Diesel fuel and natural gas double-fuel integrated injector

A technology of natural gas and injectors, which is applied in fuel injection devices, charging systems, machines/engines, etc. It can solve problems such as complex structures and unsmooth fuel switching, and achieve the effects of simple structure, reduced fuel consumption, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

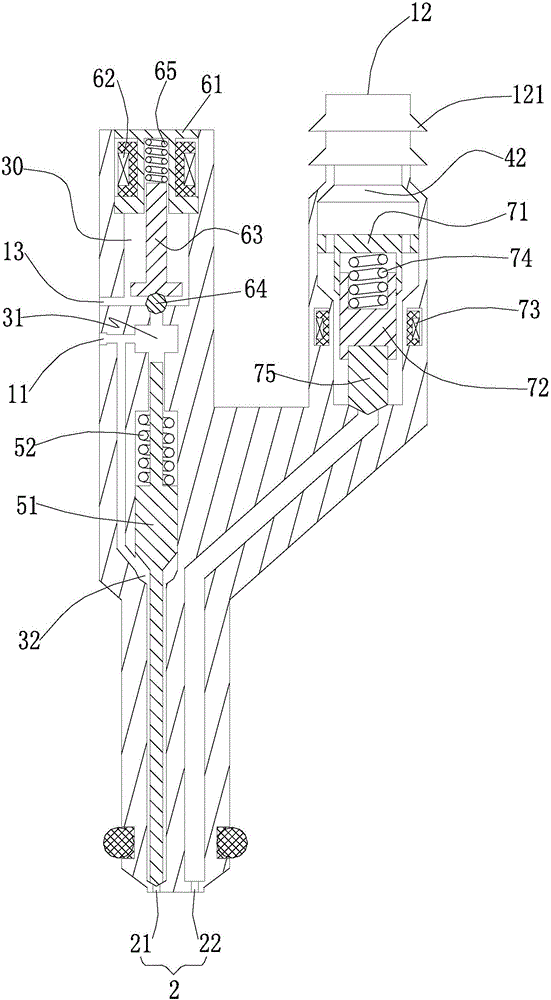

[0022] Embodiment one: if figure 1 As shown, a diesel and natural gas dual-fuel integrated injector includes an injector body, and the injector body is provided with:

[0023] The diesel fuel inlet 11 is used to connect with the high-pressure oil pipe;

[0024] The natural gas fuel inlet 12 is used to connect with the natural gas fuel supply pipeline;

[0025] Fuel injection port 2;

[0026] The first passage communicates with the diesel fuel inlet 11 and the fuel injection port 2, and the first passage is provided with a first valve chamber 30, a first pressure chamber 31, and a second pressure chamber 32 which communicate with each other sequentially from top to bottom; The diesel fuel inlet 11 communicates with the first pressure chamber 31 and the second pressure chamber 32; the second pressure chamber 32 communicates with the fuel injection port 2;

[0027] The second passage communicates with the natural gas fuel inlet 12 and the fuel injection port 2, and a second va...

Embodiment 2

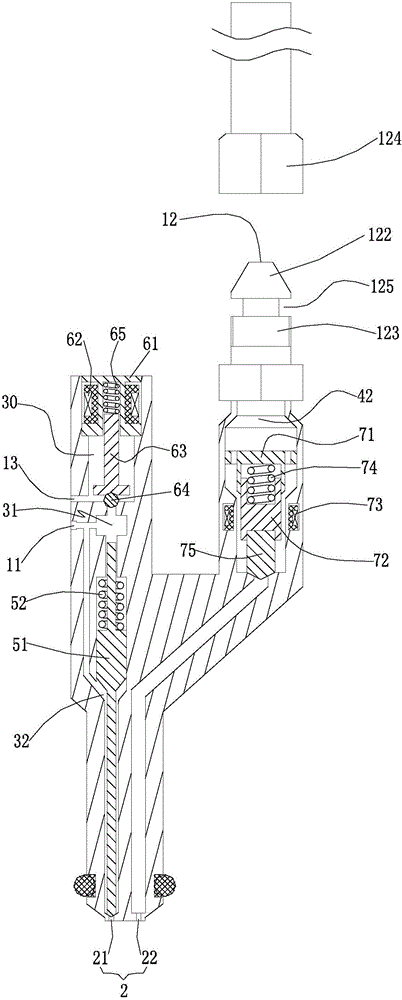

[0050] Embodiment 2: The difference from Embodiment 1 is that the natural gas fuel inlet 12 is provided with a quick connector conveniently connected to the natural gas fuel supply pipeline. The connection part 122, the locking fitting part 123 provided with threads on the outer circumference below the tapered insertion part 122, and a nut 124 which is arranged on the natural gas fuel supply pipeline and can cooperate with the locking fitting part 123, wherein, the An annular groove 125 is provided between the tapered insertion portion 122 and the locking fitting portion 123 .

Embodiment 3

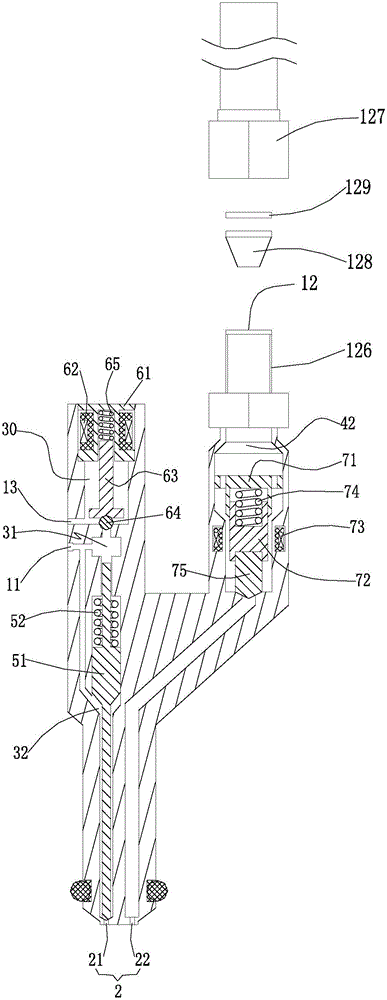

[0051] Embodiment 3: The difference from Embodiment 1 is that the natural gas fuel inlet 12 is provided with a ferrule type joint conveniently connected with the natural gas fuel supply pipeline, and the ferrule type joint includes a locking threaded outer circumference. The fitting part 126, the nut 127 that is arranged on the natural gas fuel supply pipeline and can cooperate with the locking fitting part 126, and the through hole that is arranged between the locking fitting part 126 and the nut 127 and has a cone that gradually becomes smaller Shaped piece 128 and annular gasket 129.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com