Patents

Literature

34results about How to "Meet clearance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

InactiveCN101412943AReduce repair costsReduce difficultyAdditivesRestorative materialPhysical chemistry

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, the ferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

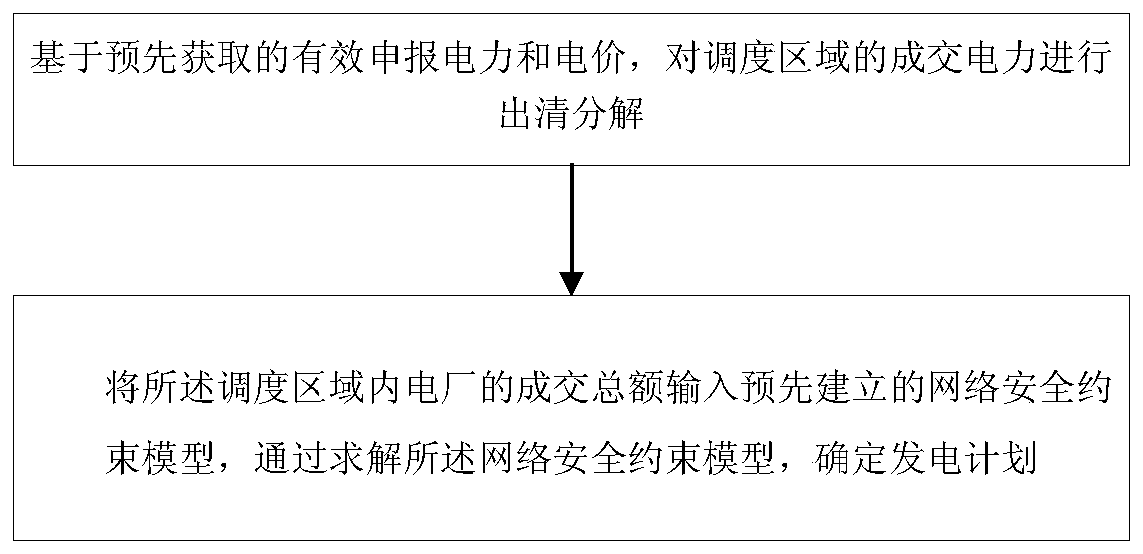

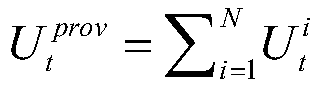

Electric power clearing decomposition method and system for cross-regional dispatching electric power spot market

PendingCN110322115ASolve the problem of clearing decompositionMeet clearance requirementsResourcesSystems intergating technologiesDecompositionElectricity price

The invention relates to an electric power clearing decomposition method and system for a cross-regional dispatching electric power spot market, and the method comprises the steps: carrying out the clearing decomposition of the transaction electric power of a dispatching region based on the pre-obtained effective declaration electric power and electricity price; determining the total transaction amount of the power plant in the dispatching area according to the transaction power of the power plant in each clearing stage obtained by clearing decomposition; wherein the clearing decomposition comprises bid quantity decomposition clearing in day-ahead bidding, day-ahead allowance decomposition clearing and intra-day spot decomposition clearing.

Owner:CHINA ELECTRIC POWER RES INST +2

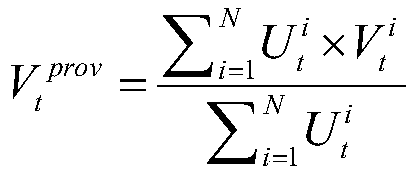

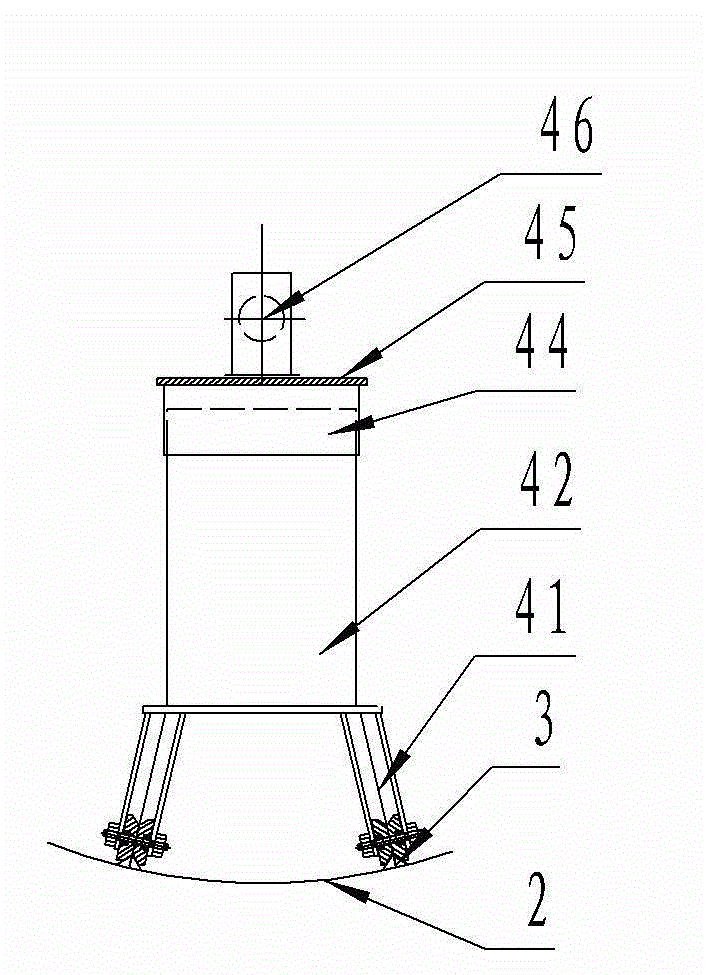

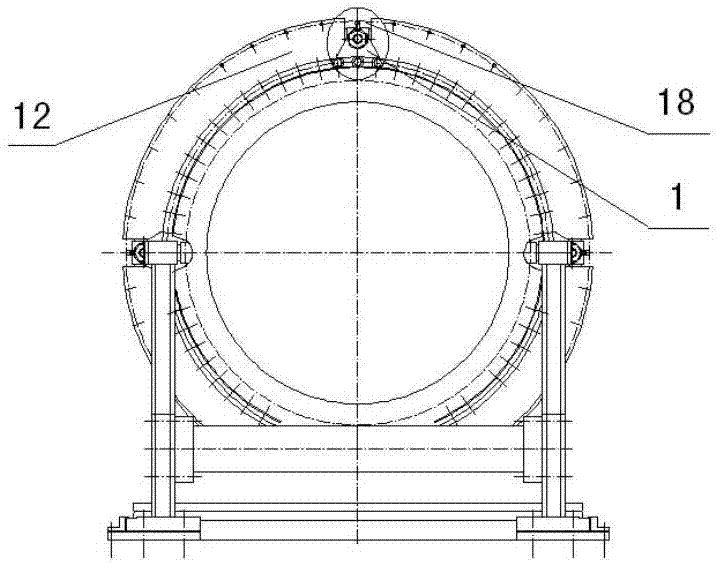

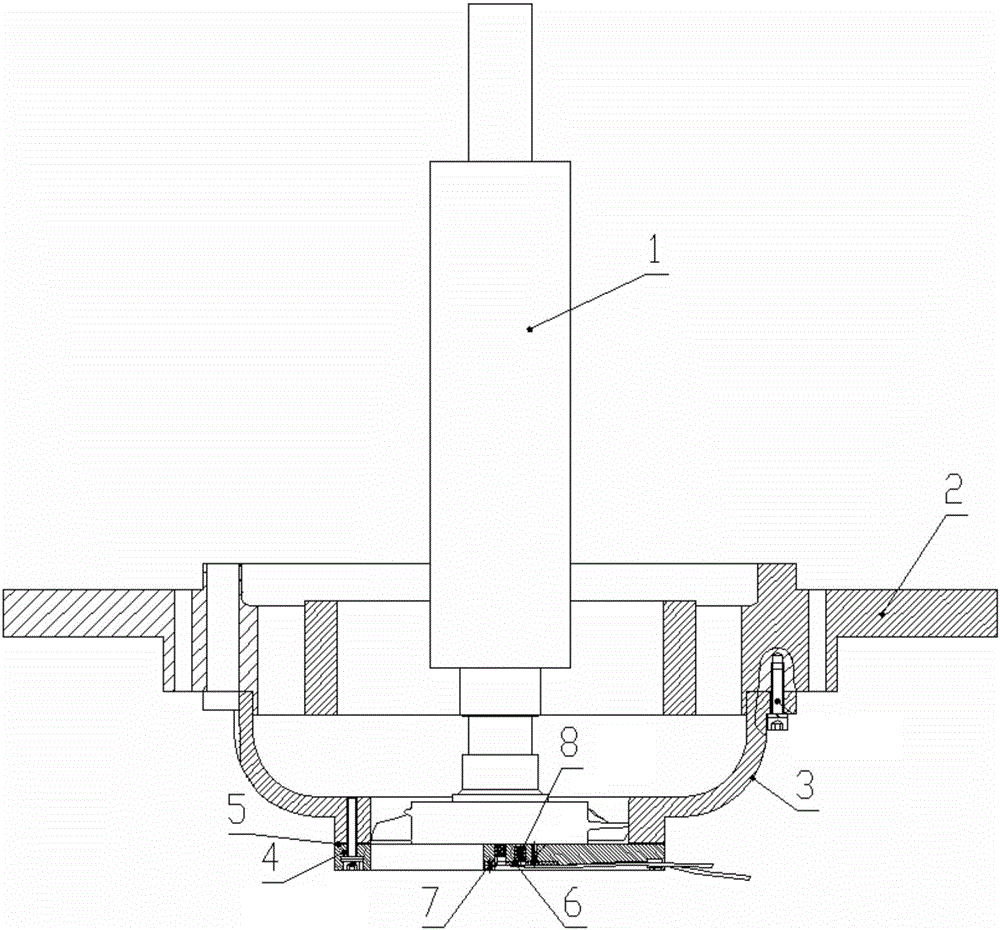

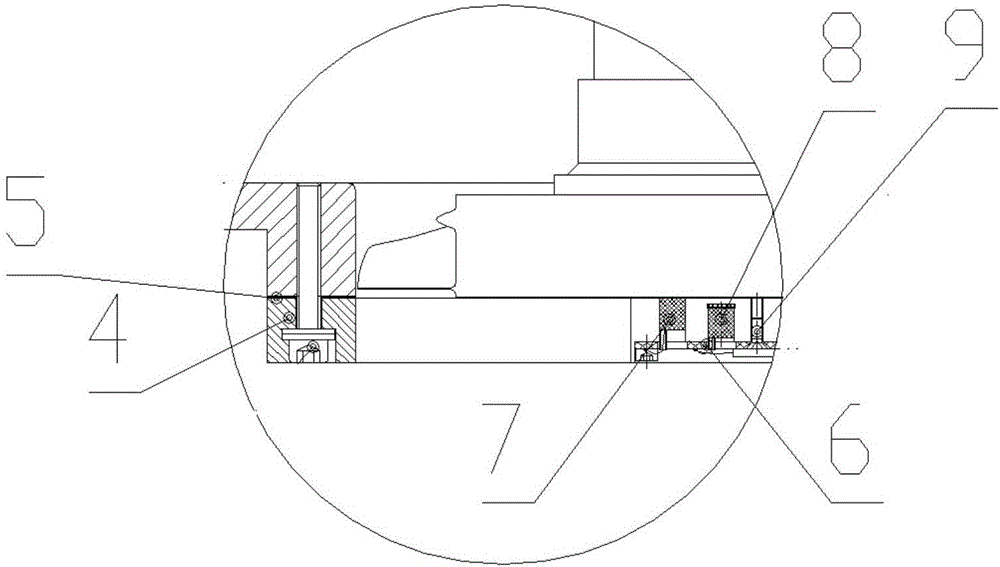

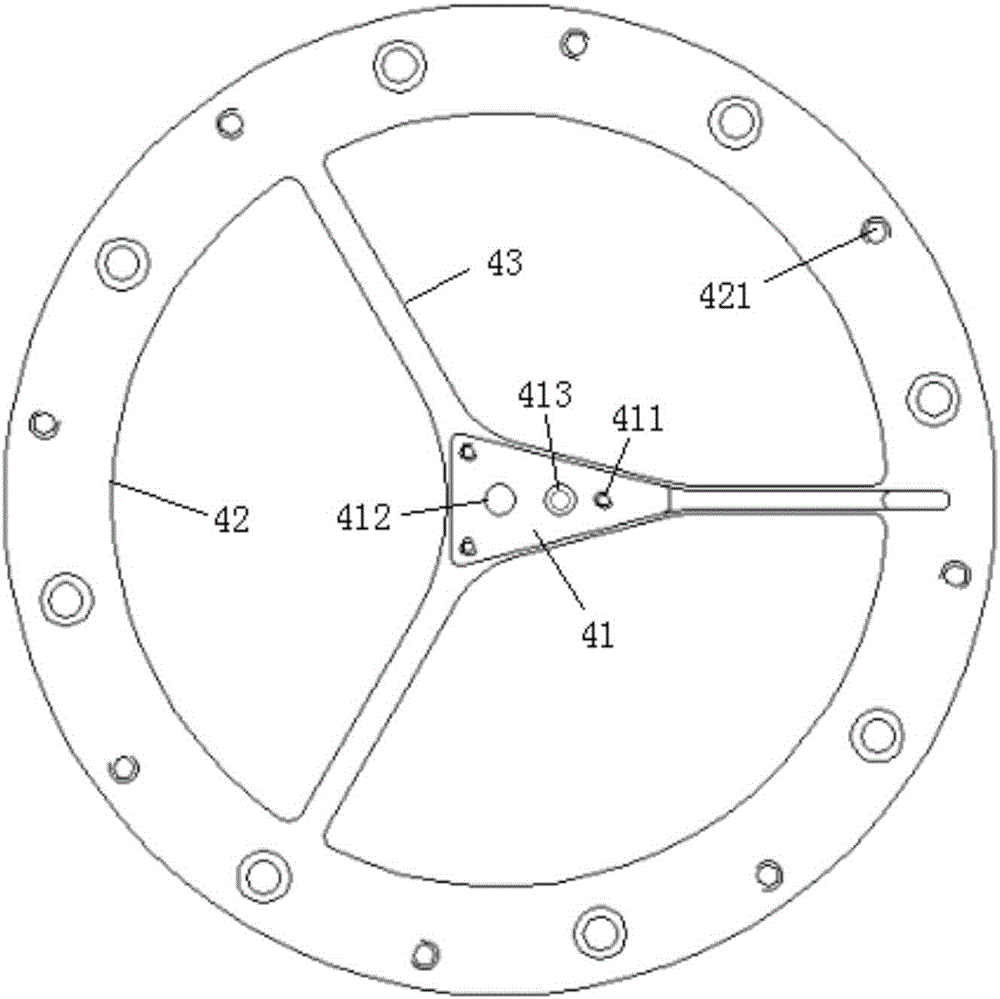

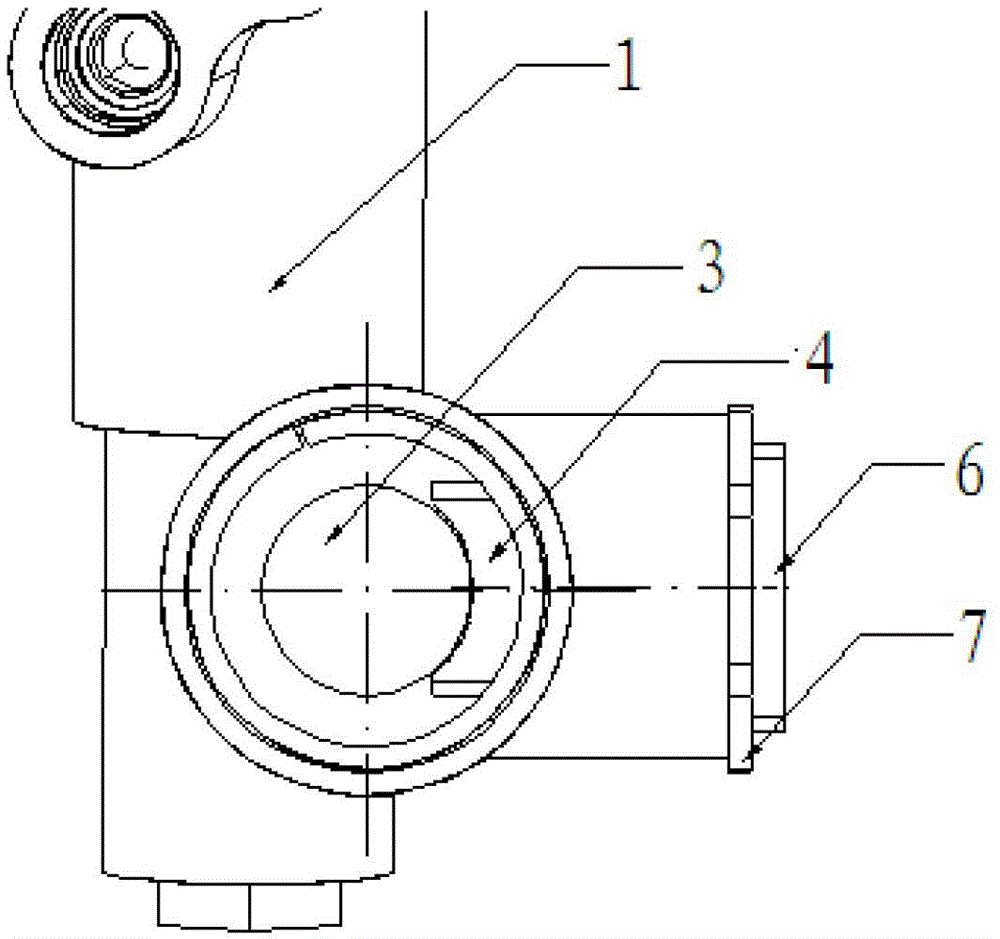

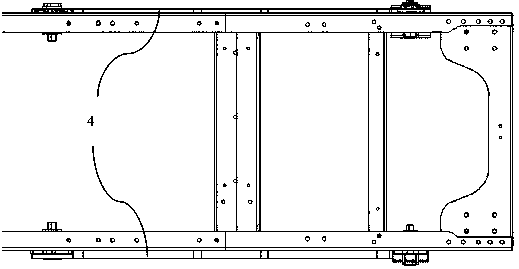

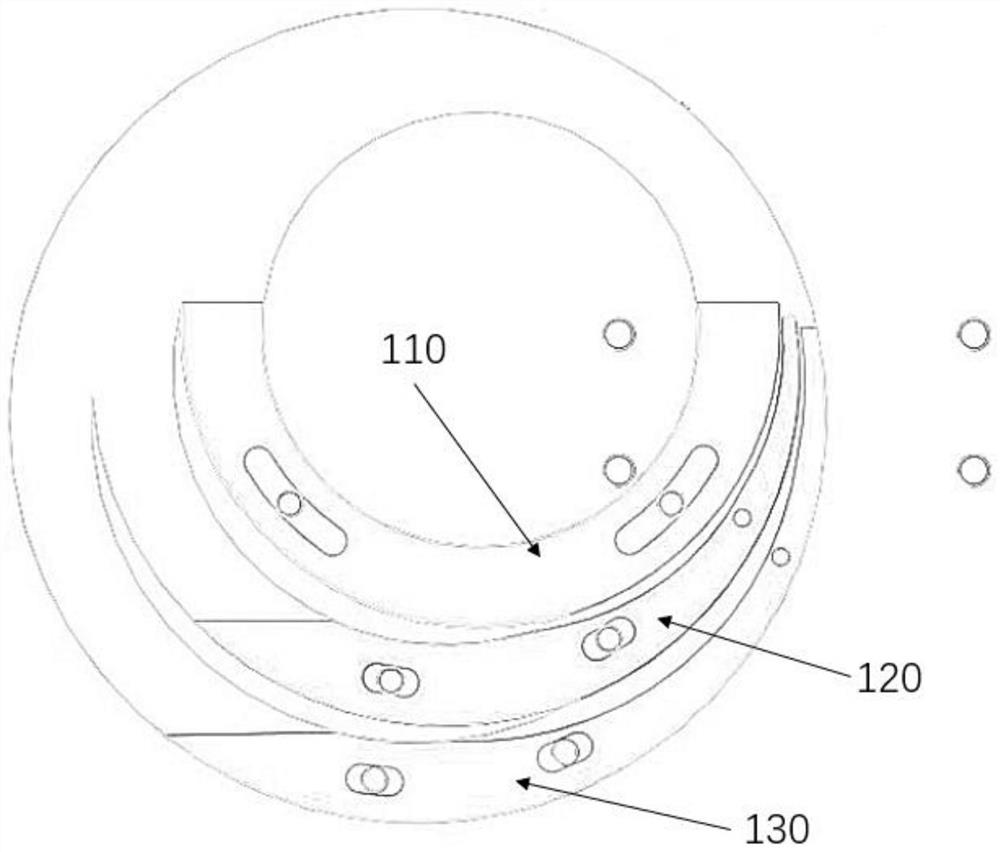

Special device for assembling of inner container and outer container of copious cooling container

The invention discloses a special device for assembling of an inner container and an outer container of a copious cooling container, in particular to a special device used for manufacturing of the copious cooling container provided with heat insulation measures, and belongs to a container used for containing or storing compressed, liquefied or solidified gases. The special device for assembling of the inner container and the outer container of the copious cooling container is characterized by being composed of a guide rail system, a tractor sliding on a guide rail, an inner container pull rod arranged at the center of one end of the inner container of the copious cooling container and a hoisting device fixed at the other end of the inner container, wherein the guide rail system is formed by the guide rail arranged at the bottom of the an outer barrel of the copious cooling container, external guide rails arranged at two ends of the guide rail and a support. Pulleys are arranged at the bottom of the special device, are stable when traveling on the guide rail and need small traction power. The special device can be adjusted laterally and vertically so that high concentricity of the inner container and the outer container can be ensured, the requirements for the gap between the inner container and the outer container of the copious cooling container can be met, and simultaneously scratching of the inner container and the outer container generated in assembling of the inner container and the outer container is avoided.

Owner:SHANDONG HONGDA TECH GRP

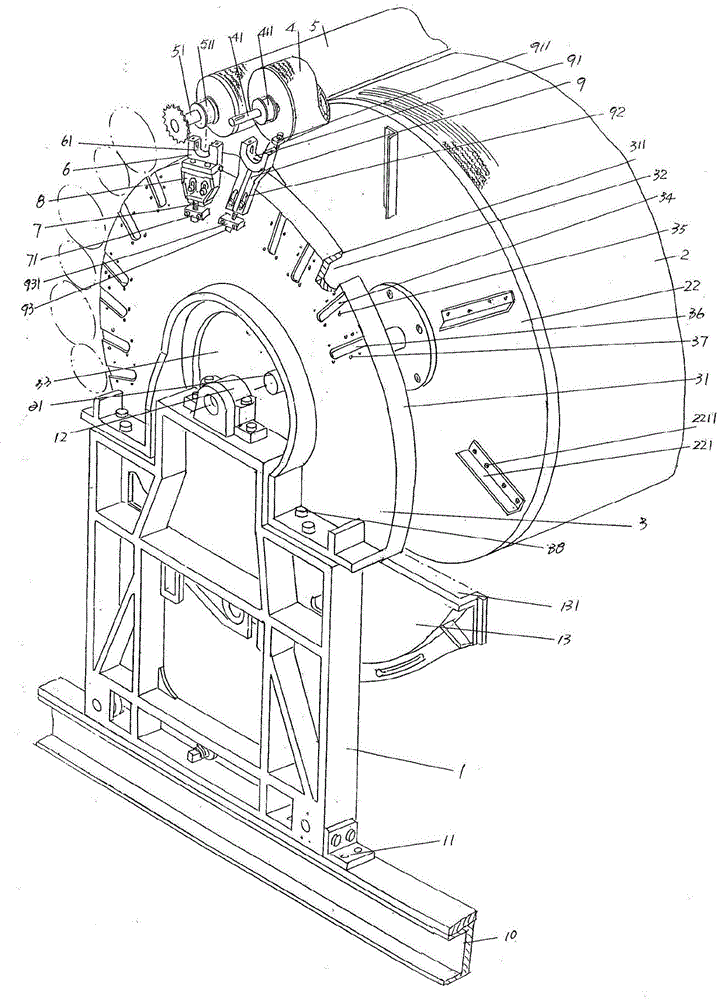

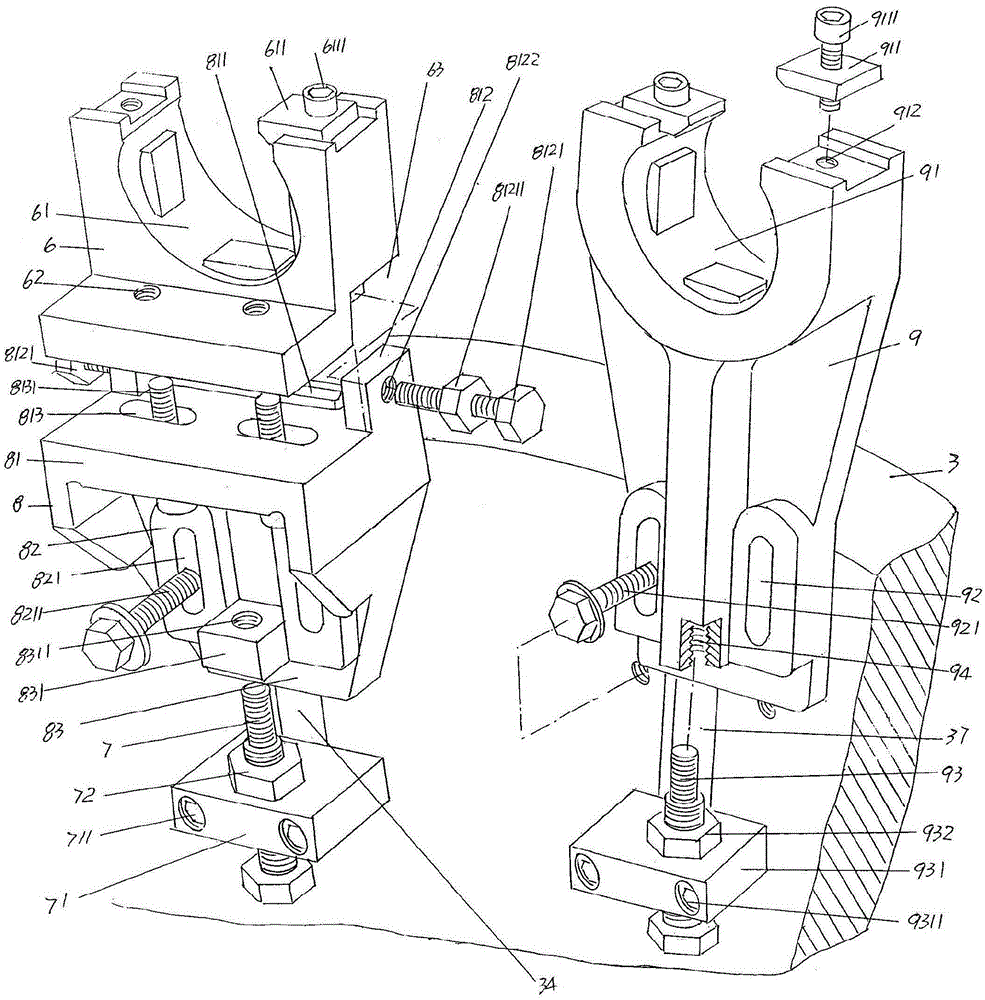

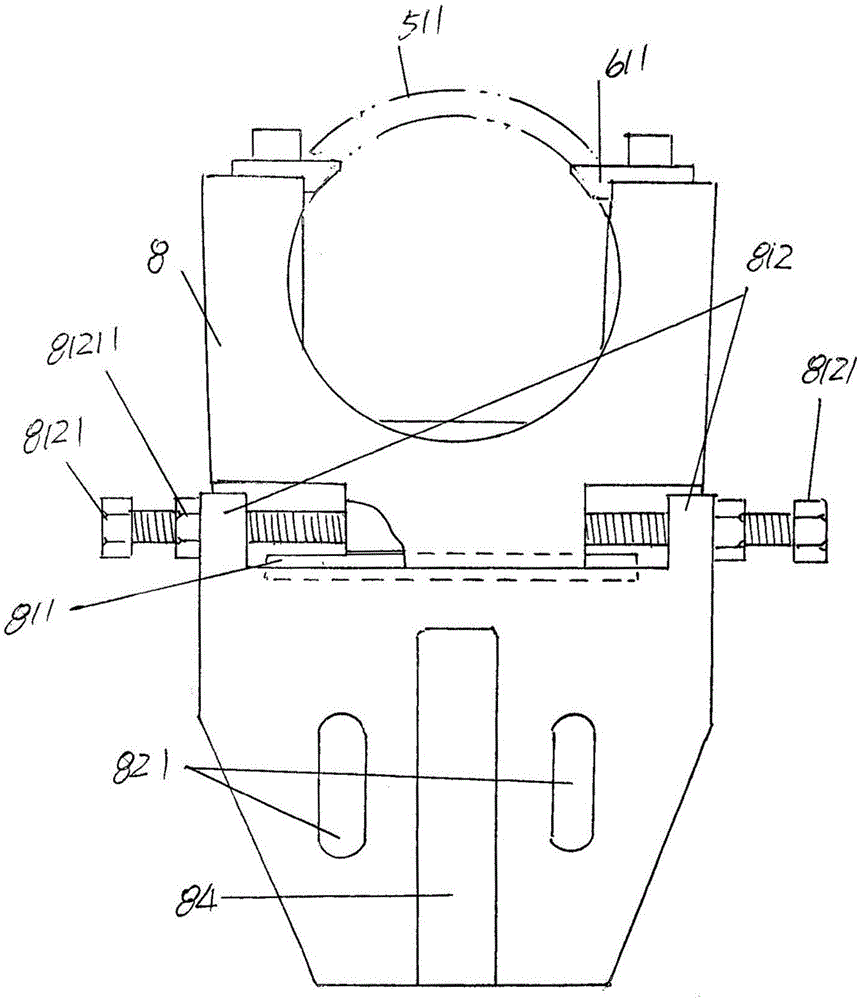

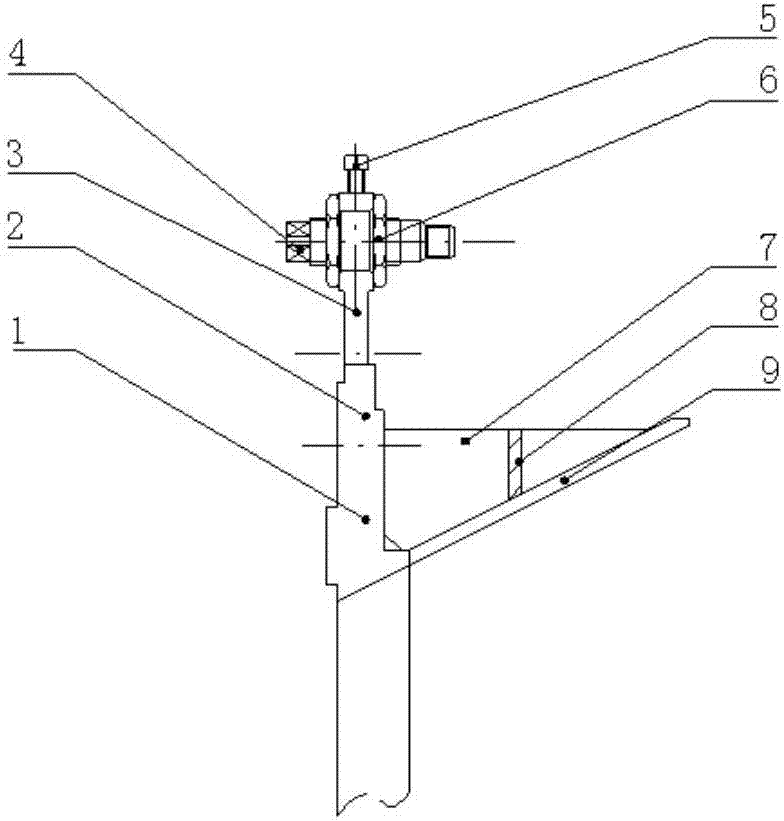

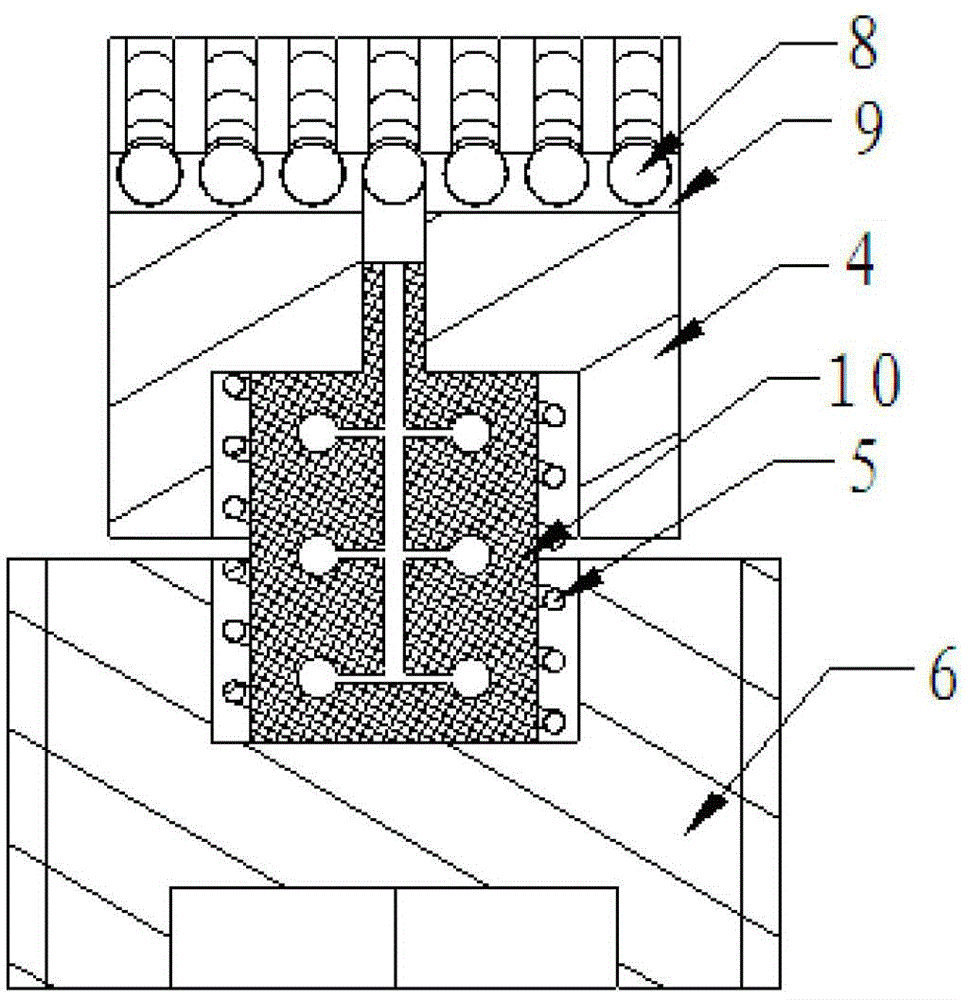

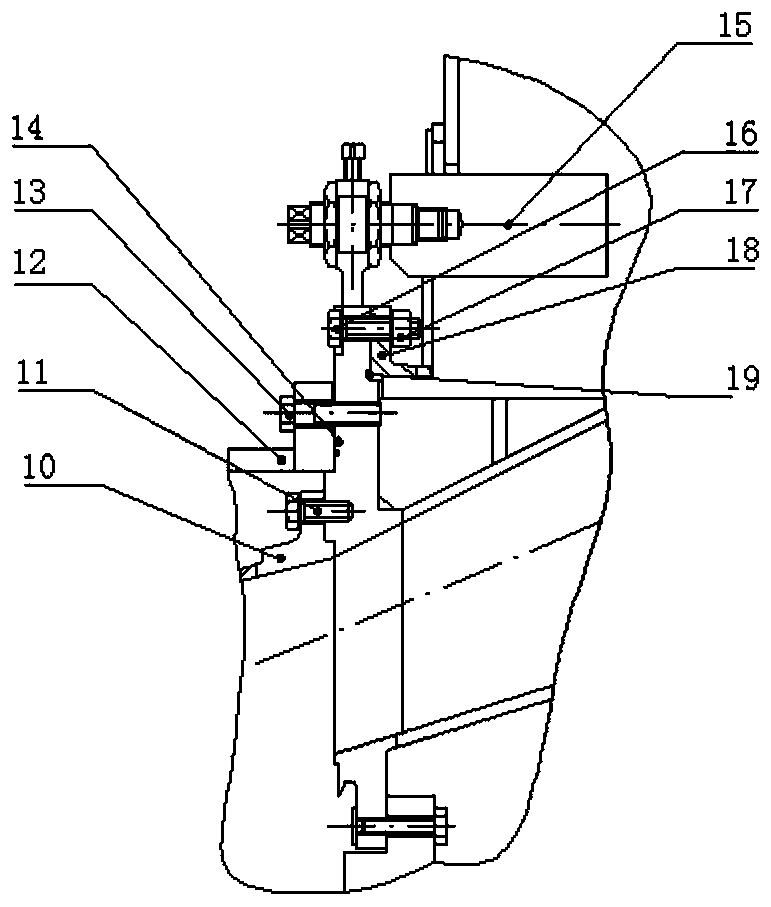

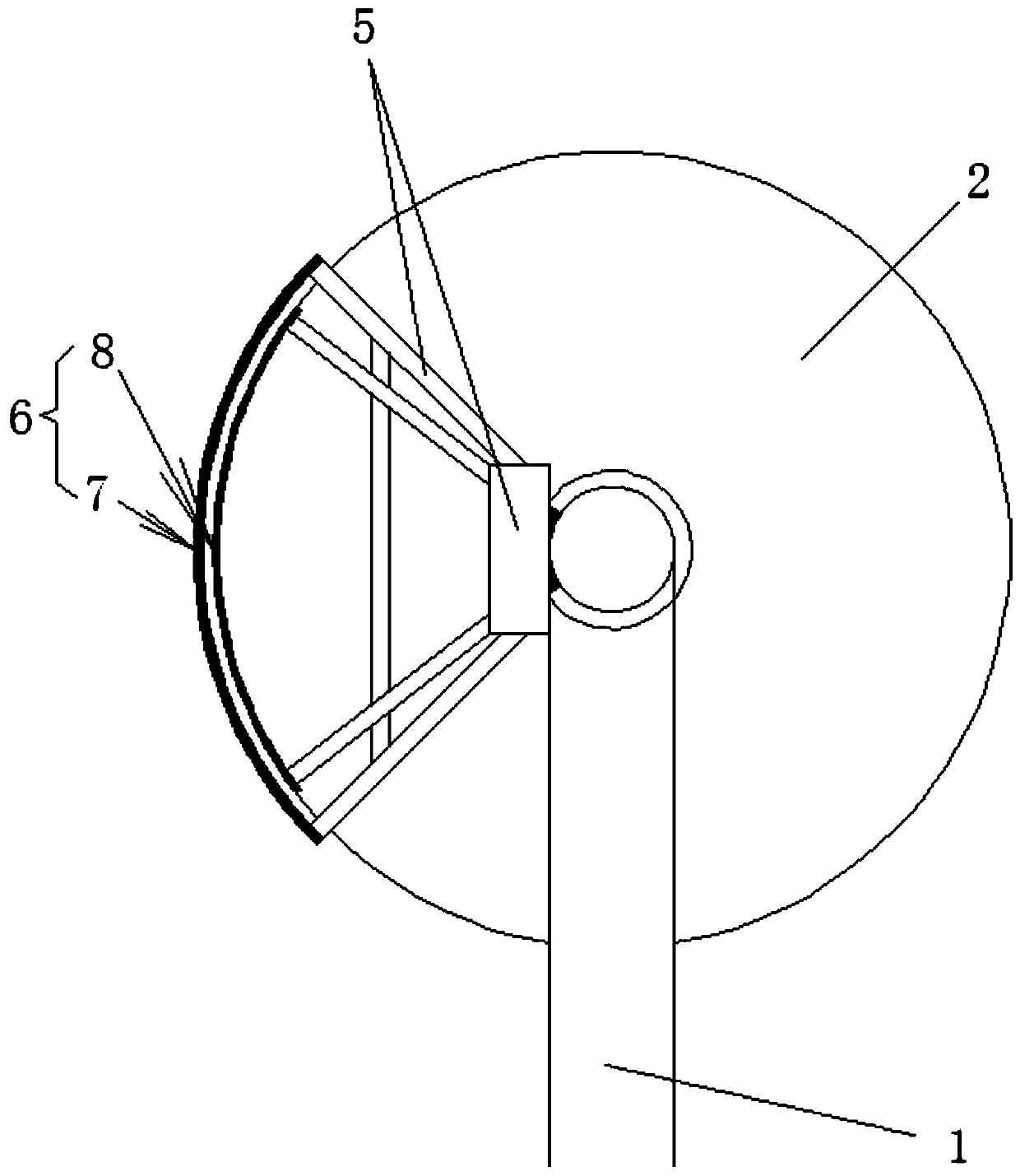

Support adjustment device for stripping roller of carding machine

The invention discloses acotton stripping roller support adjusting device of a carding machine, and belongs to the technical field of non-weaving machines. The carding machine comprises a pair of main cotton carding roller support wall plates, main cotton carding rollers, a pair of main side cotton carding roller protecting covers, a working roller and a cotton stripping roller. The cotton stripping roller support adjusting devicecomprises a cotton stripping roller support foot and cotton stripping roller support adjusting screws. The cotton stripping roller support adjusting device is characterized by furthercomprising a cotton stripping roller support foot transition adjusting base, wherein a sliding key is arranged on the top wall of the cotton stripping roller support foot transition adjusting base; adjusting screw bases are arranged at two ends of the sliding key; adjusting screws are arranged on the adjusting screw base; a pair of left and right support foot adjusting grooves are formed in the top wall of the cotton stripping roller support foot transition adjusting base; support foot connecting screws are arranged in match on the adjusting grooves; the bottom side of the cotton stripping roller support foot is placed on the sliding key; the cotton stripping roller support foot transition adjusting base is further provided with a pair of longitudinal wall; longitudinal adjusting grooves are formed in the longitudinal walls respectively; longitudinaladjusting groove screws are arranged in the longitudinal adjusting grooves; the longitudinaladjusting groove screws are connected with the main side cotton carding roller protecting covers; the cotton stripping roller support foot adjusting screws are connected with the bottom wall. According to the cotton stripping roller support adjusting device, the cotton stripping roller support foot can be adjusted leftwards and rightwards, so that the requirement on the gaps among the working rollers can be met.

Owner:缇镨(上海)新材料科技有限公司

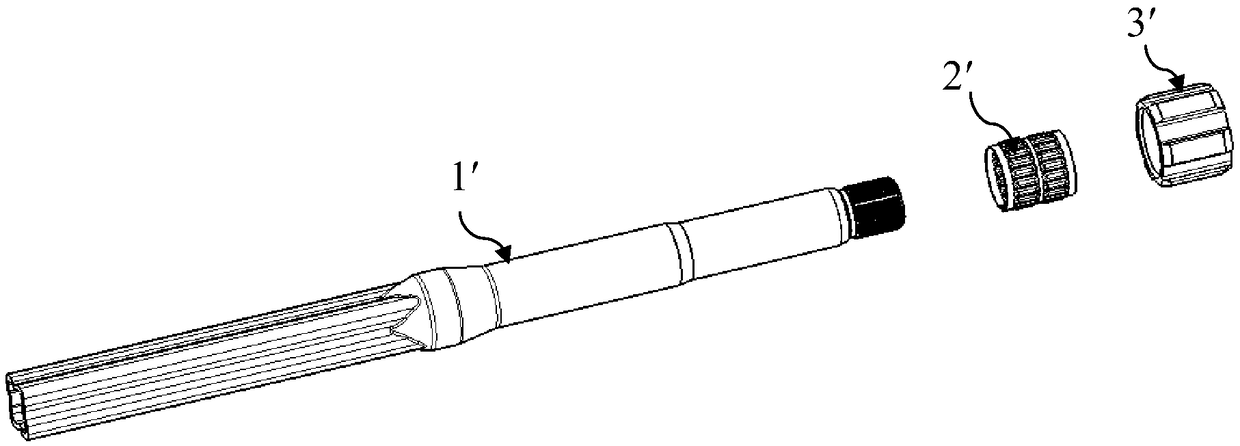

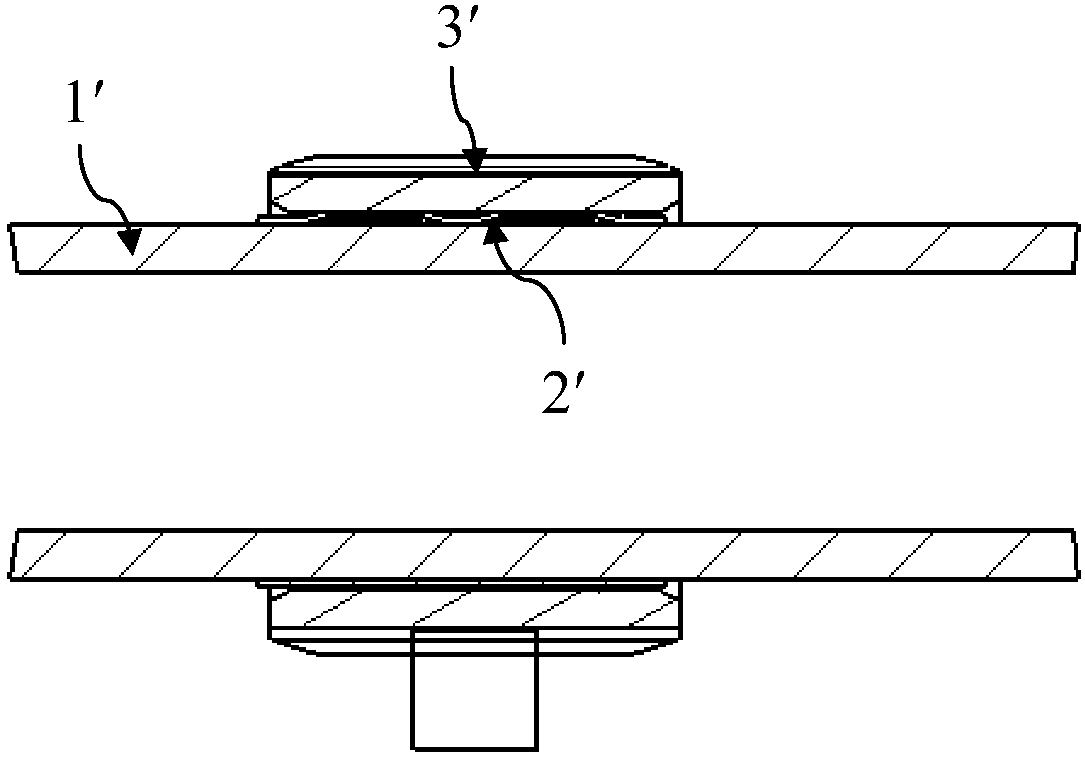

Quick inspection tooling and inspection method for installation and completion of cargo tank adjusting pad

ActiveCN109341491ASimple structureEasy to carryMechanical clearance measurementsEngineeringInspection method

The invention relates to the technical field of installation and inspection of a marine liquid cargo tank, and discloses a quick inspection tooling and an inspection method for the installation and completion of a cargo tank adjusting pad. The inspection tooling comprises a long handle and a roller sample block mounted on the long handle. The front end of the long handle is provided with a bent section, and the bent section is provided with a rotatable roller sample block. The invention greatly shortens the acceptance time after the installation of the cargo tank adjusting pad is completed, thereby shortening the production cycle.

Owner:CHENGXI SHIPYARD

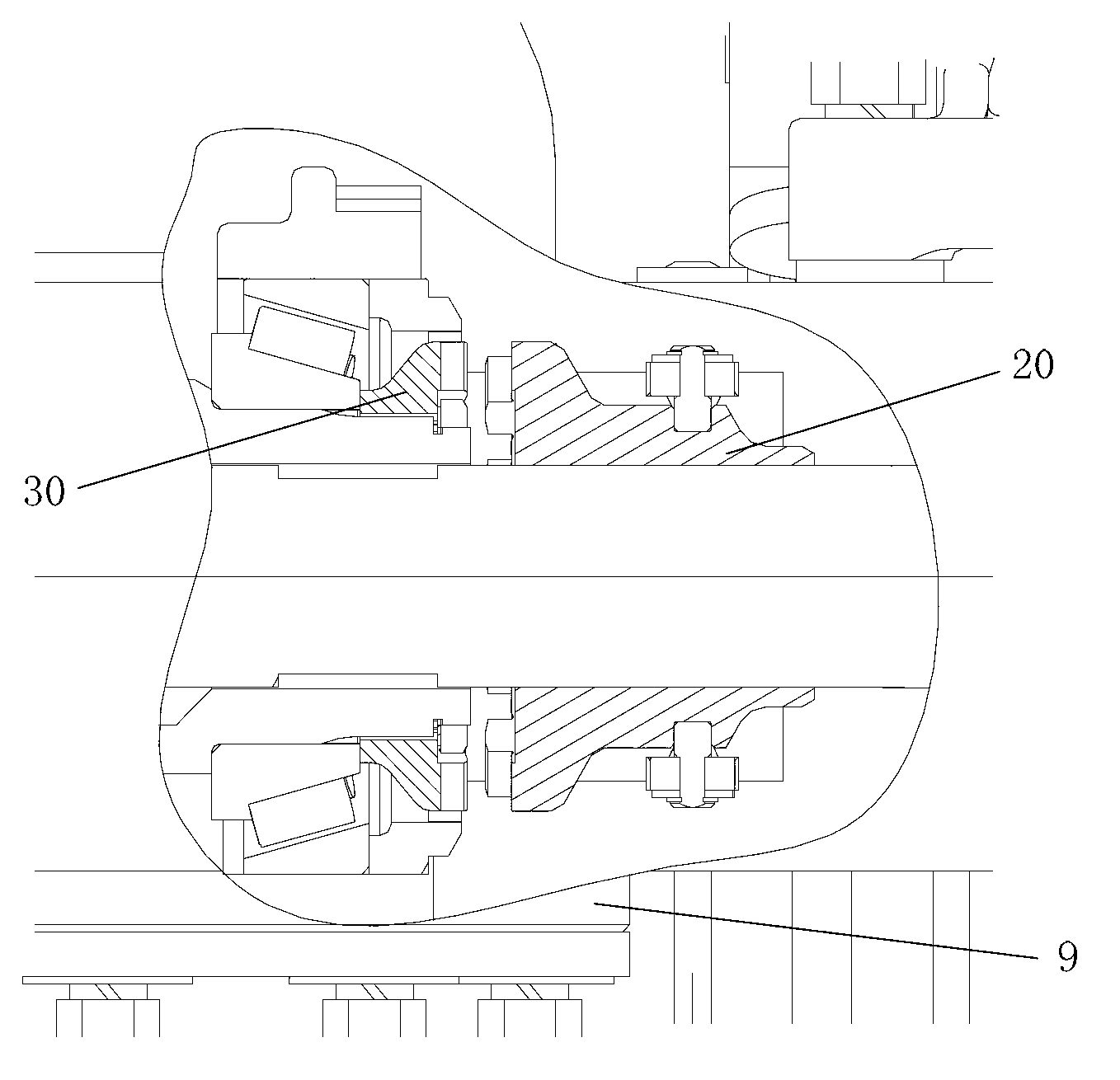

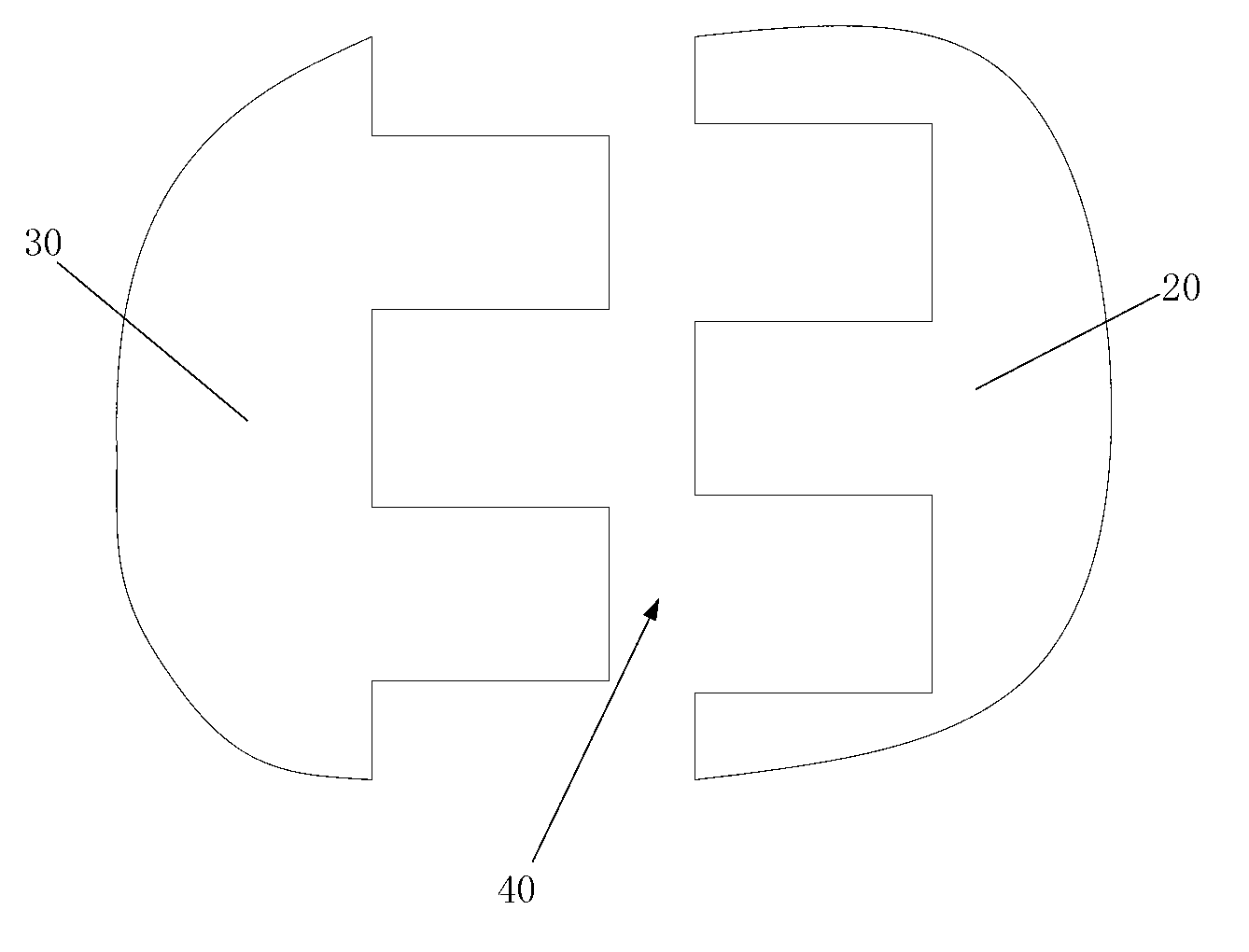

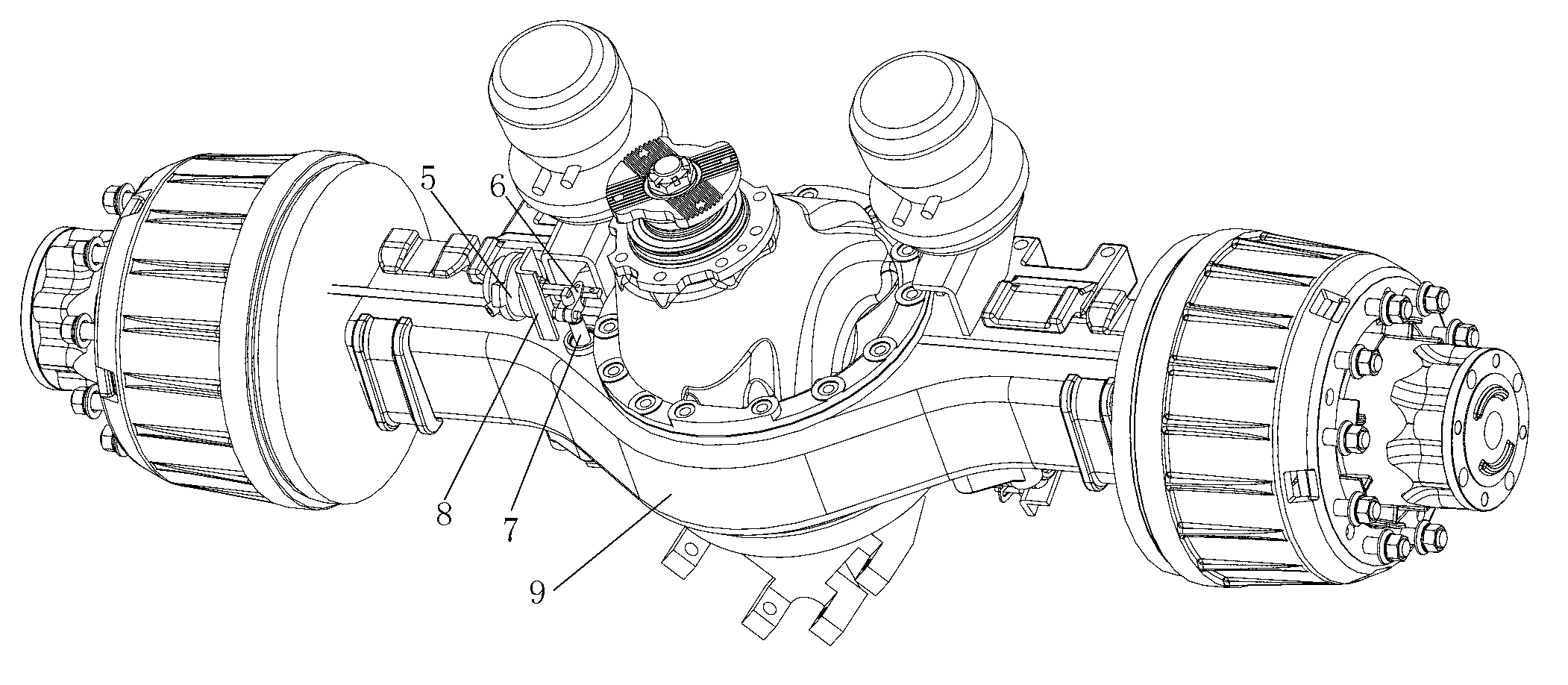

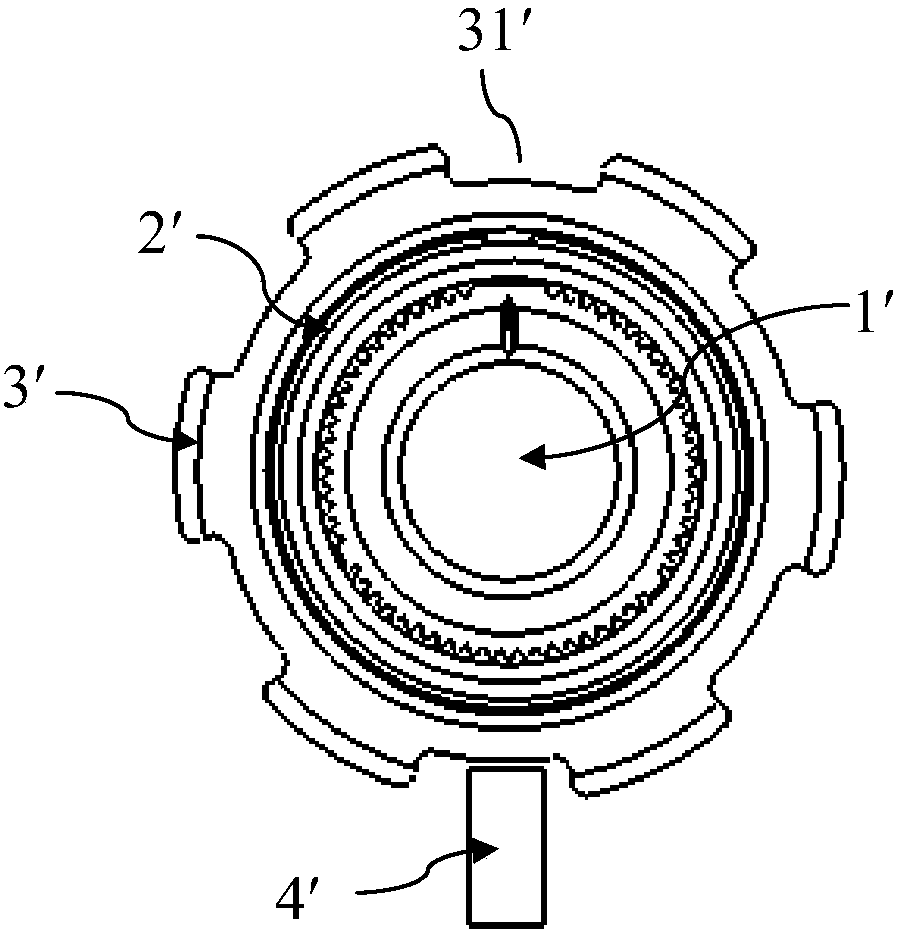

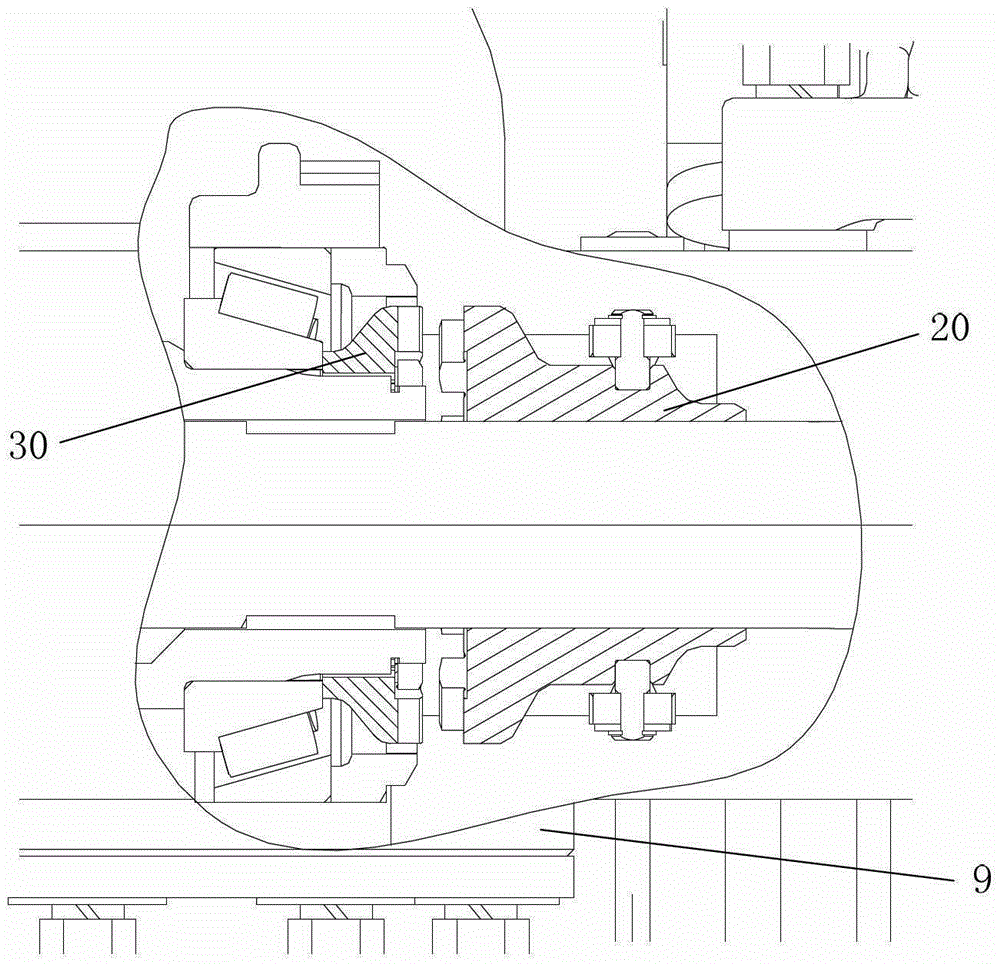

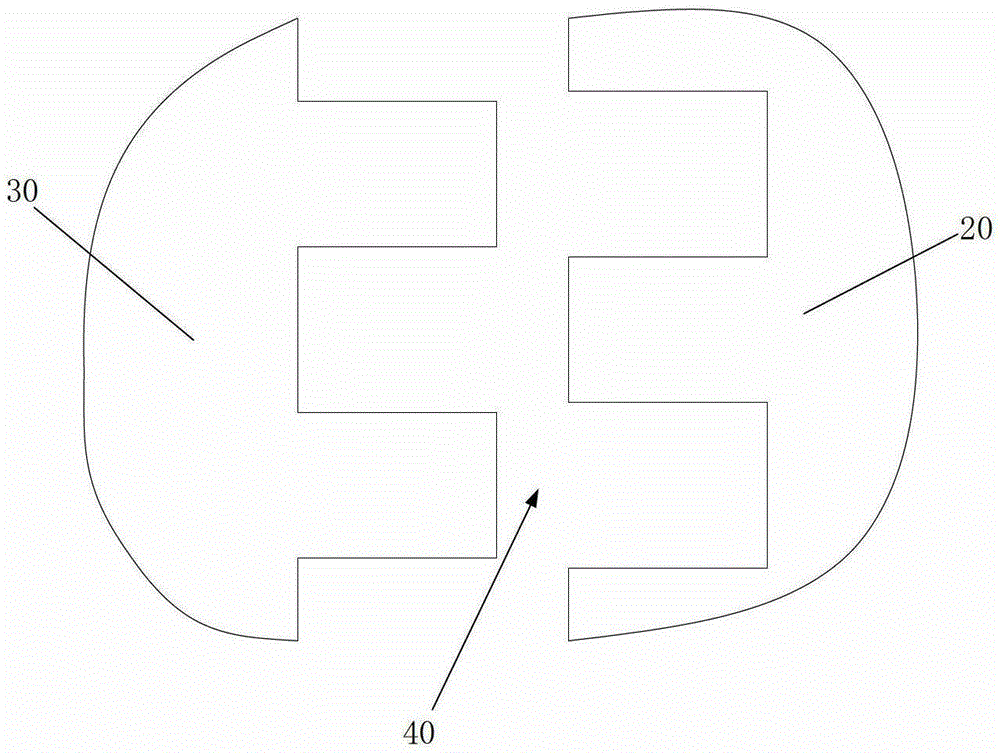

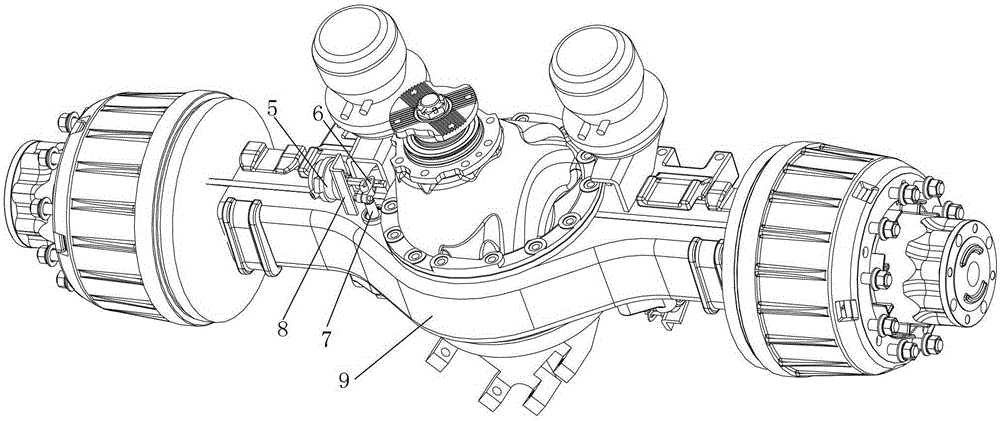

Clearance adjustment device and clearance adjustment method for differential lock

ActiveCN102840319AAchieve regulationGuaranteed assembly clearanceGearing detailsPetroleum engineering

The invention provides a clearance adjustment device for a differential lock. The clearance adjustment device is used for adjusting the clearance between a sliding engaging sleeve and a fixed engaging sleeve of the differential lock, and comprises a dial, a rotating sleeve and a pointer, wherein the dial is matched with the rotating sleeve; the rotating sleeve can be matched with a rotating shaft driving the sliding engaging sleeve to move and can rotate relative to the dial along with the rotation of the rotating shaft; the pointer is fixed on the rotating sleeve and can rotate relative to the dial along with the rotation of the rotating sleeve; and the rotating angle of the pointer can be displayed on the scale of the dial. The invention further provides a clearance adjustment method for the differential lock and a method for adjusting the clearance of the differential lock by utilizing the clearance adjustment device. Through the technical scheme provided by the invention, the clearance between the sliding engaging sleeve and the fixed engaging sleeve of the differential lock can meet the design requirement and be irrelevant to the stroke error of a cylinder, so that the differential lock can work normally.

Owner:SANY AUTOMOBILE MFG CO LTD

Ceramic grinding head material for grinder

The invention relates to a ceramic grinding head material for a grinder. The ceramic grinding head material for the grinder comprises an outer grinding head material and an inner grinding head material, wherein the outer grinding head material consists of the following components in percentage by weight: 80 to 90 percent of aluminum oxide with purity being more than or equal to 99 percent, 5 to 15 percent of magnesium oxide and 3 to 10 percent of silicon oxide; the inner grinding head material consists of the following components in percentage by weight: 25 to 45 percent of aluminum oxide with purity being more than or equal to 99 percent, 45 to 55 percent of zirconium oxide with purity being more than or equal to 94 percent, 5 to 15 percent of magnesium oxide and 3 to 10 percent of silicon oxide. According to the ceramic grinding head material for the grinder, the defects of an existing ceramic material can be overcome, and the outer grinding head material and the inner grinding head material are made of ceramic.

Owner:NINGBO CHEFSHERE KITCHEN TECH

Ceramic material for grinding head

ActiveCN106699139AMeet clearance requirementsReduce dosageCoffee millsSpice millsSilicon oxideCeramic

The invention relates to a ceramic material for a grinding head. The ceramic material comprises an outer grinding head material and an inner grinding head material, wherein the outer grinding head material is prepared from the following raw materials in percentage by weight: 80-90% of aluminum oxide of which the purity is greater than or equal to 99%, 5-15% of magnesium oxide, 3-10% of silicon oxide and 3-5% of titanium dioxide; and the inner grinding head material is prepared from the following raw materials in percentage by weight: 50-60% of aluminum oxide of which the purity is greater than or equal to 99%, 20-30% of zirconium oxide of which the purity is greater than or equal to 94%, 5-15% of magnesium oxide, 3-10% of silicon oxide and 12-20% of titanium dioxide. Through the ceramic material, the defects of the existing ceramic material can be overcome, the aim that the outer grinding head material and the inner grinding head material are manufactured by ceramics is achieved, the dosage of the zirconium oxide is reduced, and thus the production cost is lowered.

Owner:NINGBO CHEFSHERE KITCHEN TECH

Flue gas turbine adjustable diffusion section structure

ActiveCN107542501AImprove work performanceWon't touch the grindLeakage preventionMachines/enginesFlue gasTurbine

The invention discloses a flue gas turbine adjustable diffusion section structure which comprises an adjustable diffusion section, an air inlet shell, an exhausting volute and a blade shroud, whereinthe adjustable diffusion section is arranged between the air inlet shell and the exhausting volute of a flue gas turbine and is connected with the blade shroud through a first connecting bolt; an adjusting block is arranged on the exhausting volute and is connected with an axial adjusting bolt arranged on the adjustable diffusion section. The flue gas turbine adjustable diffusion section structuresolves the problem about assembling and adjusting difficulty caused by deformation, improves the assembling efficiency and has the characteristics of being simple in structure, convenient to use, lowin manufacturing cost, precise in adjustment and high in reliability.

Owner:AECC AVIATION POWER CO LTD

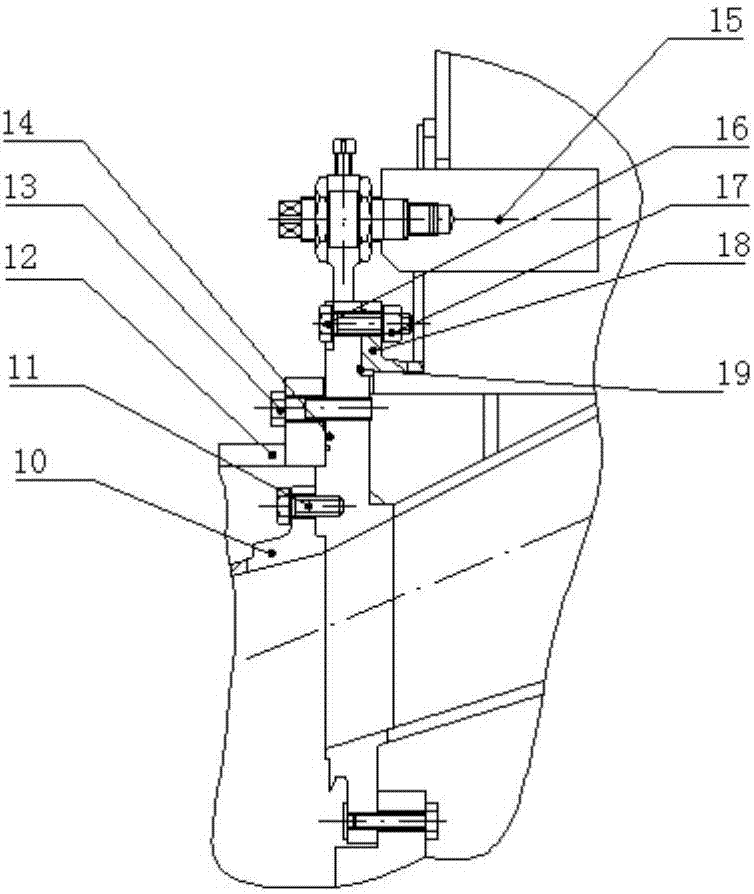

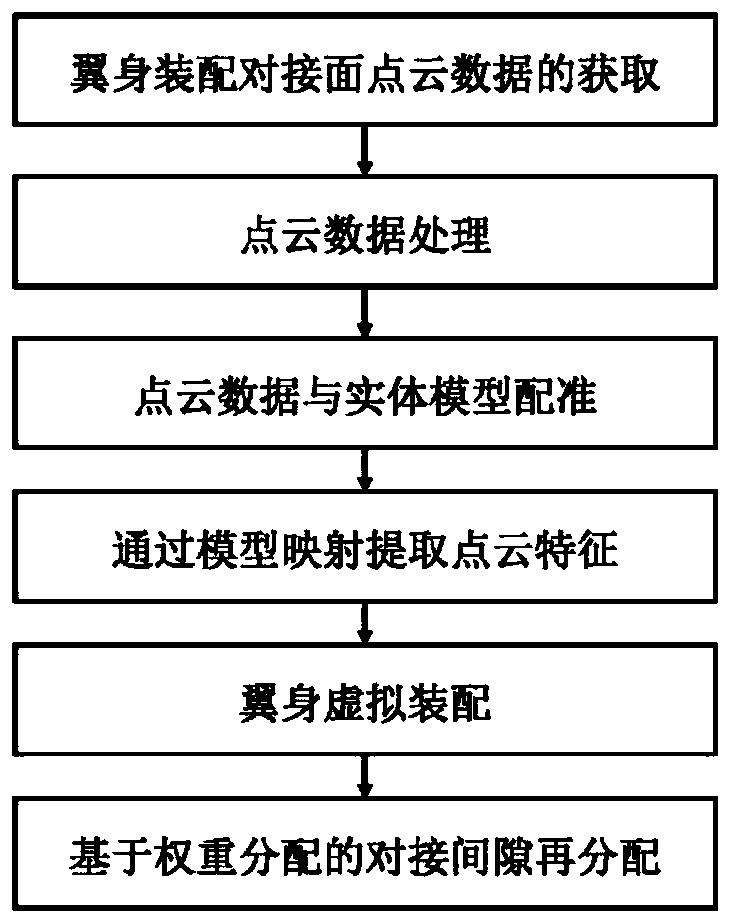

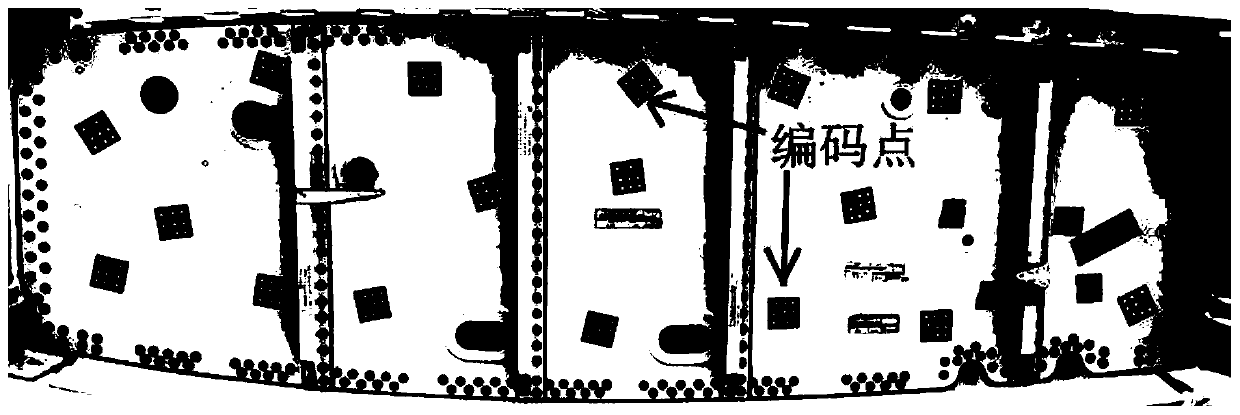

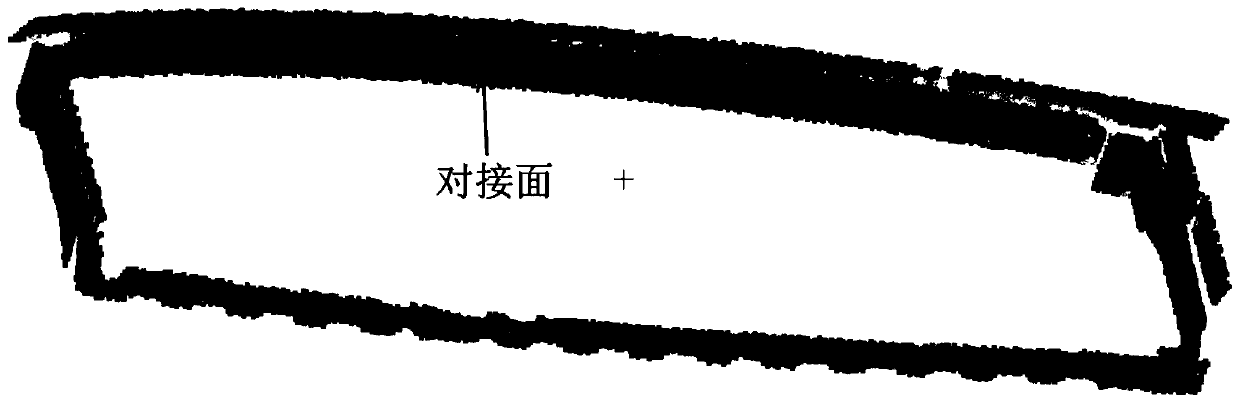

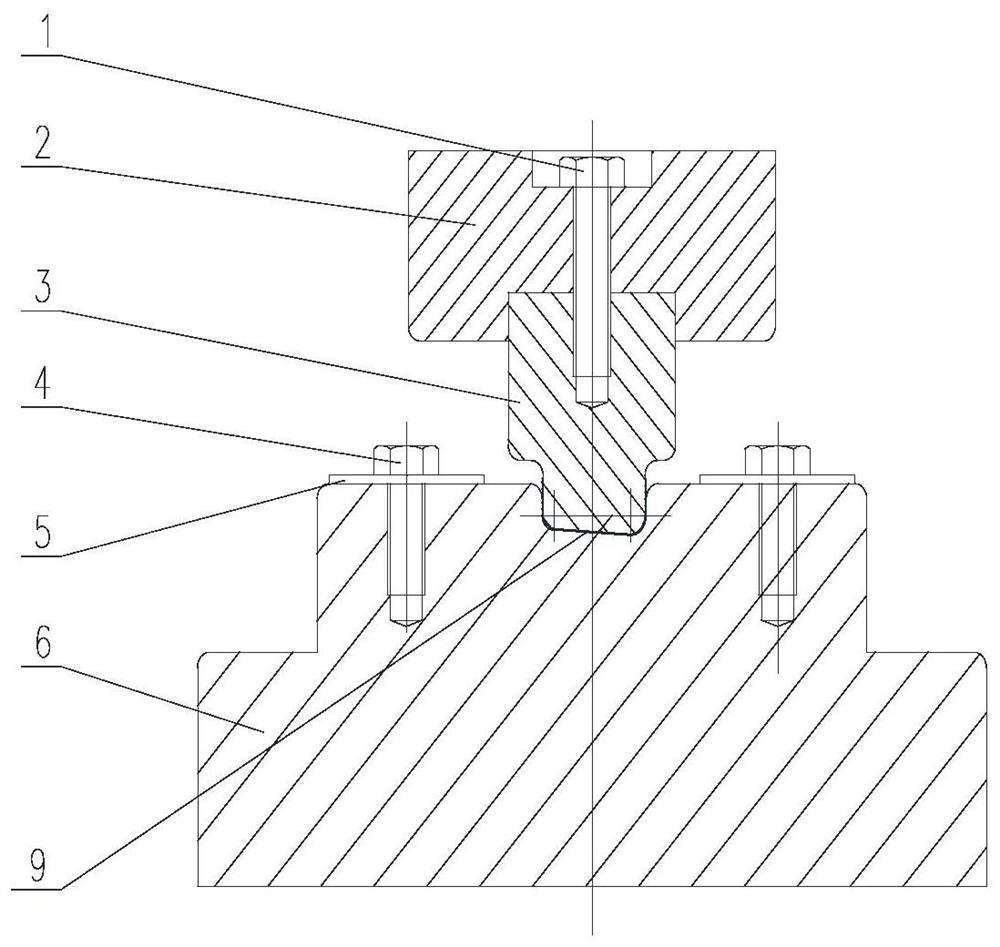

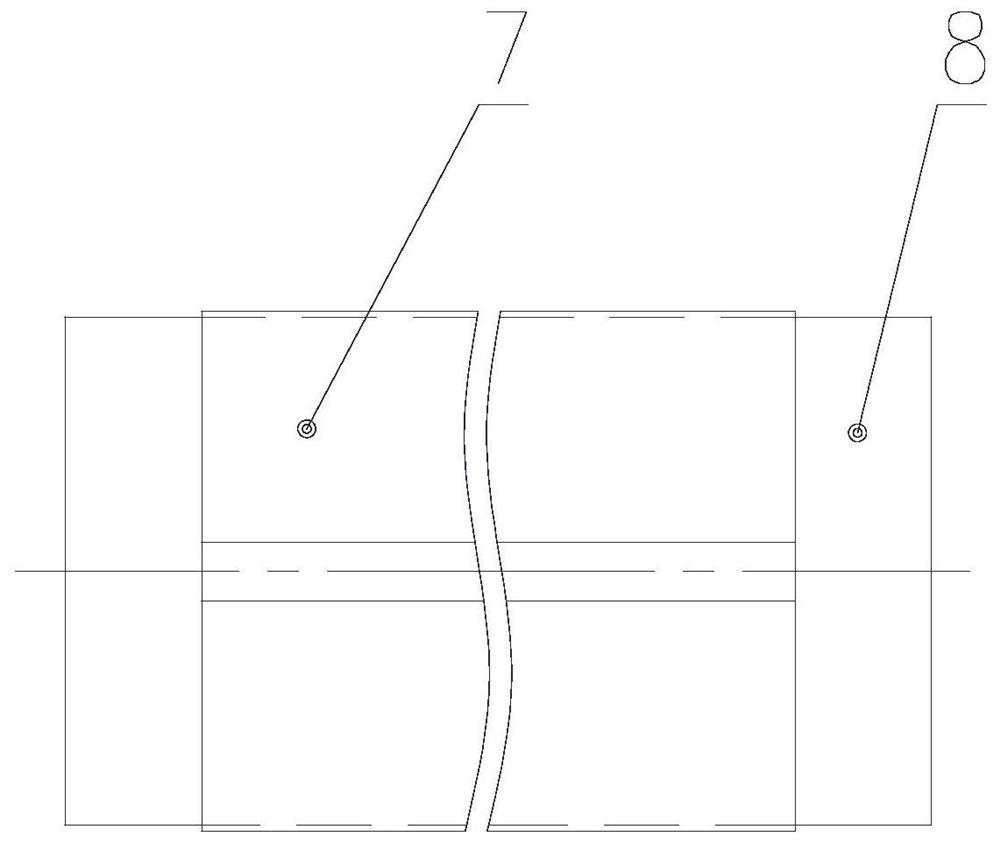

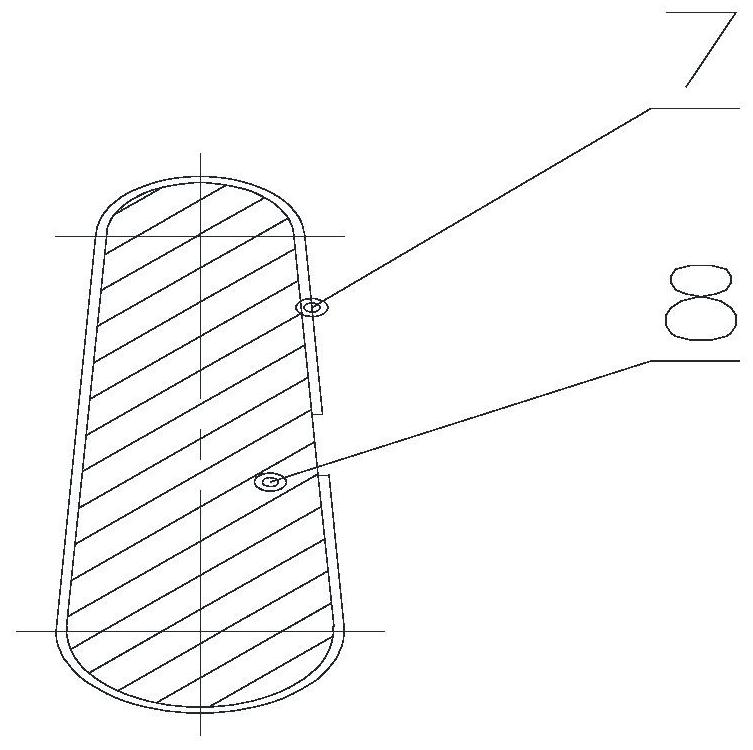

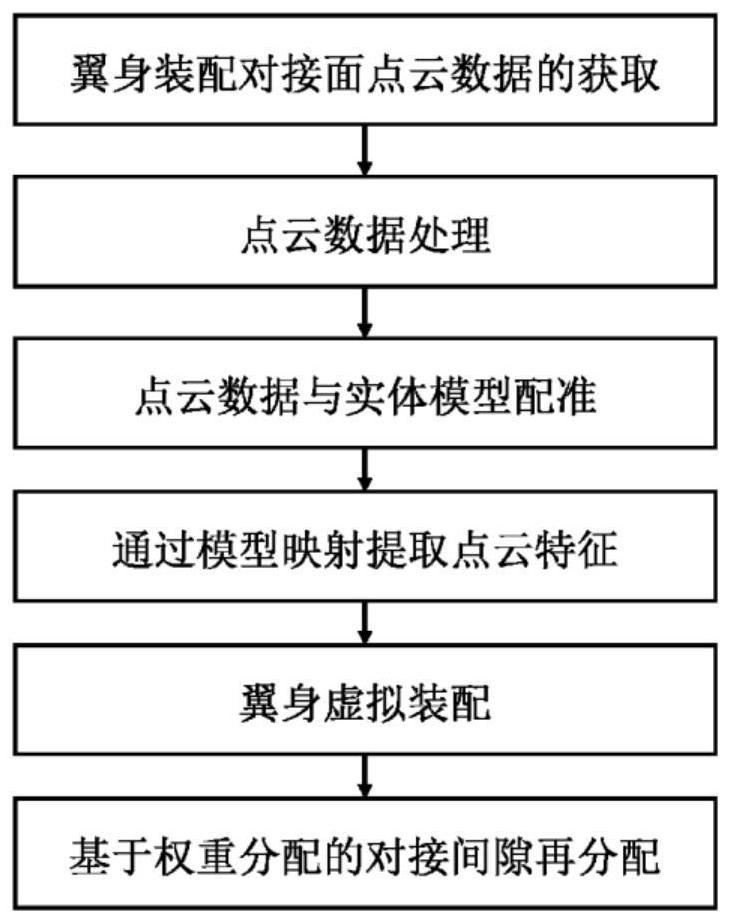

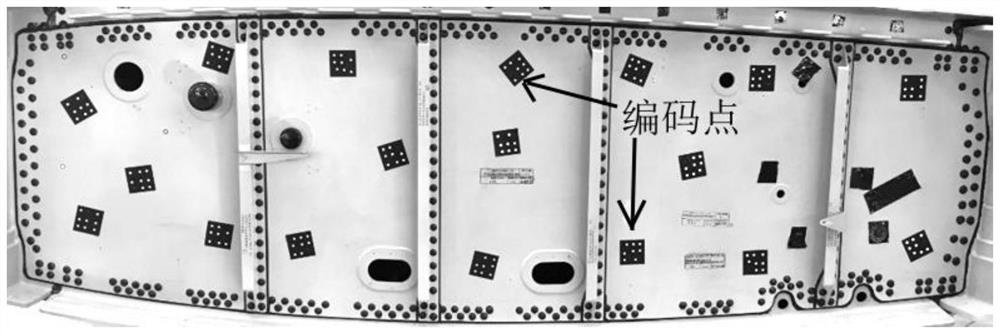

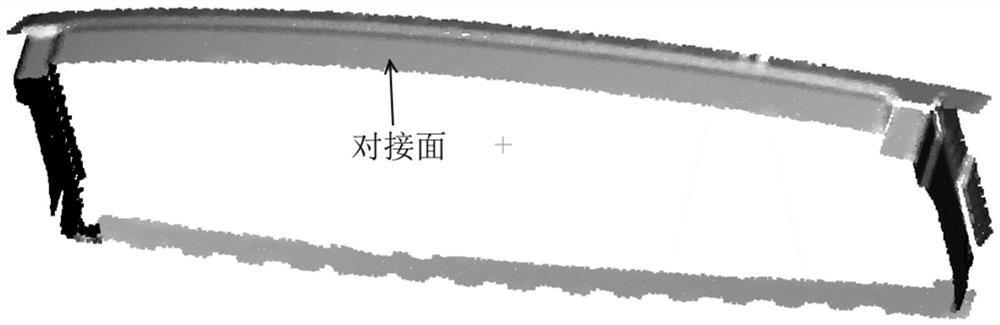

Wing body butt joint gap distribution control method based on measured data

ActiveCN111539070AControlling Butt Gap DistributionPrecise dockingGeometric CADAircraft assemblyDistribution controlPoint cloud

The invention discloses a wing body butt joint gap distribution control method based on measured data. The method comprises the steps of collecting the original point cloud data of a wing and a central wing box; preprocessing the original point cloud data of the two; registering the preprocessed point cloud data of the wing and the central wing box with corresponding solid models respectively; selecting key features during butt joint on the two entity models, mapping the key features to the registered point cloud data, and extracting corresponding point cloud features; docking the wing point cloud data and the central wing box point cloud data based on the positioning points; dividing the butt joint surface into a plurality of regions, calculating the gap of the feature points of each region after butt joint, and adjusting the weight of each region according to the gap tolerance so as to control the gap distribution. According to the method, the wing body butt joint gap distribution can be controlled through the characteristic weight according to the actual measurement data, the gap requirement during wing body assembling is met, and therefore the wing body assembling quality and production efficiency are improved, and the technical requirement for wing body butt joint gap distribution control is met.

Owner:南京耘瞳科技有限公司

Magnetic suspension motor for measuring axial sensor bracket structure of rotor

InactiveCN106500749AMeet clearance requirementsGuaranteed to workMeasurement apparatus componentsMagnetic bearingSensor holder

The invention discloses a magnetic suspension motor for measuring an axial sensor bracket structure of a rotor. The magnetic suspension motor comprises the rotor, a support, a casing, an axial sensor bracket, pads, an axial sensor circuit board, an axial sensor and an axial compensation sensor, wherein the casing is connected with the support through a screw, the axial sensor bracket is fixed on the casing through a screw, the axial sensor circuit board is fixed on the axial sensor bracket through a screw, the axial sensor and the axial compensation sensor are both mounted in the axial sensor bracket and are correspondingly connected with the axial sensor circuit board, and the pads are arranged between the axial sensor bracket and the casing. The magnetic suspension motor is advantaged in that equipment mounting debugging can be realized through only changing the quantity of the pads to realize requirements for a gap between the preset rotor and the axial sensor bracket, and thereby normal operation of the sensors during operation of the rotor and measurement accuracy of a displacement value of a magnetic bearing are both guaranteed.

Owner:NANJING CIGU TECH CORP LTD

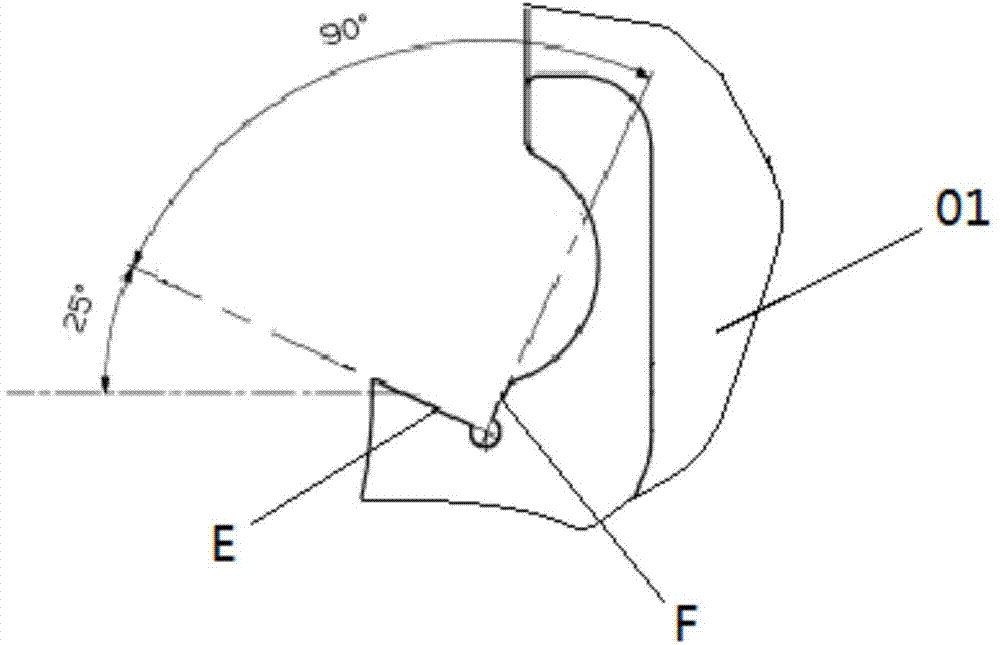

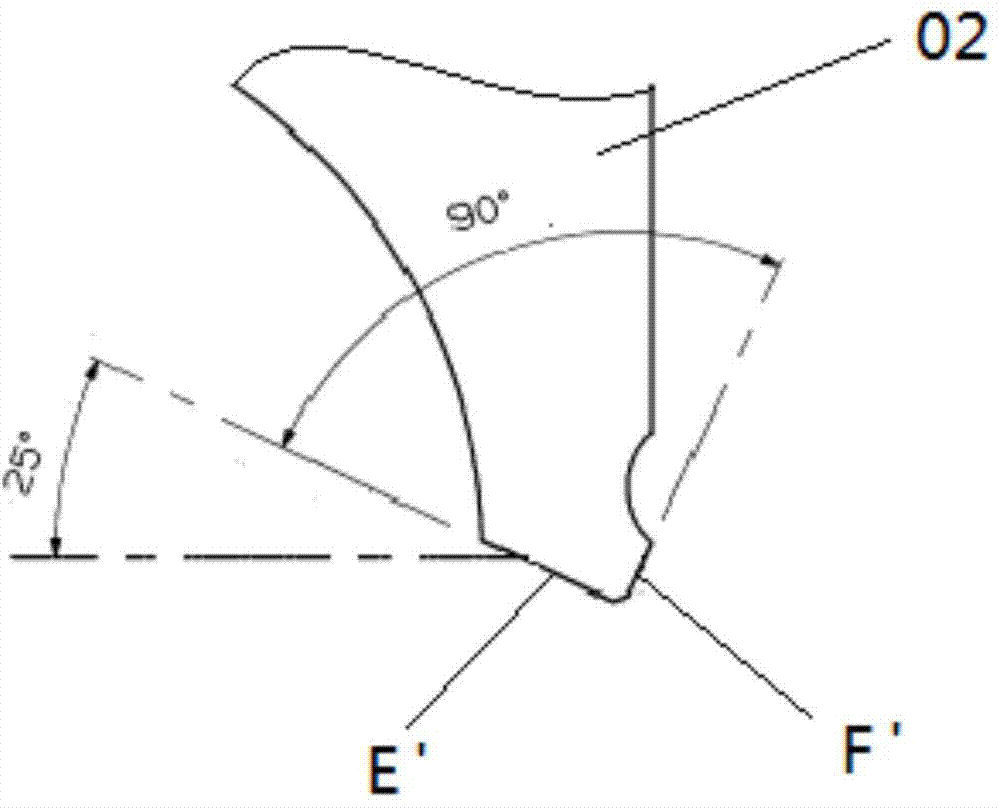

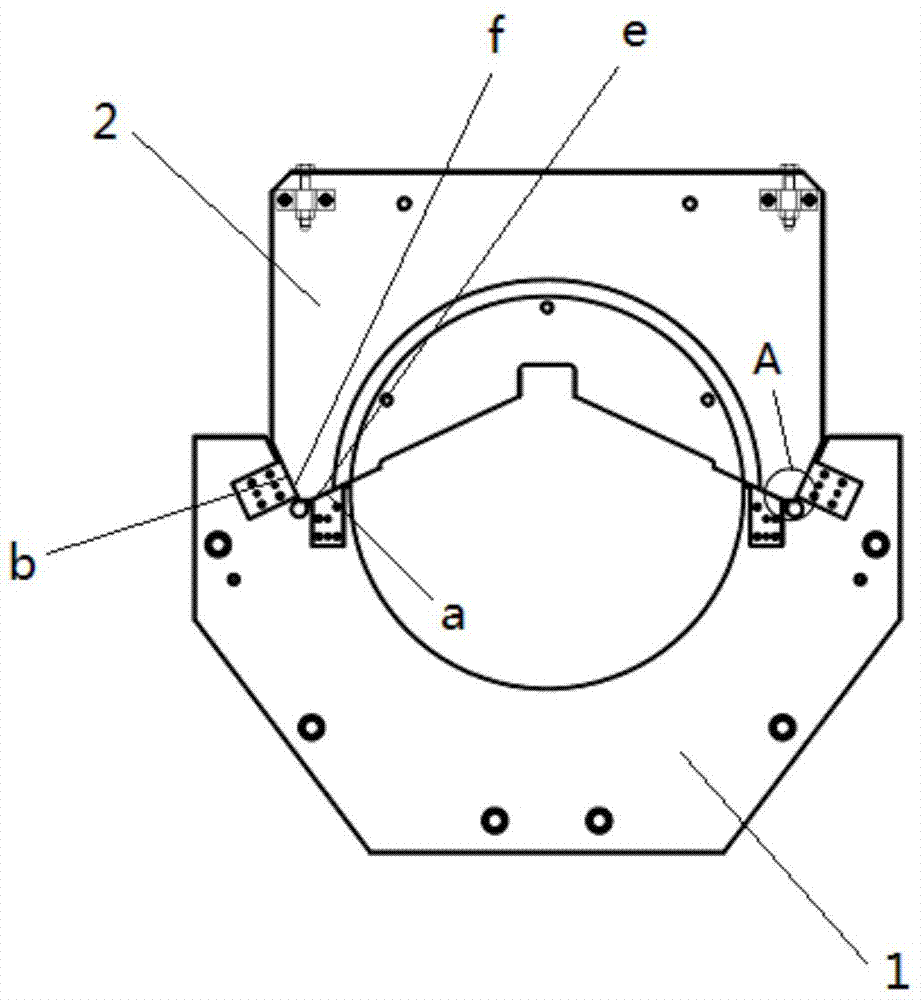

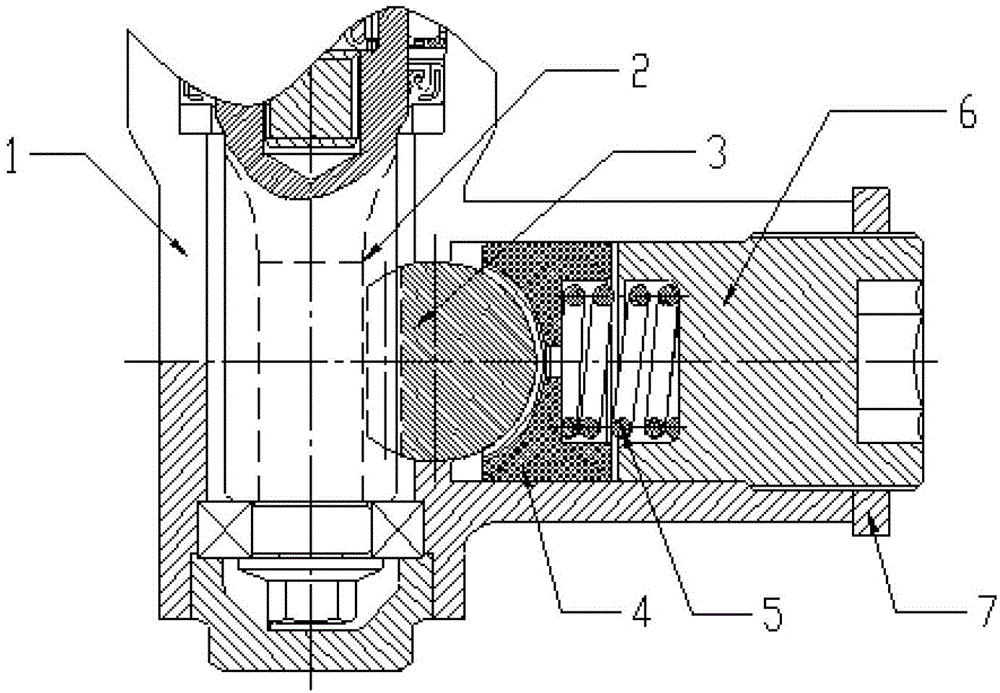

Diesel engine main bearing block and main bearing cap joint face machining method and presetting die plates therefor

ActiveCN103921156AImprove efficiency and accuracyAvoid machine time lossAutomatic control devicesPositioning apparatusMain bearingDiesel engine

Disclosed are a diesel engine main bearing block and main bearing cap joint face machining method and presetting die plates therefor. Two presetting die plates in conformity to features of main bearing block and main bearing cap joint faces are adopted. The presetting die plates are provided with two 25-degree presetting slants and two 115-degree presetting slants which are symmetric; the slants of the presetting die plates are in conformity to 25-degree slants and 115-degree slants of a main bearing block and a main bearing cap in terms of position, shape and size; the position, shape and size of the slants of the presetting die plates meet the corresponding requirements for tolerance in shape and size. The presetting die plates are paired, finished and machined, so that the requirement for a fitting gap between the main bearing block and main bearing cap joint faces is met, the requirement for the gap between the joint faces during assembly is also met, accuracy and effectiveness in machining are greatly improved, waste on machine-hour and labor and risk of workpiece scrapping are avoided.

Owner:CSSC MES DIESEL

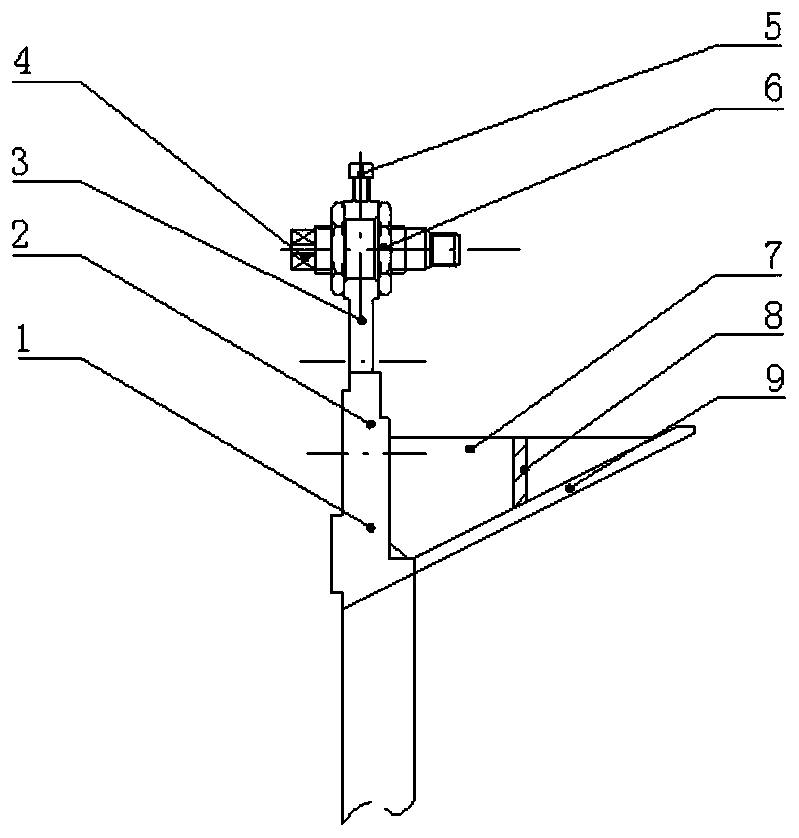

Regulation mechanism for pinion and rack steering gear

ActiveCN102897208BReduce wearReduce axial movement forceMechanical steering gearsRolling resistanceGear wheel

The invention discloses a regulation mechanism for a pinion and rack steering gear and belongs to the field of automobile steering. The mechanism comprises a pressure block, a regulating bolt and a locking nut, wherein the pressure block is arranged in a shell of the steering gear and is contacted with a rack of the steering gear; the regulating bolt is used for positioning the pressure block in the shell; and the locking nut is used for locking the regulating bolt. The regulation mechanism is characterized in that a mounting rack is arranged on the contact end face of the pressure block and the rack; rollable steel balls are arranged on the mounting rack; and the pressure block is contacted with the rack by the steel balls. According to the invention, by the arrangement of the rolling balls, the original sliding friction between the pressure block and the rack is converted into the rolling friction, so that the axial movement of the rack is reduced, the wear to the pressure block is also reduced, the gap requirement of a pinion and the rack can be met to the greatest extent and the comfort of the steering gear is improved; and the abrasion loss of the pressure block is reduced, the noise generated by the pressure block is correspondingly reduced and the regulation mechanism has an obvious improving effect on the noise level of a finished automobile.

Owner:CHERY AUTOMOBILE CO LTD

An adjustable diffuser section structure of a flue gas turbine

ActiveCN107542501BImprove work performanceWon't touch the grindLeakage preventionMachines/enginesFlue gasEngineering

The invention discloses a flue gas turbine adjustable diffusion section structure which comprises an adjustable diffusion section, an air inlet shell, an exhausting volute and a blade shroud, whereinthe adjustable diffusion section is arranged between the air inlet shell and the exhausting volute of a flue gas turbine and is connected with the blade shroud through a first connecting bolt; an adjusting block is arranged on the exhausting volute and is connected with an axial adjusting bolt arranged on the adjustable diffusion section. The flue gas turbine adjustable diffusion section structuresolves the problem about assembling and adjusting difficulty caused by deformation, improves the assembling efficiency and has the characteristics of being simple in structure, convenient to use, lowin manufacturing cost, precise in adjustment and high in reliability.

Owner:AECC AVIATION POWER CO LTD

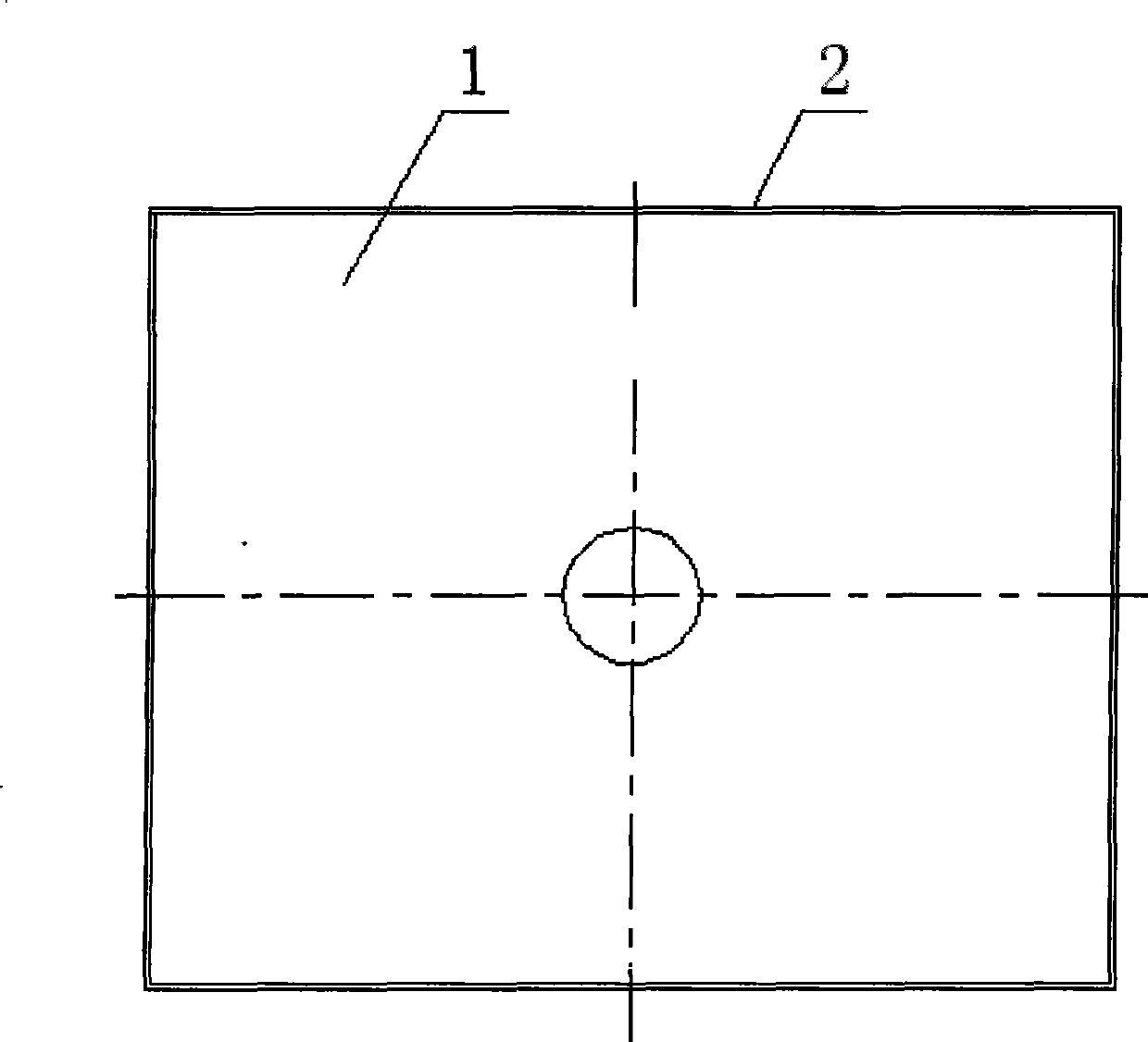

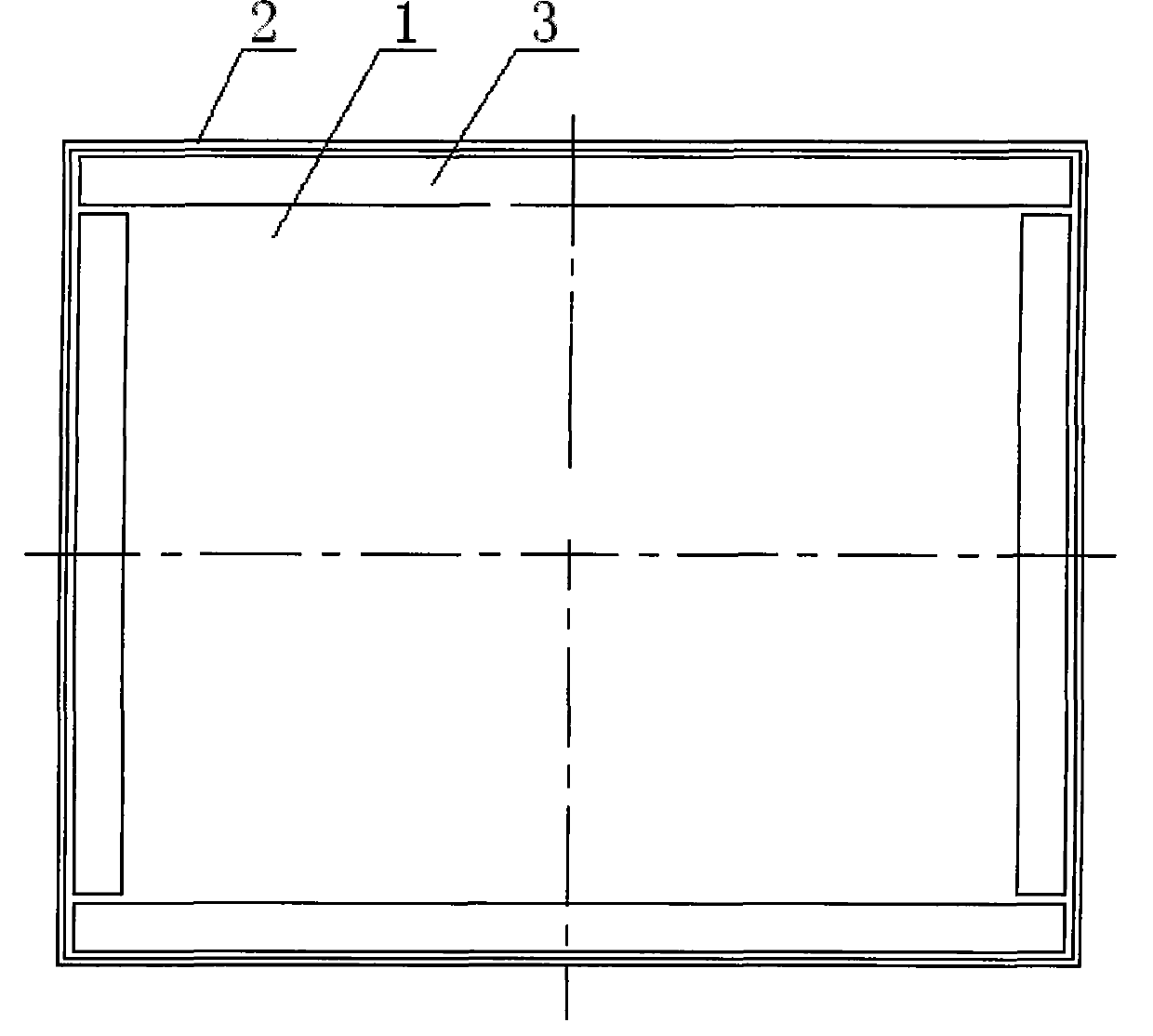

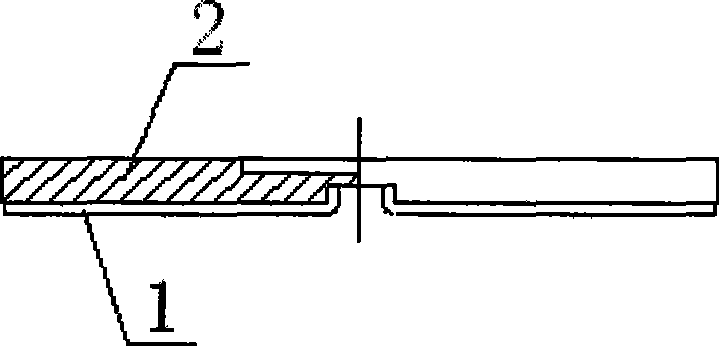

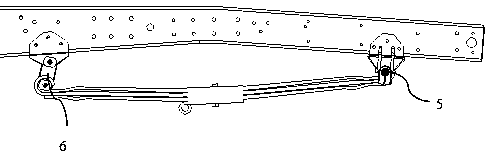

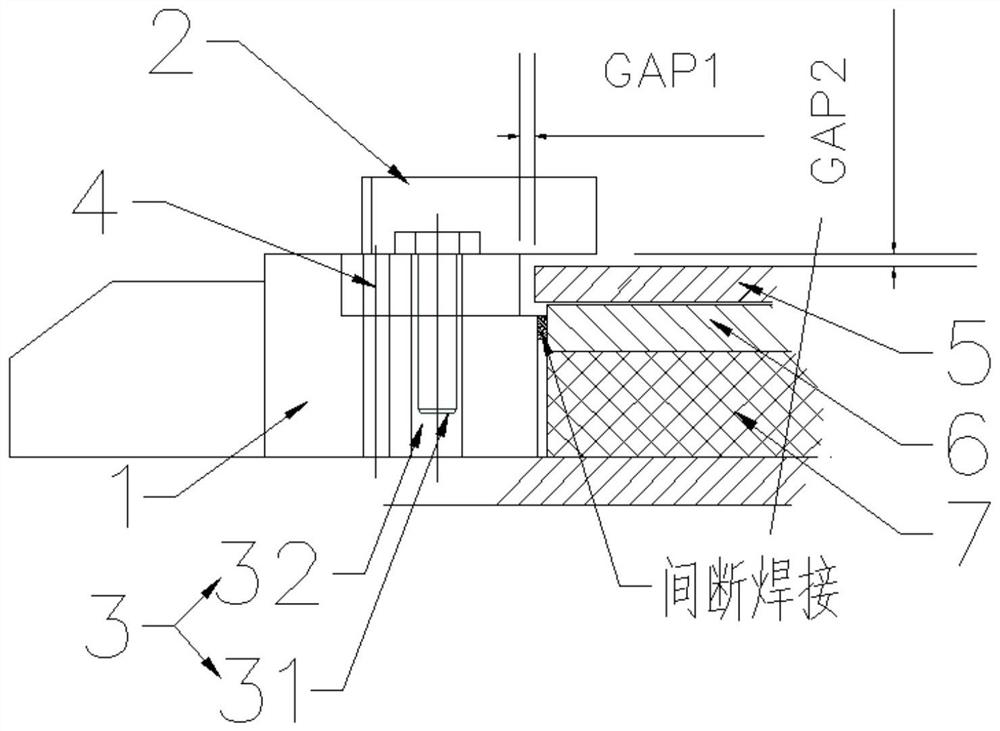

Welding method of high mirror-finished sheet in bridge support sliding panel assembly

ActiveCN101372061BSmall amount of welding deformationLess welding spatterArc welding apparatusEngineeringTungsten electrode

The invention relates to a method for welding a mirror surface lamella of a bridge support sliding panel assembly. The invention comprises the following technology procedures: baiting, lineation and location, deformation preventing treatment and tungsten electrode gon arc intermittent welding without filling welding wires. The method has simple frock structure, low manufacture cost, convenient use, and good commonality. A mirror surface lamella (1) has tiny welding deflection, and has small clearance with a basal body sliding panel (2), therefore, the welding line is not superelevation, the mirror surface (1) of the lamella is not destroyed, and the rate of finished products of welding and machining is greatly increased. The method is simple, easy to popularize and is applicable to other occasions of lamella welding.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

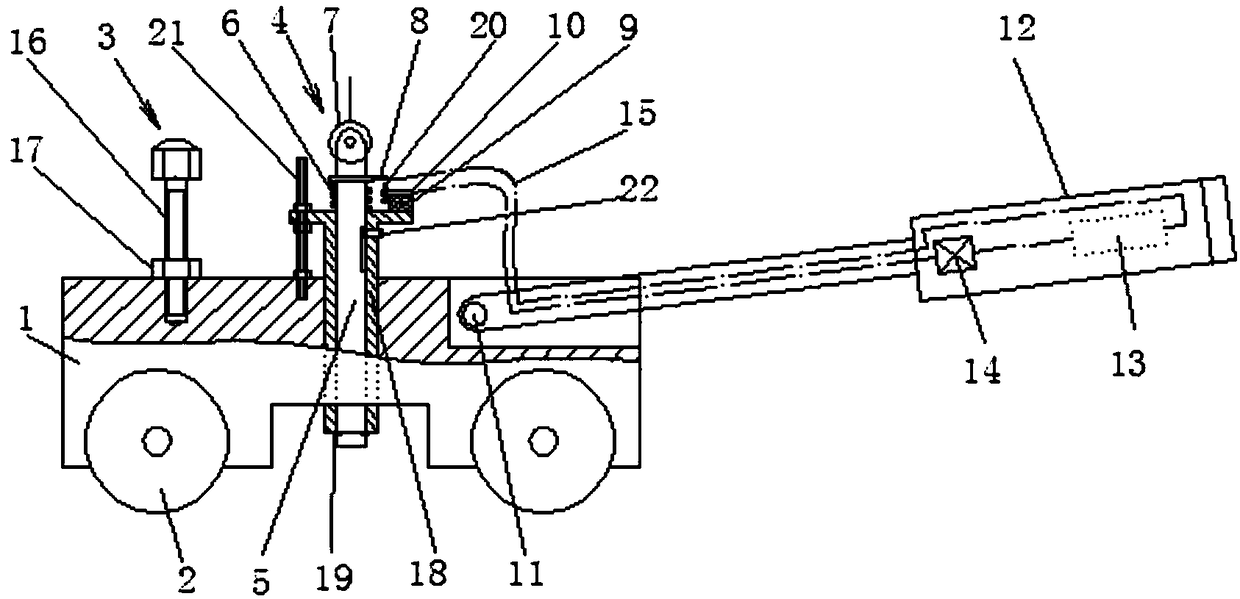

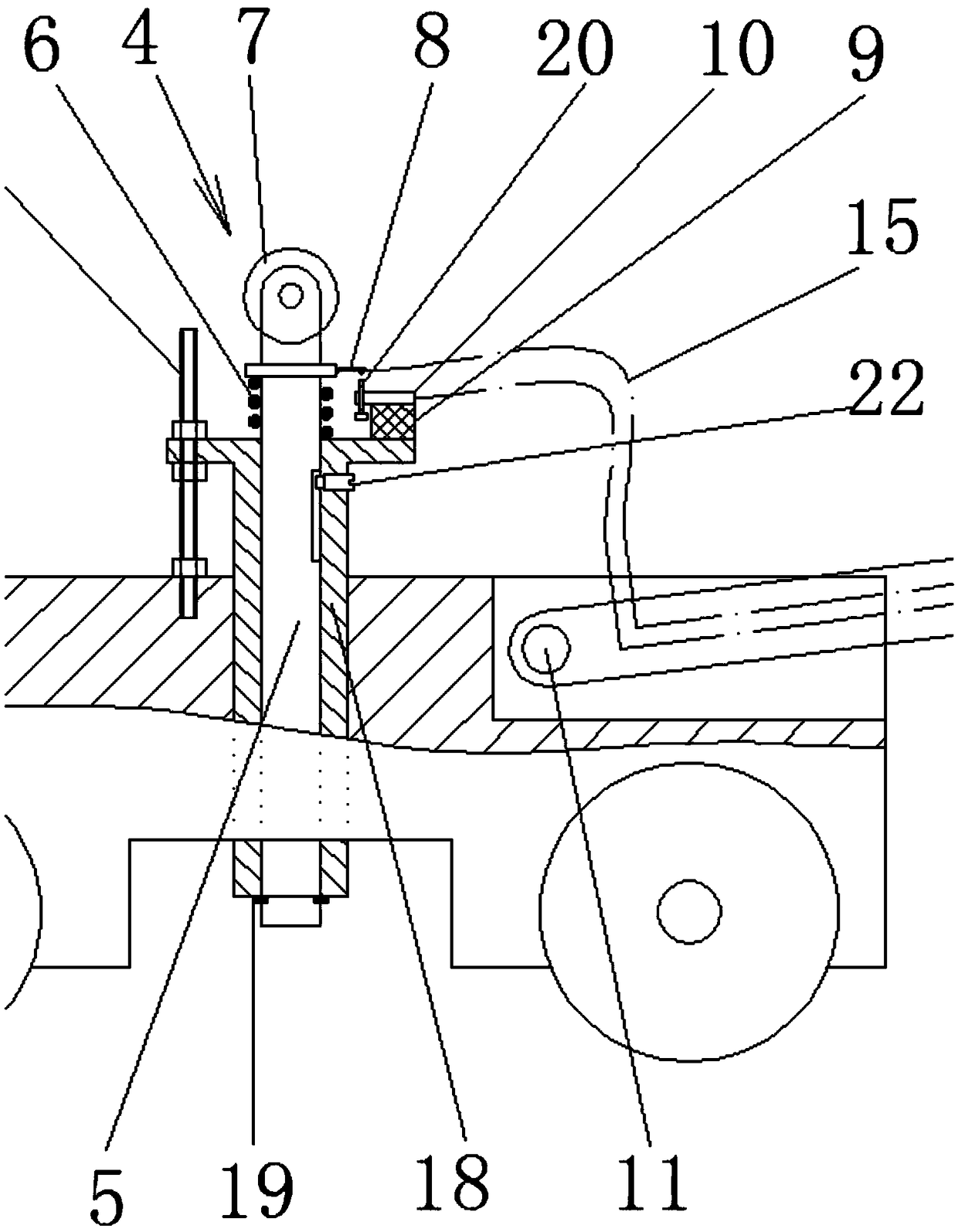

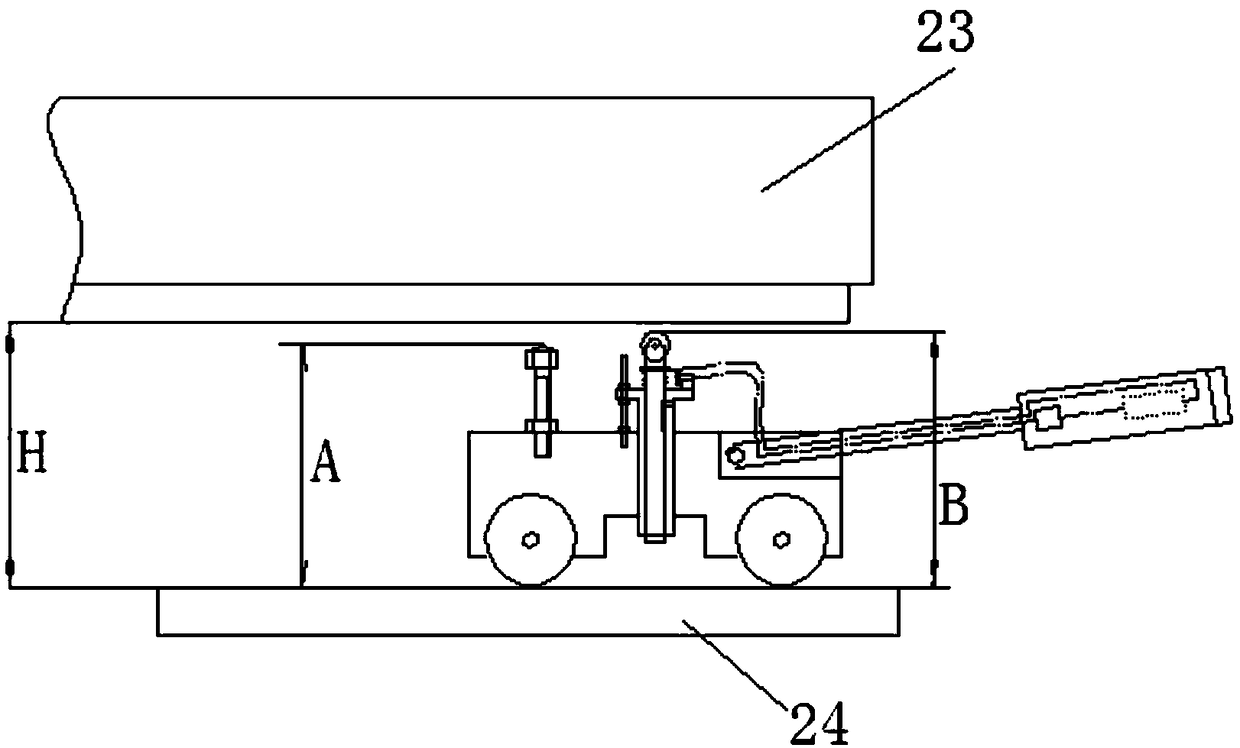

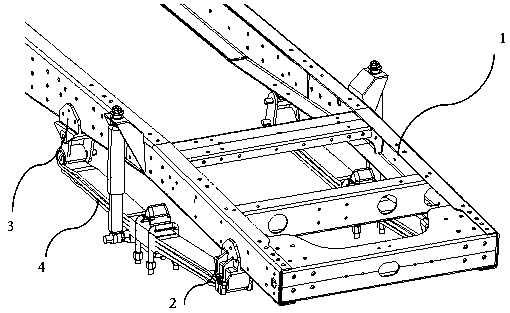

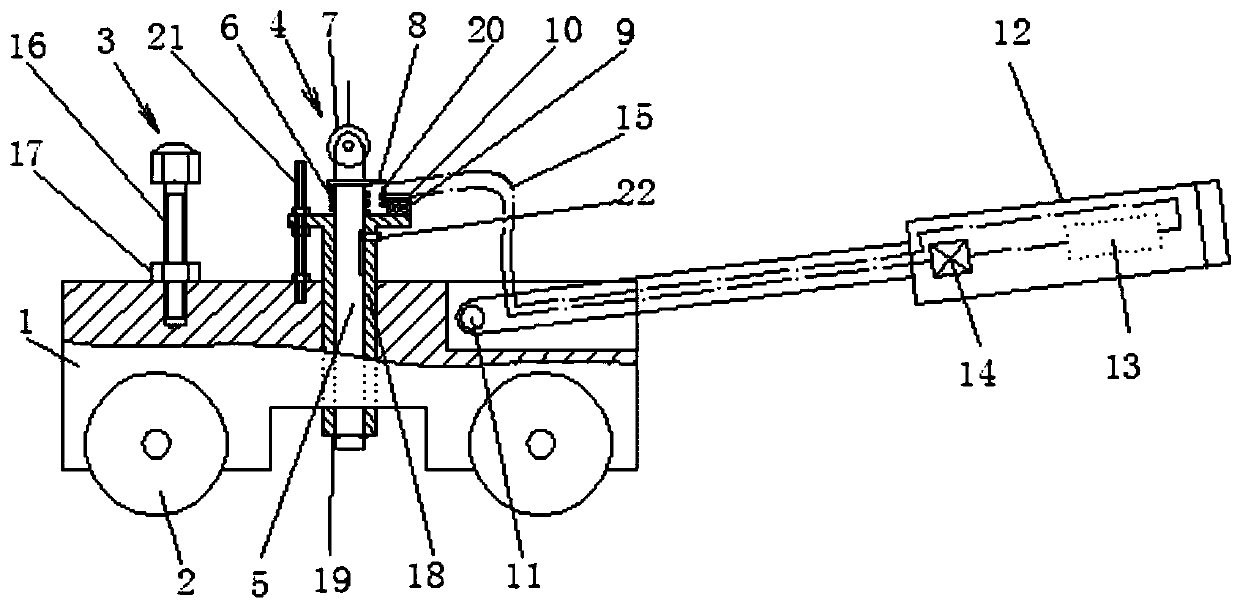

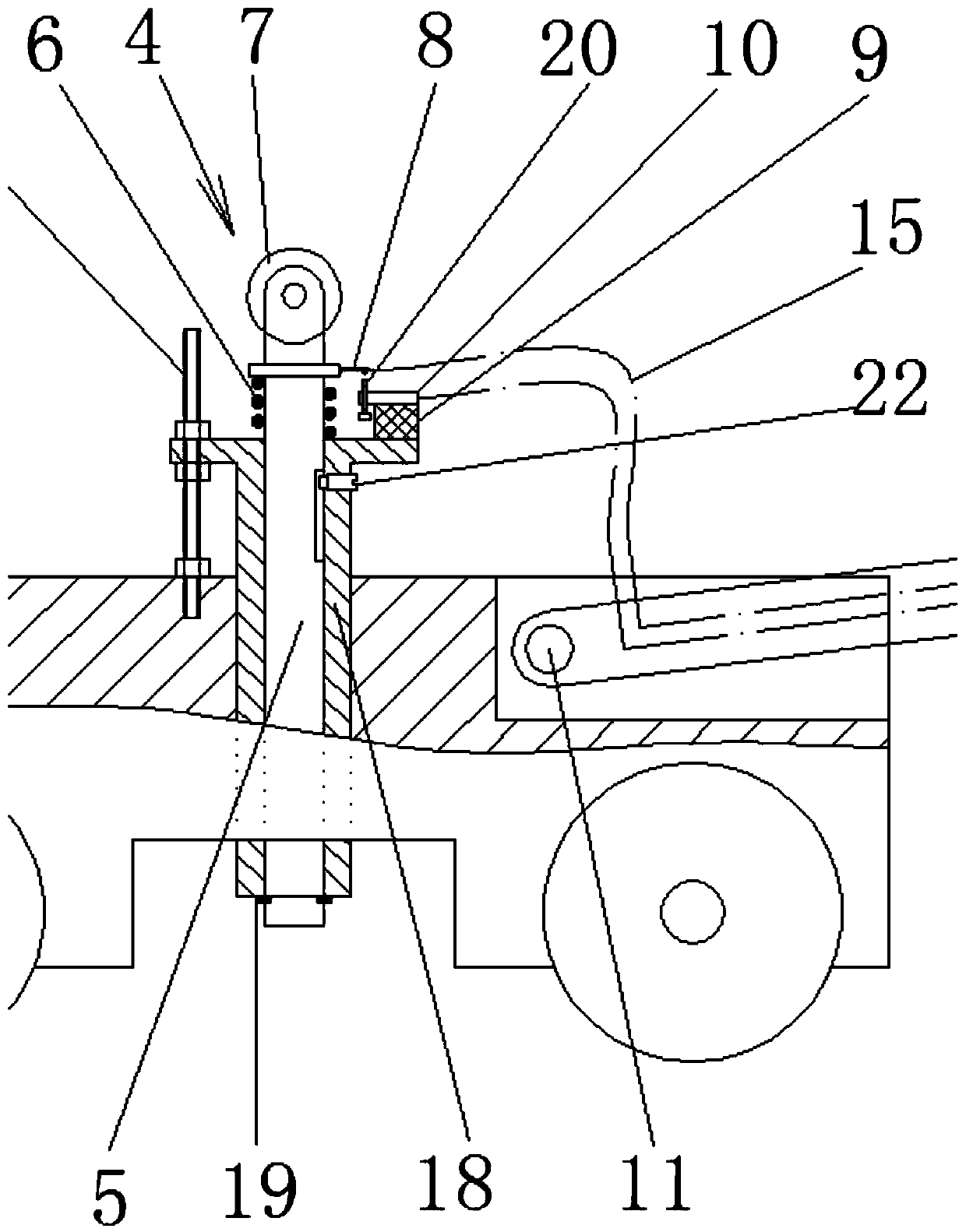

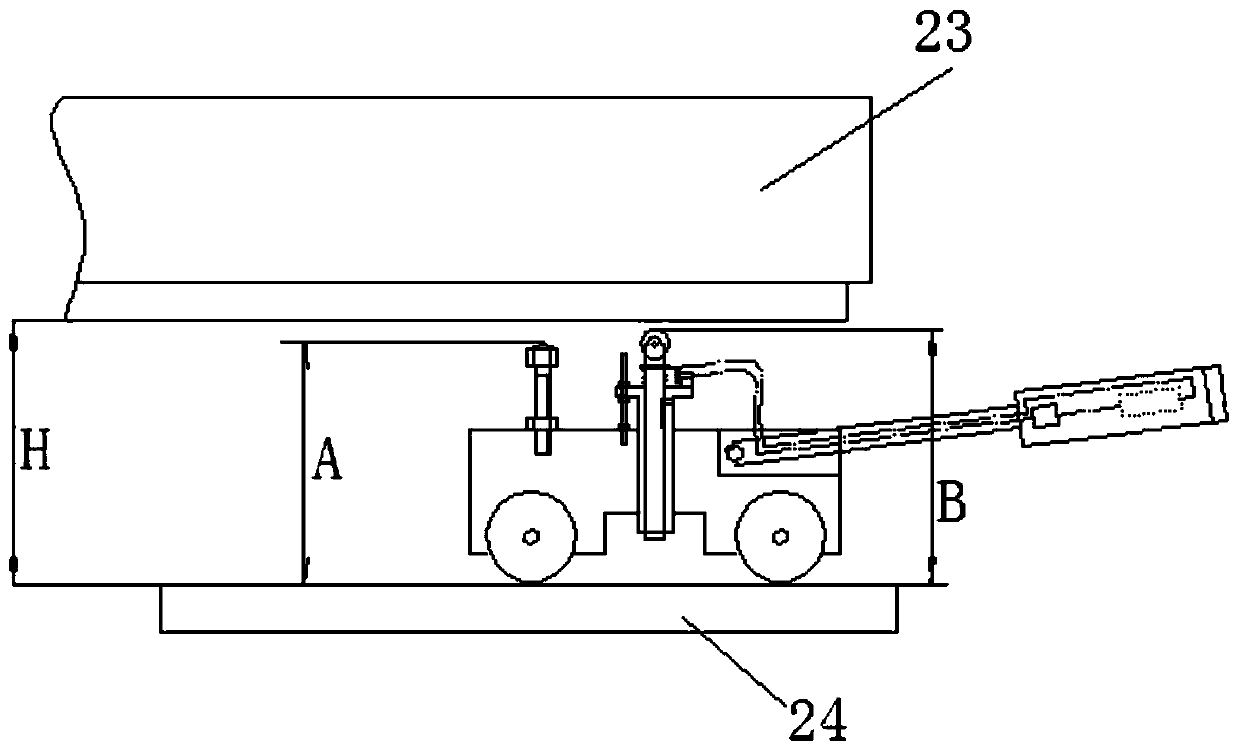

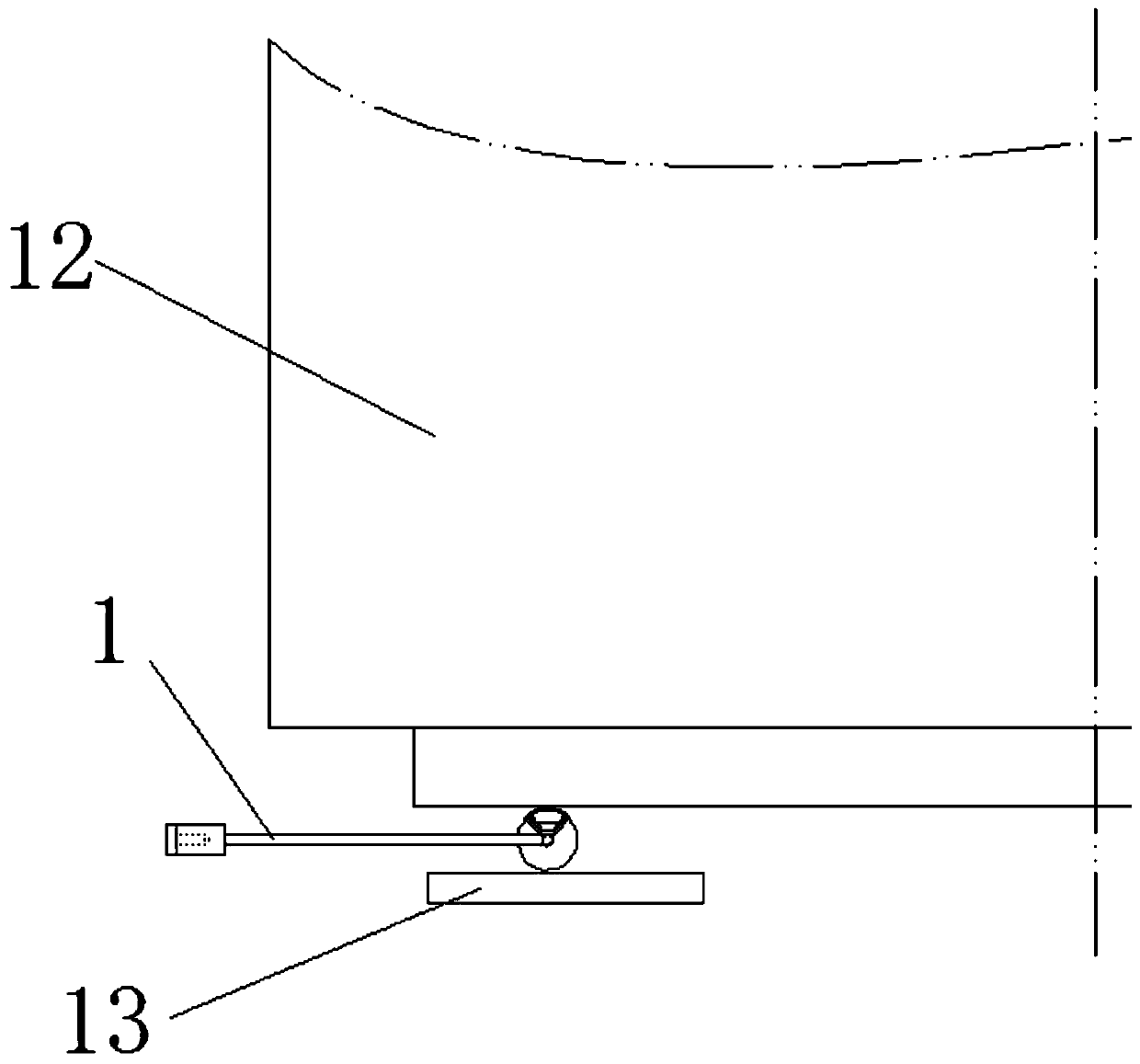

A mini vehicle for inspecting installation of adjusting pads of asphalt ship cargo tanks

The invention relates to the technical field of installation inspection of asphalt ship cargo tanks, and discloses a mini vehicle for inspecting installation of adjusting pads of asphalt ship cargo tanks. The mini vehicle includes a vehicle body. At that upper part of the vehicle body, a general gauge and a floating stop gauge are arranged. The top height of the general gauge is equal to the minimum value of the height between the bottom plane of the cargo tank and the adjusting pad before the cargo tank falls. The floating stop gauge comprises an upright lifting lever, the lifting lever is lifted upward by a spring, the upper end of the lifting lever is provided with a roller, and the lifting lever is connected with a first metal contact piece. An upper part of that vehicle body is provided with an insulating block. A second metal contact piece is arranged on the insulating block. When the first metal contact piece and the second metal contact piece just contact, the height of the uppermost end of the roller wheel is equal to the maximum value of the height between the bottom plane of the cargo tank and the adjusting pad before the cargo tank falls. The rear part of the vehicle body is connected with a handle through a hinge shaft, and the handle is provided with a battery and a signal lamp. The mini vehicle can improve detection efficiency and has good convenience.

Owner:CHENGXI SHIPYARD

Offset connection fixing structure of center lines of plate springs and center lines of lower wing surfaces of longitudinal beams

InactiveCN110271374ASimple structureReasonable designLeaf springsResilient suspensionsMiddle lineBattery system

The invention discloses an offset connection fixing structure of center lines of plate springs and center lines of lower wing surfaces of longitudinal beams. The offset connection fixing structure is characterized in that the plate springs have the center lines in the longitudinal direction of a vehicle, and the plate springs are each roughly and equally divided into two parts by the center lines; and the lower wing surfaces of the longitudinal beams have the center lines in the longitudinal direction of the vehicle, and the lower wing surfaces of the longitudinal beams are each roughly and equally divided into two parts by the center lines; front lifting lugs and rear lifting lugs are partially connected in an overlapped mode on the horizontal plane, and the center lines of the plate springs and the center lines of the longitudinal beams are fixed together in an offset mode; and the front lifting lugs and the rear lifting lugs are in an h shape and in an L shape, so that the plate springs are partially covered under the lower wing surfaces of the longitudinal beams, and the front lifting lugs and the rear lifting lugs of the plate springs are fixed to the longitudinal beams of a chassis and are connected with plate spring elastic pieces. The offset connection fixing structure of the center lines of the plate springs and the center lines of the lower wing surfaces of the longitudinal beams has the advantages that the structure is simple, the design is reasonable, the center distance of the plate springs is increased by changing the form of the lifting lugs of the plate springs, the lifting lugs of the plate springs can adjust the size covered under the lower wing surfaces of the longitudinal beams according to the requirements of a whole vehicle, and thus the spacing of the plate springs can meet the clearance requirements of an arrangement scheme of a middle-mounted chassis in a standard battery system.

Owner:北京华田汽车科技有限公司

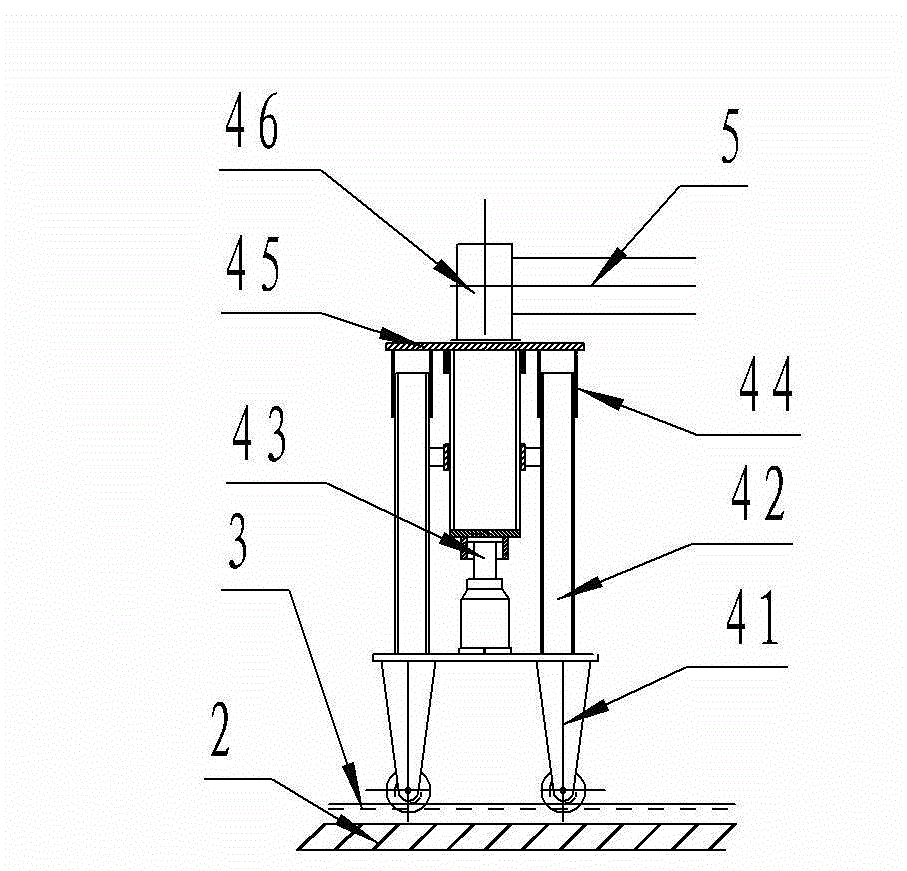

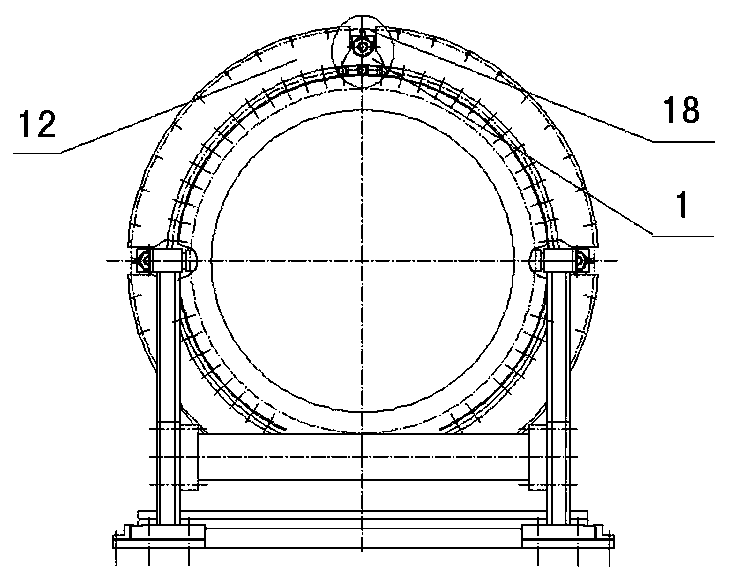

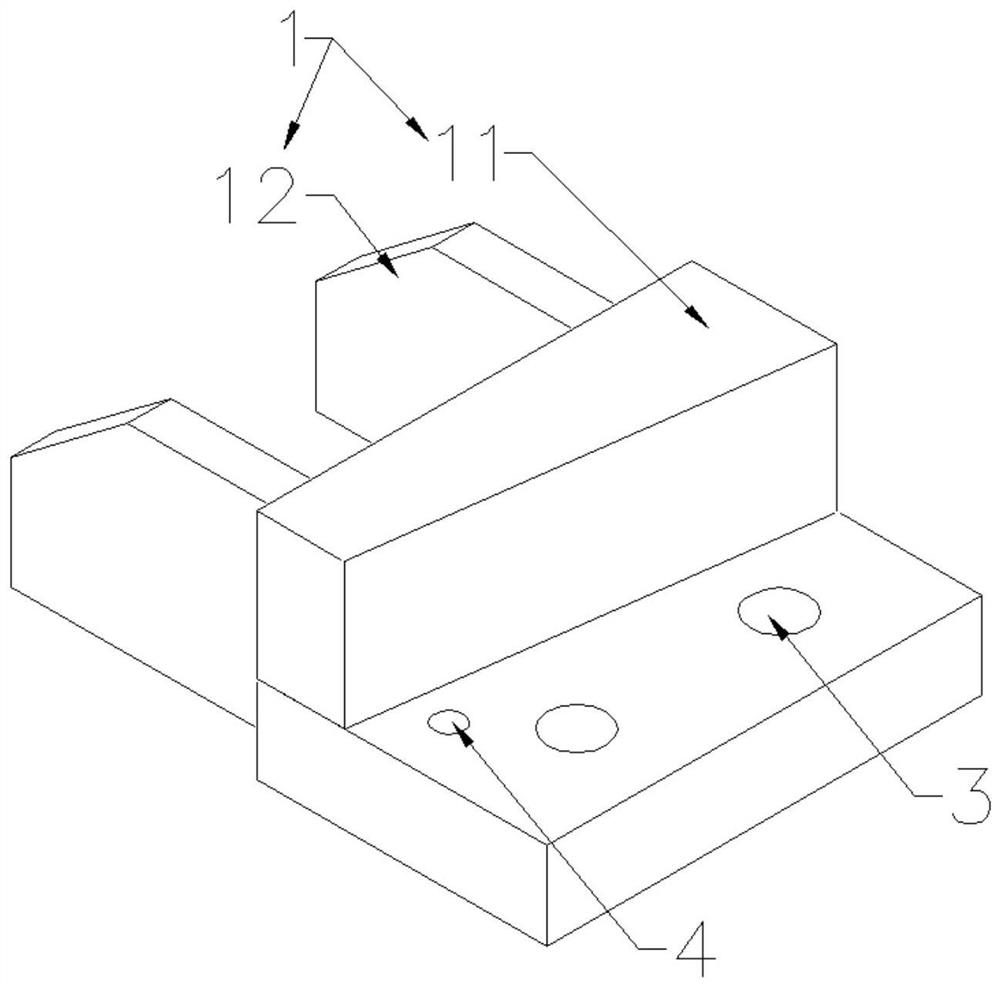

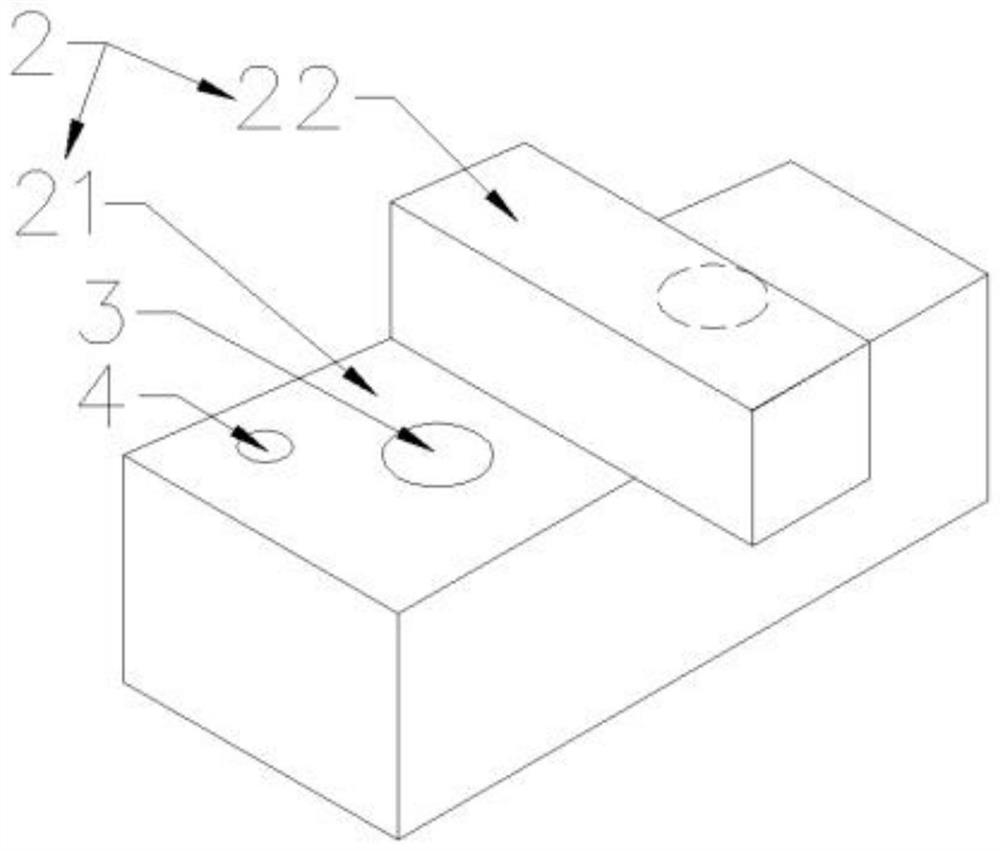

Detachable saturated submersible pressure cabin footing limiting mechanism and using method thereof

ActiveCN113859485AEasy installation and post-maintenanceSave timeHull partsUnderwater equipmentStructural engineeringWelding deformation

The invention discloses a detachable saturated submersible pressure cabin footing limiting mechanism and a using method thereof. The detachable saturated submersible pressure cabin footing limiting mechanism comprises a detachable adjusting block and a detachable fixing block, the fixing block comprises a step-shaped fixing base, the adjusting block comprises a horizontal limiting block and a vertical limiting block, the horizontal limiting block is detachably fixed to a step of the fixing base through a connecting piece, and one side of the horizontal limiting block is attached to the vertical surface of the upper step of the fixing base so as to limit the left-right movement of a cabin footing; and the vertical limiting block is fixed to the horizontal limiting block, and the end, away from the vertical face of the upper step of the fixing base, of the vertical limiting block exceeds the horizontal limiting block to limit vertical movement of the cabin footing. The influence of welding deformation on the precision of an adjusting block can be effectively avoided, and installation and later maintenance are facilitated; and the adjusting block can be independently disassembled and then reassembled after being machined, so that the time is greatly shortened, and the clearance precision requirement of long-term use of equipment is met.

Owner:广州黄船海洋工程有限公司

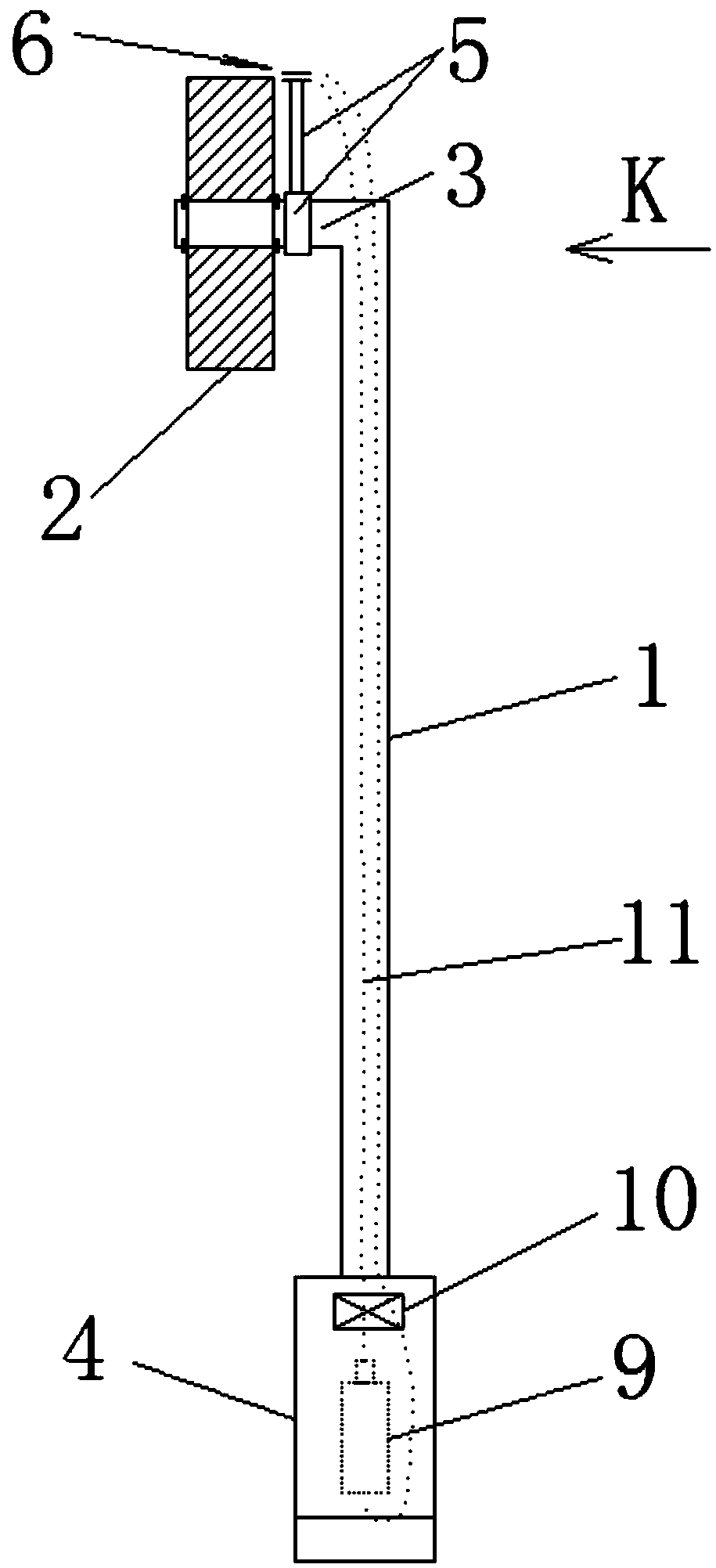

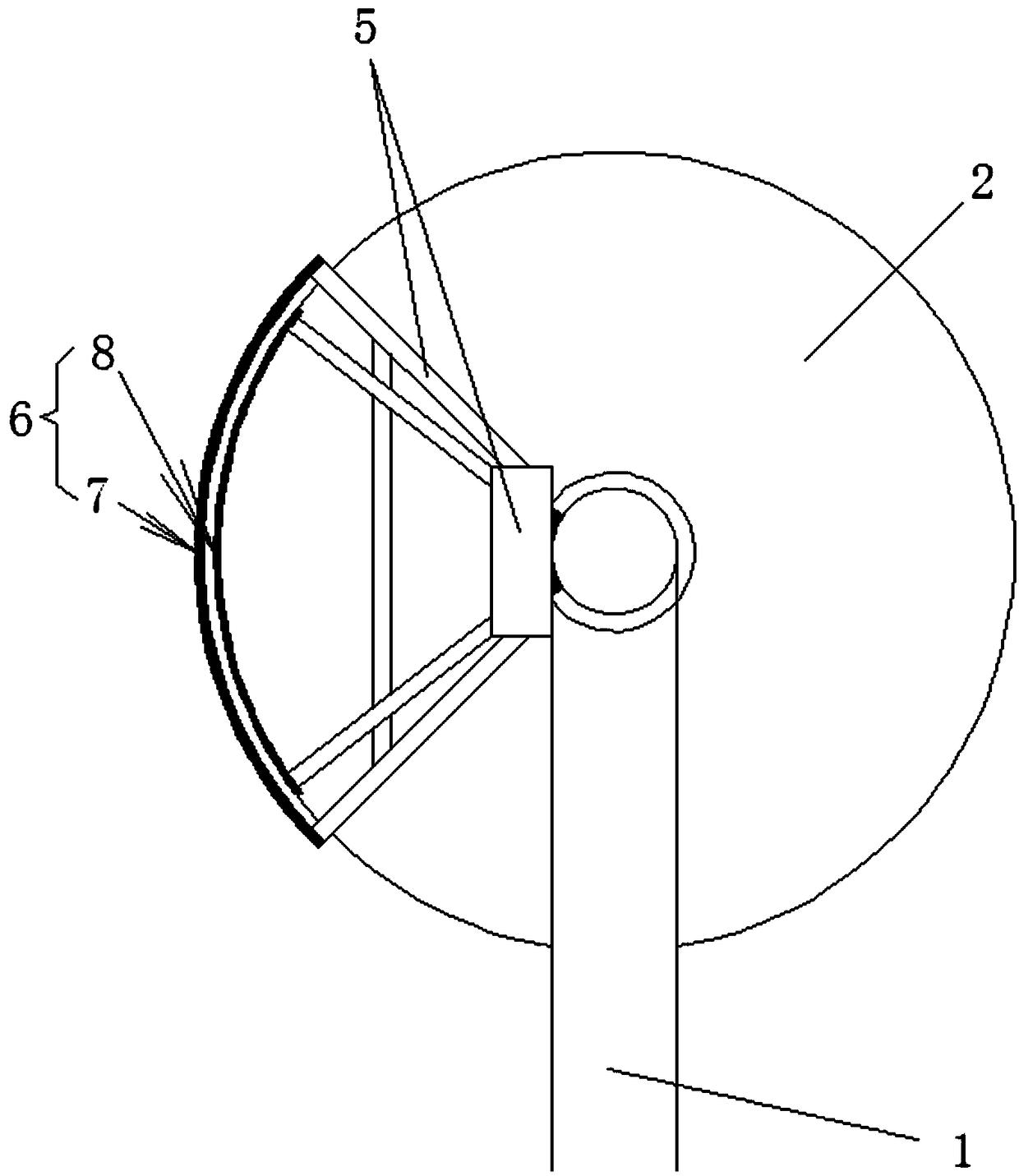

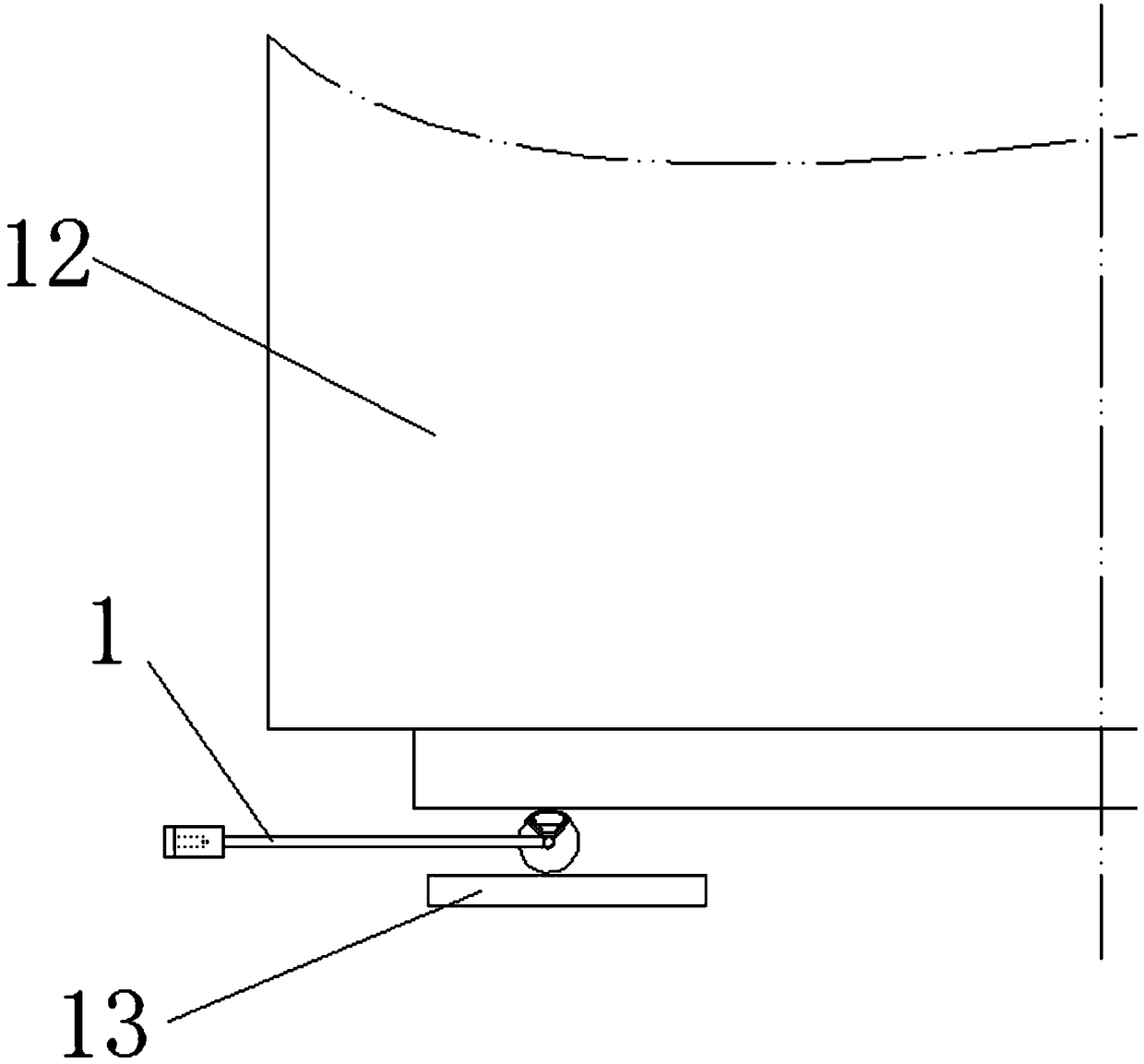

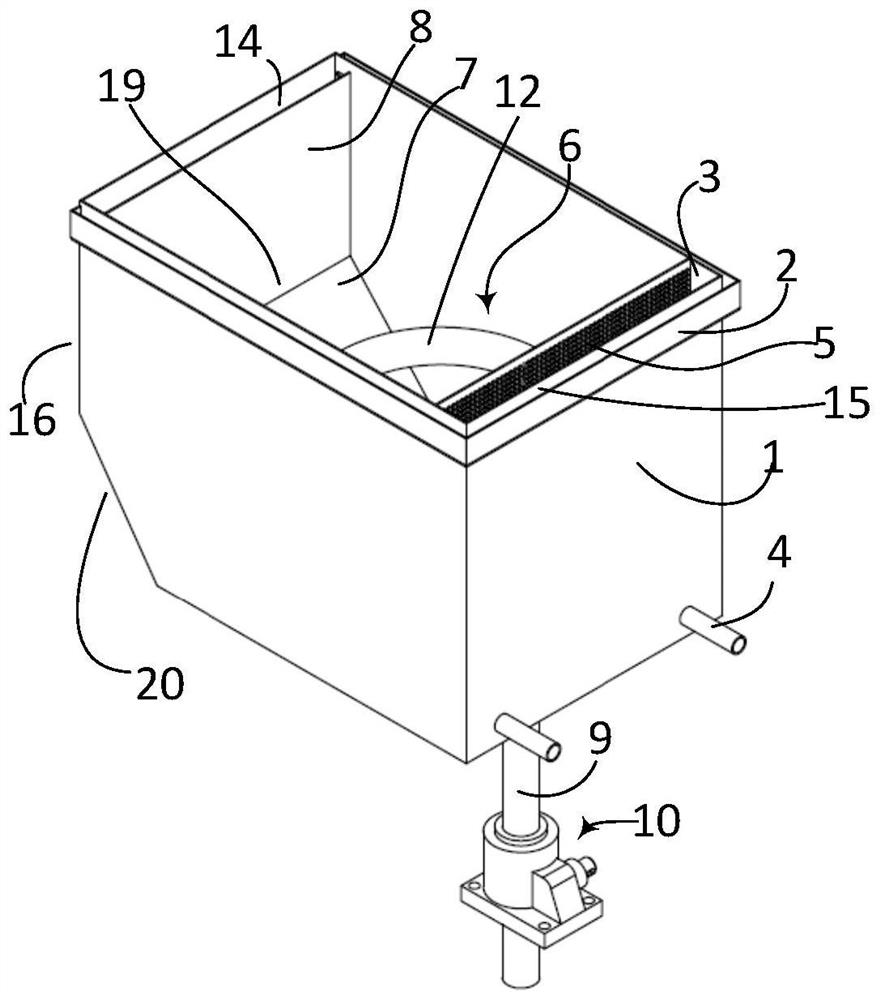

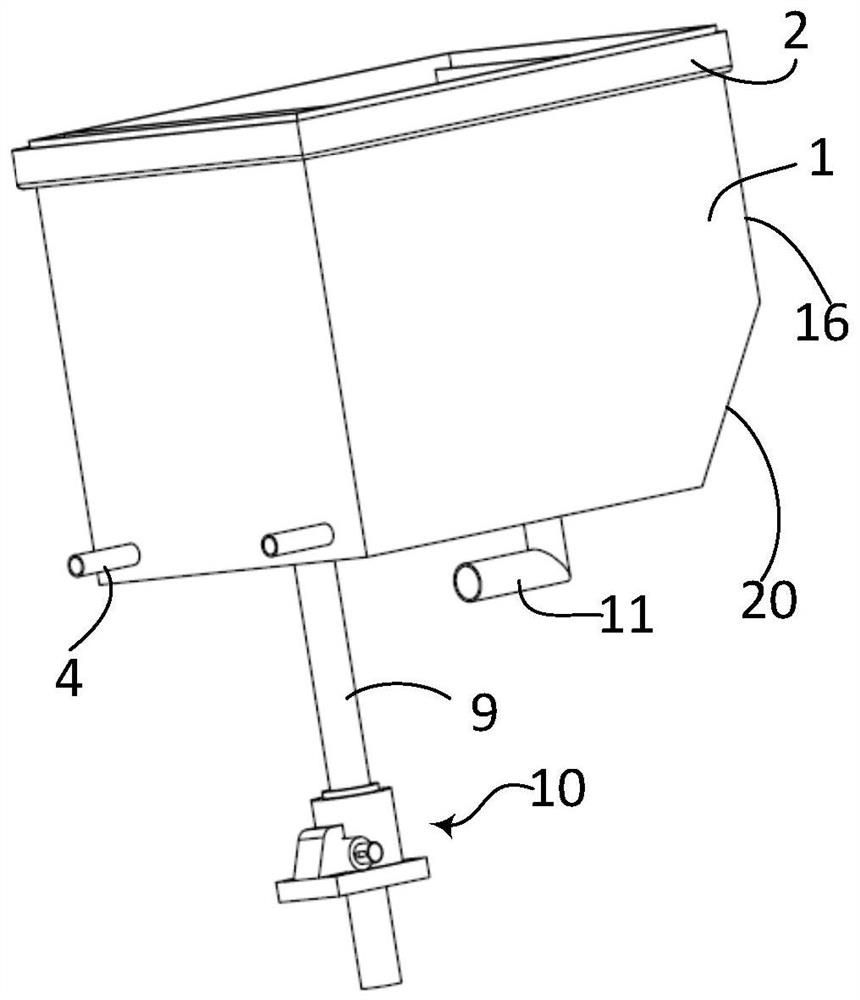

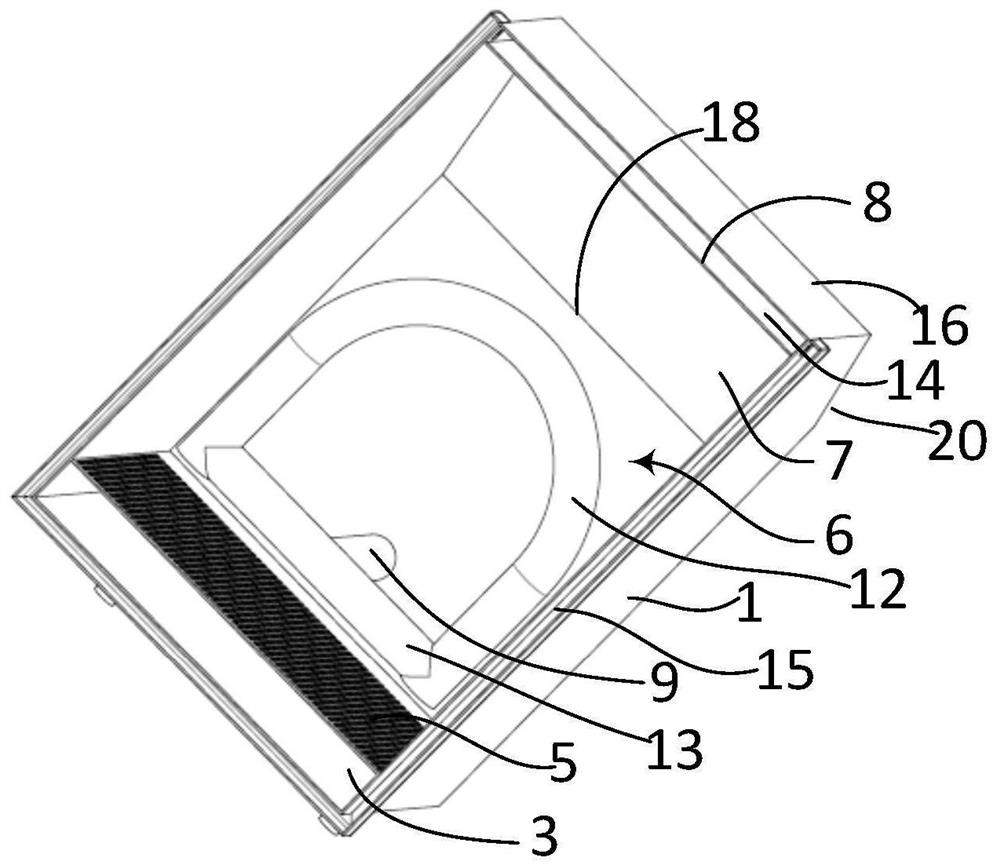

Spinning coagulating bath device

ActiveCN112708953AStable startLightweightArtificial thread manufacturing machinesSpinningEngineering

The invention discloses a spinning coagulating bath device, and belongs to the technical field of textile machinery. The spinning coagulating bath device comprises a water tank (1), a water diversion partition plate (8) and a bundling godet assembly (6), wherein the water diversion partition plate (8) is arranged in the water tank (1), so that a containing space in the water tank (1) is divided into a first containing space (17) and a second containing space (14) by the water diversion partition plate (8); the bundling godet assembly (6) is arranged in the first containing space (17); a first through hole (18) is formed in the bottom of the second containing space (14), and the second containing space (14) communicates with the outside through the first through hole (18); and the height of the water diversion partition plate (8) is smaller than the top edge of the water tank (1). According to the spinning coagulating bath device, stable fluid in a coagulating bath body can be guaranteed, and in addition, due to the arrangement of the water diversion partition plate (8), it is guaranteed that the water tank (1) can be completely filled with solvent, and the gap requirement of cooling side blowing is met.

Owner:CHINESE TEXTILE ACAD

Ceramic grinding head material for grinder

The invention relates to a ceramic grinding head material for a grinder. The ceramic grinding head material for the grinder comprises an outer grinding head material and an inner grinding head material, wherein the outer grinding head material consists of the following components in percentage by weight: 80 to 90 percent of aluminum oxide with purity being more than or equal to 99 percent, 5 to 15 percent of magnesium oxide and 3 to 10 percent of silicon oxide; the inner grinding head material consists of the following components in percentage by weight: 25 to 45 percent of aluminum oxide with purity being more than or equal to 99 percent, 45 to 55 percent of zirconium oxide with purity being more than or equal to 94 percent, 5 to 15 percent of magnesium oxide and 3 to 10 percent of silicon oxide. According to the ceramic grinding head material for the grinder, the defects of an existing ceramic material can be overcome, and the outer grinding head material and the inner grinding head material are made of ceramic.

Owner:NINGBO CHEFSHERE KITCHEN TECH

Rotor Slot Liner Bending Tool for Wet Winding Motors

ActiveCN111633127BEffective protectionAvoid sheddingShaping toolsManufacturing dynamo-electric machinesElectric machineClassical mechanics

The present invention designs a rotor slot lining bending tool for wet winding motors. Put the rotor slot lining on the lower mold of the bending tool, fix the slot lining on the lower mold groove by adjusting the positioning plate on the lower mold, and place the rotor Put the copper bar on the rotor slot liner and coincide with the positioning groove on the lower die at the same time, install the upper die handle on the upper die with screws, press the copper bar and the slot liner into the lower die slot at the same time, so that the outer surface of the copper bar One side is fully attached to the slot liner, the upper mold is removed, and the outer slot liner is attached to the copper strip. The shape of the slot liner of the present invention has no wrinkles and deformations, and the copper strips covered with the slot liner can be smoothly loaded into the rotor core slots. The slot shape of the lower mold of the tool is designed according to the shape of the copper strips. After assembly, the slot liner and copper strips can Seamless fit, and finally achieve the effect of protecting the copper strip.

Owner:HARBIN ELECTRIC POWER EQUIP

Control method of wing-body joint gap distribution based on measured data

ActiveCN111539070BControlling Butt Gap DistributionPrecise dockingGeometric CADAircraft assemblyPoint cloudAlgorithm

The invention discloses a method for controlling the distribution of wing-body butt joint gaps based on measured data, comprising: collecting original point cloud data of the wing and a central wing box; preprocessing the original point cloud data of the two; The point cloud data of the wing and the central wing box are registered with the corresponding solid models; select the key features when docking on the two solid models, map the key features to the registered point cloud data, and extract the corresponding point cloud Features; dock the wing point cloud data and the central wing box point cloud data based on the positioning points; divide the docking surface into multiple regions, calculate the gap between the feature points of each region after docking, and adjust the gap of each region according to the gap tolerance Weights to control the gap distribution. The invention can control the distribution of the wing-body butt joint gap through the characteristic weight according to the measured data, and meet the gap requirement during the wing-body assembly, thereby improving the assembly quality and production efficiency of the wing-body, and solving the technical demand for the distribution control of the wing-body butt joint gap.

Owner:南京耘瞳科技有限公司

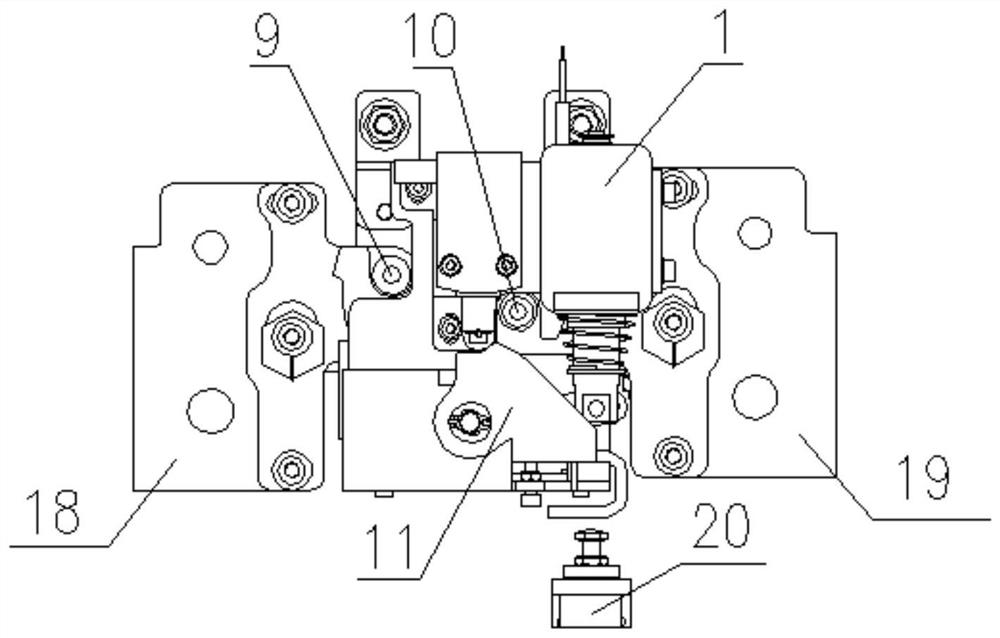

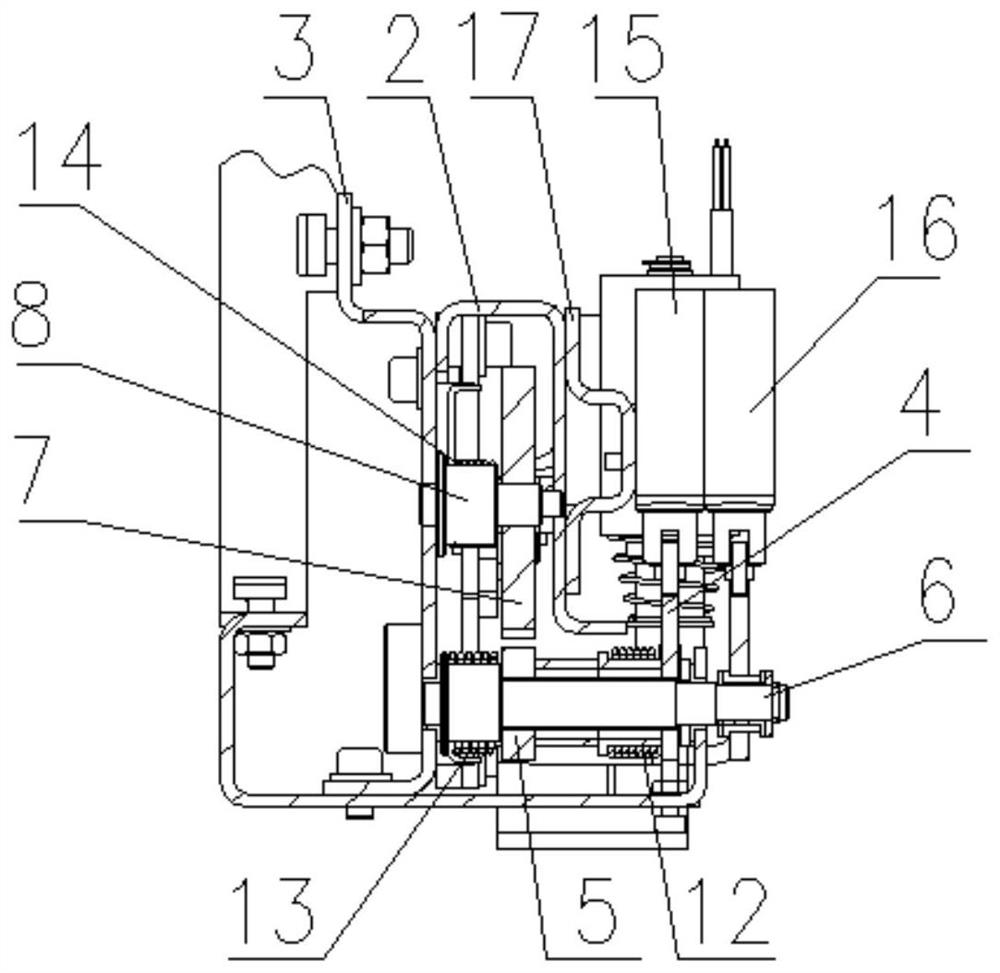

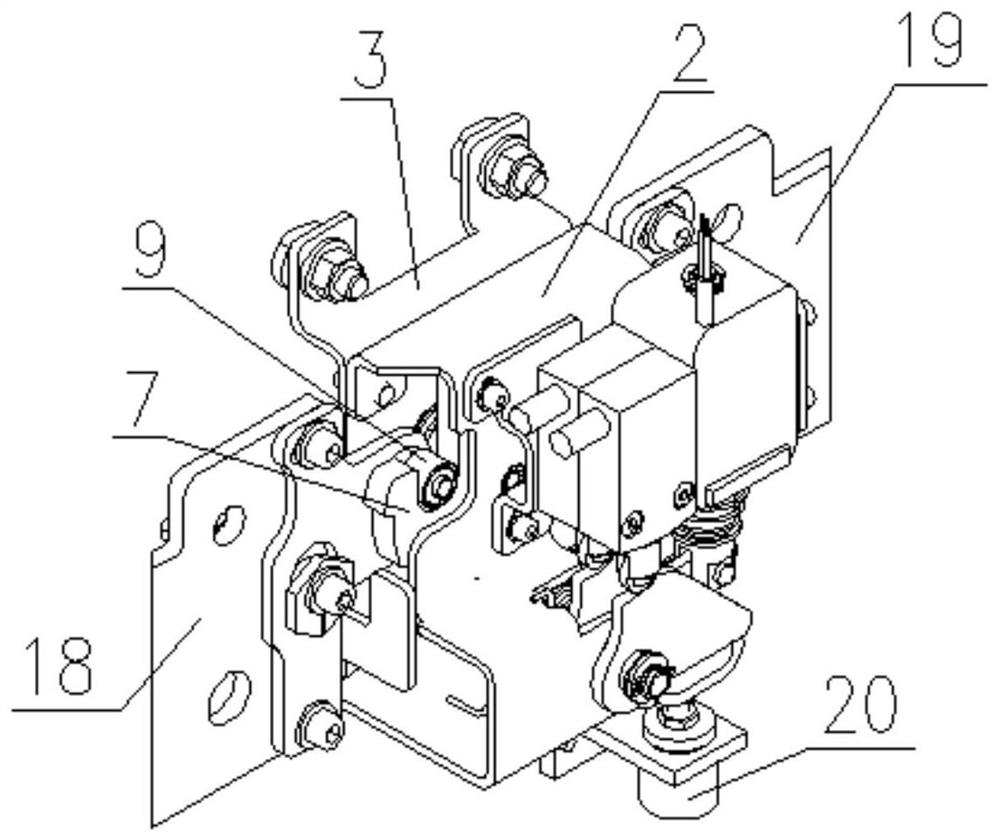

An electric locking device for subway screen doors

ActiveCN107514187BGuaranteed accuracyMeet modular design requirementsNon-mechanical controlsTorsion springElectromagnet

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

A miniature trolley used for installation and inspection of asphalt cargo tank adjustment pads

The invention relates to the technical field of installation inspection of asphalt ship cargo tanks, and discloses a mini vehicle for inspecting installation of adjusting pads of asphalt ship cargo tanks. The mini vehicle includes a vehicle body. At that upper part of the vehicle body, a general gauge and a floating stop gauge are arranged. The top height of the general gauge is equal to the minimum value of the height between the bottom plane of the cargo tank and the adjusting pad before the cargo tank falls. The floating stop gauge comprises an upright lifting lever, the lifting lever is lifted upward by a spring, the upper end of the lifting lever is provided with a roller, and the lifting lever is connected with a first metal contact piece. An upper part of that vehicle body is provided with an insulating block. A second metal contact piece is arranged on the insulating block. When the first metal contact piece and the second metal contact piece just contact, the height of the uppermost end of the roller wheel is equal to the maximum value of the height between the bottom plane of the cargo tank and the adjusting pad before the cargo tank falls. The rear part of the vehicle body is connected with a handle through a hinge shaft, and the handle is provided with a battery and a signal lamp. The mini vehicle can improve detection efficiency and has good convenience.

Owner:CHENGXI SHIPYARD

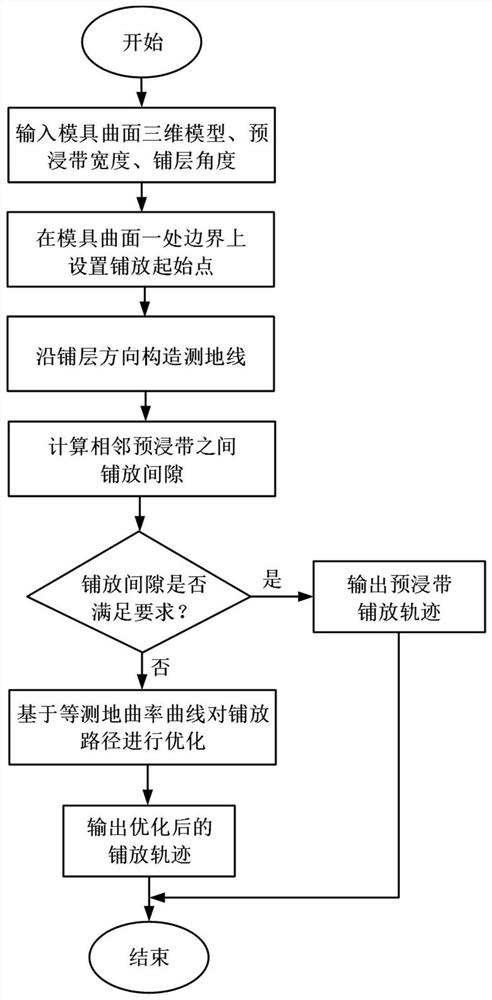

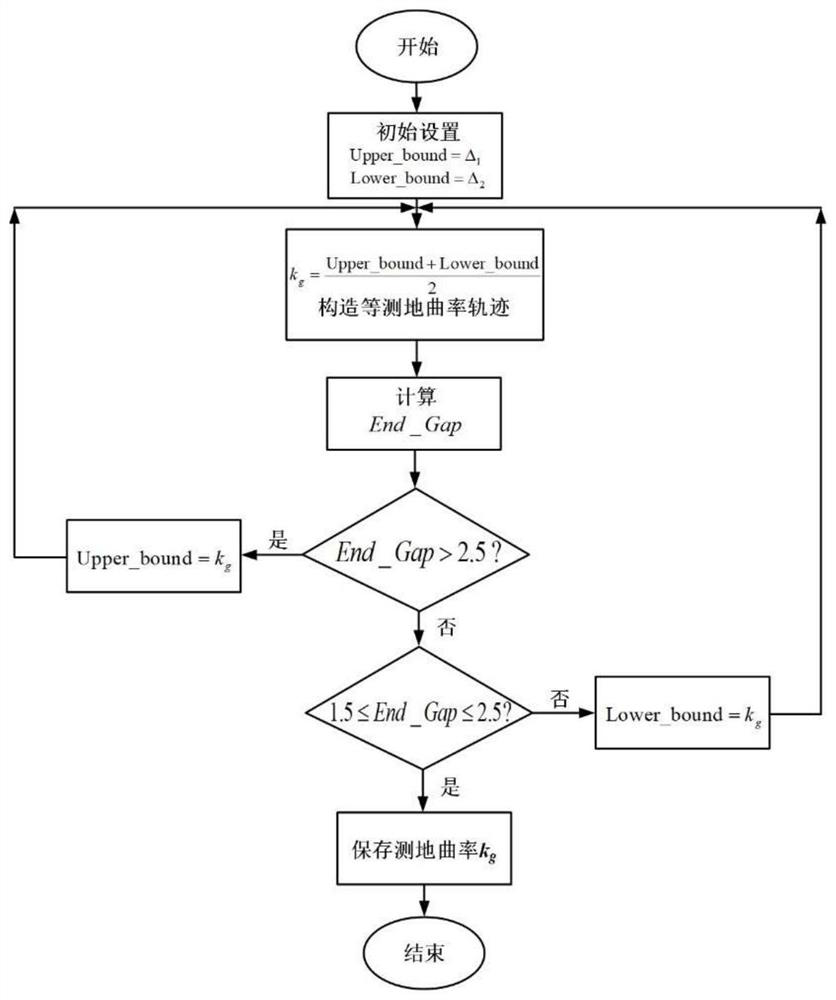

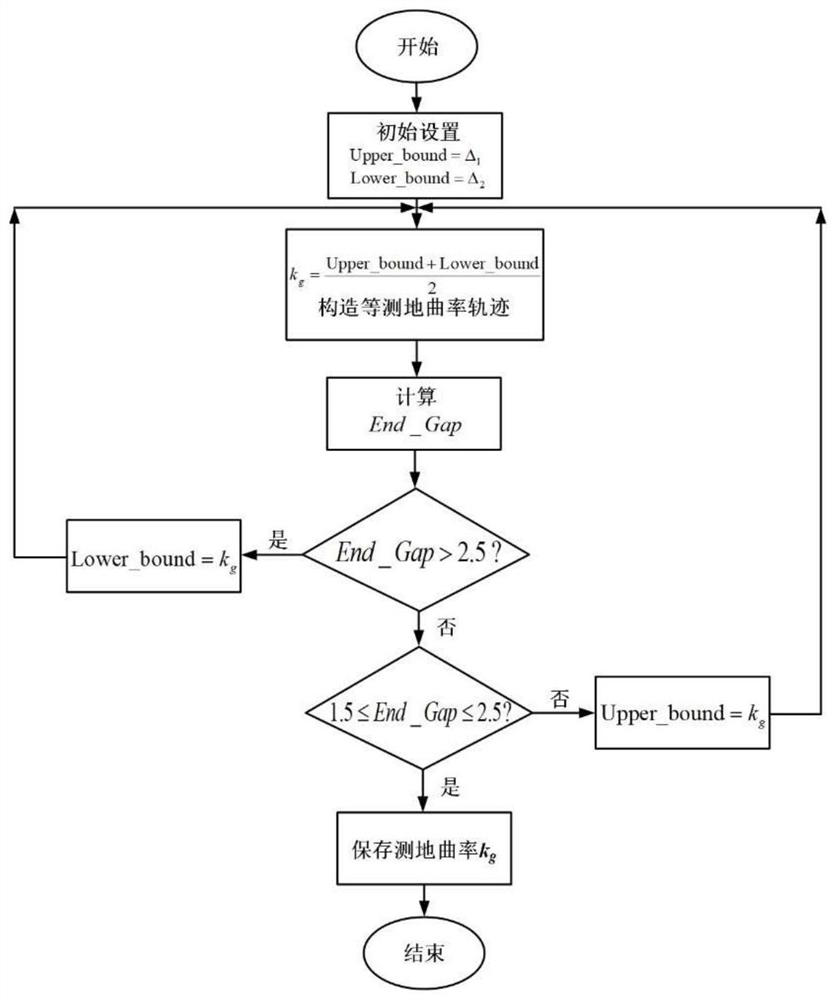

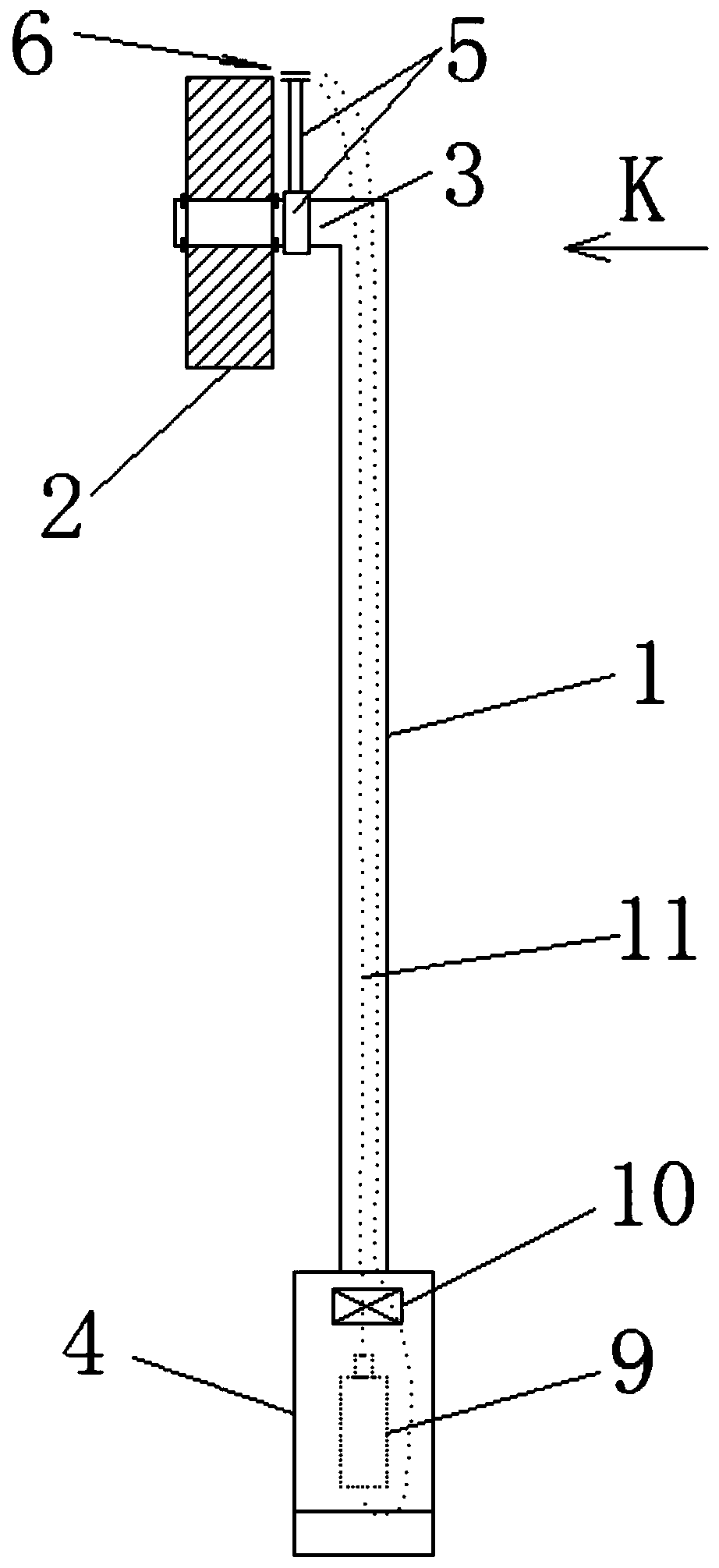

An Automatic Tape Laying Trajectory Planning Method Based on Isogeodesic Curvature Curves

ActiveCN111832172BDoes not generate coverageReduce complexityDesign optimisation/simulationImage data processingStructural engineeringTrajectory planning

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A fast inspection tool and inspection method for cargo tank adjustment pads after installation

ActiveCN109341491BSimple structureEasy to carryMechanical clearance measurementsEngineeringIndustrial engineering

Owner:CHENGXI SHIPYARD

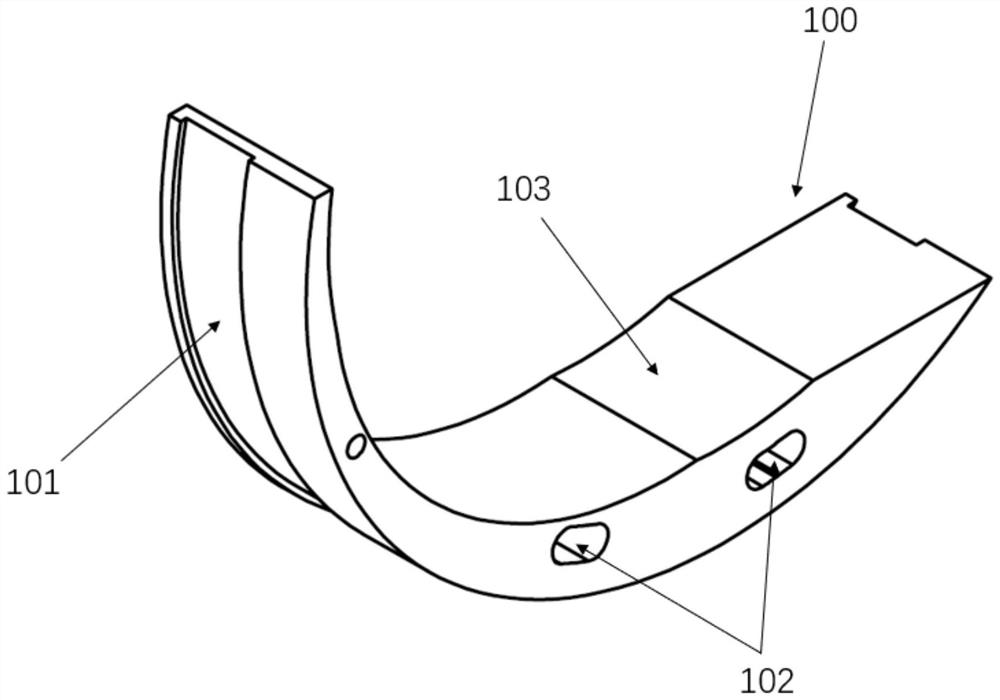

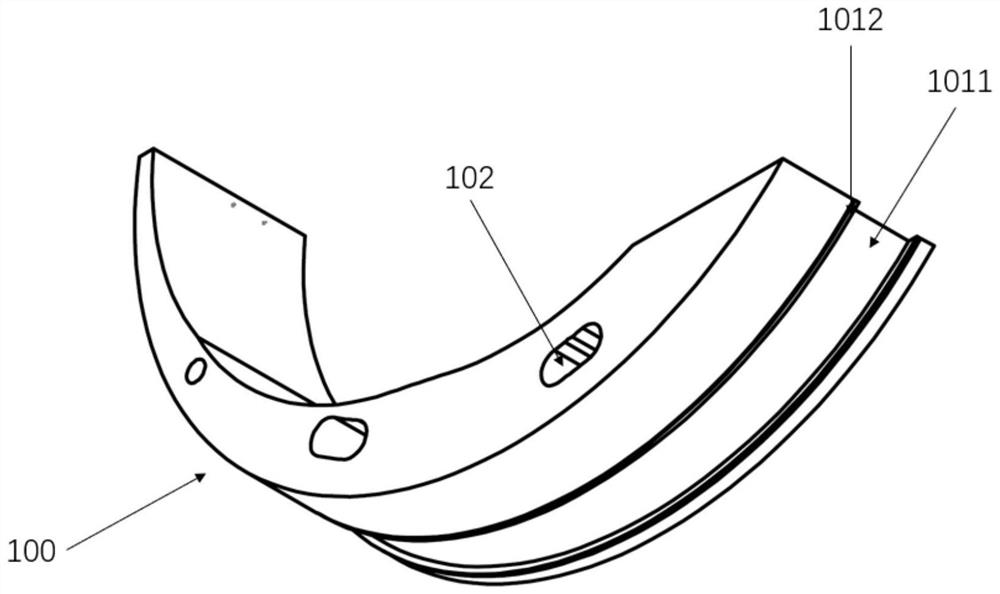

Bundle assembly for superconducting tape encapsulation and device for preparing high-temperature superconducting tape with inner-encapsulated optical fiber

ActiveCN112863760BSimple structureImprove encapsulationSuperconductors/hyperconductorsSuperconductor devicesFiberHigh temperature superconducting

The present invention relates to a superconducting tape packing assembly and a high-temperature superconducting tape manufacturing device for enclosing optical fibers in the technical field of superconducting preparation devices. The outer surface of the plate is provided with a guiding and limiting groove along the circumferential direction, and the guiding and limiting groove penetrates from one end to the other end of the clustering plate. In the present invention, guide and limit grooves are provided through the outer peripheral surface of the arc-shaped cluster plate, so that the upper and lower metal packaging tapes, superconducting tapes, and measuring optical fiber wire bundles can be changed and positioned through the guide and limit grooves, and the superconducting tape can The direction and position of the wire harness are effectively limited during the material packaging process, the structure is simple, and the packaging effect is outstanding.

Owner:SHANGHAI JIAOTONG UNIV

Ceramic material for grinding head

ActiveCN106699139BMeet clearance requirementsReduce dosageCoffee millsSpice millsSilicon oxideCeramic

The invention relates to a ceramic material for a grinding head. The ceramic material comprises an outer grinding head material and an inner grinding head material, wherein the outer grinding head material is prepared from the following raw materials in percentage by weight: 80-90% of aluminum oxide of which the purity is greater than or equal to 99%, 5-15% of magnesium oxide, 3-10% of silicon oxide and 3-5% of titanium dioxide; and the inner grinding head material is prepared from the following raw materials in percentage by weight: 50-60% of aluminum oxide of which the purity is greater than or equal to 99%, 20-30% of zirconium oxide of which the purity is greater than or equal to 94%, 5-15% of magnesium oxide, 3-10% of silicon oxide and 12-20% of titanium dioxide. Through the ceramic material, the defects of the existing ceramic material can be overcome, the aim that the outer grinding head material and the inner grinding head material are manufactured by ceramics is achieved, the dosage of the zirconium oxide is reduced, and thus the production cost is lowered.

Owner:NINGBO CHEFSHERE KITCHEN TECH

Locking ring assembly and steering column

InactiveCN108263467AAnti-theftMeet clearance requirementsAnti-theft devicesSteering columnsInterference fitSteering column

The invention discloses a locking ring assembly used to be installed on a steering mandrel. The locking ring assembly comprises an allowance ring and a locking ring sleeve. The locking ring sleeve hasa sleeve hole used for the steering mandrel to pass through. One end of the locking ring sleeve is provided with an allowance ring installing end, and the other end of the locking ring sleeve is provided with a lockpin cooperation end. The allowance ring is in the allowance ring installing end in interference fit, and is coaxially arranged with the sleeve hole. The lockpin cooperation end is provided with at least a lockpin insertion hole communicated with the sleeve hole. The invention also discloses a steering column. Through making the allowance ring installing end and the lockpin cooperation end be separated by a distance, a cooperation region between the allowance ring and the locking ring sleeve and the cooperation region of the locking ring sleeve and the lockpin would not be overlapped, so that integrated thickness after the allowance ring and the locking ring sleeve are assembled together is reduced, gap requirement of an inner sleeve and the steering mandrel is satisfied. The steering mandrel can enter the inner sleeve when the steering mandrel is crumpled while realizing locking of the steering mandrel.

Owner:THYSSENKRUPP PRESTA SHANGHAI

Differential lock gap adjustment device and differential lock gap adjustment method

ActiveCN102840319BAchieve regulationGuaranteed assembly clearanceGearing detailsPetroleum engineering

The invention provides a differential lock gap adjustment device, which is used for adjusting the gap between a sliding engagement sleeve and a fixed engagement sleeve of a differential lock, comprising a dial, a rotary sleeve and a pointer; the dial is matched with the rotary sleeve, The rotating sleeve can cooperate with the rotating shaft that drives the sliding engagement sleeve to move, and can rotate relative to the dial with the rotation of the rotating shaft; the pointer is fixed on the rotating sleeve and can move with the rotating sleeve The rotation of the pointer rotates relative to the dial, and the rotation angle of the pointer can be displayed on the scale of the dial. The invention also provides a method for adjusting the differential lock clearance and a method for adjusting the differential lock clearance by using the differential lock clearance adjustment device. Through the technical solution provided by the invention, the gap between the sliding engagement sleeve and the fixed engagement sleeve of the differential lock can be guaranteed to meet the design requirements, regardless of the stroke error of the cylinder, so that the differential lock can work normally.

Owner:SANY AUTOMOBILE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com