An Automatic Tape Laying Trajectory Planning Method Based on Isogeodesic Curvature Curves

A geodesic curvature and trajectory planning technology, applied in instrumentation, design optimization/simulation, image data processing, etc., can solve problems such as large local deformation of prepreg tape, and achieve the effect of reducing the amount of deformation and reducing the degree of cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

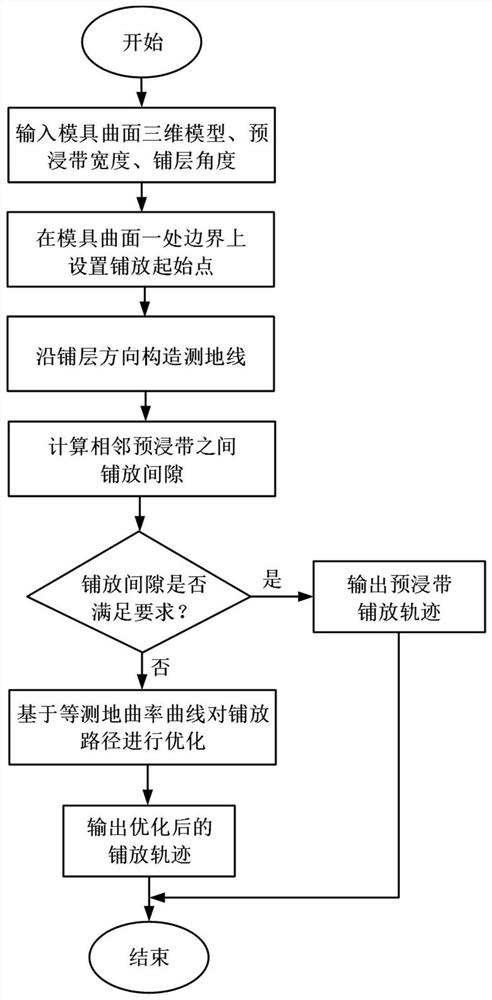

[0046] like figure 1 As shown in the figure, an automatic tape laying trajectory planning method based on an equal geodesic curvature curve is characterized in that, it includes the following steps:

[0047] S1. Input the three-dimensional model of the mold surface to be laid, the width W of the prepreg tape, and the laying direction of the prepreg tape;

[0048] S2. Select a boundary of the mold surface, and set a plurality of starting points for laying prepreg tapes on the boundary, so that the distance between the adjacent laying starting points on the boundary of the mold surface is W+s, where the unit of s is is mm and s∈(0,1];

[0049] S3. Construct a geodesic line along the starting point set in step S2 respectively, until the trajectory of the geodesic line reaches another boundary of the curved surface, and the direction of the geodesic line is the same as the laying direction of the prepreg tape in step S1;

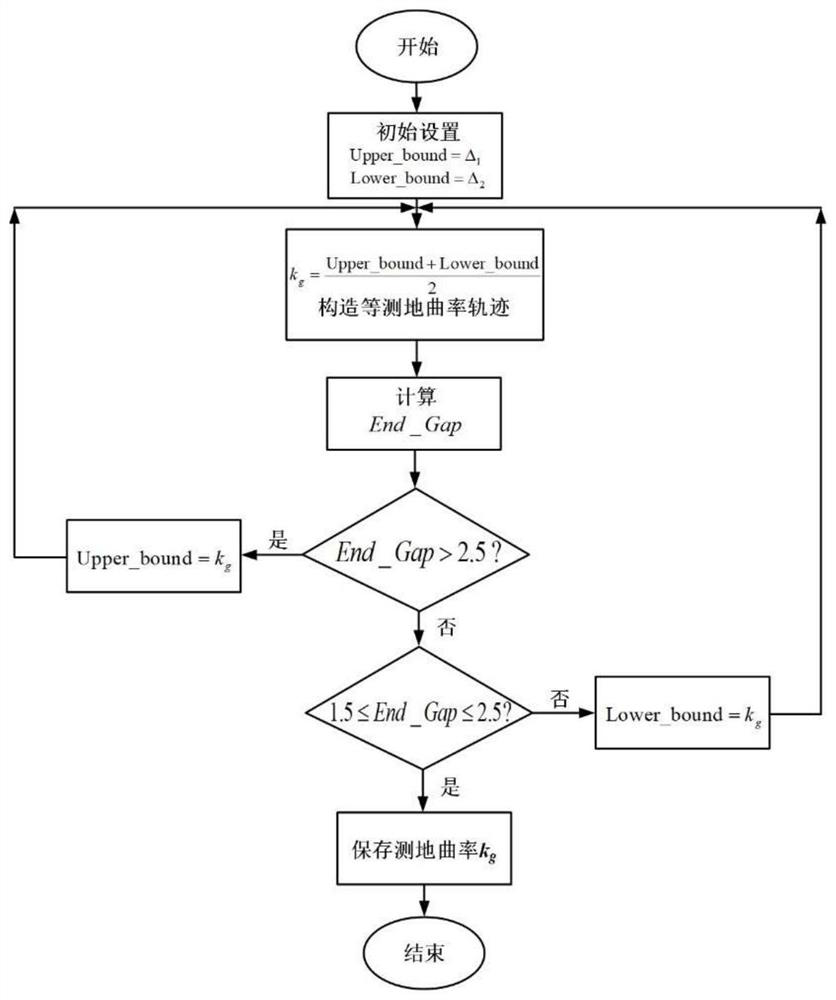

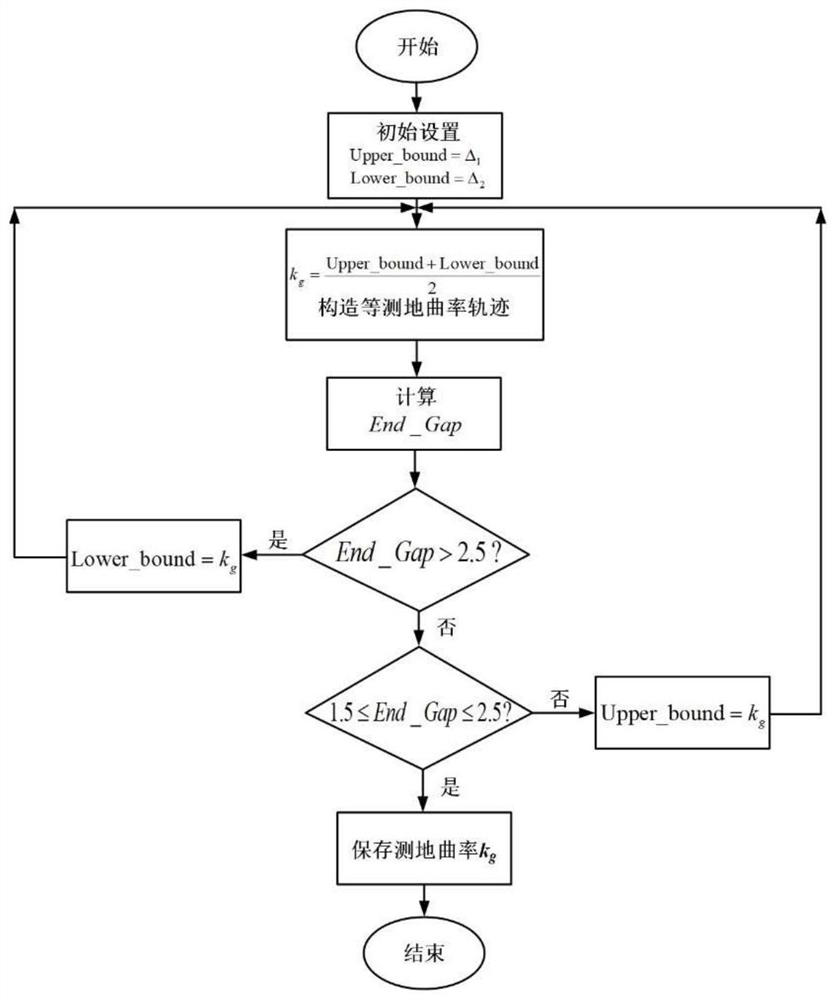

[0050] S4. Using the geodesic constructed in step S3 as ...

Embodiment 2

[0081] A kind of automatic tape laying trajectory planning method based on equal geodesic curvature curve, is characterized in that, comprises the following steps:

[0082] S1. Input the three-dimensional model of the mold surface to be laid, the width W of the prepreg tape, and the laying direction of the prepreg tape;

[0083] S2. Select a boundary of the mold surface, and set a plurality of starting points for laying prepreg tapes on the boundary, so that the distance between the adjacent laying starting points on the boundary of the mold surface is W+s, where the unit of s is is mm and s∈(0,1];

[0084] S3. Construct a geodesic line along the starting point set in step S2 respectively, until the trajectory of the geodesic line reaches another boundary of the curved surface, and the direction of the geodesic line is the same as the laying direction of the prepreg tape in step S1;

[0085] S4. Using the geodesic constructed in step S3 as the proposed laying track of the pre...

Embodiment 3

[0125] In this embodiment, a process for automatic tape laying trajectory planning on a hyperboloid mold is provided, as follows:

[0126] S1. Input the 3D model of the hyperboloid mold, the width of the prepreg tape is 150mm, and the layering direction is 0 degrees; such as Figure 4 As shown, the size of the hyperboloid mold is 1000mm×5000mmm;

[0127] S2. Set up multiple prepreg tape laying starting points on one boundary of the hyperboloid mold, and at the same time ensure that the distance between the adjacent laying starting points on the mold boundary is 151mm;

[0128] S3. Such as Figure 5 As shown, starting from each layup start point, construct geodesics along the layup direction until the locus of the geodesics reaches the other boundary of the surface;

[0129] S4. Take the geodesic line as the proposed tape laying track during the laying process of the prepreg tape, and calculate the size of the laying gap between the adjacent prepreg tapes. Large laying gap, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com