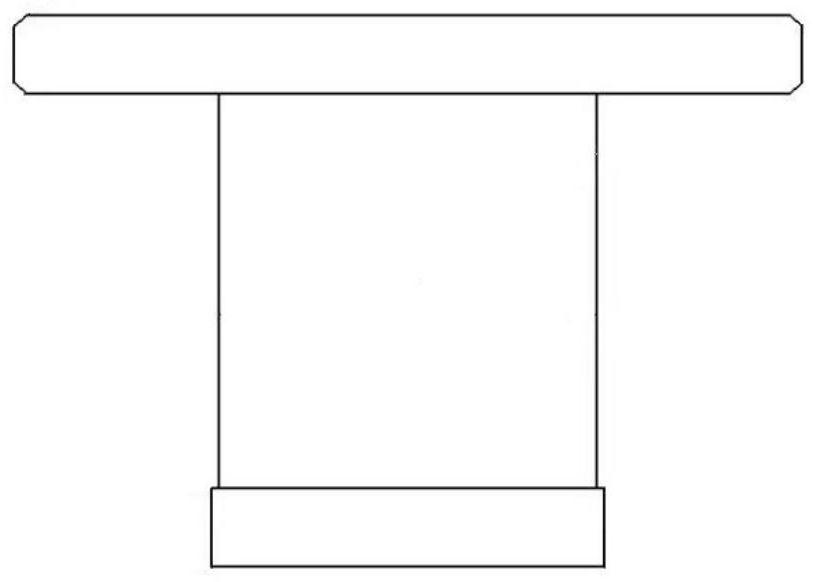

A composite structure aluminum alloy formwork

ActiveCN103437546BGuarantee the final qualityFasten the connectionForming/stuttering elementsBuilding productComposite structure

The invention discloses an aluminum alloy template with a composite structure. The aluminum alloy template with the composite structure comprises a main template (1), a ladder-shaped connecting slot (3) and a lock catch (4), wherein the ladder-shaped connecting slot (3) is connected in the middle of the lower part of the main template (1); the lock catch (4) is respectively in locked connection with the main template and the ladder-shaped connecting slot (3). The aluminum alloy template with the composite structure has the beneficial effects that the templates are connected by the ladder-shaped connecting slot, so that the connection is firmer, the sealing degree is better, a leakage phenomenon is almost not produced during concrete casting, and the final quality of the building product is ensured. Moreover, the template can be reused, the cleaning is time-saving and labor-saving, and the service life of the template is also greatly prolonged; the connecting construction efficiency adopting the ladder-shaped connecting slot is greatly improved by 3-5 times in comparison with the existing construction efficiency.

Owner:云南建投建材科技有限责任公司 +1

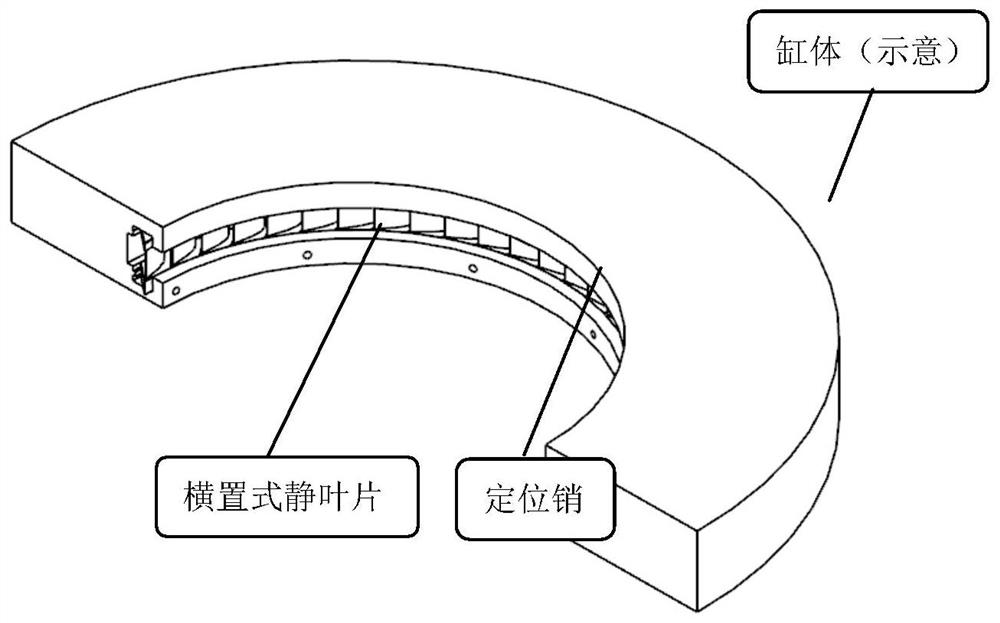

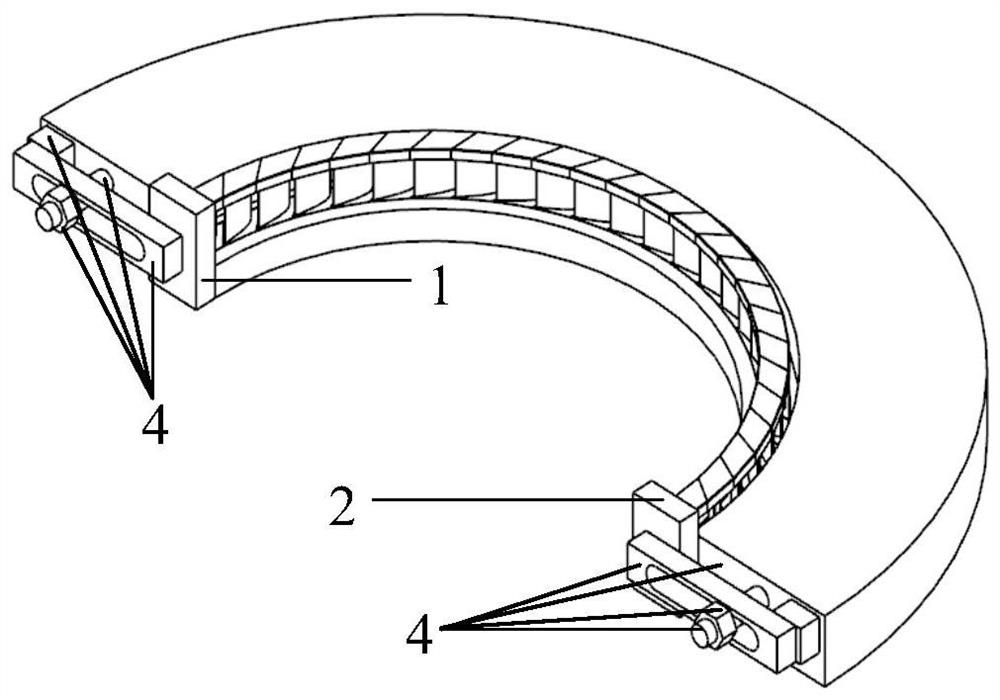

Transverse stator blade assembling method and positioning tool

ActiveCN114211438AAccurately guarantee the positionPlay a positioning roleWork holdersRadial positionStructural engineering

The invention discloses a transverse static blade assembling method and a positioning tool. The tool comprises a first check block and a pressing mechanism thereof, a tail check block and a pressing mechanism thereof, and a plurality of wedge-shaped filler strips. The head check block and the tail check block are used for limiting the circumferential installation positions of the head stator blade and the tail stator blade so as to guarantee that the circumferential installation positions of all the stator blades in the half circle are accurate, and the two pressing mechanisms are used for fixing the head check block and the tail check block to split faces at the two ends of the air cylinder respectively so as to fix all the stator blades in an installation groove of the air cylinder. The wedge-shaped filler strip is used for filling a gap between the outer arc of the crown of the stator blade and the outer circle of the cylinder mounting groove and limiting the radial position of the stator blade in the cylinder mounting groove. The positioning tool can well solve the problems of guaranteeing the assembly precision of the transverse stator blade and fixing the whole position, is simple in structure and convenient to operate, and effectively guarantees the final quality of products.

Owner:DONGFANG TURBINE CO LTD

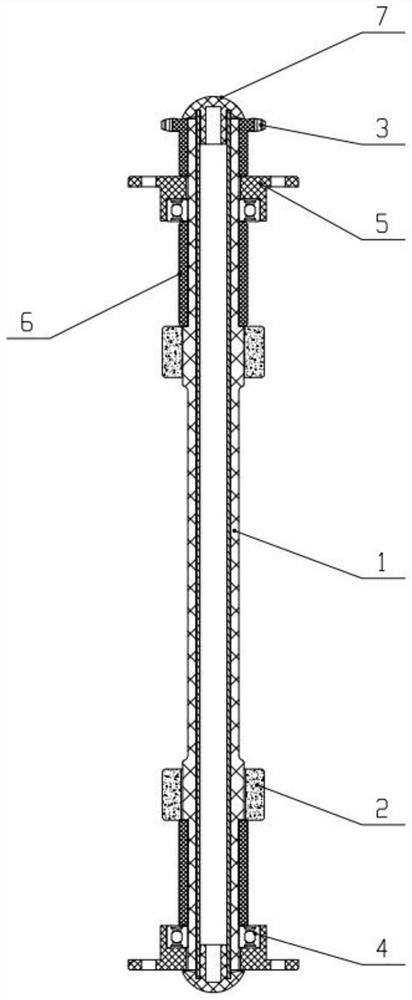

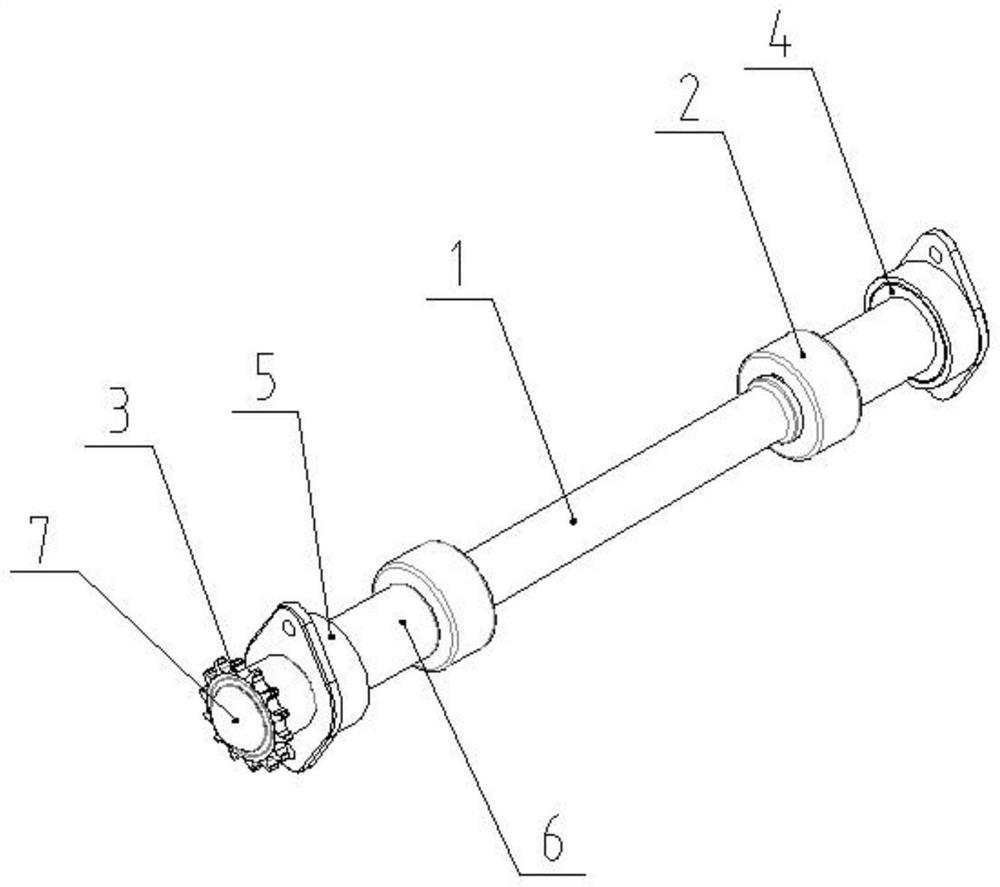

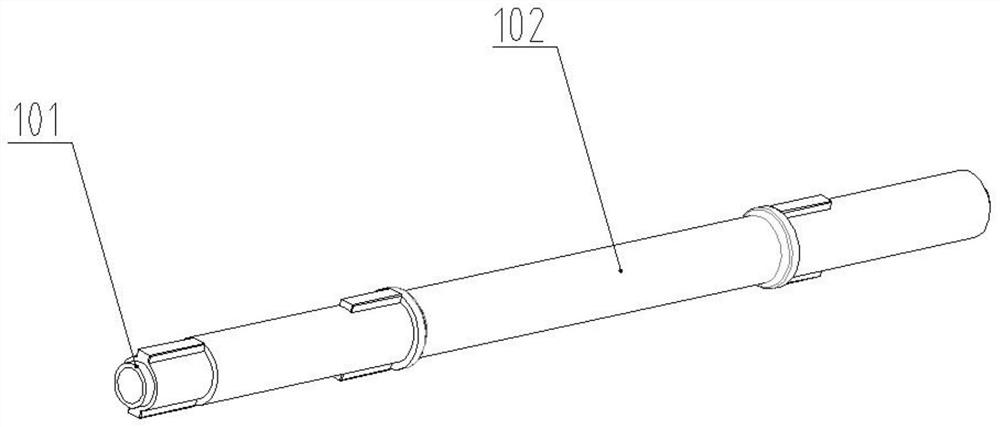

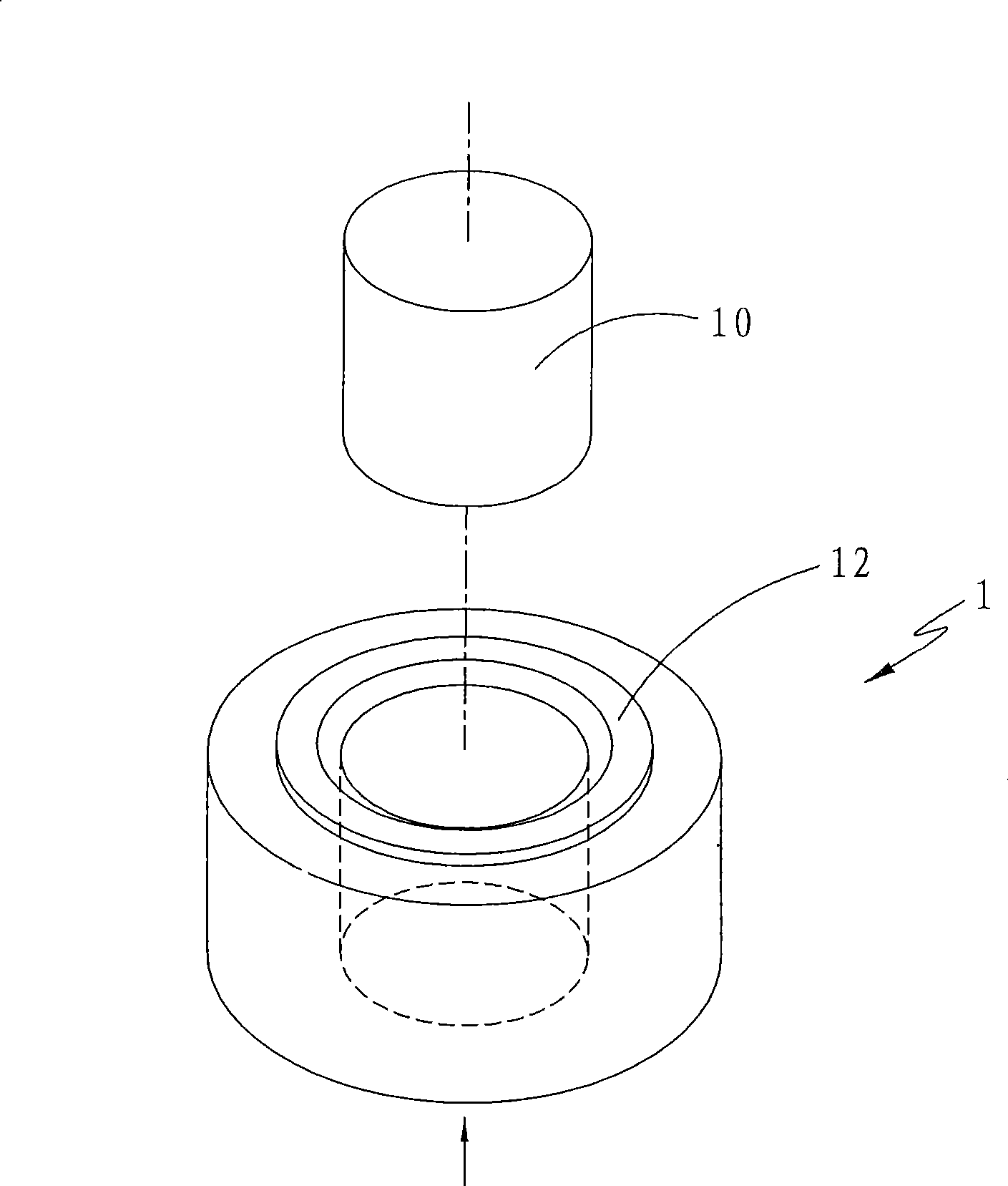

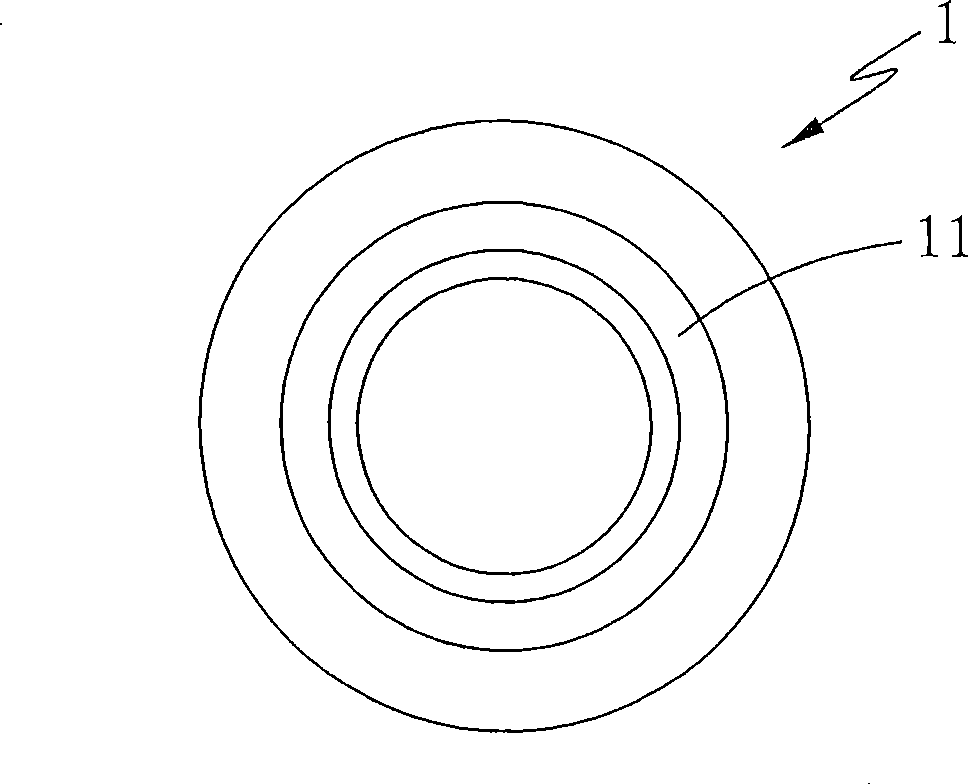

Shaft assembly for lithium battery material production and combination method thereof

PendingCN113895900AReduce security risksAvoid pollutionCouplings for rigid shaftsRollersMechanical engineeringBattery cell

The invention discloses a shaft assembly for lithium battery material production. The shaft assembly comprises a conveyance shaft, wherein the conveyance shaft comprises a hollow supporting shaft and a wrapping layer wrapping the outer surface of the supporting shaft, the conveyance shaft is sleeved with two rollers, one end of the conveyance shaft is sleeved with a transmission wheel, bearings are arranged between the transmission wheel and the rollers, and bearing seats matched with the bearings are arranged outside the bearings. The shaft assembly for lithium battery material production can meet the use requirement of customized conveyance in special industries and the special requirement of multi-product production, and reduce the potential safety hazard of the use environment; in the production process of the lithium battery material, the low-zinc, low-copper and high-temperature-resistant conveyance requirements can be met, pollution from external metal elements in the raw material conveyance process is avoided, the sintering quality of the raw materials is guaranteed, and the potential safety hazard of battery discharge caused by raw material pollution in the production process is reduced; and the rated conveyance load can be increased only by adjusting the thickness of the coating layer according to the mass of conveyed products, machining of a metal piece is avoided, and the production cost is saved.

Owner:NANJING PANDA ELECTRONICS +1

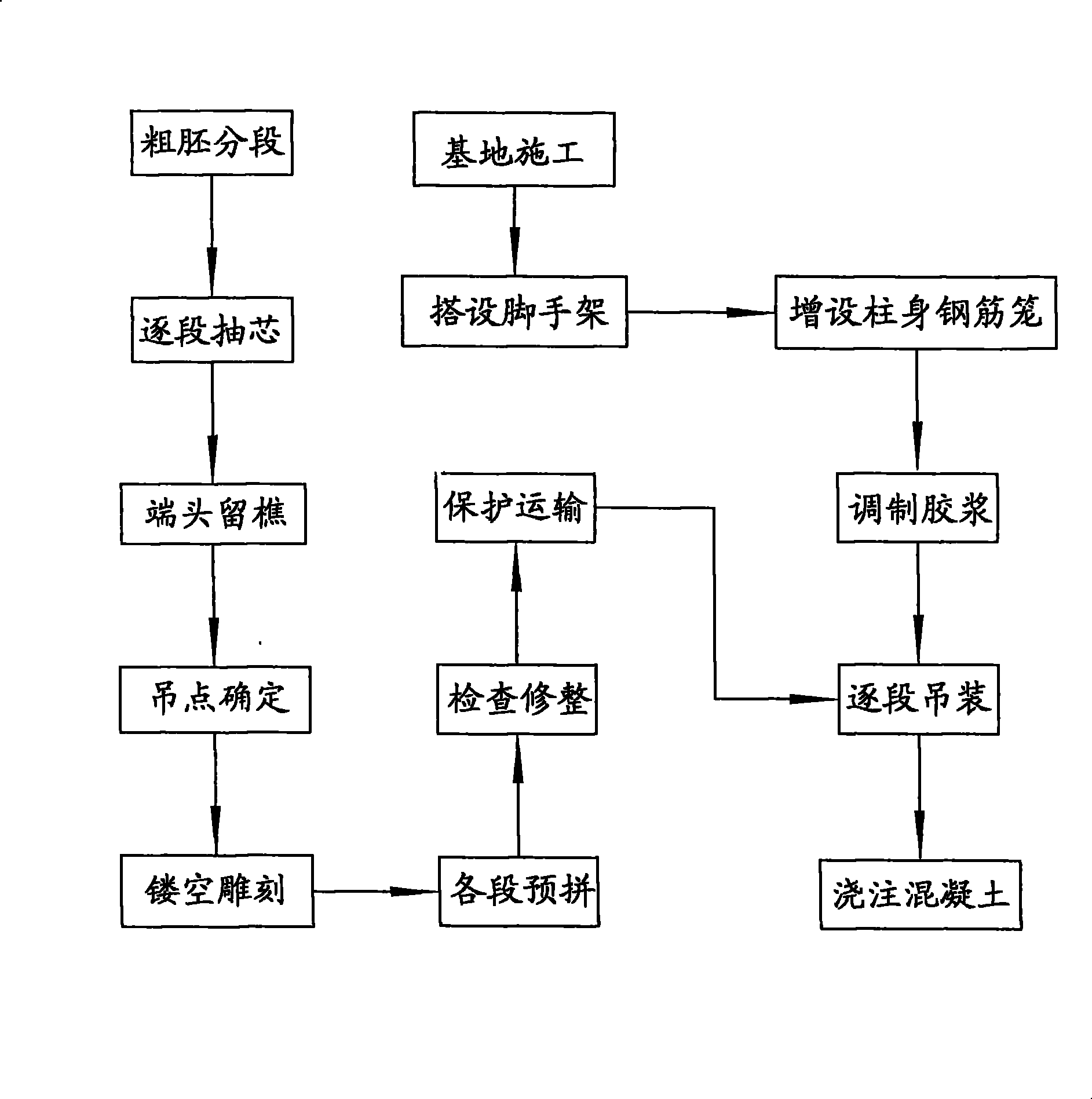

Large-scale hollowed-out embossed hollow stone column construction method

InactiveCN101513813BEnsure hollow qualityEasy to determineOrnamental structuresEarthquake resistanceStone carving

The invention discloses a large-scale hollowed-out embossed hollow stone column construction method. The method comprises the following steps of subsection of raw embryo, core drawing section by section, remaining of tenon at end tip, determination of a suspension centre, hollowed-out carving, pre-splicing of each section and other steps. As the method adopts computer typesetting manufacturing technology to simulate the large-scale hollowed-out embossed hollow stone column, the technology simulates the three-dimensional integrated effect of the large-scale hollowed-out embossed stone column and represents the hollowed-out depth degree of stone carving. The method simulates the hollowed-out degree of an embossed pattern through a computer, further optimizes the hollowed-out pattern to ensure the hollowed-out quality of embossment before the carving operation, also can provide intuitional reference for the three-dimensional effect of the hollowed-out embossment of the large-scale stone column, better determines the cutting position of the embossment and has the advantages of accurate positioning, easy assembly, high mounting precision, high hollowed-out quality, and the like. In addition, the method adopts a structure of combining the hollow stone column and core reinforced concrete; and the structure has the advantages of good performances of earthquake resistance and typhoon resistance.

Owner:FUJIAN MINNAN CONSTR ENG

Flat-surface milling machine

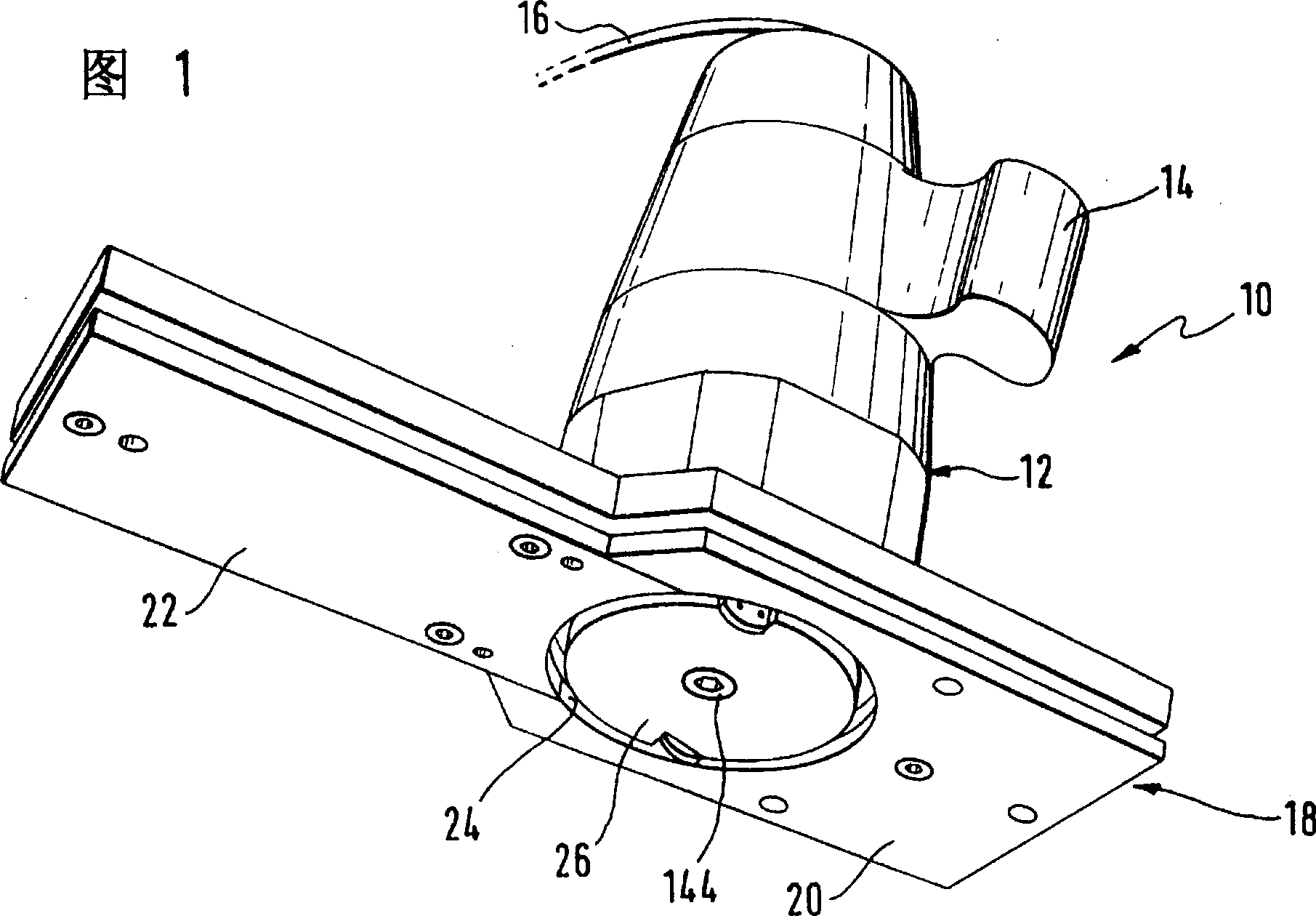

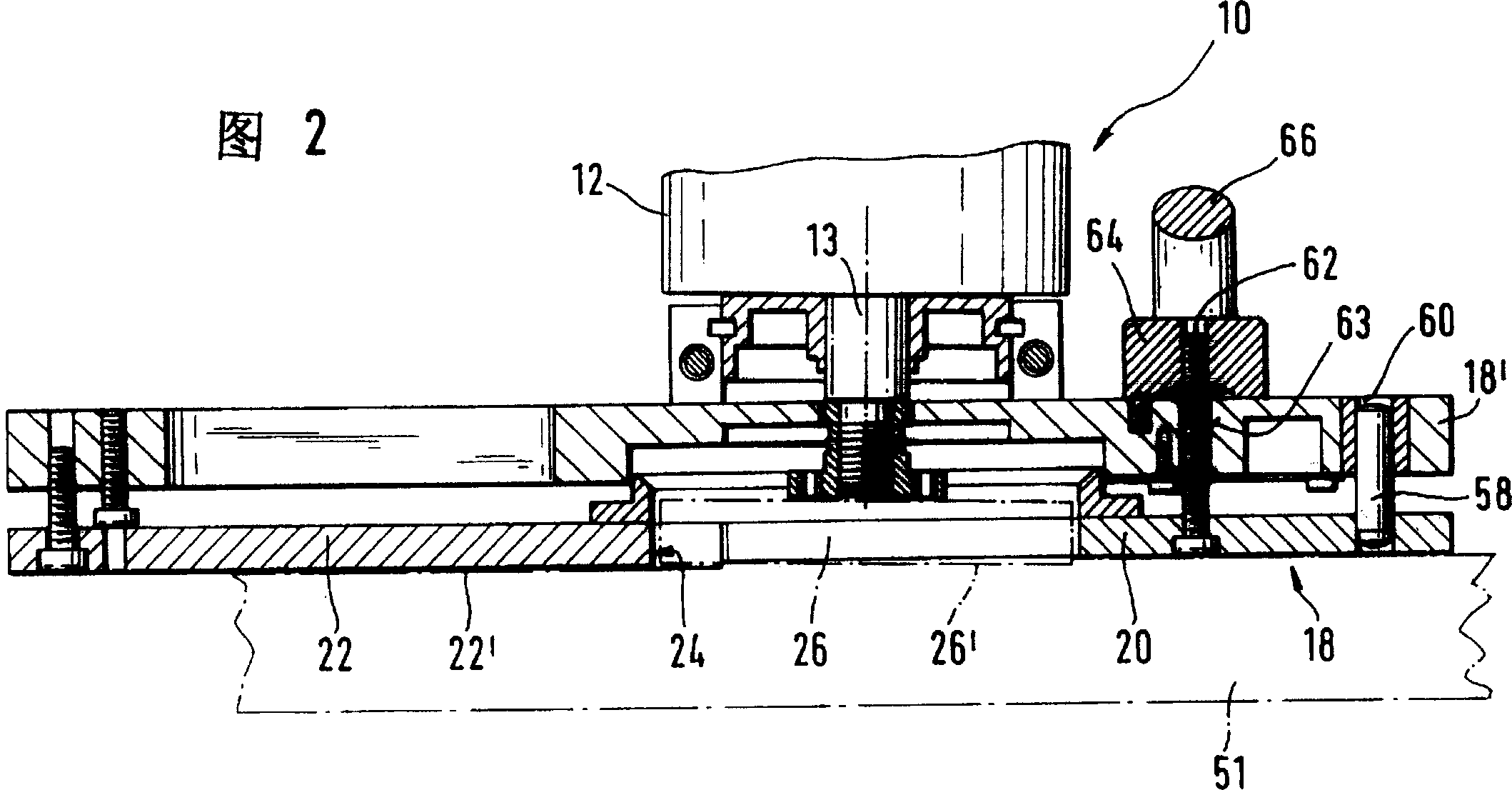

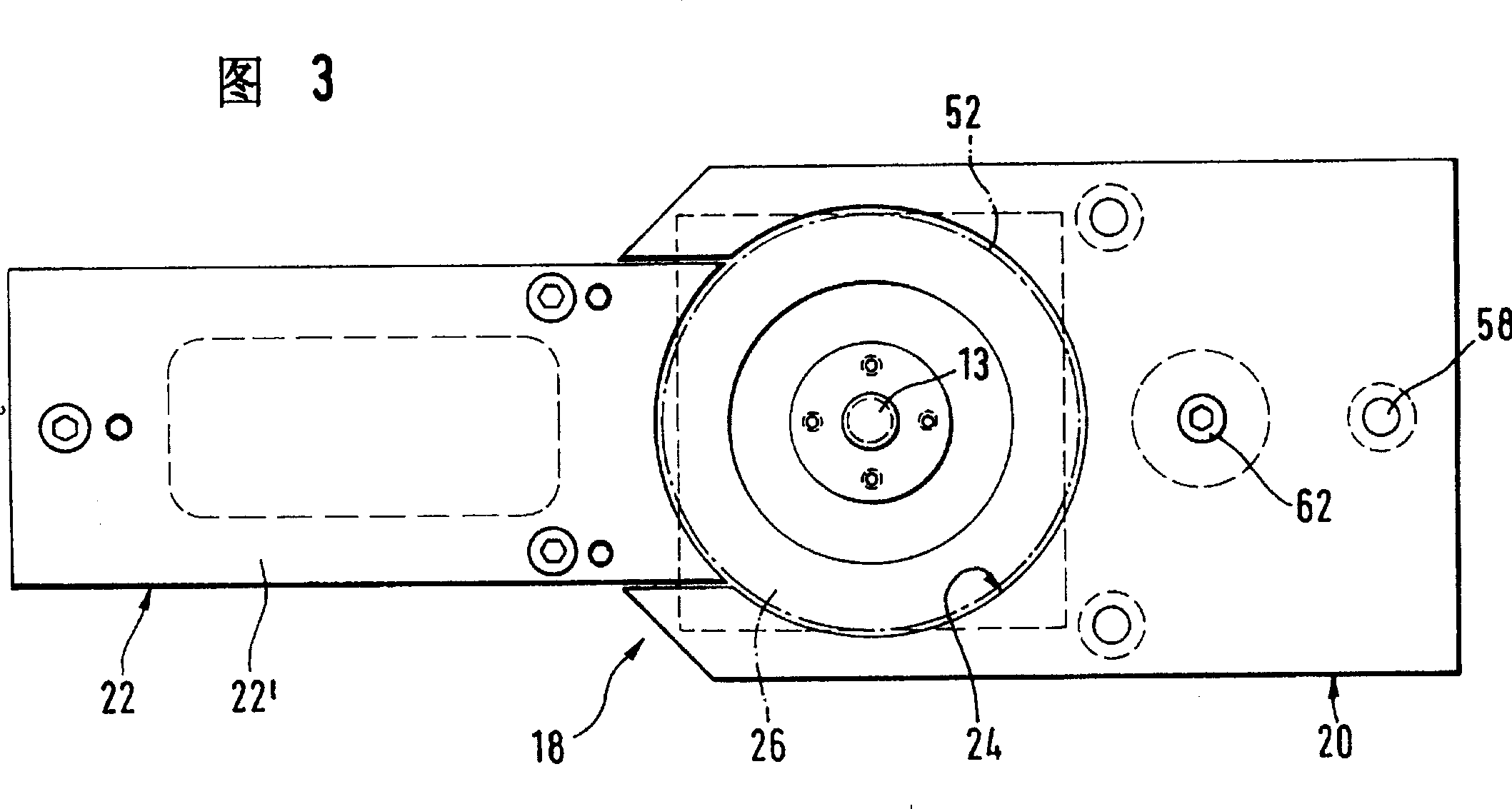

InactiveCN1087676CGuarantee the final qualityEasy to installRotary cutting toolsSmoothing machinesWood machiningHand held

The present invention relates to a machine (10) for milling flat surfaces and for woodworking, wherein said machine comprises a drive motor which is connected to a working shaft (13) having at one free end a milling head (26) provided with milling edges (48, 50) on its front face (28). The milling head (26) is made in the form of a preferably disc-shaped body which is parallel to the surface of the work. The milling edges are supported by a preferably flat blade (38, 40) which is removably mounted on the milling head and comprises a main edge as well as a secondary edge. The purpose of this invention is to provide a particularly efficient flat-surface milling machine in the shape of a hand-held machine-tool. This machine (10) is reduced in weight and size and includes a housing (12) with a handle (14). The milling head (26) includes a blade (38) which has no main edge (50) and is provided with a secondary edge (48) only.

Owner:ROBERT BOSCH GMBH

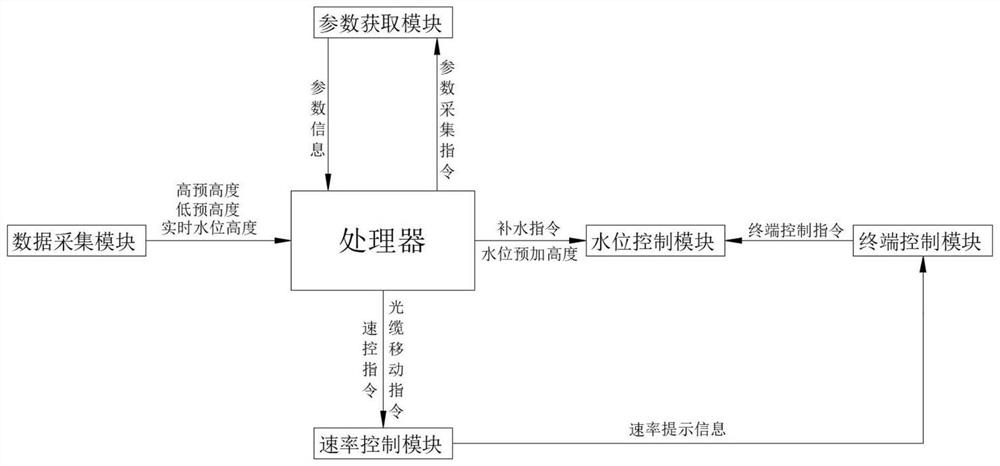

Multi-water-tank water level monitoring and analyzing system based on big data

PendingCN114485862AGuarantee the final qualityReduce lossMachines/enginesLevel indicatorsProcess engineeringData acquisition module

The invention relates to the field of optical cable production, and aims to solve the problems that the final quality of a finished product is affected due to the fact that water in an existing water tank is insufficient and the temperature of an optical cable cannot be reduced easily, and serious waste of water resources can be caused if a good cooling effect can be achieved if cooling water is continuously added into a cold water tank. The system comprises a data acquisition module, a processor, a parameter acquisition module, a rate control module, a water level control module and a terminal control module, the system controls the real-time water level height to continuously rise through the water level control module, and it is guaranteed that water in water tanks is sufficient; the temperature of the optical cable can be reduced, the final quality of a finished product is guaranteed, the water level in the water tank is increased in real time, the cooling effect can still be guaranteed when the water amount is small, and a large amount of cooling water is not used, so that water resource loss is reduced.

Owner:安徽天凯光通信技术有限公司

Method for processing magic cube box

InactiveCN112265321AHigh degree of automationGuarantee the final qualityBox making operationsPaper-makingCartonStructural engineering

The invention discloses a method for processing a magic cube box. The method comprises the following steps of cutting: binding boards and various packing paper used for decorating the binding boards are cut by using paper box cutting equipment; line pressing: the cut binding boards and the packing paper are die-cut to a half penetration depth so that the paper box can be subsequently bent according to a preset position; pretreatment: the binding boards are folded into a box shape through a magic cube box packaging device, and the packing paper used for decorating the outer walls of box bodiesis pasted on the binding boards to fix binding boxes, so that inner boxes with stable structures are formed; complete packaging: the bottom packing paper and the inner packing paper are added for thefixed inner boxes; arrangement: the packed inner box individuals are arranged; and connection: the inner boxes are connected through the packing paper. Through the arrangement of a shaping box and thepacking paper structure, the automation degree of the binding board packing paper is improved, and meanwhile, the binding boards are simply fixed by the packing paper so that the effective fixing effect can be achieved, so that the subsequent processing is facilitated, the production efficiency is guaranteed, and the final quality of products is guaranteed.

Owner:浙江翌星包装科技有限公司

Micron-sized particle stacking compactness testing device and testing method thereof

ActiveCN113504149AAccurate packing densityBulk density test is accurateSpecific gravity measurementMicron scaleCritical condition

The invention discloses a micron-sized particle stacking compactness testing device and a testing method thereof, and belongs to the technical field of material science and engineering, and the testing device comprises a piston, an outer sleeve, a filter membrane, a stainless steel filter screen, a perforated sheet, a sealing washer, a perforated supporting assembly, a liquid storage assembly and a demolding device. According to the testing device, filtering media with pore diameters and strength from small to large are combined to form the filtering assembly, so that the maximum bearable stress is greatly increased while the rejection rate is ensured, and the application range is enlarged. The invention further discloses the testing method of the device, the close packing state of the particles can be accurately judged, and the packing compactness of the micron-sized particles can be tested. According to the testing device and the testing method, the problems that the influence of particle clusters cannot be completely eliminated, critical condition judgment is subjective and the like in an existing method are solved, accurate testing of the micron-sized particle stacking compactness is achieved, and prediction of the rheological property of a solid-liquid mixture, optimization of the proportion and even guarantee of the final quality of the product in actual engineering are facilitated.

Owner:SOUTHEAST UNIV

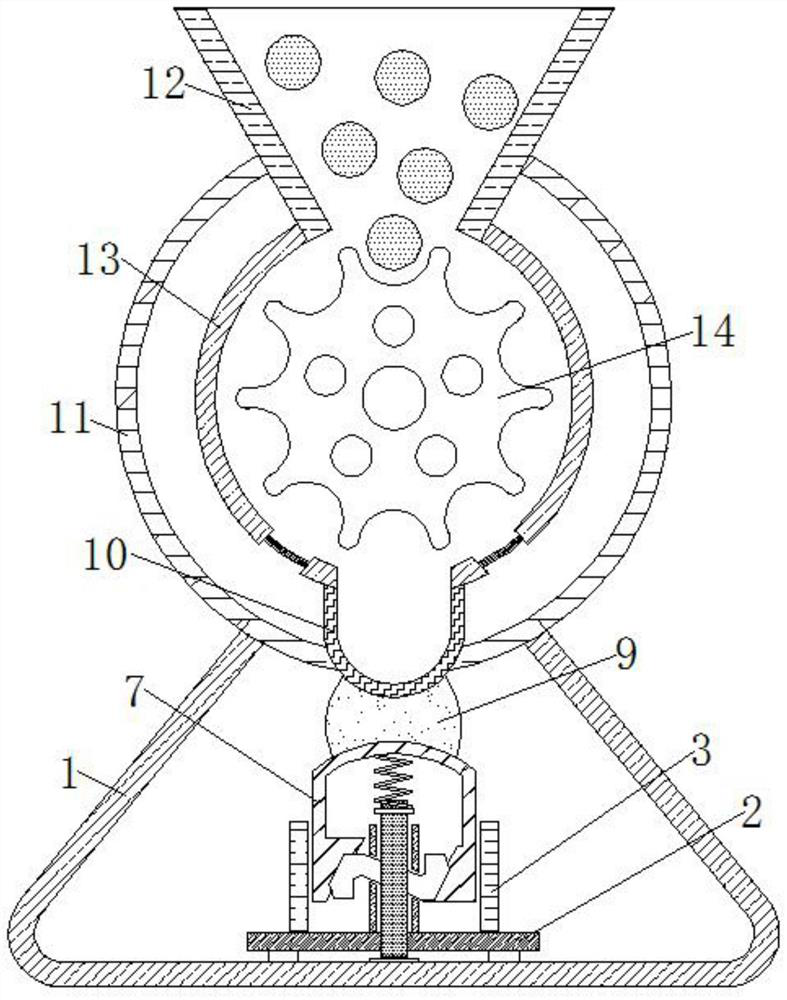

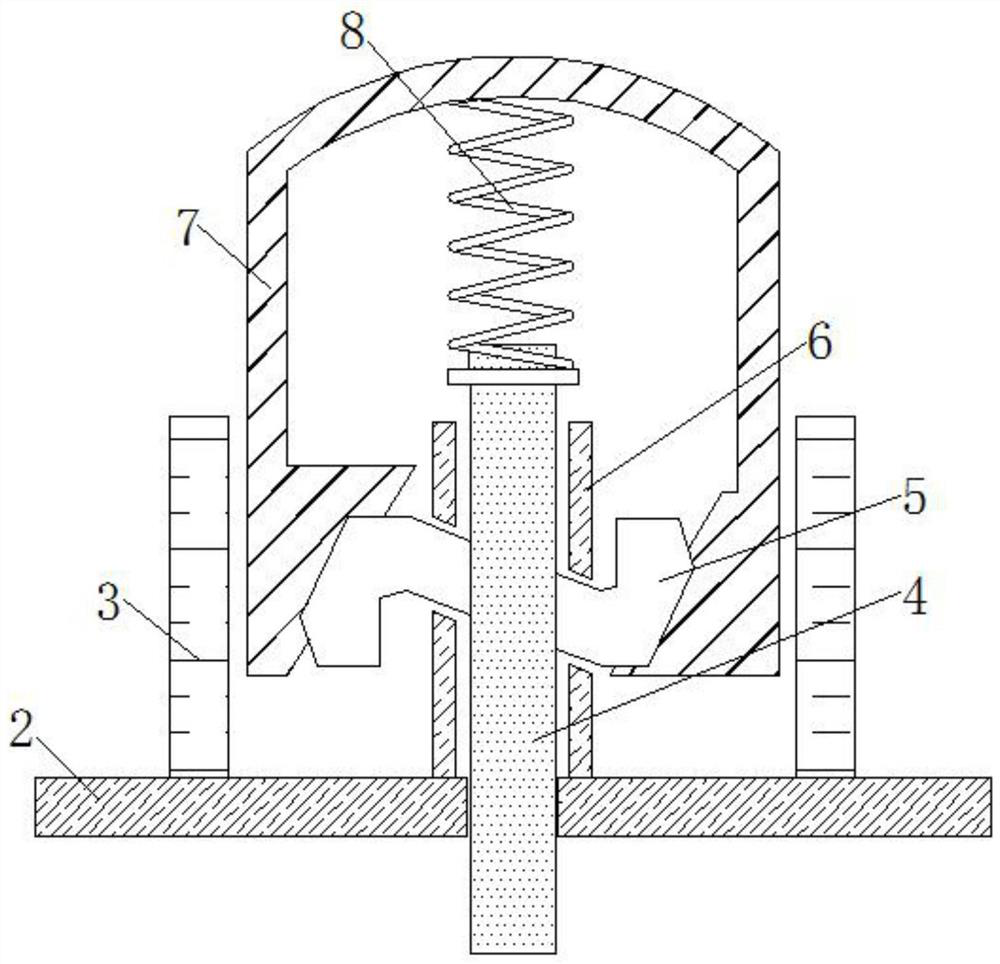

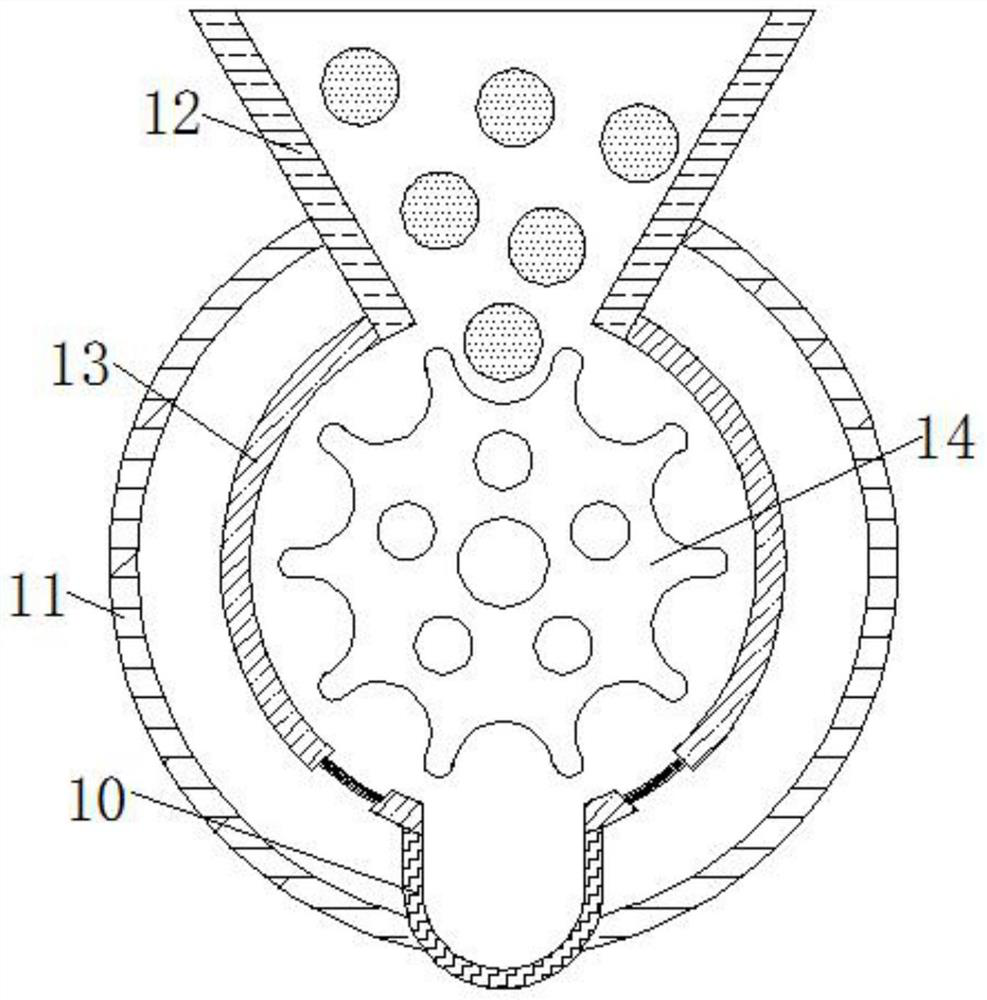

A packaging device for finished pharmaceutical products based on gravity buffering

ActiveCN110435941BAvoid accumulationGuarantee the final qualitySolid materialStructural engineeringPill

The invention relates to the technical field of medical processing, and discloses a packaging device for finished medical products based on gravity buffering, comprising: a base, a fixing frame is fixedly installed at the lower end of the inside of the base, and a fixing cylinder is fixedly installed on the upper surface of the fixing frame, A movable rod is fixedly installed in the middle of the fixed frame, and a movable bar is plugged inside the movable rod, and limit rods are movably installed at both ends of the movable bar, and the two ends of the movable bar penetrate and extend to both sides of the limit rod A movable block is movably connected, and a compression spring is elastically connected between the upper end of the movable block and the upper end of the movable rod. The upper end of the movable block is movably installed with a packing box, and the upper end of the packing box is movably installed with a discharge port. The base The upper end is fixedly installed with a collection shell. Through the combined use of the feed inlet, the distribution shell and the buffer frame, the pills can be separated individually, effectively avoiding the accumulation of the pills, and ensuring the final quality of the pills.

Owner:江西裕康医药有限公司

A detection method for the position of the leakage point of the underground concrete diaphragm wall

ActiveCN113203527BGuarantee the final qualityDiversity guaranteedDetection of fluid at leakage pointProtective foundationLocation detectionStructural engineering

This application relates to a detection method for the location of the leakage point of an underground concrete diaphragm wall, which includes S1: digging a preliminary survey well outside the diaphragm wall; S2: pumping groundwater inside the diaphragm wall; S3: observing the water level of the preliminary survey well to determine the drop of the water level The initial survey well corresponding to the diaphragm wall is the direction of the leakage point; S4: Dig a detection trench outside the leakage point area of the diaphragm wall, and use a partition to divide the detection trench into multiple detection intervals; S5: Towards the detection trench Fill water and observe the water level of each detection interval. If the water level of a certain detection interval drops, determine the position of the leakage point corresponding to the continuous wall of the detection interval; S6: Pump out the water in the detection groove, take out the partition, and keep two partitions on both sides of the detection interval. Plate, backfill the rest of the detection area; S7: Irrigate the detection area step by step, and wait for a period of time after each irrigation, and observe the water level change. If the water level drops for a certain time, determine the position corresponding to the water level height as the final leak point position. The present application has the effect of improving the comprehensiveness of the position detection of the leakage point of the continuous wall.

Owner:JIANGSU TESTING CENT FOR QUALITY OF CONSTR ENG

Mold for injection molding of plastic water cup

ActiveCN113001885AGuaranteed stitchingGuarantee the final qualityDomestic articlesStructural engineeringMechanical engineering

Owner:佛山市鑫斐翔精密模具有限公司

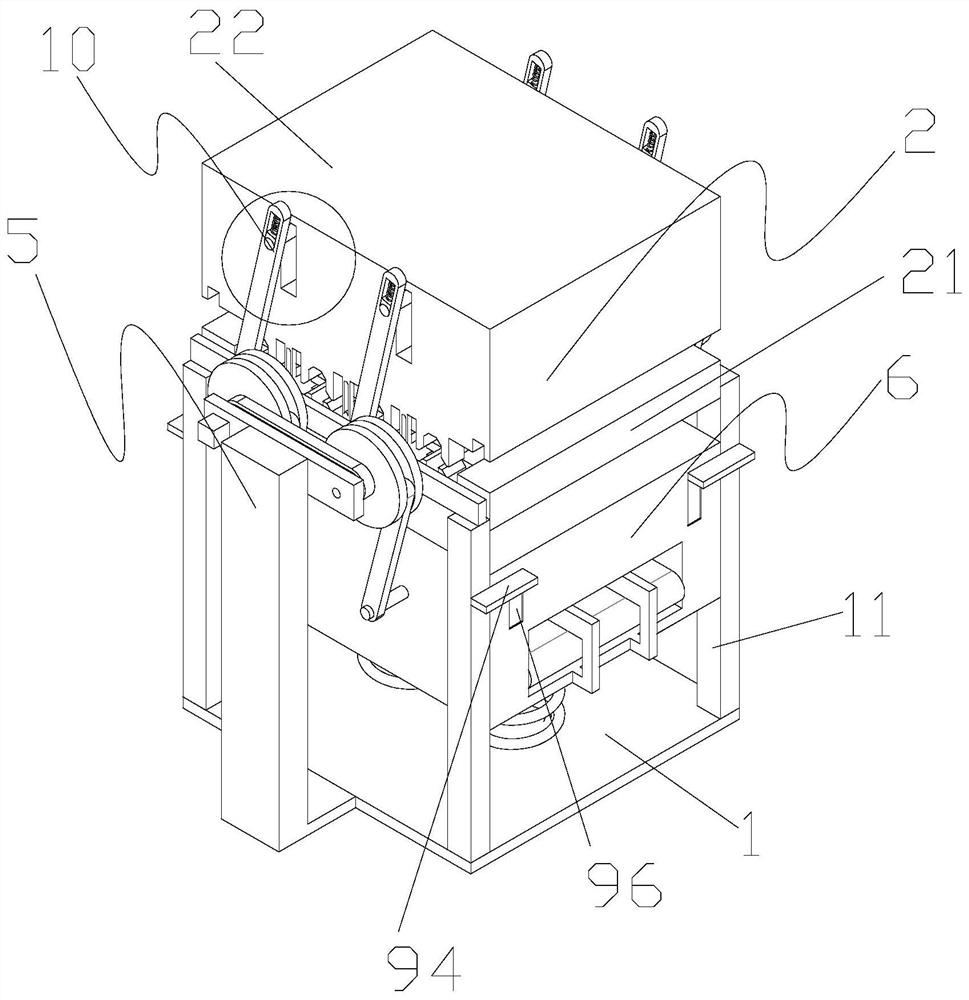

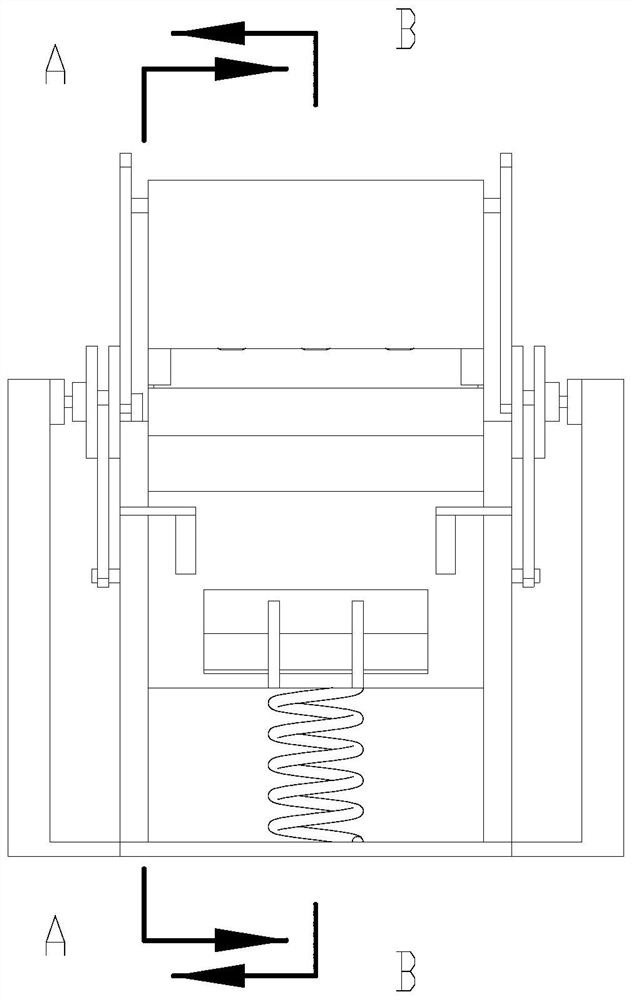

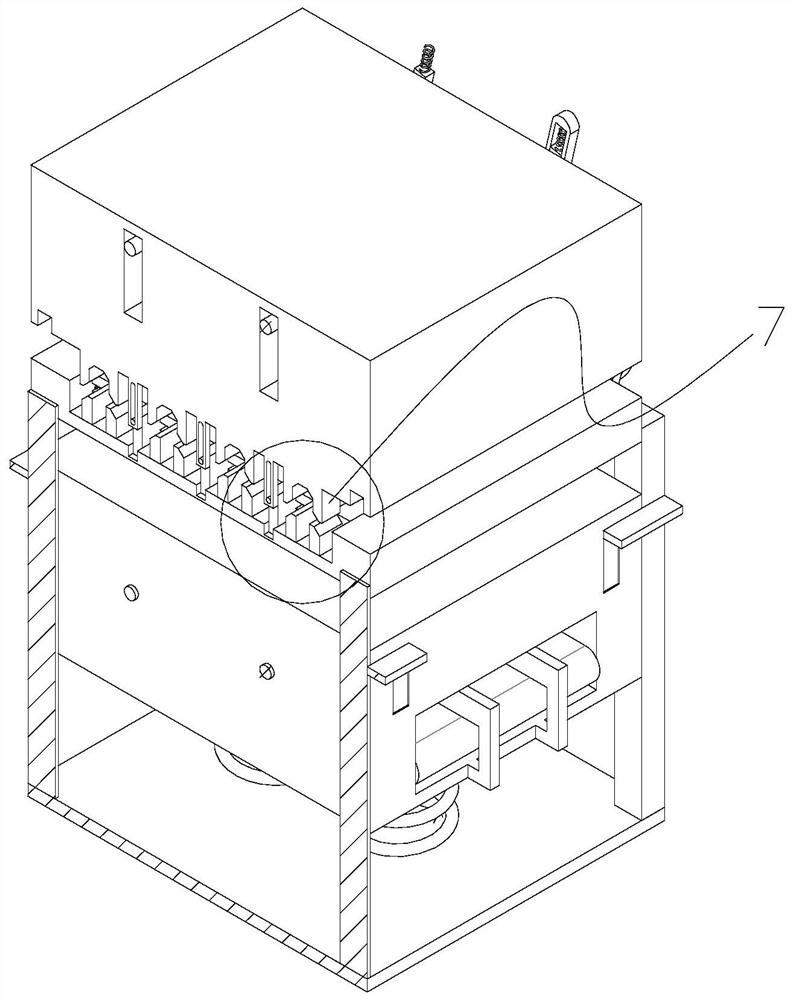

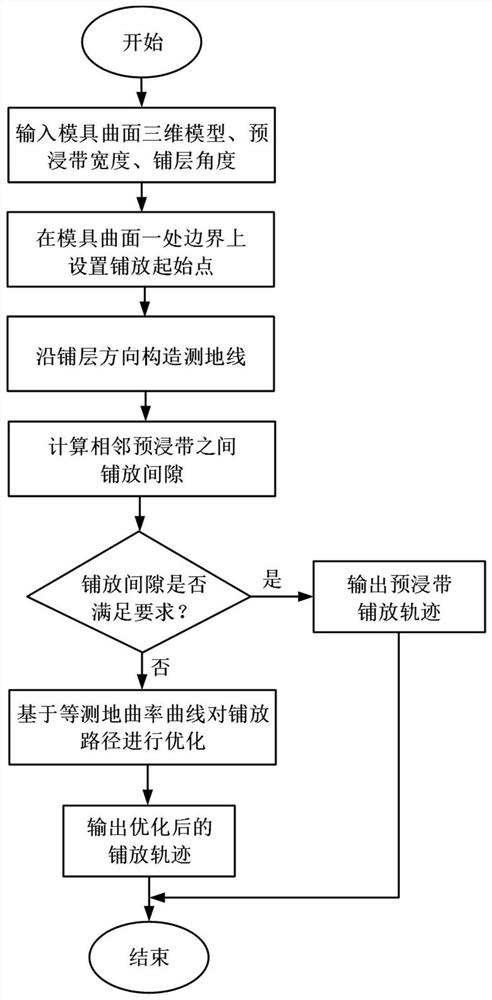

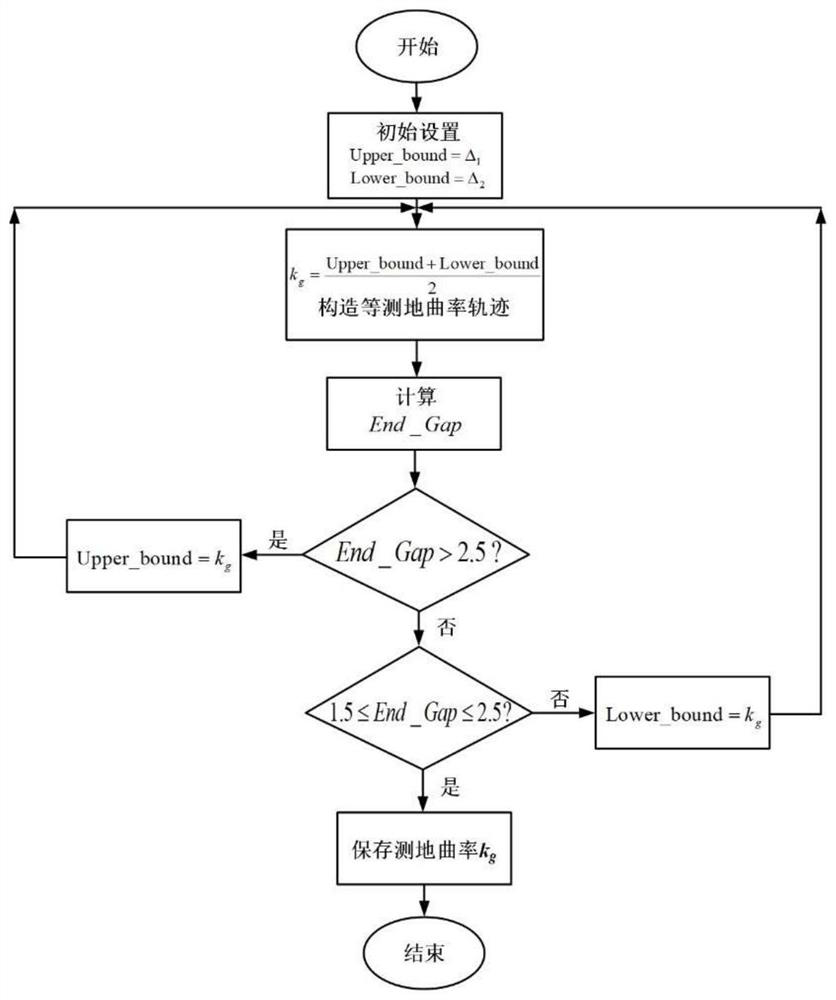

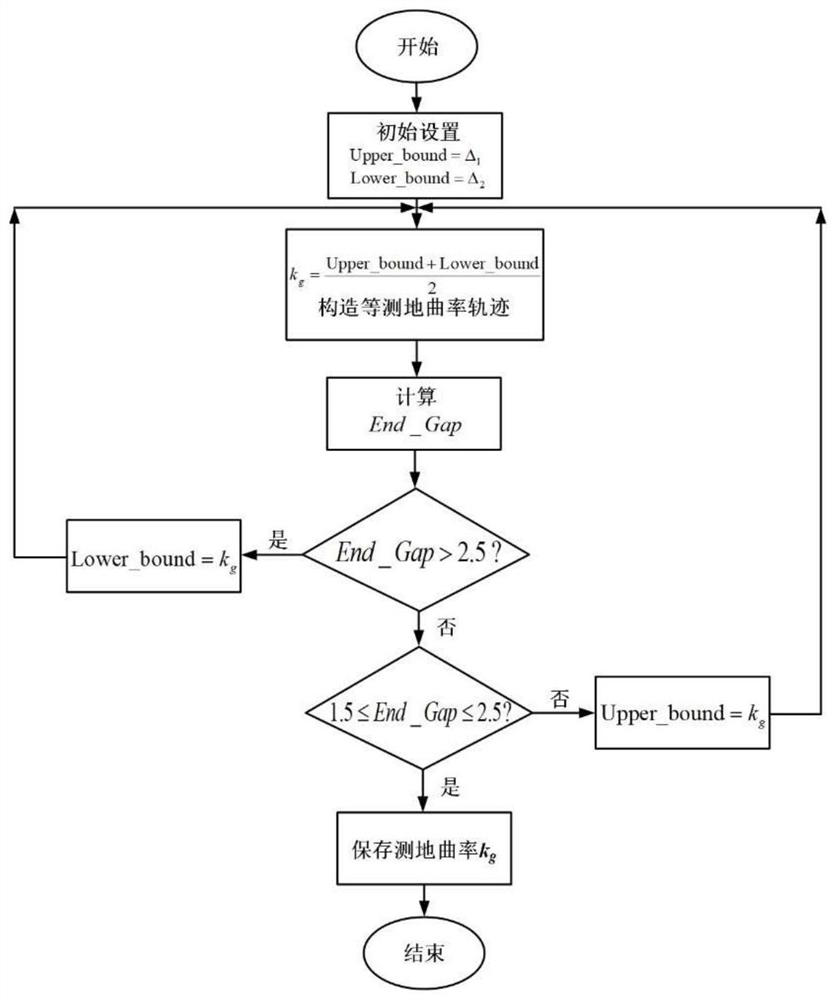

An Automatic Tape Laying Trajectory Planning Method Based on Isogeodesic Curvature Curves

ActiveCN111832172BDoes not generate coverageReduce complexityDesign optimisation/simulationImage data processingStructural engineeringTrajectory planning

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com