Diesel engine main bearing block and main bearing cap joint face machining method and presetting die plates therefor

A technology for main bearing caps and main bearing housings, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of low precision, large influence on measurement results, and low processing efficiency, so as to improve accuracy and Efficiency, avoiding the effect of machine tool time loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited thereby.

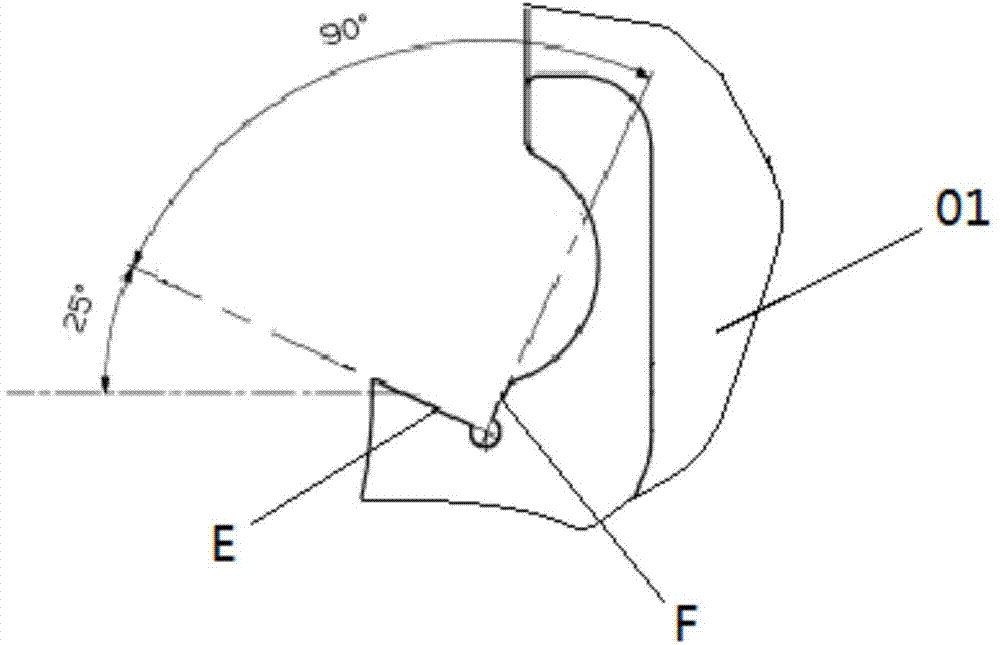

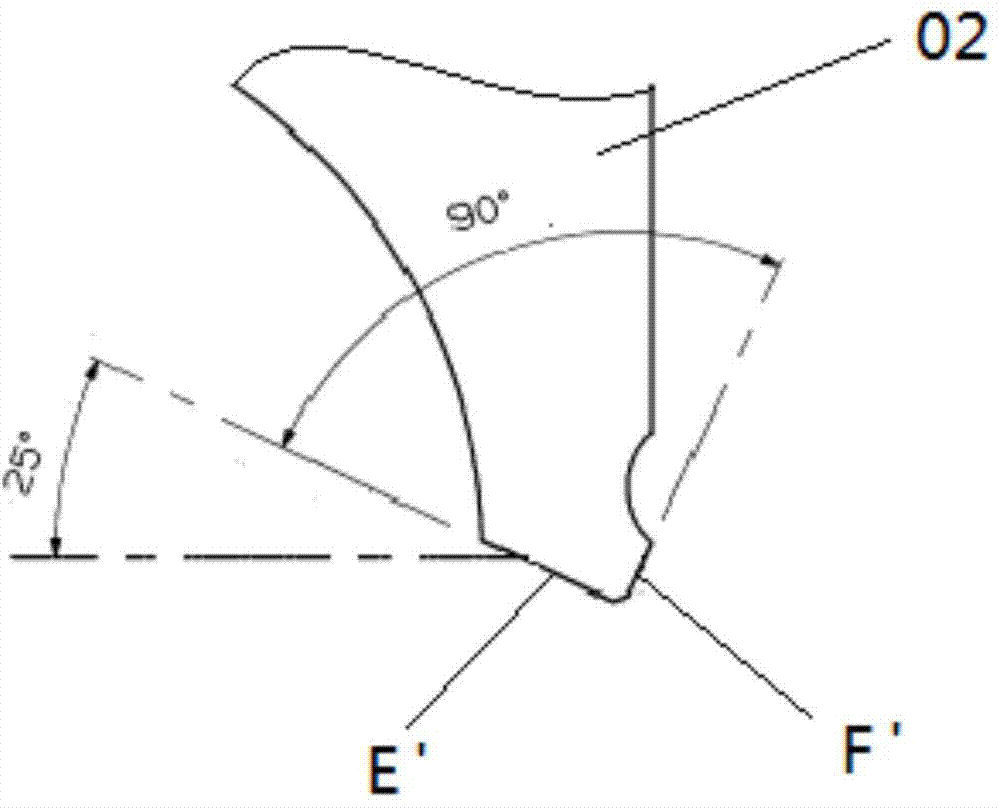

[0039] The processing method described in the present invention is used for the processing of the connection surface between the main bearing seat and the main bearing cover of a large marine low-speed diesel engine, please refer to figure 1 , the connecting surface of the main bearing seat is an inner concave slope, which is composed of two symmetrically distributed slopes E of 25 degrees and two slopes F of 115 degrees, the angle of 25 degrees slope E is 25 degrees with the horizontal plane, and the angle of 115 degree slope F is formed with the horizontal plane 115° angle, i.e. 90° to 25° slope E; see figure 2 , the connecting surface of the main bearing cap is a convex slope, which is also composed of two 25-degree slopes E' and two 115-degree slopes F' ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com