Patents

Literature

61results about How to "Avoid the risk of obsolescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Instant air energy heat-pump water heater and control method thereof

InactiveCN103900249AReduced persistenceGuaranteed continuityFluid heatersElectricityPlate heat exchanger

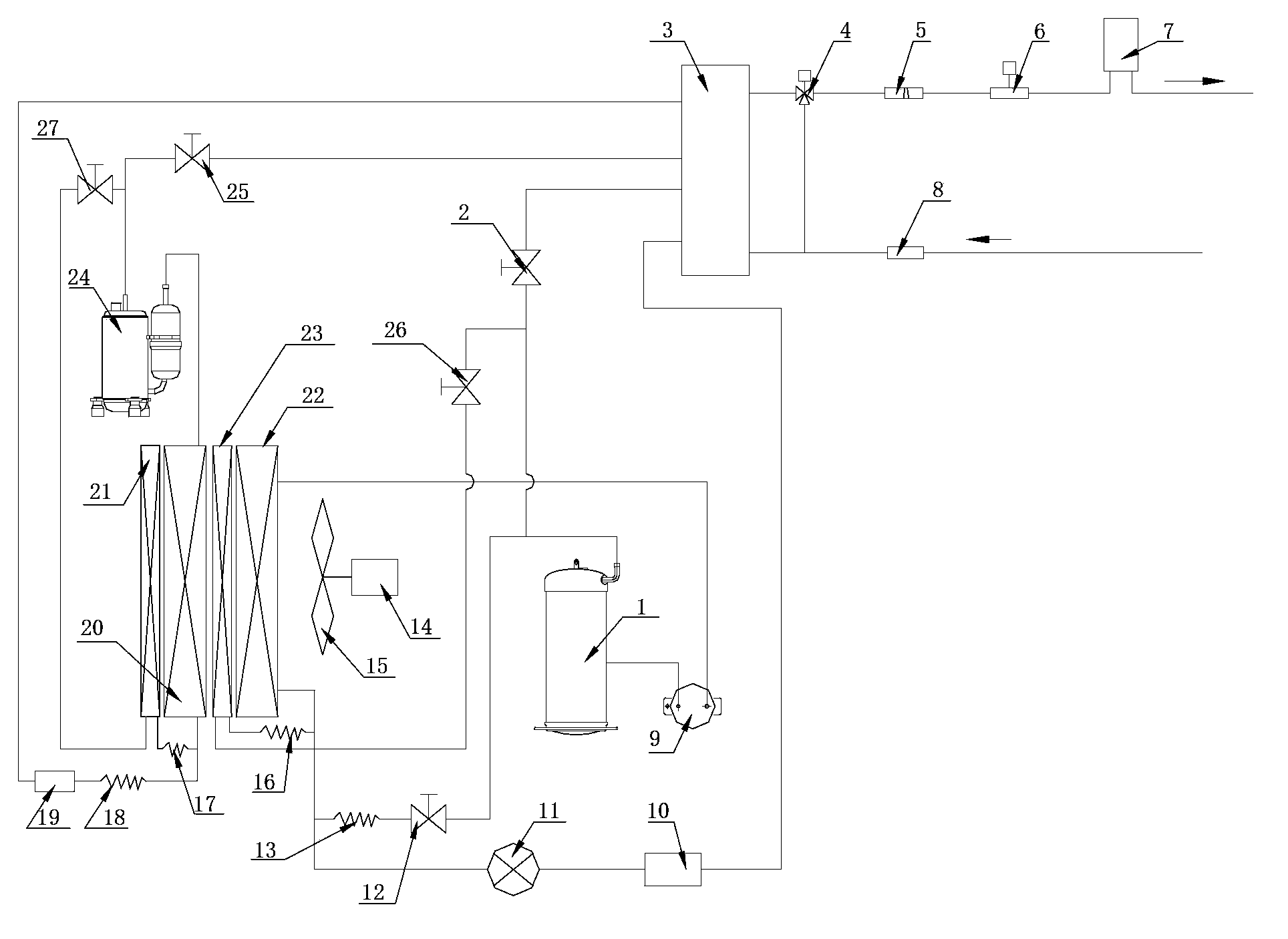

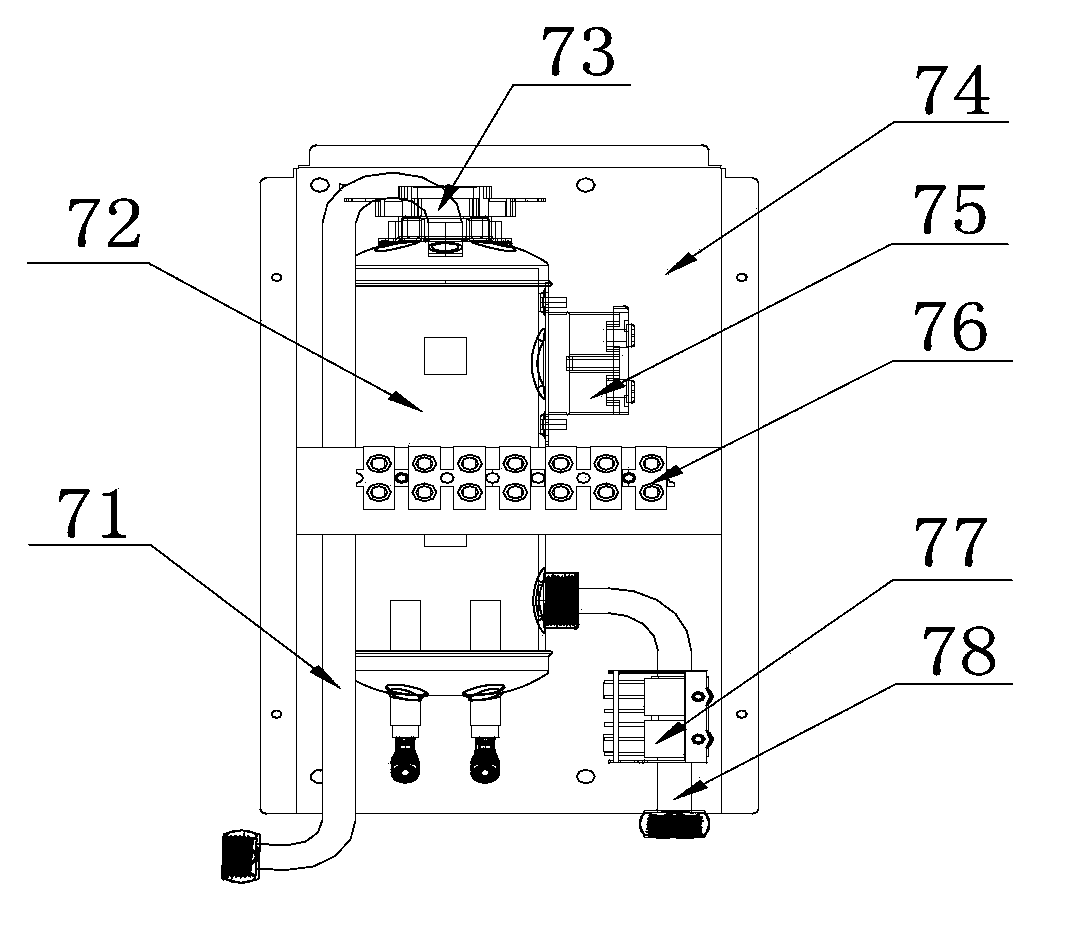

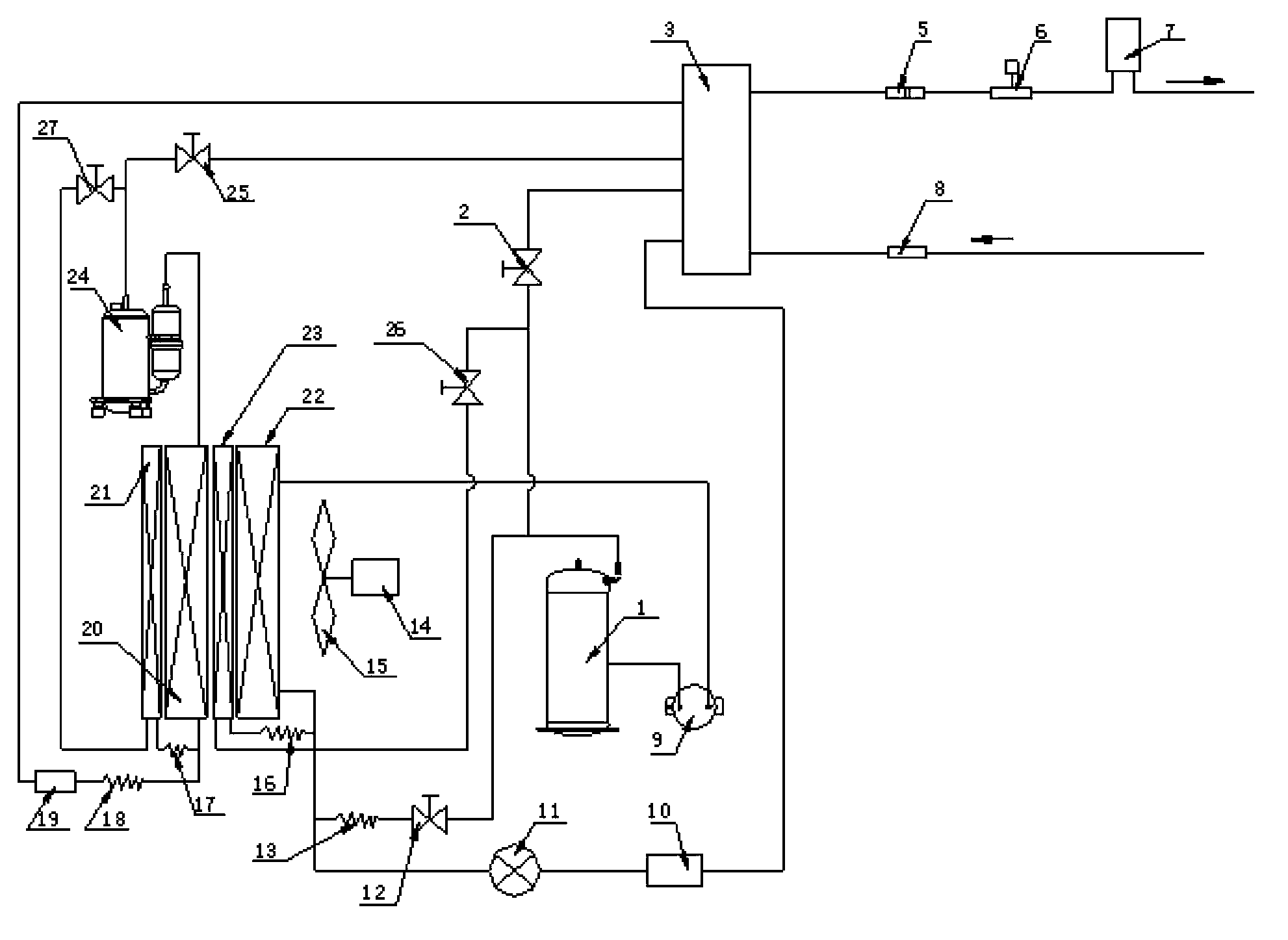

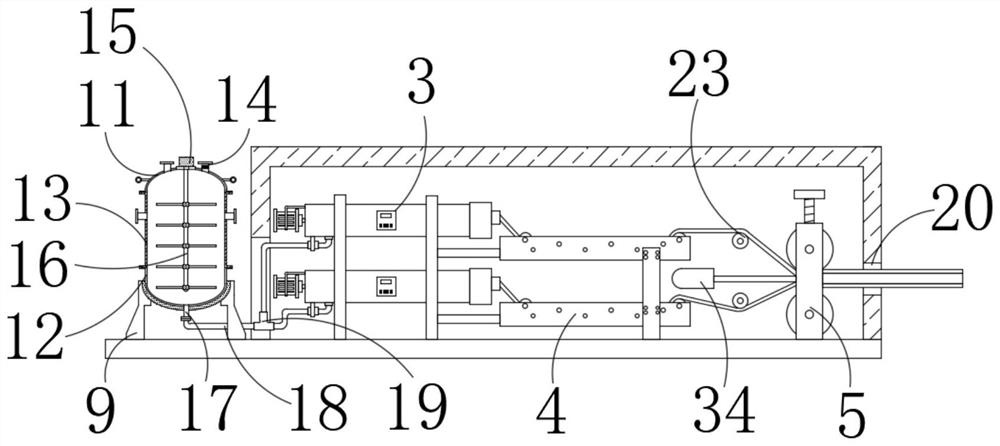

The invention discloses an instant air energy heat-pump water heater and a control method thereof. The water heater comprises a first heat-pump circulation circuit, a second heat-pump circulation circuit, a water way pipeline part module, an electrical heating module and a control module. Each heat-pump circulation circuit is provided with a compressor and a condenser. The water way pipeline part module comprises a water inlet pipeline, a heat-pump heating pipeline and a water outlet pipeline, wherein the water inlet pipeline, the heat-pump heating pipeline and the water outlet pipeline are sequentially communicated with one another. A water flow regulating valve is arranged in the communication pipeline. The electrical heating module is arranged on the water outlet pipeline. The condensers in the two heat-pump circulation circuits and the heat-pump heating pipeline are integrated in a plate heat exchanger or a double-pipe heat exchanger. The control module is used for controlling the working modes of the two compressors, the working mode of a second compressor, the working mode of the electrical heating module and the working mode of the water flow regulating valve. The instant air energy heat-pump water heater is instant and can ensure water supply at constant temperature without a water tank, is simple in structure and improves operating stability and reliability of a heat pump unit.

Owner:FUZHOU AQUAPOWER ELECTRIC WATER HEATER

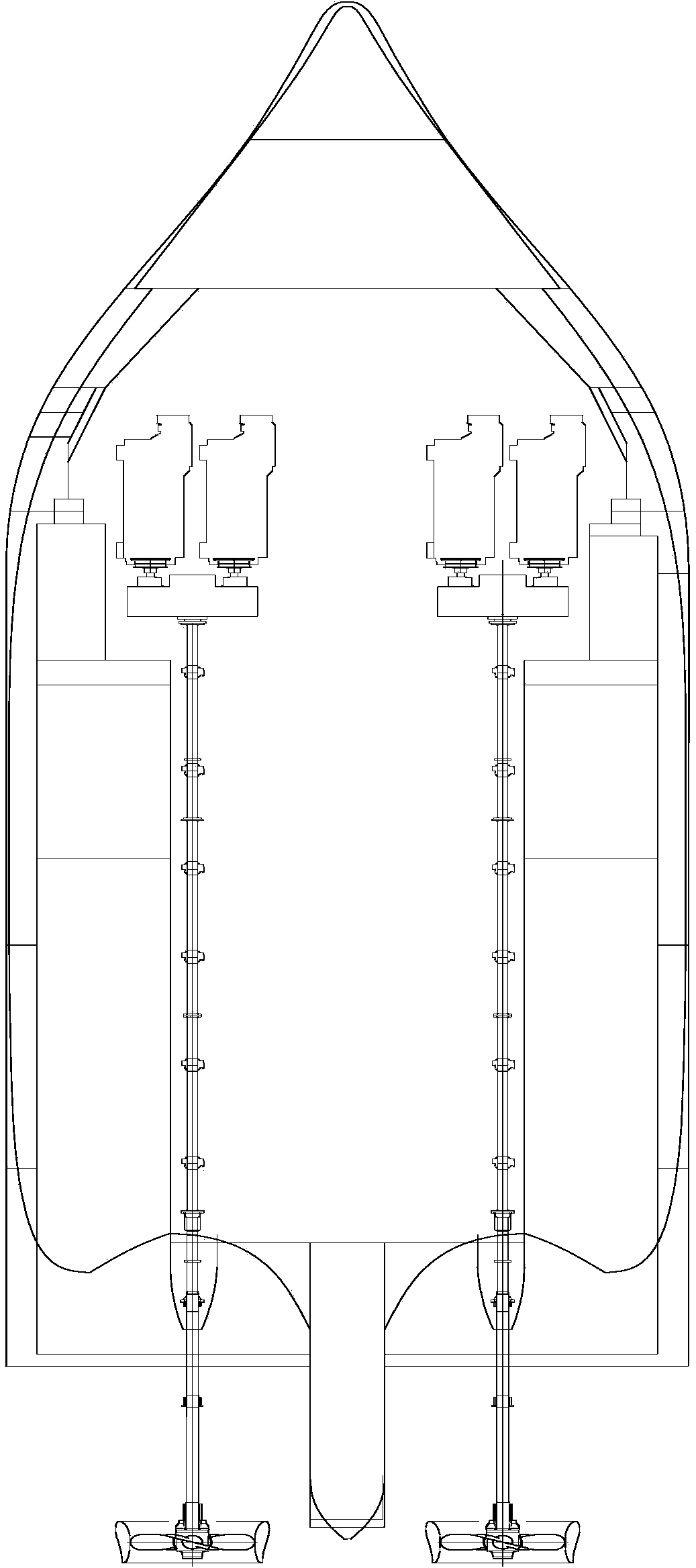

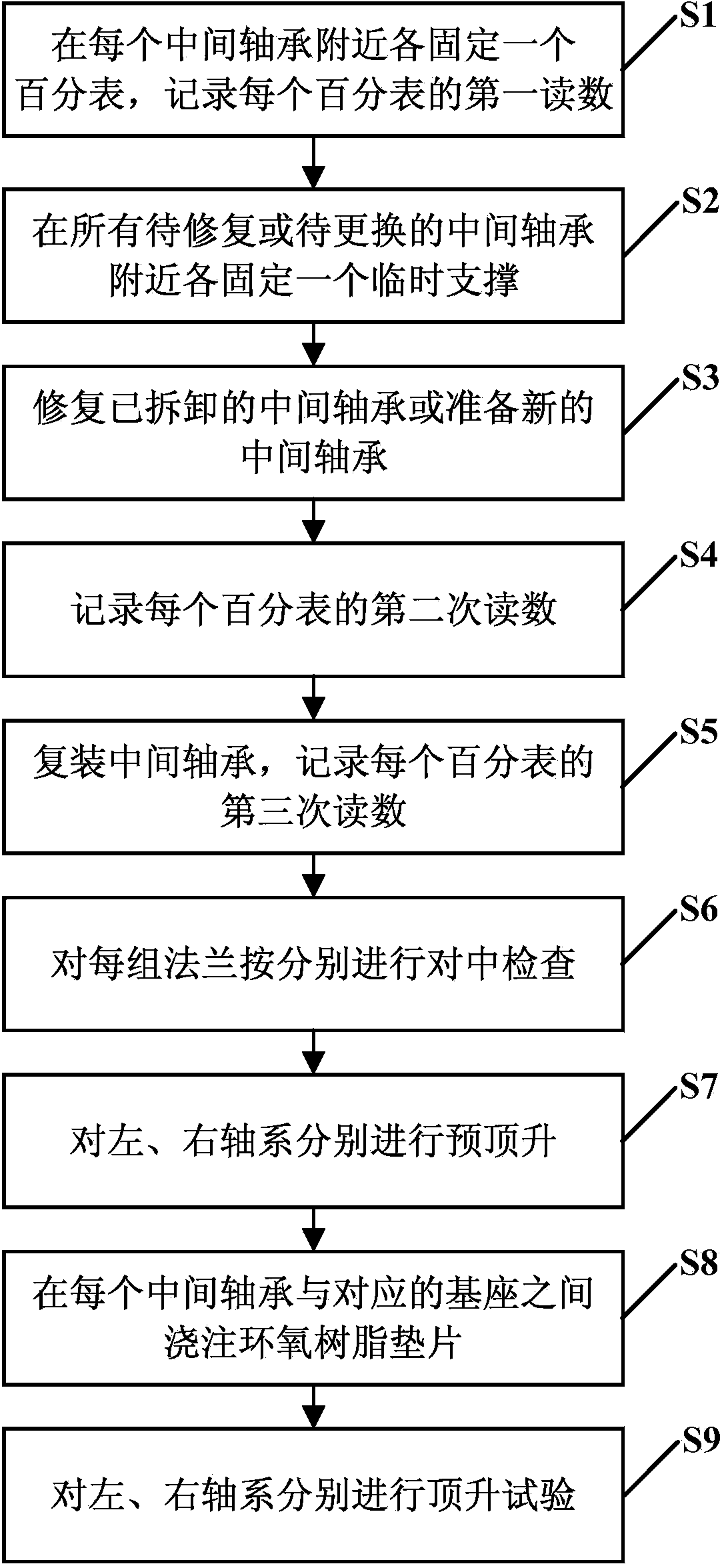

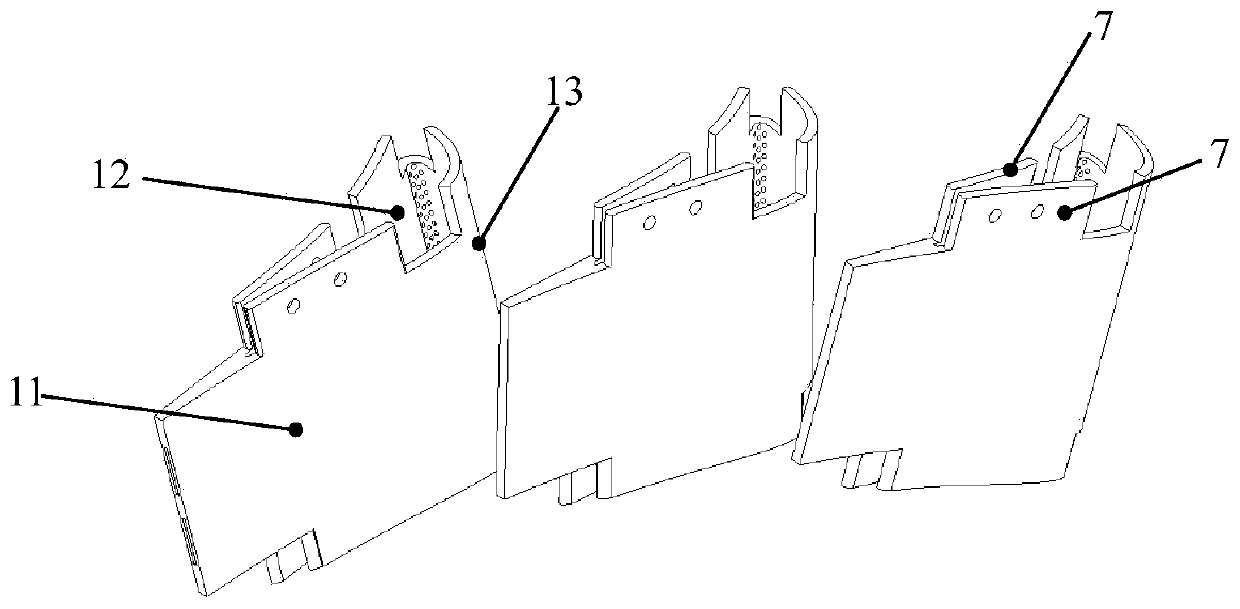

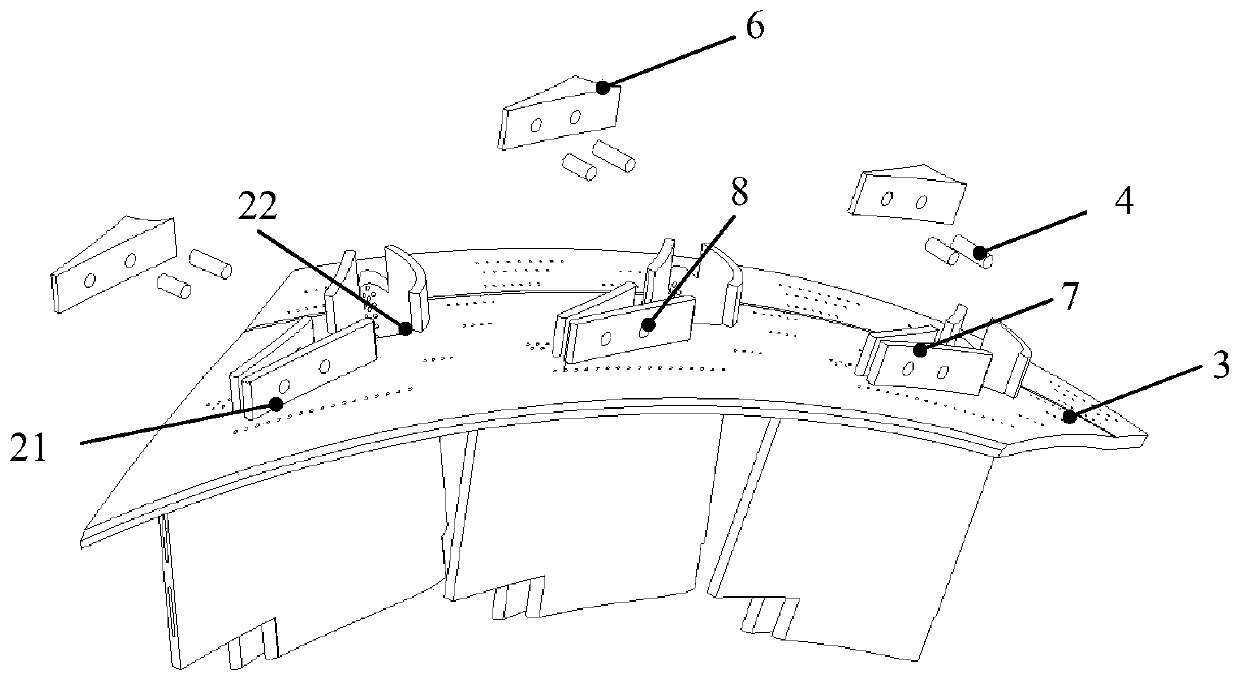

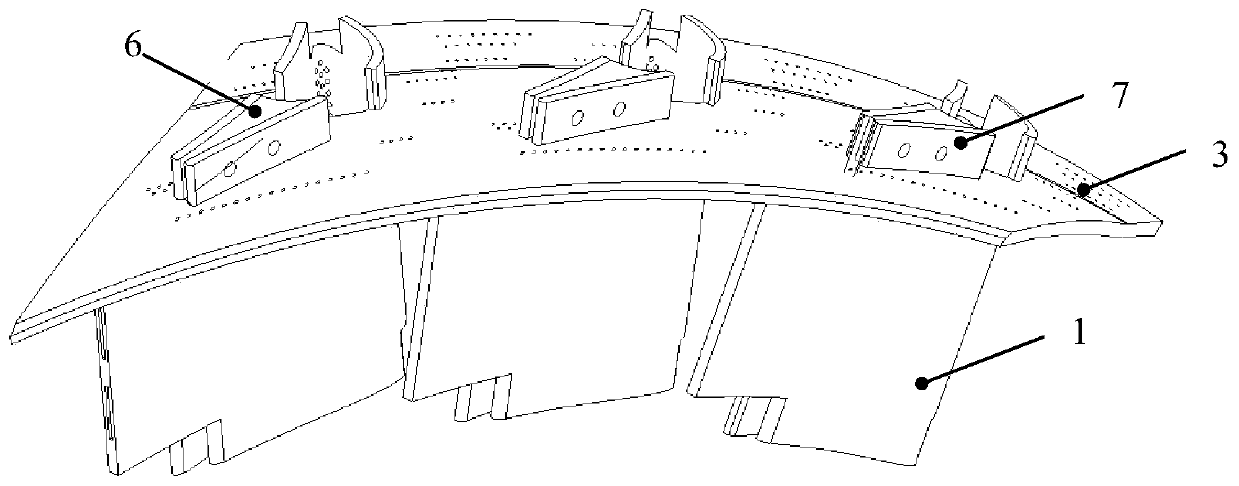

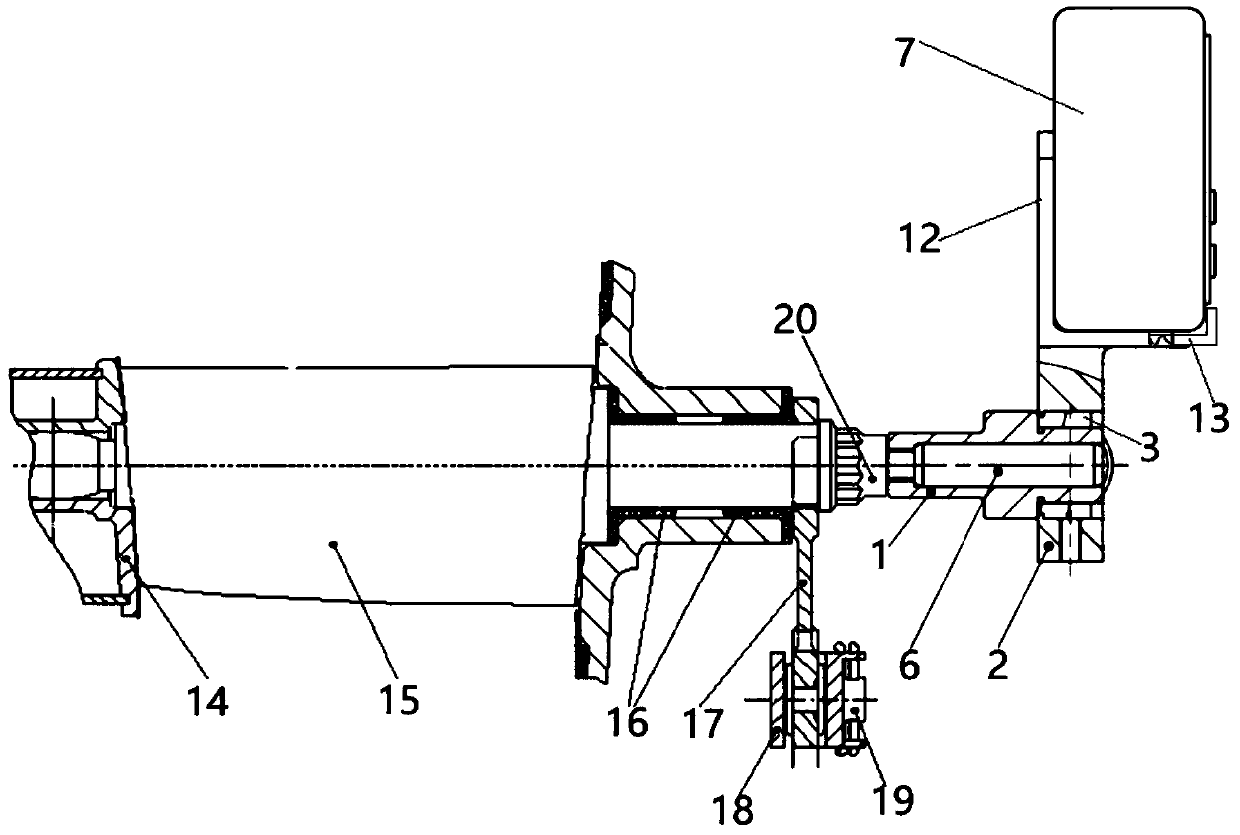

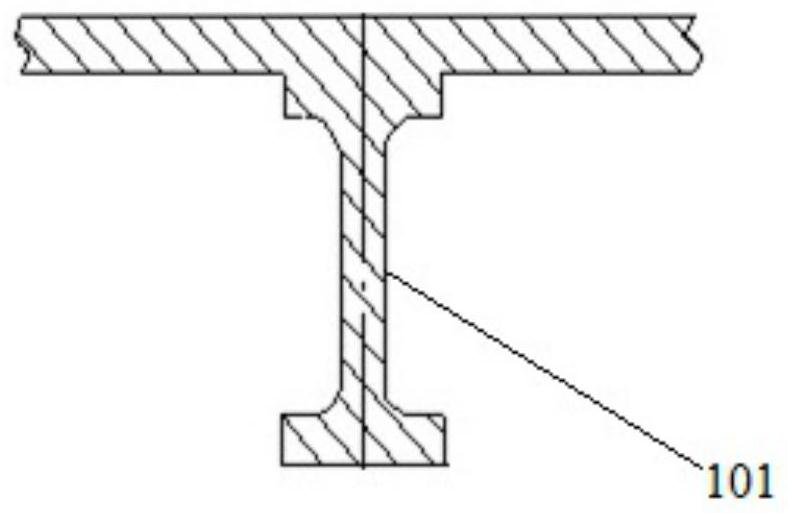

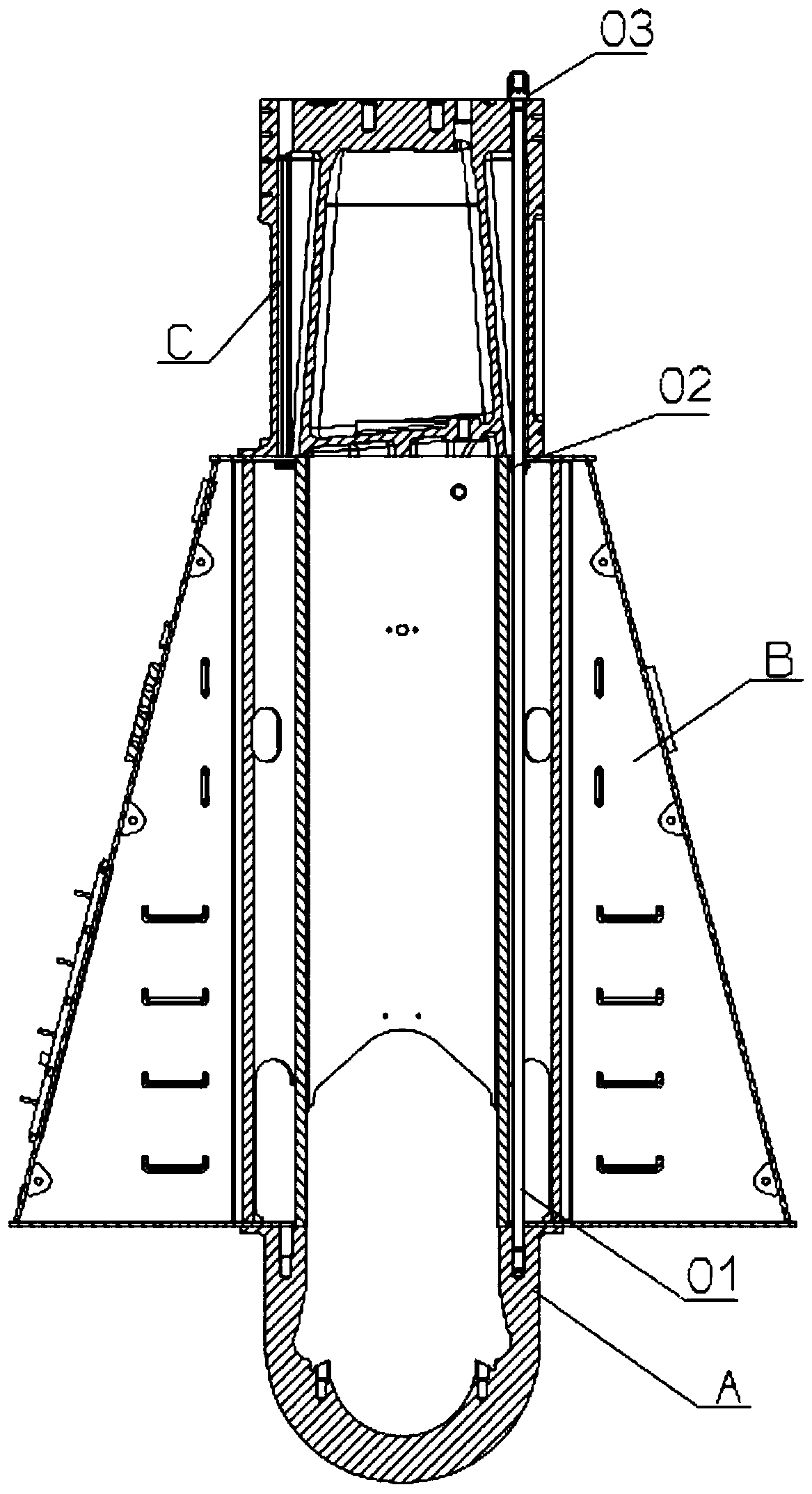

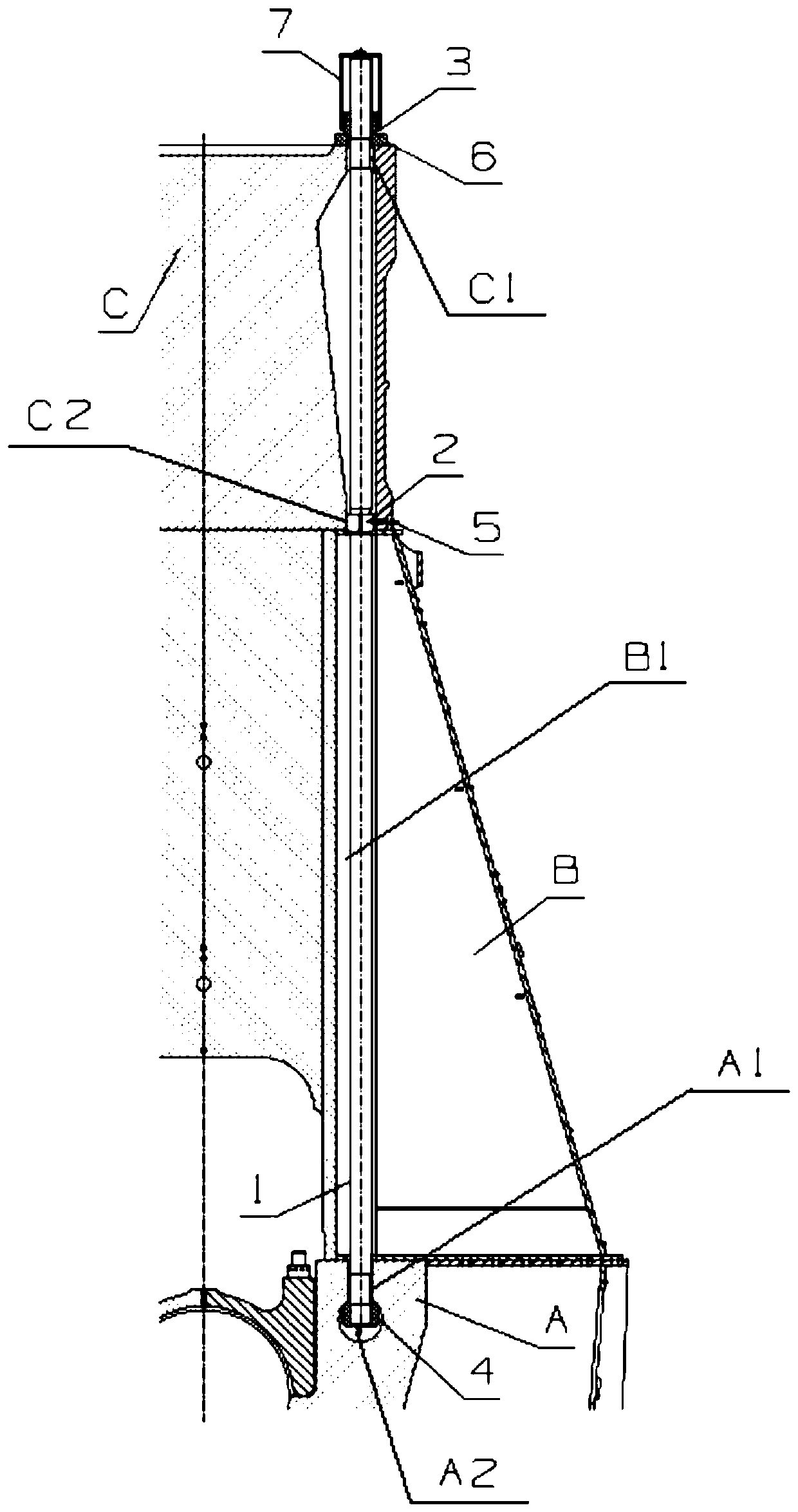

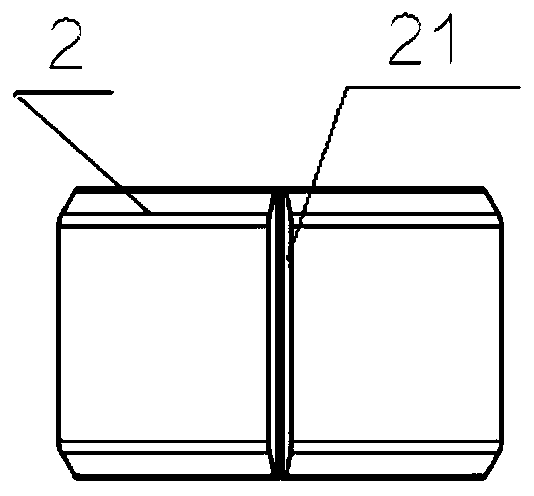

Method for repairing or replacing intermediate bearings in connecting state of ship shafting flanges

ActiveCN104386205ASimple construction processQuickly restore alignmentWatercraft hull designVessel partsEpoxyThrust bearing

The invention discloses a method for repairing or replacing intermediate bearings in a connecting state of ship shafting flanges, and relates to the field of ships. The method comprises the following steps: a dial indicator is fixed near each intermediate bearing, and temporary supports are fixed near all the intermediate bearings to be repaired or replaced; the detached intermediate bearings are repaired, or new intermediate bearings are prepared; the intermediate bearings are remounted; each set of flanges is centered; the pre-jacking is performed for a left shafting and a right shafting; epoxy resin gaskets are cast between the intermediate bearings and corresponding bases; and the jacking test is performed for the left shafting and the right shafting. The method can reduce the workload of detaching and remounting the shafting flanges, can simplify the shafting centering construction technology process in the remounting of the intermediate bearings, and enables quick recovery of the shafting centering state after the remounting of the intermediate bearings, so that the risk of incapability of recovering the centering state of the shafting after the disconnection of the flanges is effectively prevented, and the risk of wastes of base panels of gear boxes with thrust bearings inside is further prevented.

Owner:WUCHANG SHIPBUILDING IND

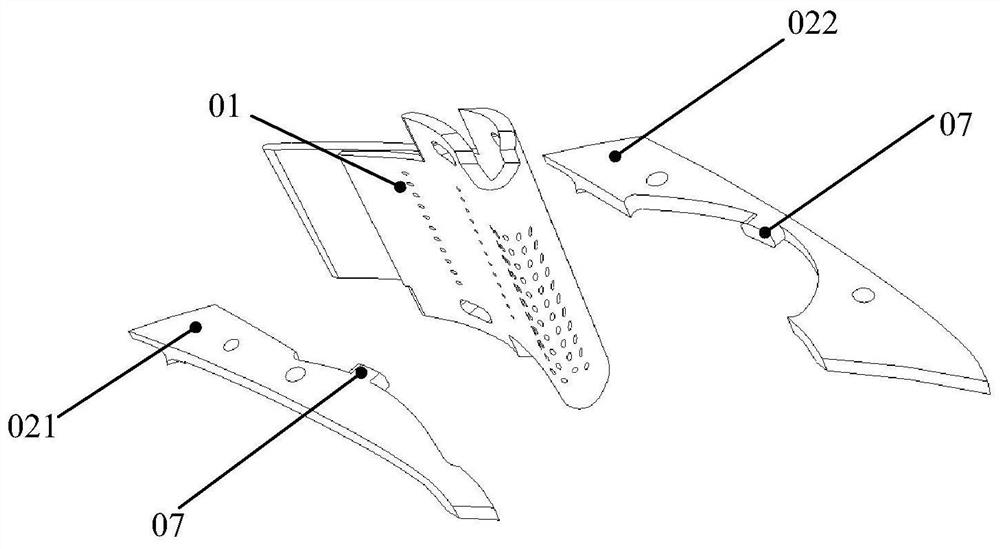

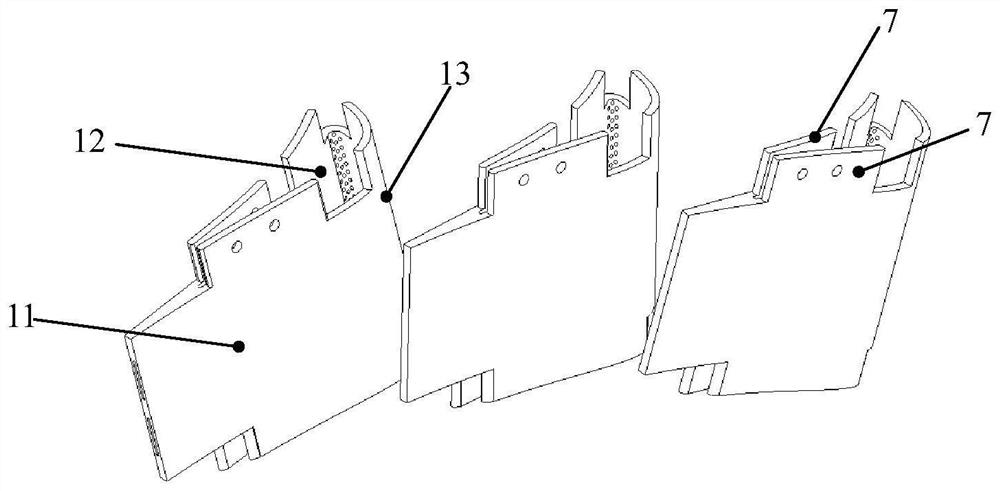

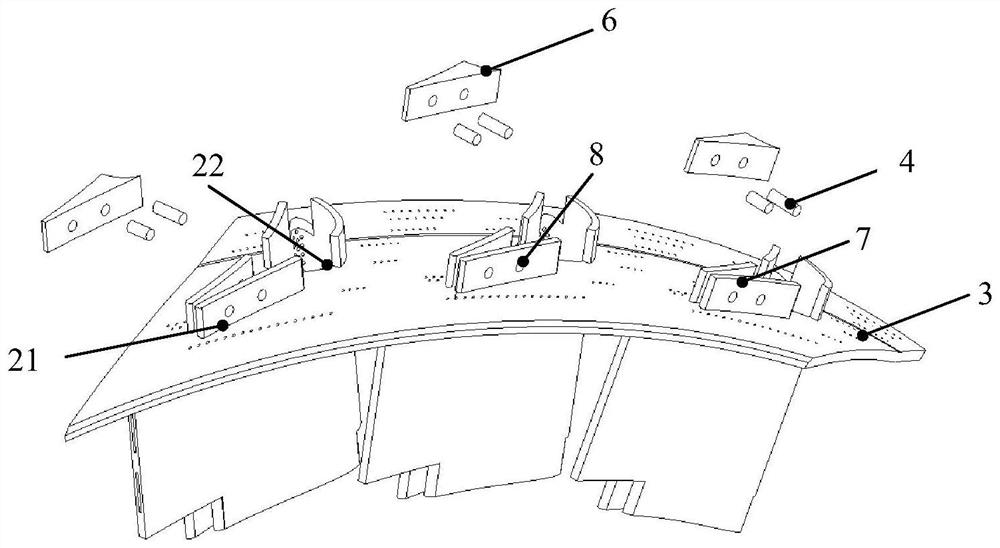

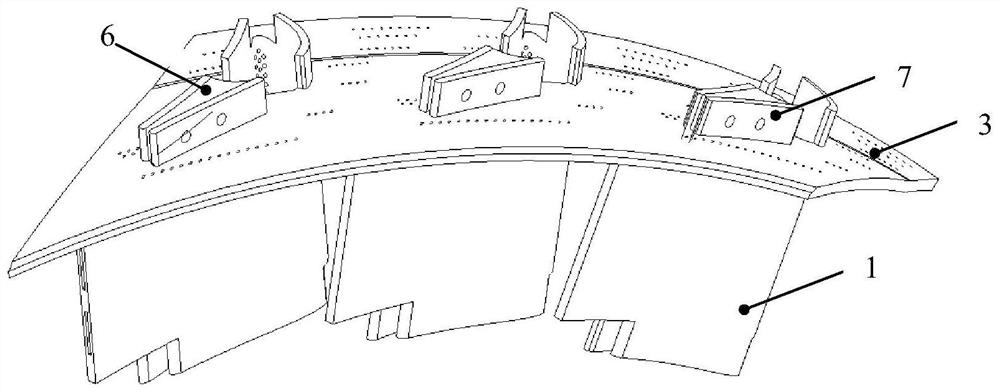

Aero-engine ceramic matrix composite fixation guider blade structure and molding method thereof

ActiveCN110966049AAvoid the defects of insufficient strengthGood workmanshipStatorsMachines/enginesEngineeringTurbine

The invention belongs to the technical field of preparation of an aero-engine fixation guider, relates to an aero-engine ceramic matrix composite fixation guider blade structure and a molding method thereof, and is to overcome the structural defects that an existing CMC guider blade prefabricated body is unreasonable in design and poor in blade root strength. A turbine guider blade manufactured in an integrated assembly mode comprises multiple stages of guide blades, parts are integrally assembled in a riveting mode, and an assembly structure adopts a SiC ceramic matrix to achieve welding; aneffective space between an upper edge plate and an outer casing is fully utilized, the blade body and the upper edge plate are installed and positioned through limiting rivets and a limiting table, the SiC ceramic matrix is deposited on the whole product through the CVI technology, and integrated preparation is completed; by means of the structure, the complex SiC / SiC multi-connected high-pressure guide blade has good manufacturability, the edge plate and the blade are easier to manufacture and more reliable to install, and the dimensional precision of a final product is easier to guarantee;and the structure can be fully applied to medium-sized and large-sized engines and five-generation engines.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

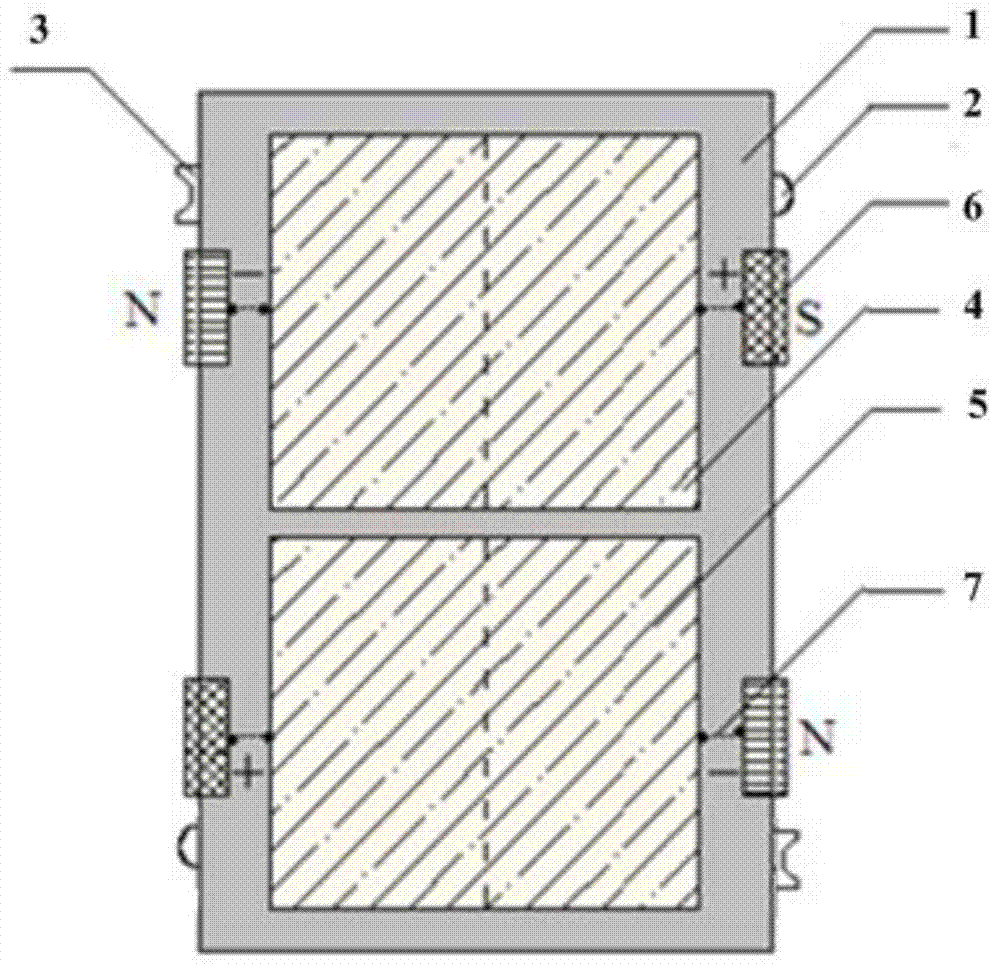

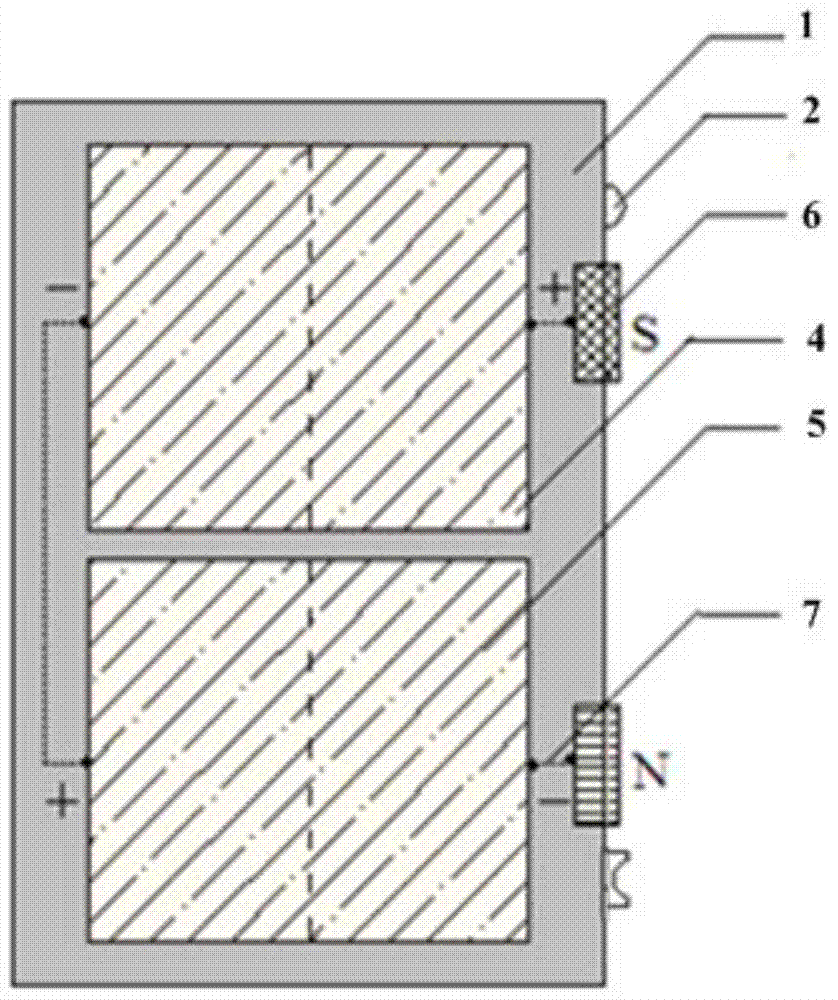

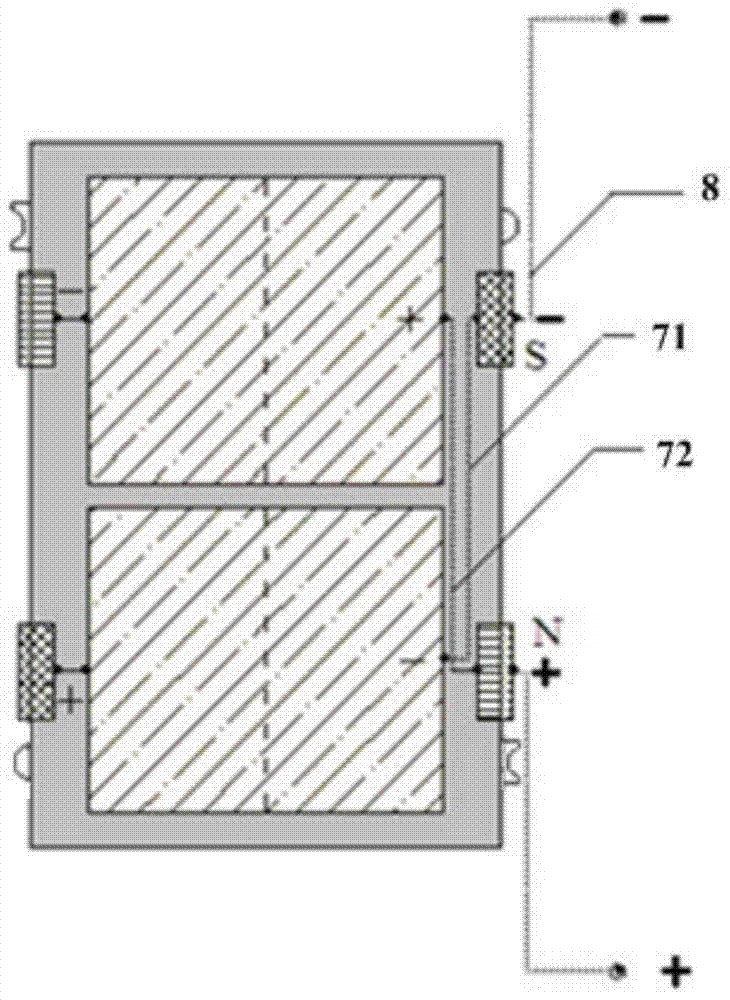

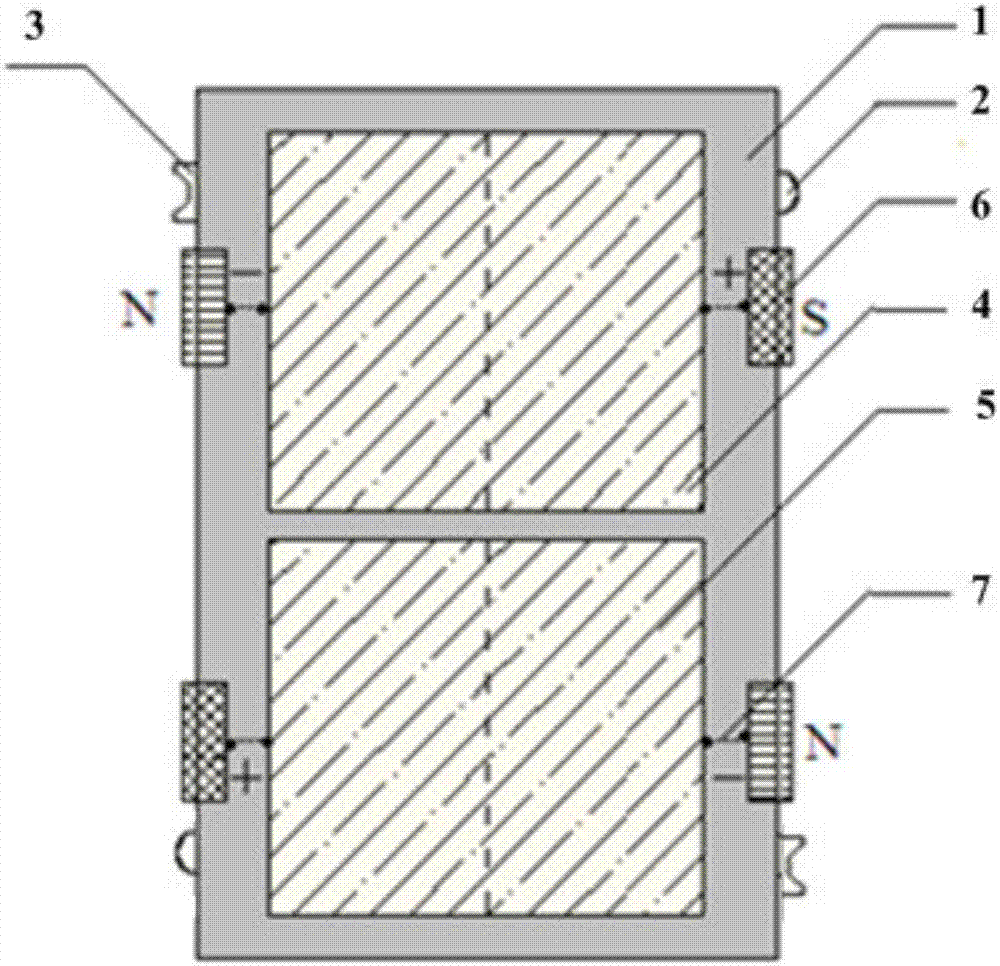

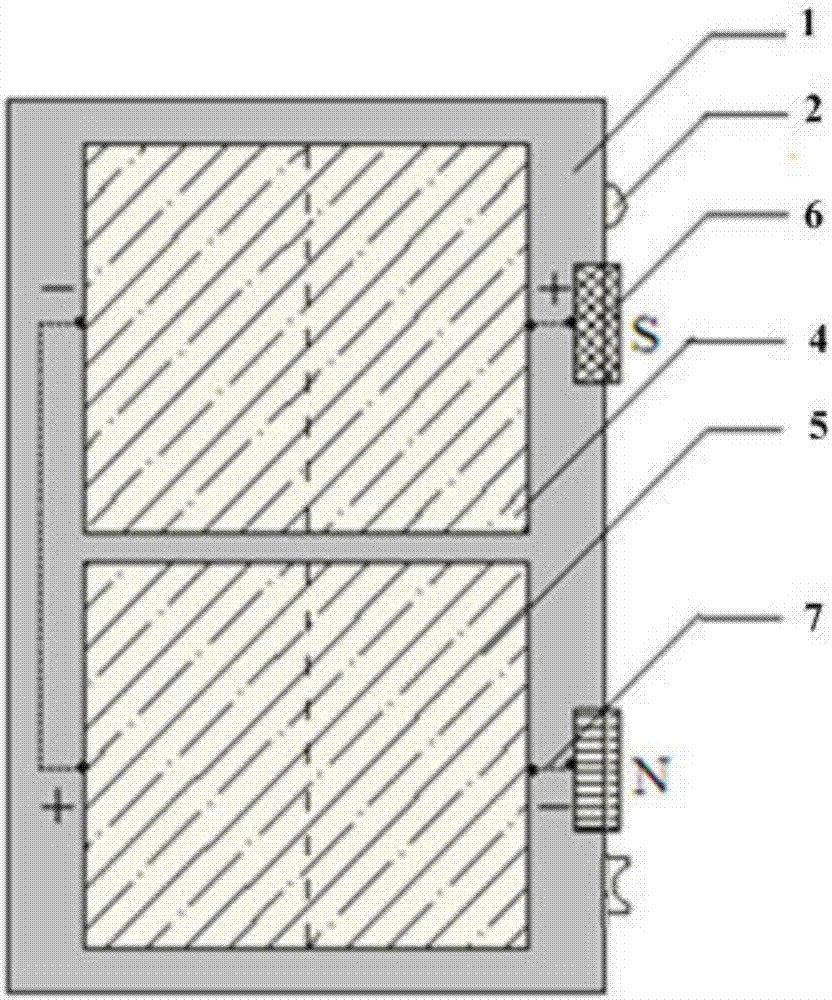

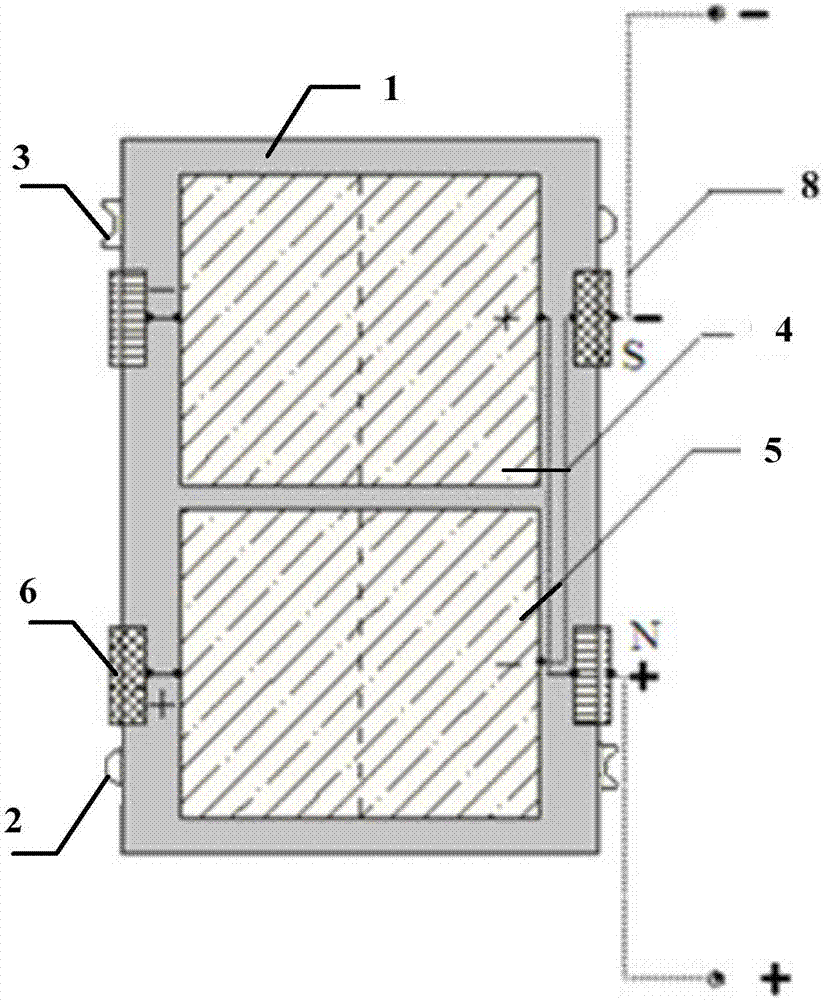

Solar battery packaging sheets and solar battery components

ActiveCN104506131AAvoid the risk of obsolescenceEnable connectivityPhotovoltaicsPhotovoltaic energy generationElectrical batteryMagnet

The invention discloses a solar battery packaging sheet. The solar battery packaging sheet comprises a packaging bottom plate, a first series battery stack, a second series battery stack and magnets, wherein the first series battery stack and the second series battery stack are independently packaged on the packaging bottom plate; the positive electrode of the first series battery stack and the negative electrode of the second series battery stack are positioned on the identical side of the packaging sheet; the magnets are respectively embedded to the two sides of the packaging sheet; the edges of the magnets are positioned at the outer parts of the edges of the packaging sheet; the output electrodes of the first series battery stack and the second series battery stack are respectively connected with the magnets beside the series battery stacks according to different requirements. The invention further provides another three solar battery packaging sheets and solar battery components comprising the solar battery packaging sheets. The packaging sheets and the battery components provided by the invention can meet different requirements on power of users, and are small in size, convenient to carry and low in cost.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

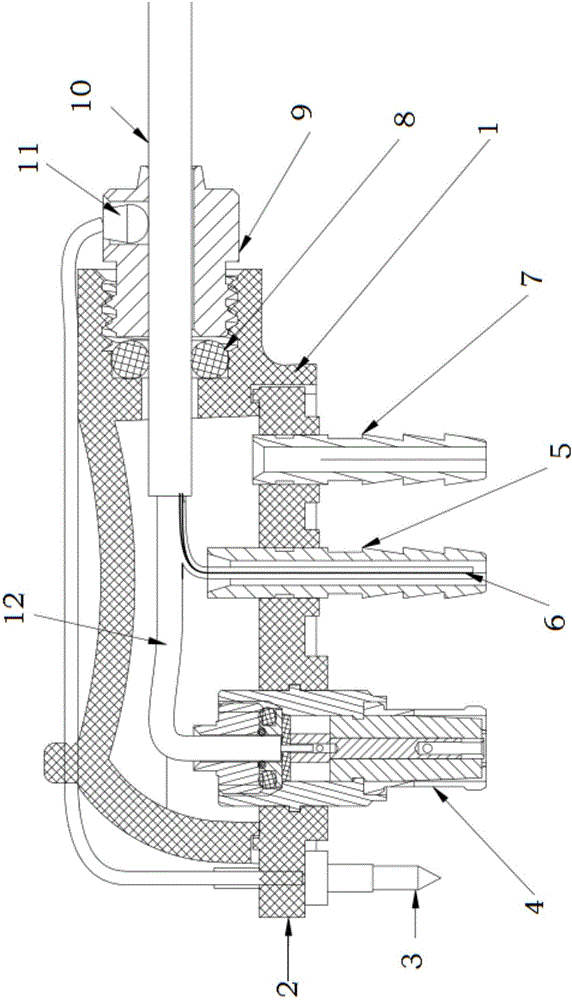

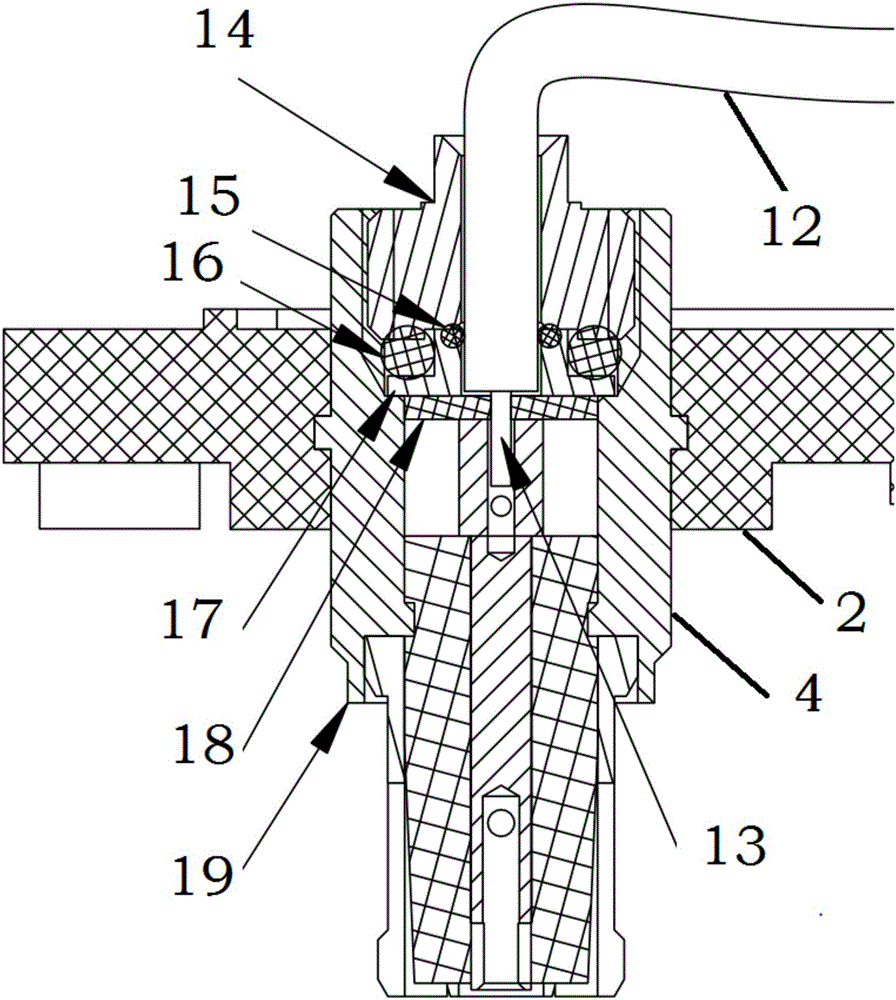

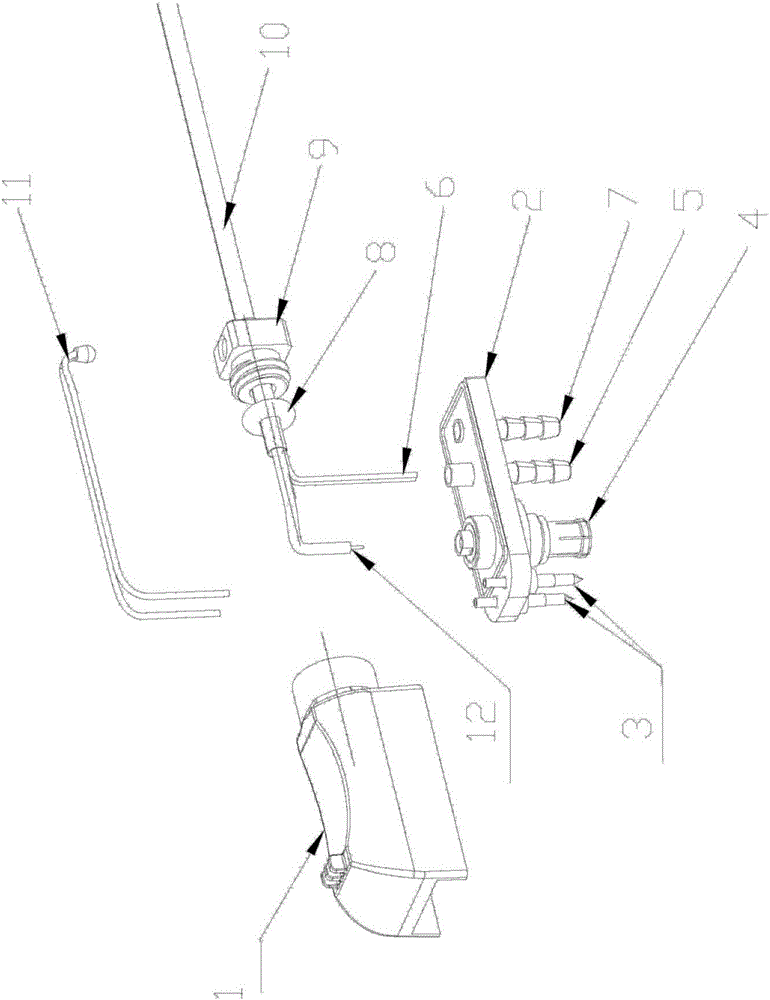

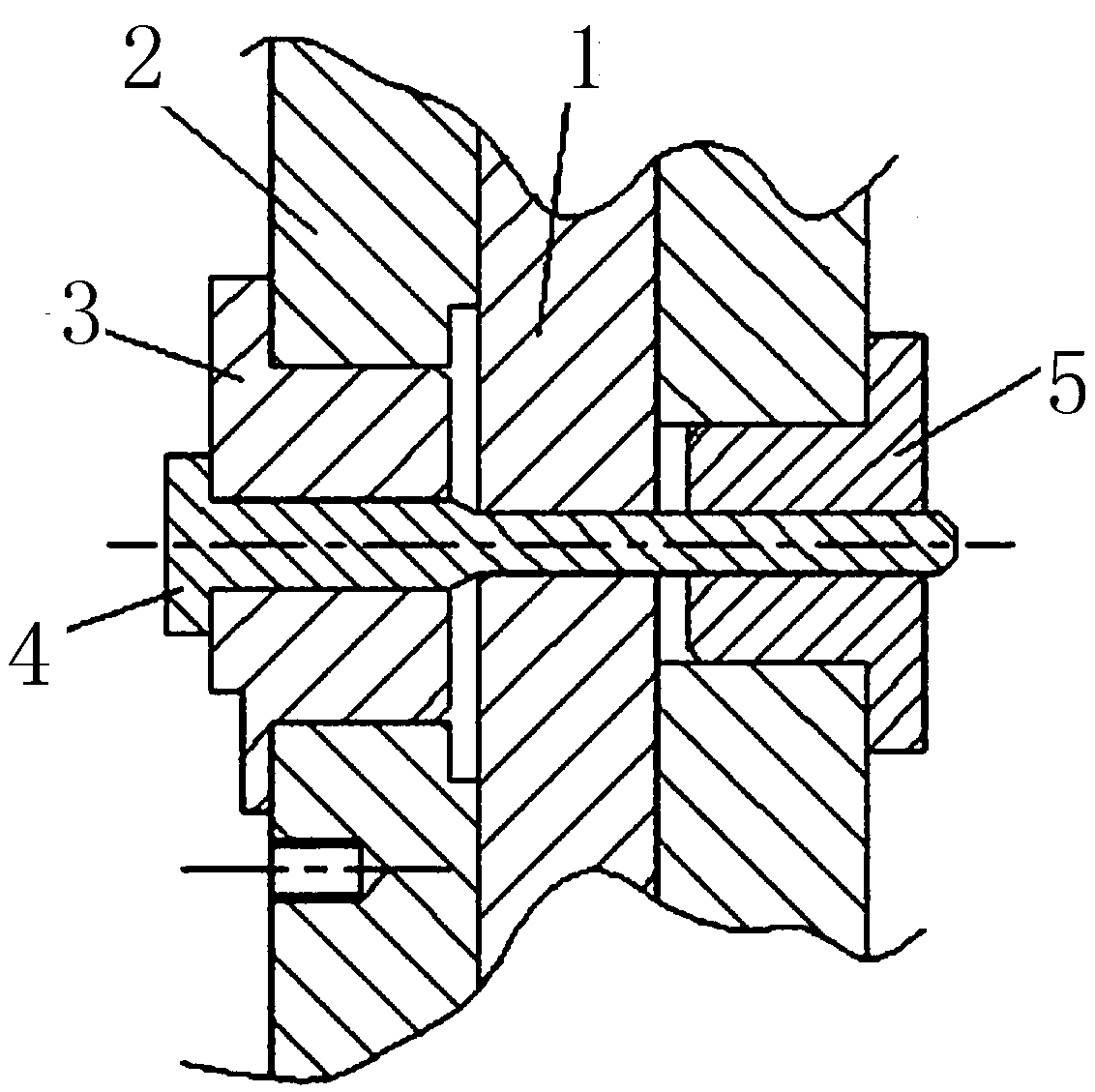

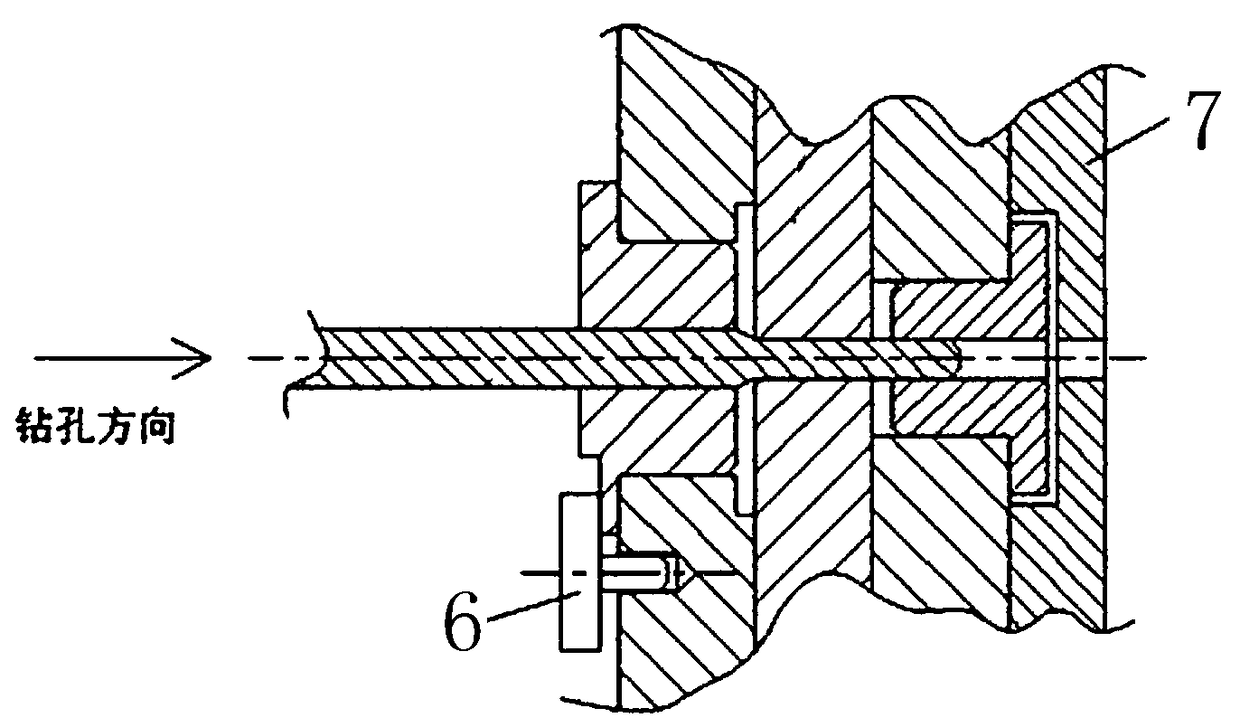

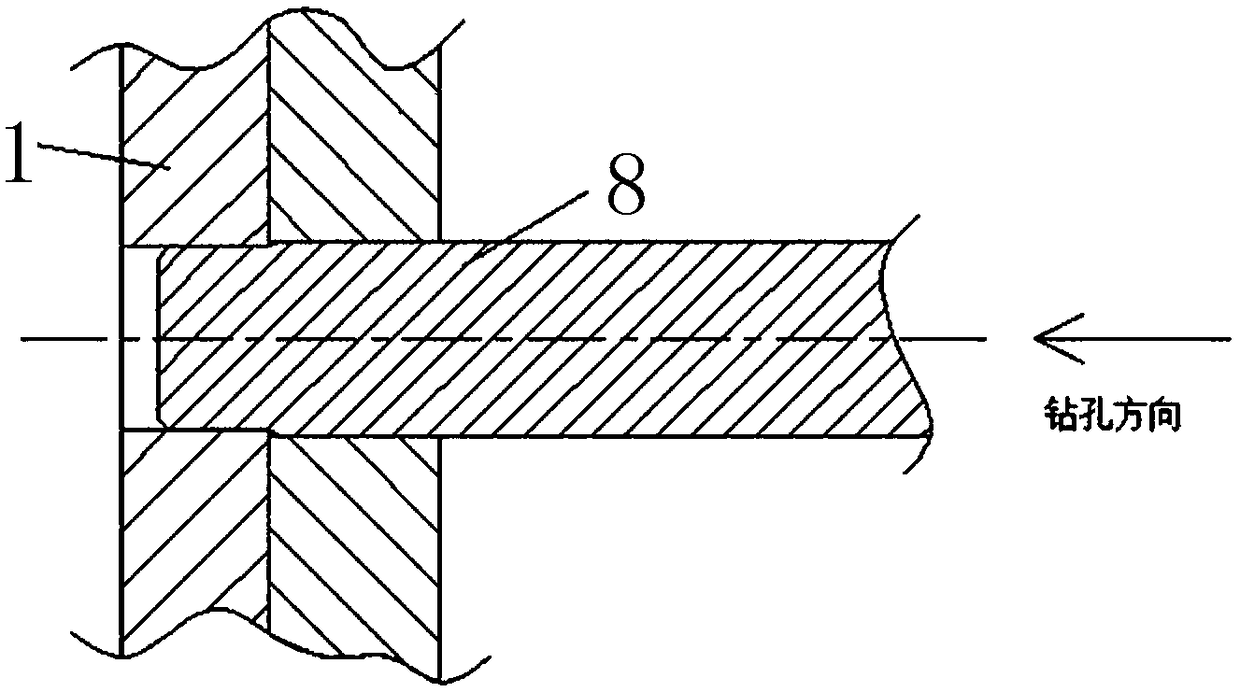

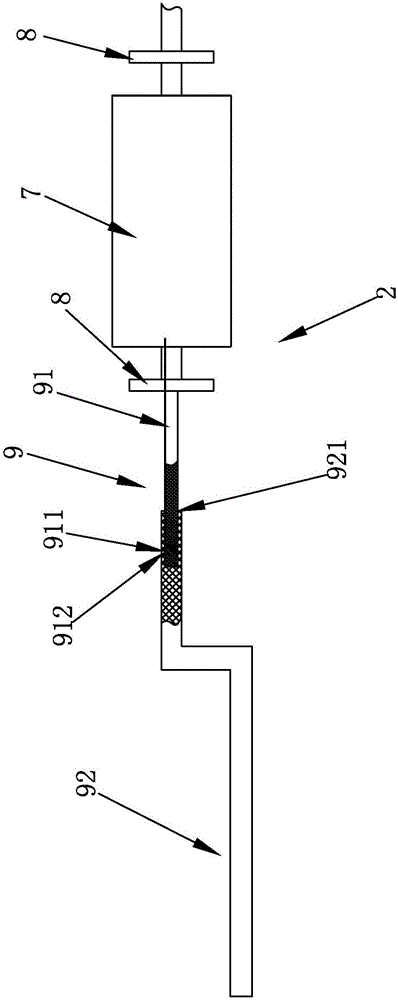

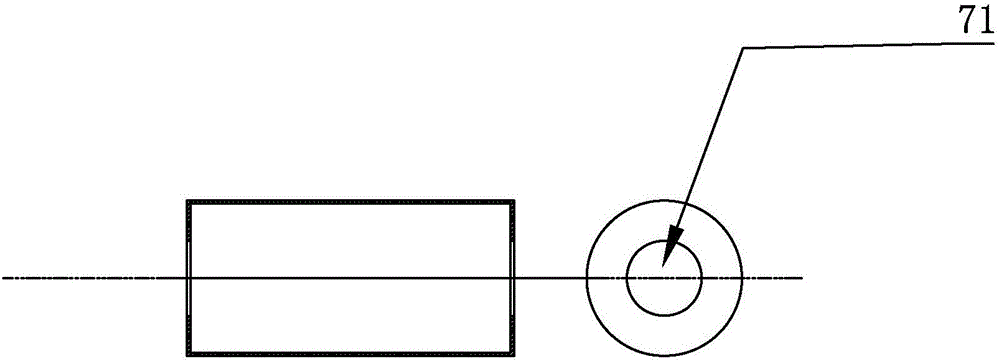

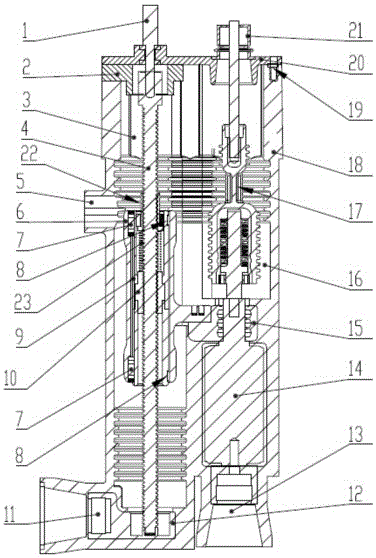

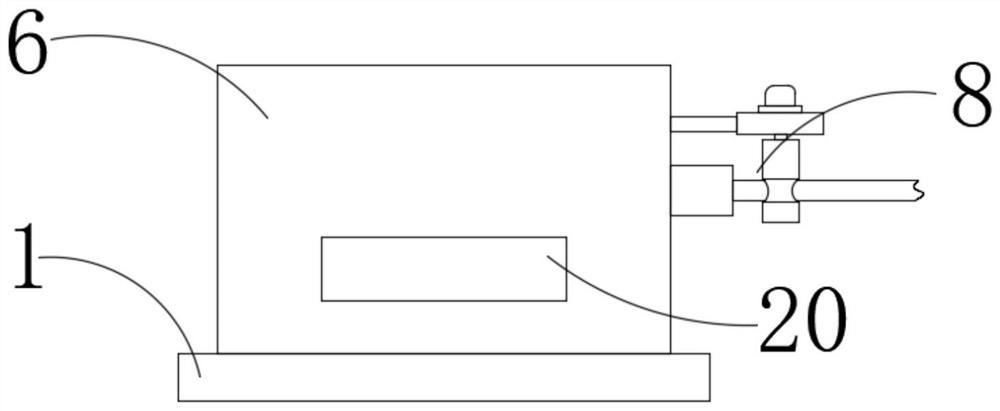

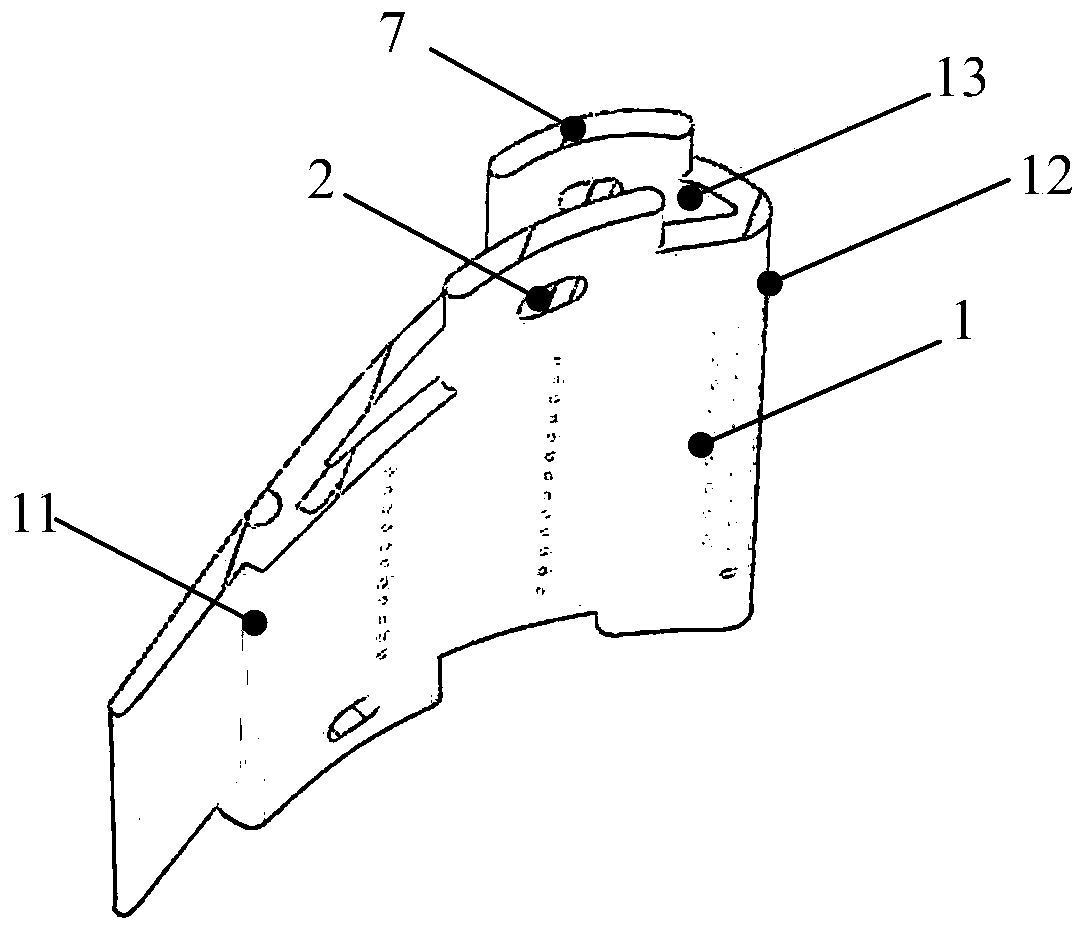

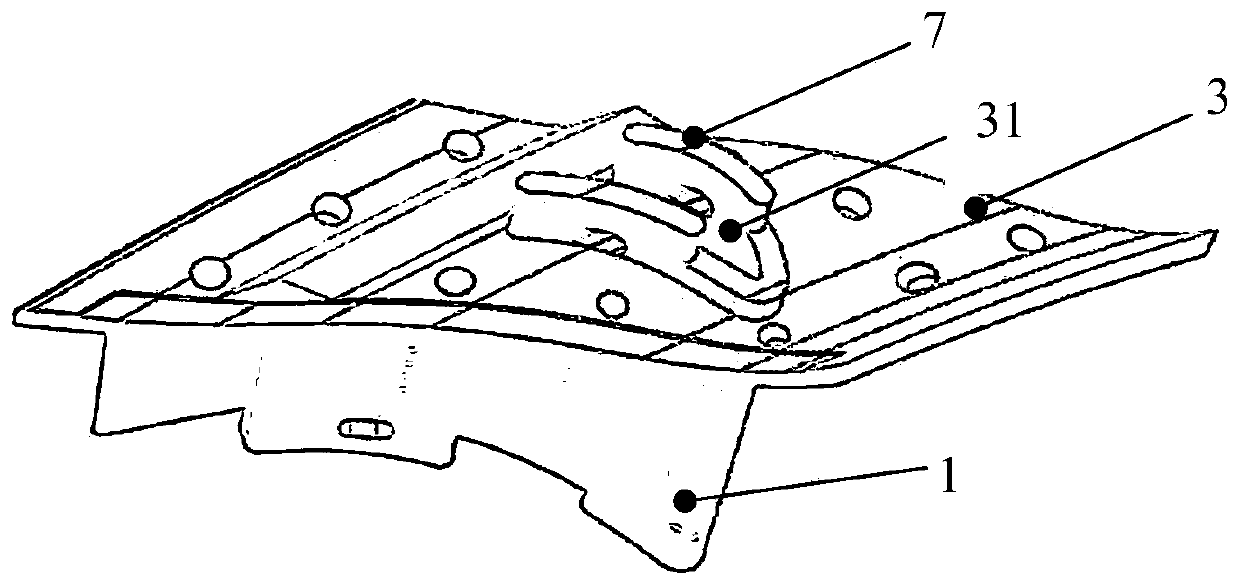

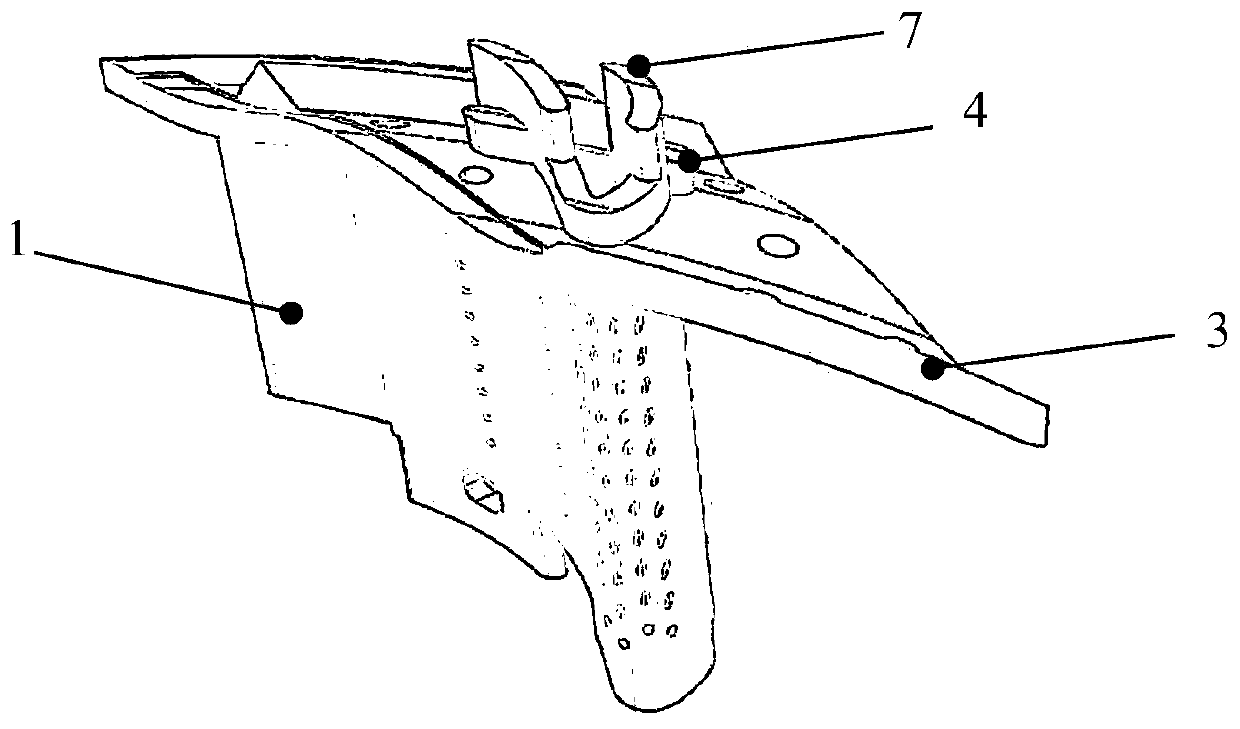

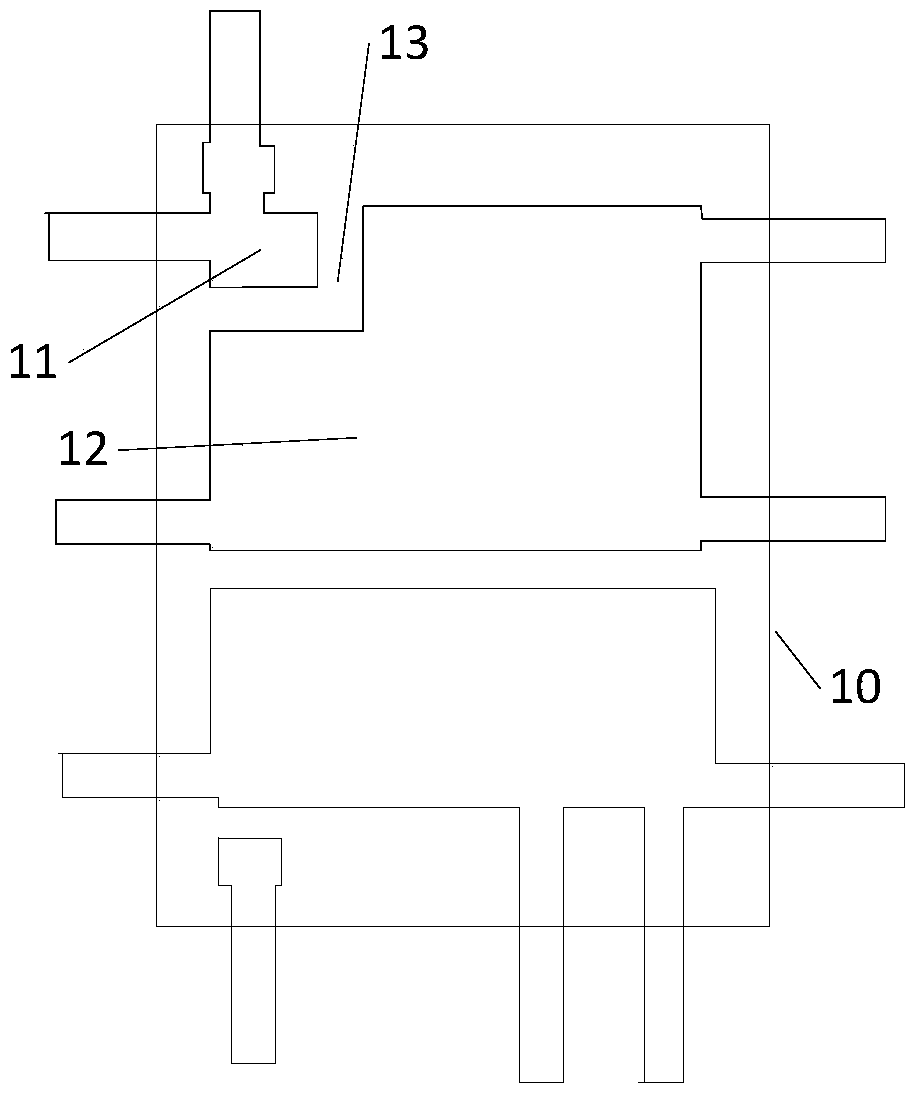

Ablation needle water tank sealing structure

ActiveCN106321987AReduce weightSimple welding processPipesSurgical instruments for heatingAgricultural engineeringWelding process

An ablation needle water tank sealing structure is characterized in that a water tank (1), a water tank cover plate (2), a nut (9) and a rod sleeve (10) are included; the water tank (1) and the water tank cover plate (2) are in sealed connection; the rod sleeve (10) stretches into the water tank (1); the nut (9) is arranged between the rod sleeve (10) and the water tank (1); the nut (9) is in threaded connection with the water tank (1); and a rod sleeve sealing ring (8) is arranged at the connecting position of the nut (9) and the water tank (1). According to the ablation needle water tank sealing structure, the welding process is simplified, the weight of the water tank is reduced, the sealing reliability is increased, and the production efficiency is improved.

Owner:CANYON MEDICAL INC

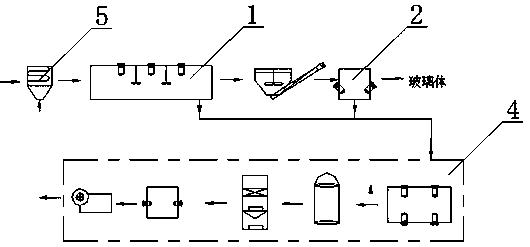

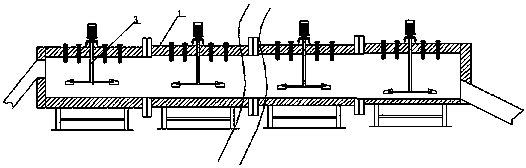

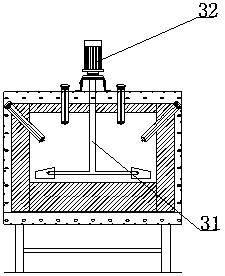

Solid and liquid hazardous waste plasma cracking and vitrification disposal equipment and solid and liquid hazardous waste plasma cracking and vitrification disposal method

The invention aims to provide solid and liquid hazardous waste plasma cracking and vitrification disposal equipment and a solid and liquid hazardous waste plasma cracking and vitrification disposal method, wherein a glass body is hung to a wall to block and scrap and the work efficiency is high. The equipment comprises a plasma incineration cracking furnace for pre-treating reduction of hazardouswaste and a vitrification melting furnace which vitrifies the reduced ash. A discharge port of the plasma incineration cracking furnace communicates to a feed inlet of the vitrification melting furnace. Reduction and vitrification are carried out successively.

Owner:OUKA ENVIRONMENT PROTECTION SCI & TECH SHANDONG PROV

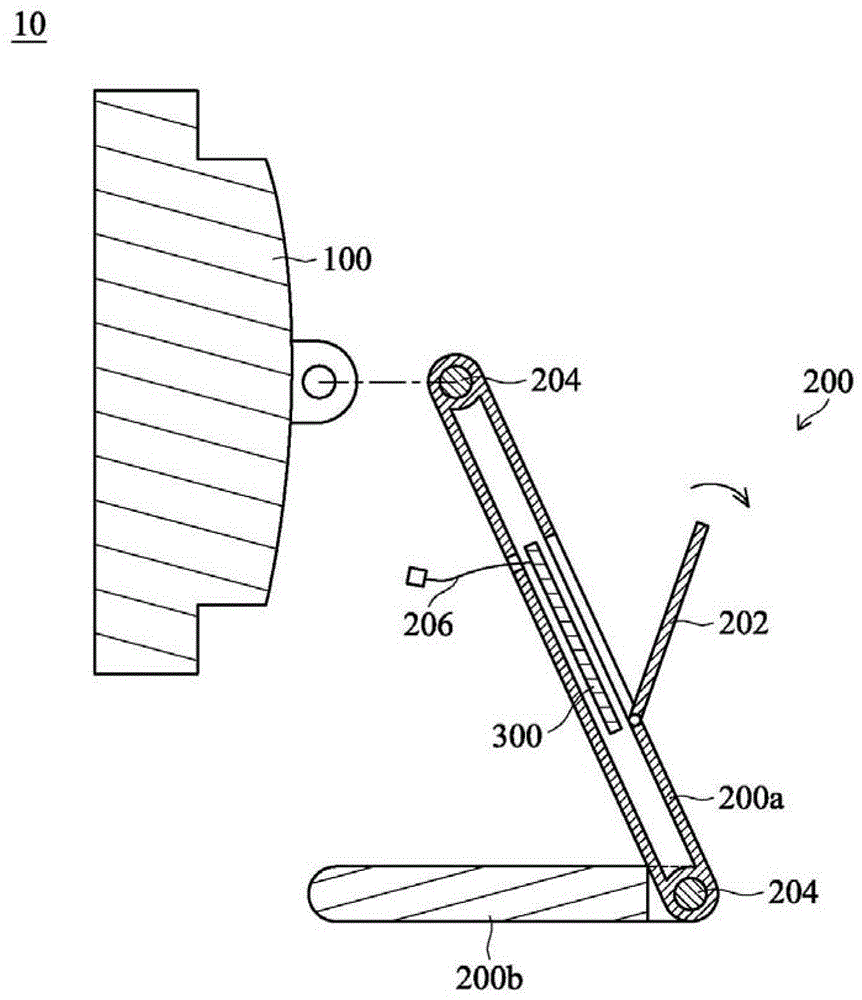

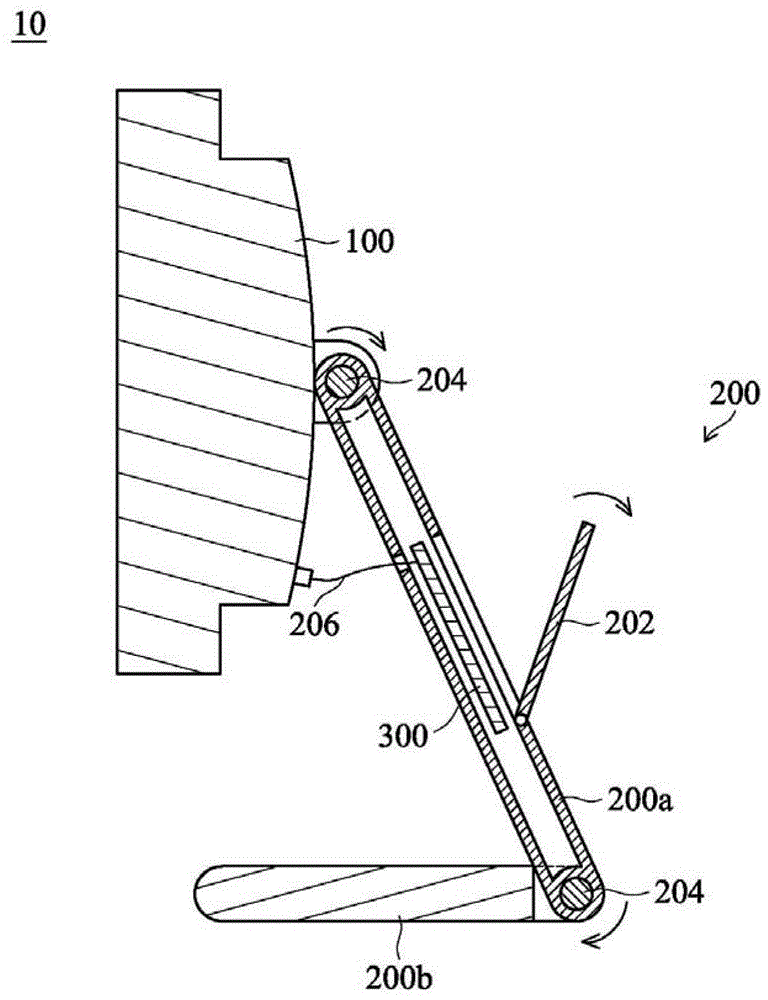

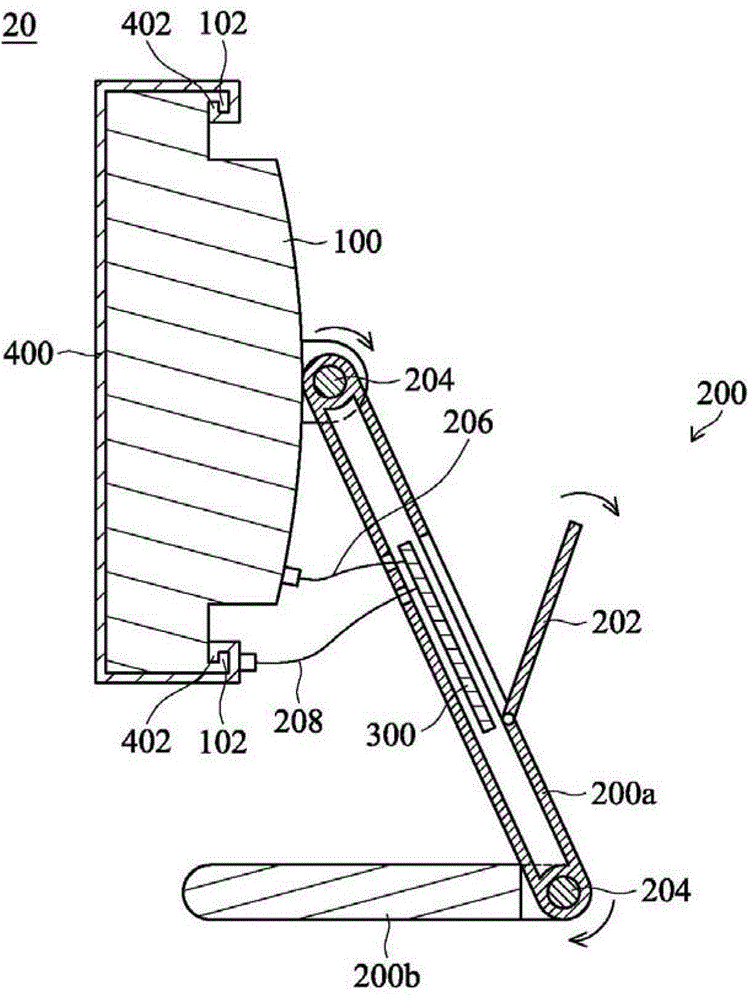

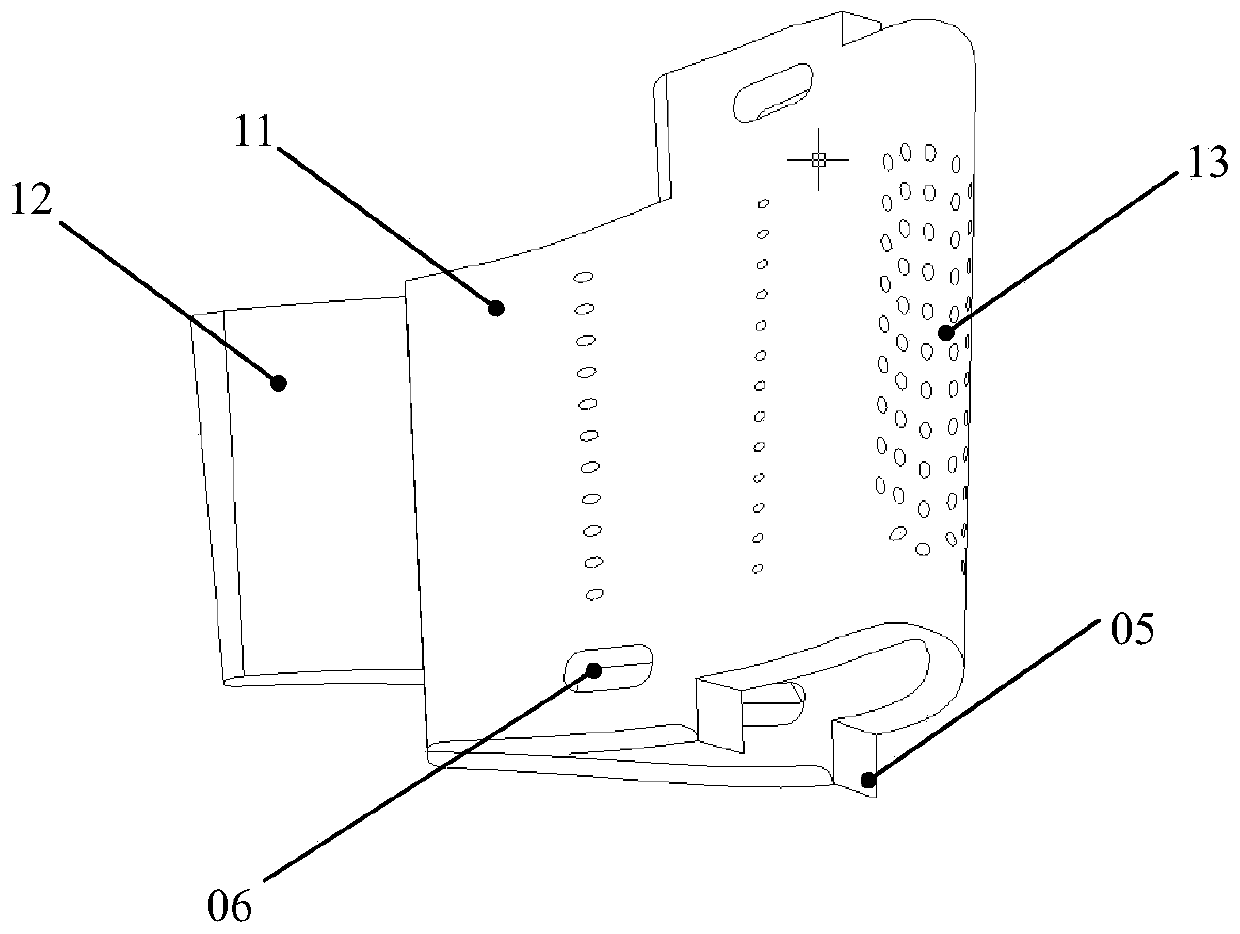

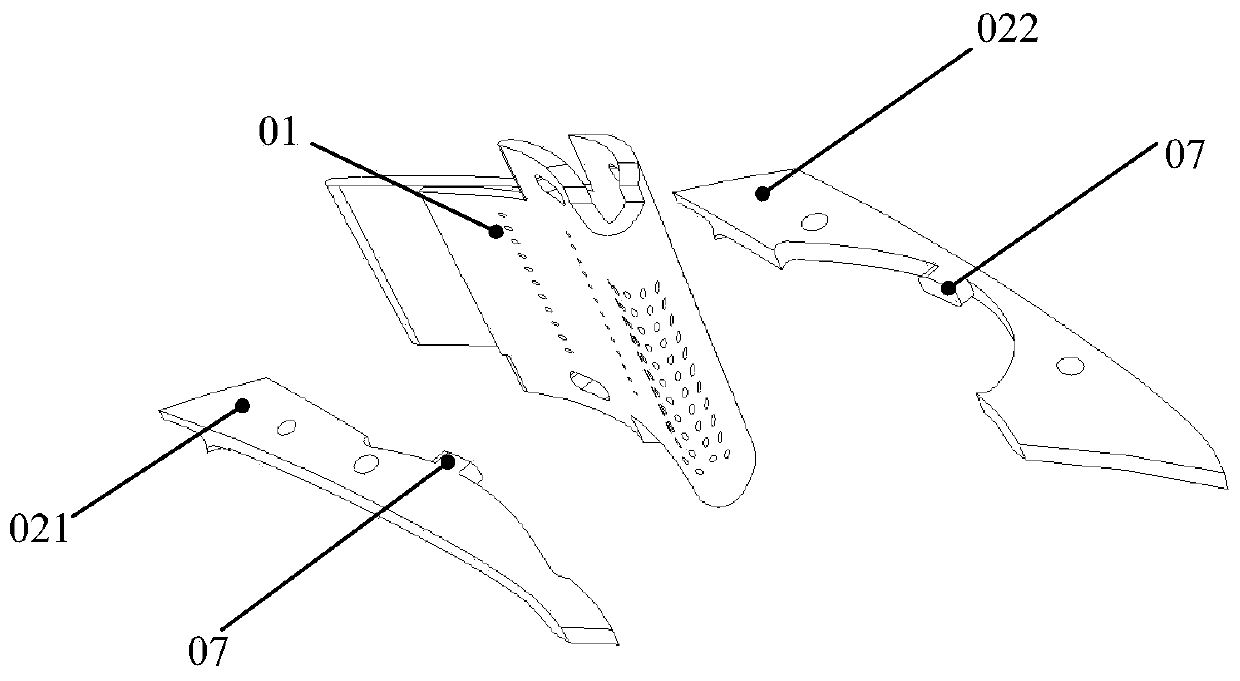

Electronic device

InactiveCN104035488AAvoid the risk of obsolescenceEasy maintenanceDigital data processing detailsComputer moduleDisplay device

The invention discloses an electronic device. The electronic device comprises a display, a support structure and a host plate. The support plate is used for supporting the display and is provided with a covering body. The display is detachably pivoted to the support structure. The host plate is arranged in the support structure and is approximately corresponding to the covering body. According to the invention, the host plate of the electronic device is arranged in the support structure provided with a covering body which can be opened, so that the host plate is separated from the display, the risk of scrapping is avoided for the whole electronic device, and the maintenance and the replacement of the host plate are convenient. In addition, the display is detachably pivoted to the support structure, and a touch control module is mounted in an external-mounting manner, so that various requirements of users can be met, the software and hardware of an original electronic device can be retained so as to achieve more efficient resource application.

Owner:WISTRON CORP

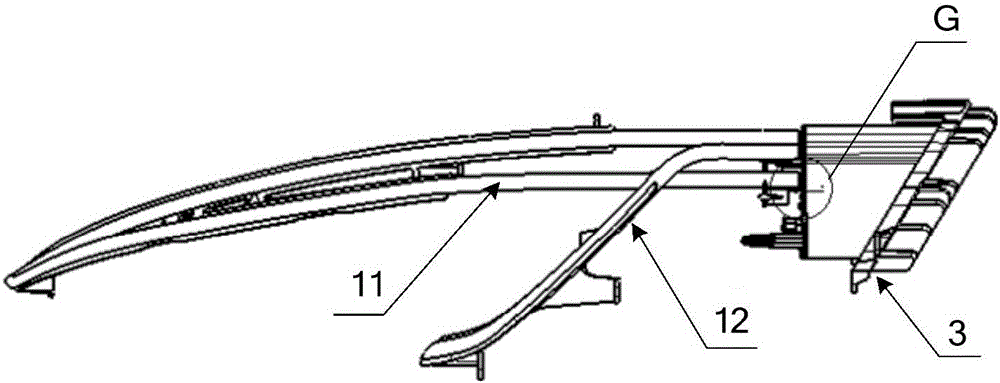

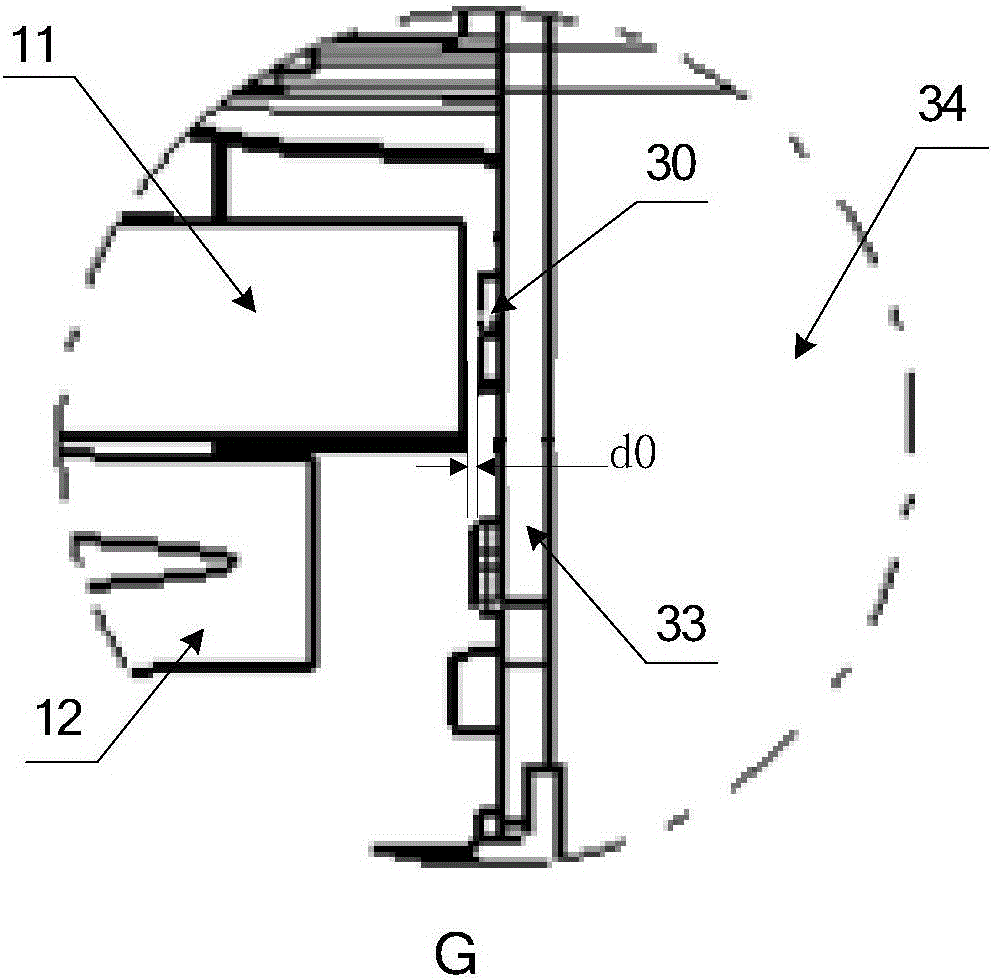

Light guide grading LED protection cover structure and light guide grading automotive lamp thereof

InactiveCN106122871ANot bruisedAvoid the risk of obsolescenceMechanical apparatusLighting heating/cooling arrangementsLight guideEffect light

The invention discloses a light guide grading LED protection cover structure and a light guide grading automotive lamp thereof, relates to arrangement of a common car lighting or signal device, in particular to the light guide grading LED protection cover structure for protecting a light guide grading automotive lamp LED chip and an automotive lamp using the light guide grading LED protection cover structure. The light guide grading automotive lamp comprises a light guide for automotive lamp grading and a circuit board mounted with an LED chip in an adhering manner; an LED protection cover surrounding the LED chip is equipped on the LED chip side of the circuit board; the height H of the LED protection cover is equal to the sum of the height h of the LED chip and the minimum protective gap d; the length and width of the LED protection cover are greater than those of the LED chip and less than those of a light inlet surface of the light guide to ensure that the light inlet surface of the light guide does not touch the semiconductor chip of the LED chip under any condition and to protect the semiconductor chip of the LED chip from being damaged, so that the light guide collides with the LED chip due to automotive vibration or deformation of the light guide to finally cause the risk that the automotive lamp is integrally scrapped.

Owner:HASCO VISION TECHNOLOGY CO LTD

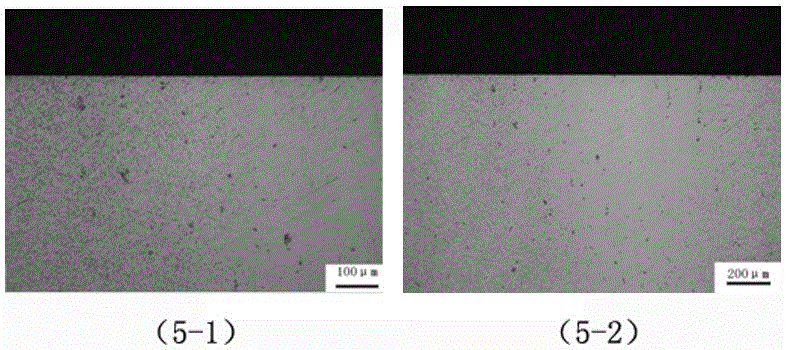

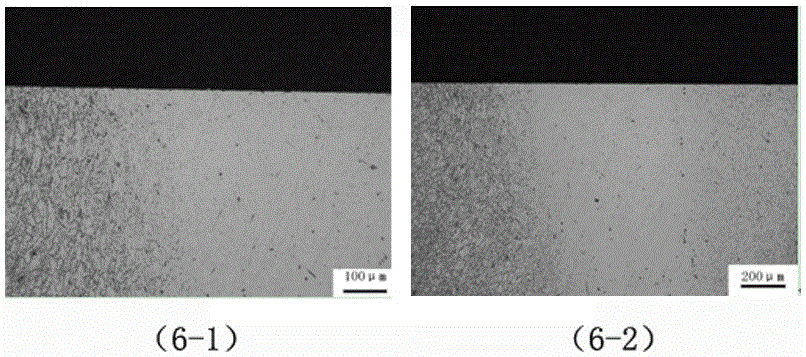

Technique for removing alumina-titanium dioxide coating of engine labyrinth disc type part

The invention provides a technique for removing an alumina-titanium dioxide coating of an engine labyrinth disc type part. The technique includes the steps that the engine labyrinth disc type part is immersed in a strong alkaline solution for 20-30 minutes by a hanging tool for chemical oil removal; the part which is subjected to chemical oil removal is sequentially washed with warm water at 40-50 DEG C and cold water; the washed part is immersed into concentrated nitric acid with the concentration of 345-520 g / L by the hanging tool for 6-24 hours, and the part is taken out every two hours to remove the alumina-titanium dioxide coating on the surface in a brushing mode; and the surface of the acid-immersed part is flushed till the alumina-titanium dioxide coating is completely removed. The technique can be widely applied to coating repair of the engine labyrinth disc part, the repairing period of the part is greatly prolonged, and the percent of pass is up to 100%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Aero-engine ceramic matrix composite fixed guider blade structure and forming method thereof

ActiveCN111102017AGood workmanshipEasy to prepareEfficient propulsion technologiesStatorsSmall engineEngineering

The invention relates to a fixed guider blade structure and forming, in particular to an aero-engine ceramic matrix composite fixed guider blade structure and a forming method thereof, and belongs tothe technical field of aero-engine fixed guider preparation. According to the aero-engine ceramic matrix composite fixed guider blade structure and the forming method thereof, a turbine guider blade is prepared in an integrated assembly mode, parts are integrally assembled in a riveting mode, an assembly structure adopts a SiC ceramic matrix to achieve welding, and therefore the defect that the strength of a blade root is insufficient due to a conventionally sewed and formed prefabricated body can be overcome; protrusions on a first lower edge plate and a second lower edge plate are directly riveted with the blade in a limiting mode and then riveted with a third lower edge plate and a fourth lower edge plate through riveting rivets, a SiC ceramic matrix is deposited on a whole product through a CVI technology, and therefore integrated preparation is completed; and in this way, the SiC / SiC high-pressure guide blade has good manufacturability, a margin plate and the blade are simpler toprepare and more reliable to install, and the structure can be fully applied to small engines such as civil turboshaft engines and turbojet engines.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

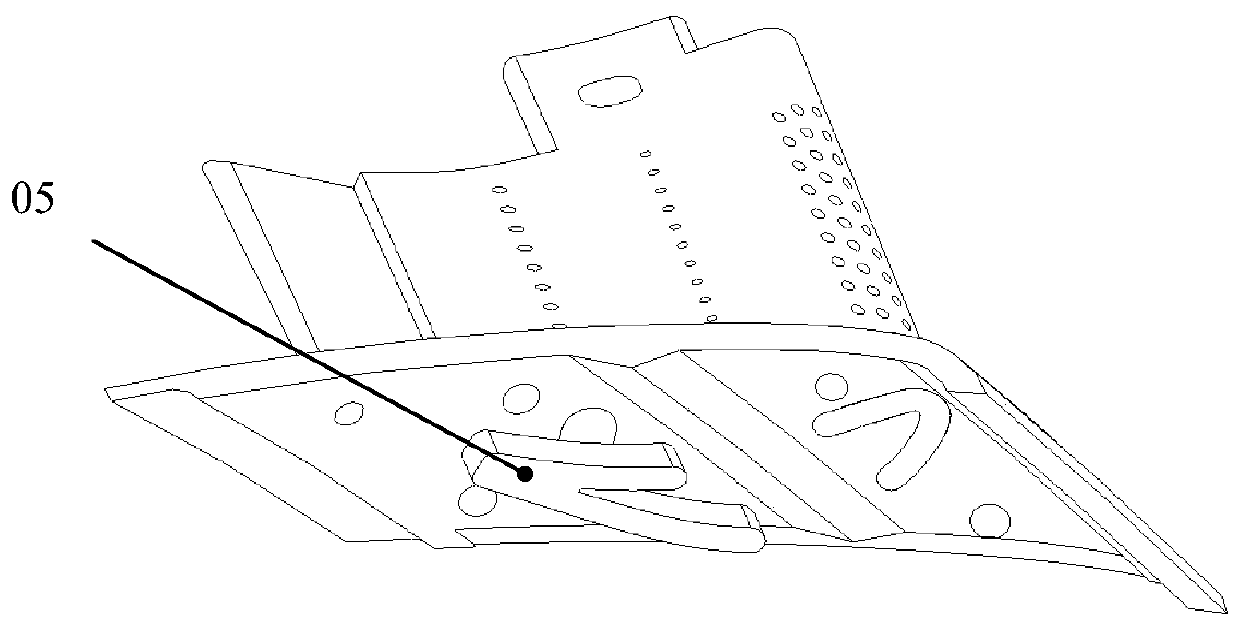

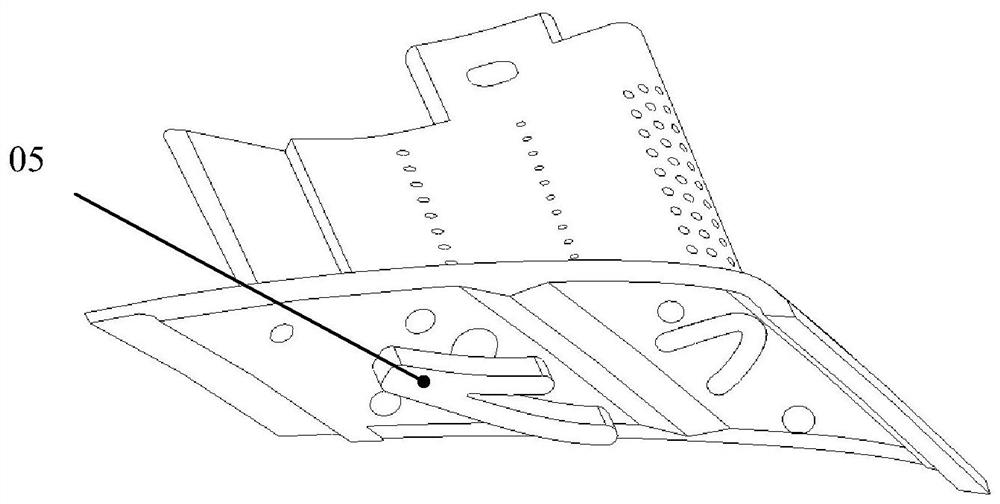

Method for machining a reverse hole of large sandwich blind hole structure of aircraft

InactiveCN108889985AAvoid the risk of obsolescenceInterlayer depth is not limitedDrill jigsBoring/drilling machinesEngineeringDrill

The invention relates to a processing method for a large sandwich blind hole structure reverse hole of an aircraft. The reverse hole processing is carried out through the steps of making an initial hole, positioning a drill template, reaming, making a final hole and inspecting, etc. After the operation of the large sandwich blind hole reverse hole, the coaxiality and the hole diameter of the holemeet the engineering requirements.

Owner:AVIC SAC COMML AIRCRAFT

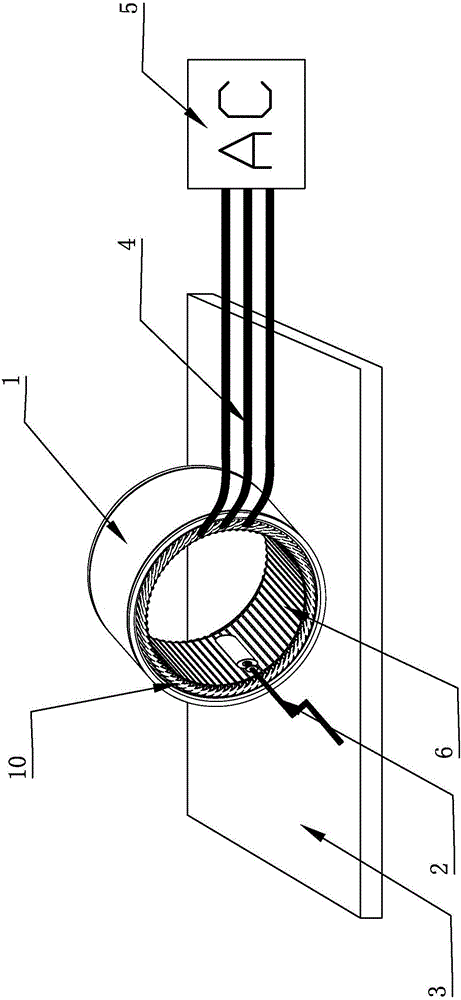

Three-phase AC motor stator winding coil mismatched wiring detection apparatus and the detection method

InactiveCN105911422ASimple structureReduce manufacturing costElectric winding testingElectric machineEngineering

The invention belongs to the technical field of motor detections, in particularly, a three-phase AC motor stator winding coil mismatched wiring detection apparatus and the detection method. The apparatus comprises an insulation work bench, a stator core on the insulation work bench, a three-phase winding power wire and an alternate power source in connection with the three-phase winding power wire. The inner round surface of the stator core is provided with a winding coil. The other end of the three-phase winding power wire in connection with the alternate power source is attached to the surface of the winding coil to form a rotary magnetic field. The winding coil is provided with a squirrel-cage type thin wall rotor detection component. There is some gap between the squirrel-cage type thin wall rotor detection component and the winding coil and the squirrel-cage type thin wall rotor detection component can rotate and move in the circumferential direction of the winding coil in a sliding manner. The three-phase AC motor stator winding coil mismatched wiring detection apparatus and the detection method provided by the invention are cost-effective and easy to operate. Prior to a dip coating process, it is possible to detect whether a stator core with a winding coil is wired correctly or not.

Owner:JINGJI TECH JIAXING CO LTD

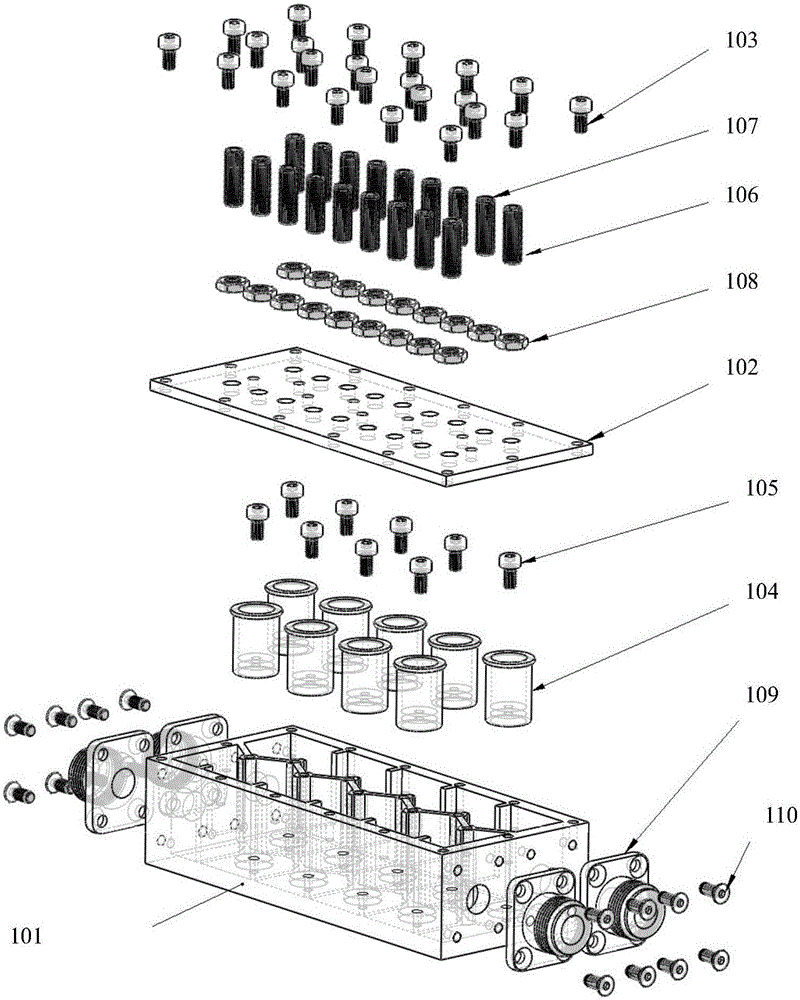

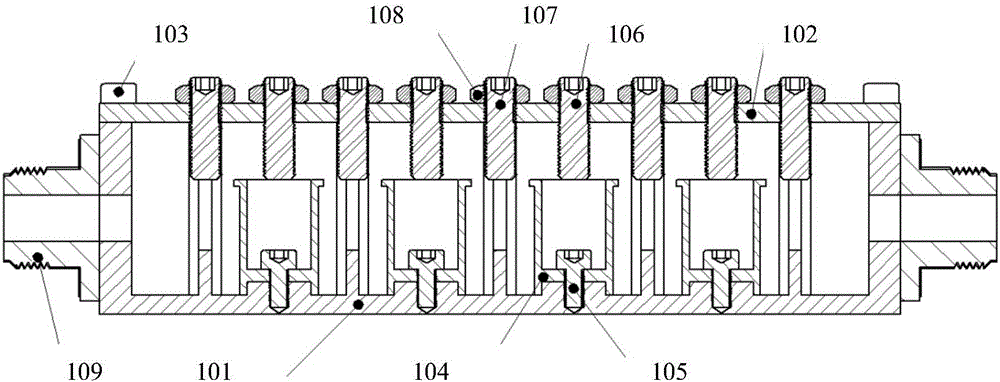

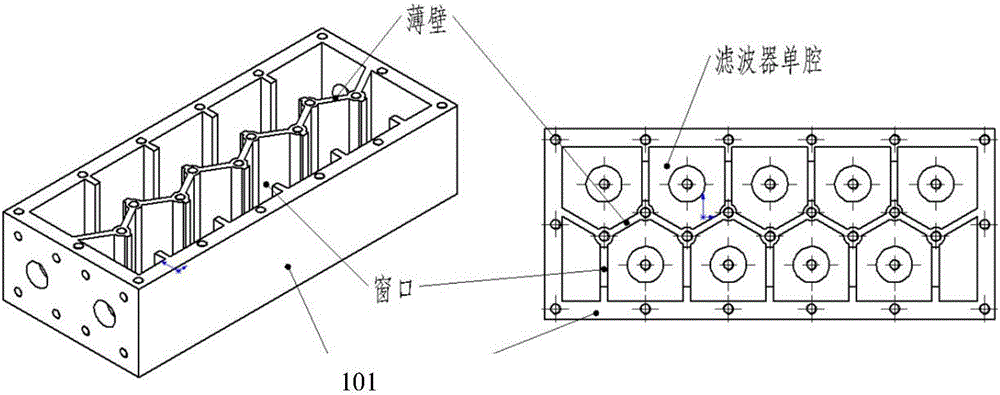

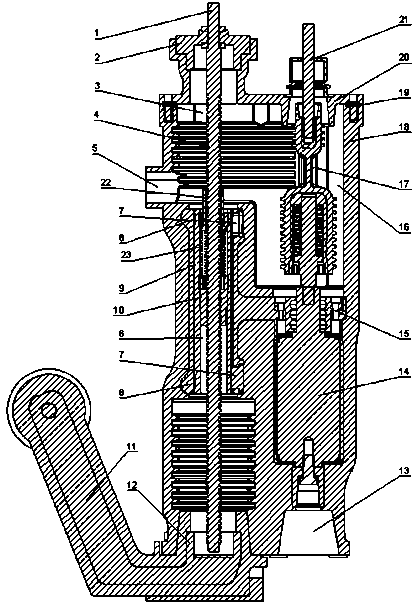

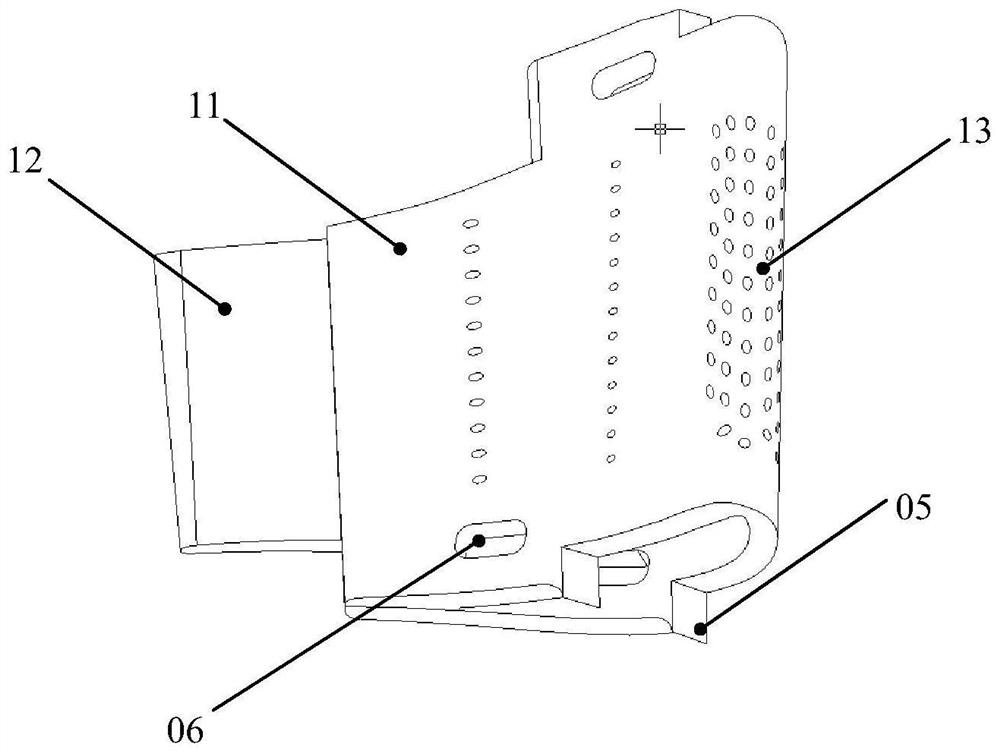

Coaxial cavity filter

InactiveCN106169637AAvoid the risk of obsolescenceIncrease profitWaveguide type devicesResonant cavityStructural engineering

The invention discloses a coaxial cavity filter. The coaxial cavity filter comprises single modular cavities, resonant rods, a cover plate, tuning screws, coupling screws and filter joints, wherein the cover plate is provided with grooves, the grooves are used for installing the single modular cavities, the upper ends of the single modular cavities are fixed in the cover plate grooves so as to be enclosed with the cover plate to form resonant cavities; the multiple single modular cavities are spliced together to form connected resonant cavities so as to form a filter cavity; the resonant rods are arranged at the bottom portions inside the single modular cavities; the tuning screws and the coupling screws are arranged on the cover plate and partially extend into the resonant cavities; and the filter joints are fixed on the single modular cavities at the head end and the tail end of the coaxial cavity filter. The coaxial cavity filter does not need a filter housing, is simple in processing and assembling process and good in interchangeability and can be repeatedly used.

Owner:TONGYU COMM INC

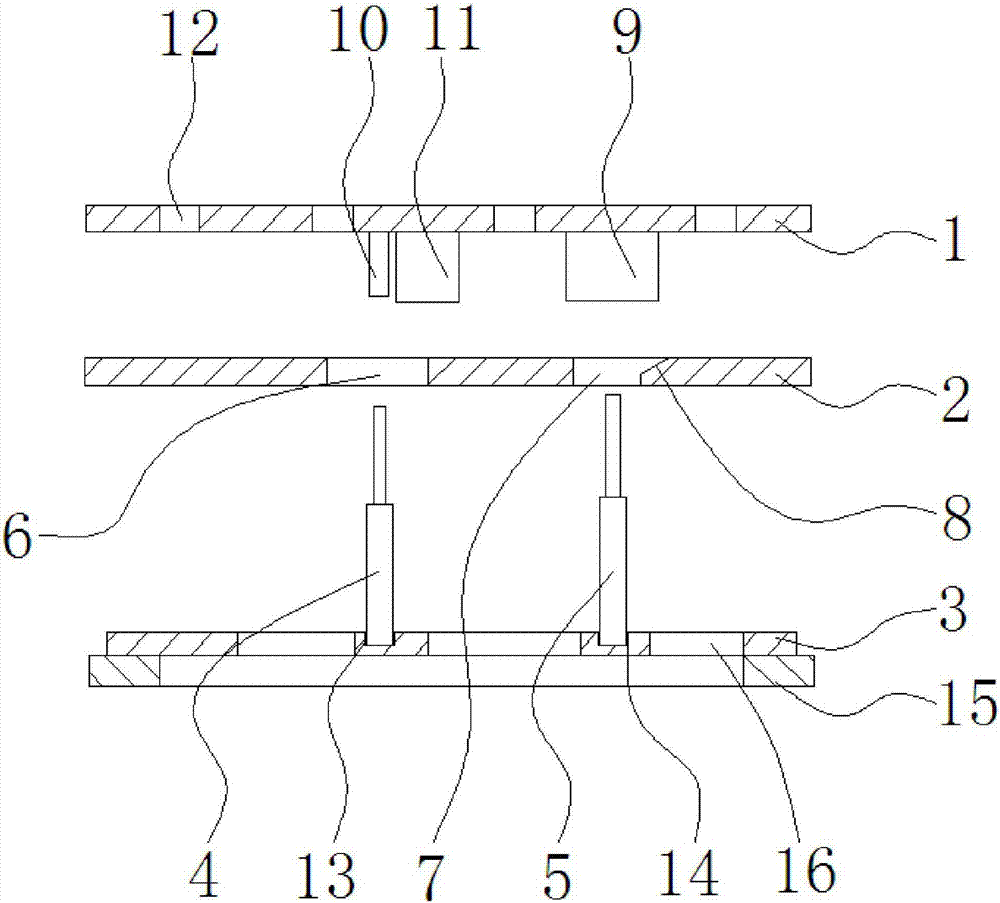

High-efficiency full waste cleaning and die cutting anti-adhesion integrated waste cleaning device

PendingCN107263926AReduce investmentImprove efficiencyBox making operationsPaper-makingEnvironmental engineeringDie cutting

The invention relates to the technical field of printing equipment, in particular to a high-efficiency full waste cleaning and die cutting anti-adhesion integrated waste cleaning device. The integrated waste cleaning device comprises an upper waste cleaning plate, a middle waste cleaning plate and a lower waste cleaning plate which are sequentially arranged from top to bottom. A plurality of lower waste cleaning pins and a plurality of lug folding ejector pins are arranged on the upper surface of the lower waste cleaning plate. The middle waste cleaning plate is provided with a waste cleaning hole and an upper lug folding hole, and a lug folding oblique plane is arranged on the side edge of the upper lug folding hole. A lug folding sponge, an upper waste cleaning pin and a waste cleaning sponge tightly adjacent to the upper waste cleaning pin are arranged on the lower surface of the upper waste cleaning plate. The lug folding sponge is vertically arranged over the upper lug folding hole. The upper waste cleaning pin and the waste cleaning sponge are both vertically arranged over the waste cleaning hole. The high-efficiency full waste cleaning and die cutting anti-adhesion integrated waste cleaning device has the beneficial effects that the functions of waste cleaning and anti-adhesion lug ejection are combined together, the manual lug carrying process is omitted, production efficiency is greatly improved, the fixed asset investment is reduced, manpower and material resources are greatly saved, the reliability is high, the danger of product rejection is avoided, and the wasting of energy and resources is reduced.

Owner:CHONGQING HONGJIN PRINTING

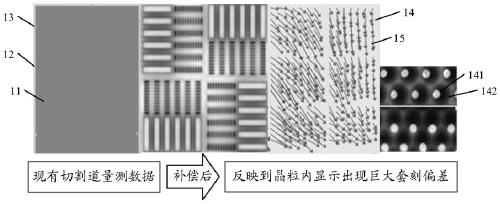

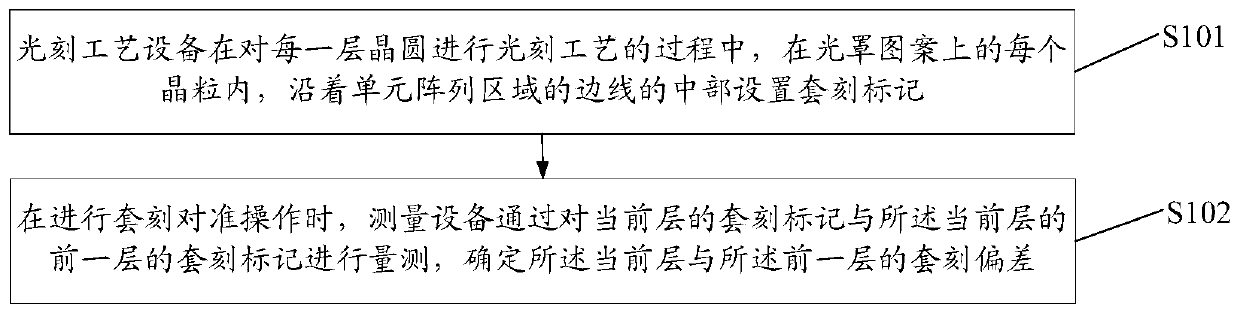

Overlay deviation determination method and system

ActiveCN111158217AAvoid the risk of obsolescenceAccurate Overlay DeviationSemiconductor/solid-state device testing/measurementFinal product manufactureLithography processEngineering

The embodiment of the invention discloses an overlay deviation determination method and system, wherein the method comprises the steps of setting an overlay mark along the central part of a side boundary in a unit array region during a process of carrying out the photoetching technology on each layer of wafer and in each crystal grain on a photomask pattern; and when the overlay alignment operation is carried out, measuring the overlay mark of the current layer and the overlay mark of the previous layer of the current layer through a measuring device, and determining the overlay deviation of the current layer and the previous layer.

Owner:YANGTZE MEMORY TECH CO LTD

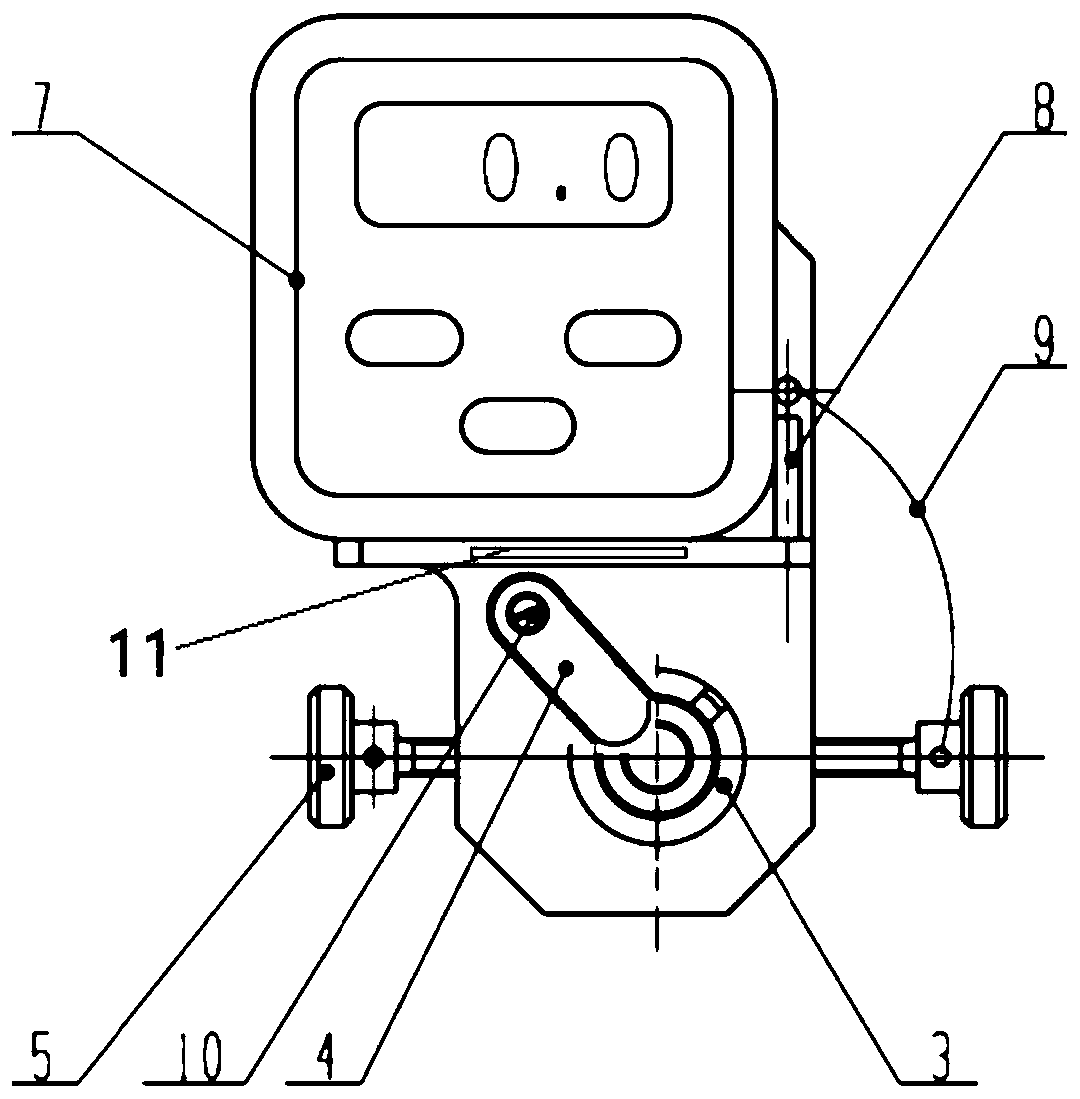

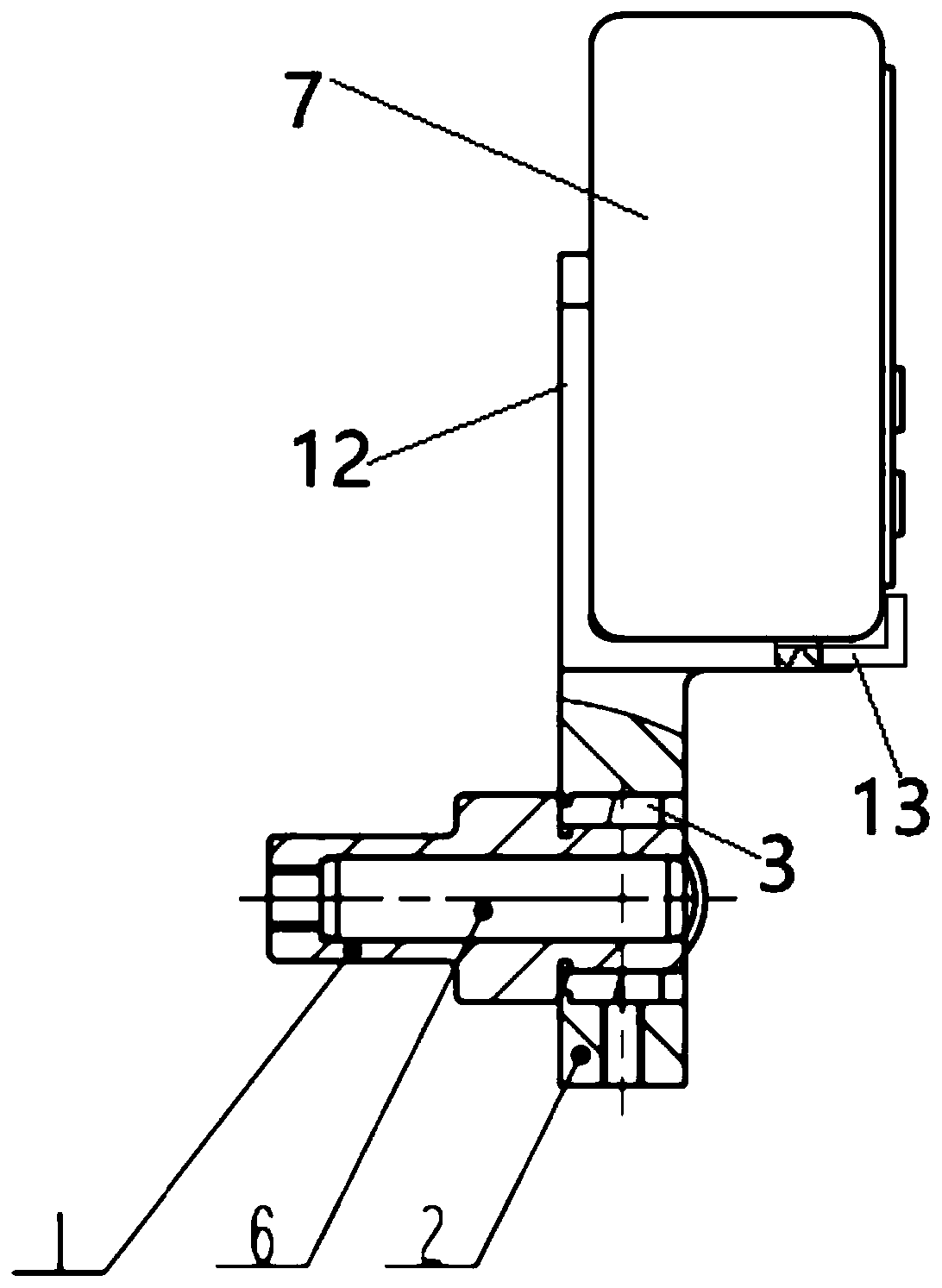

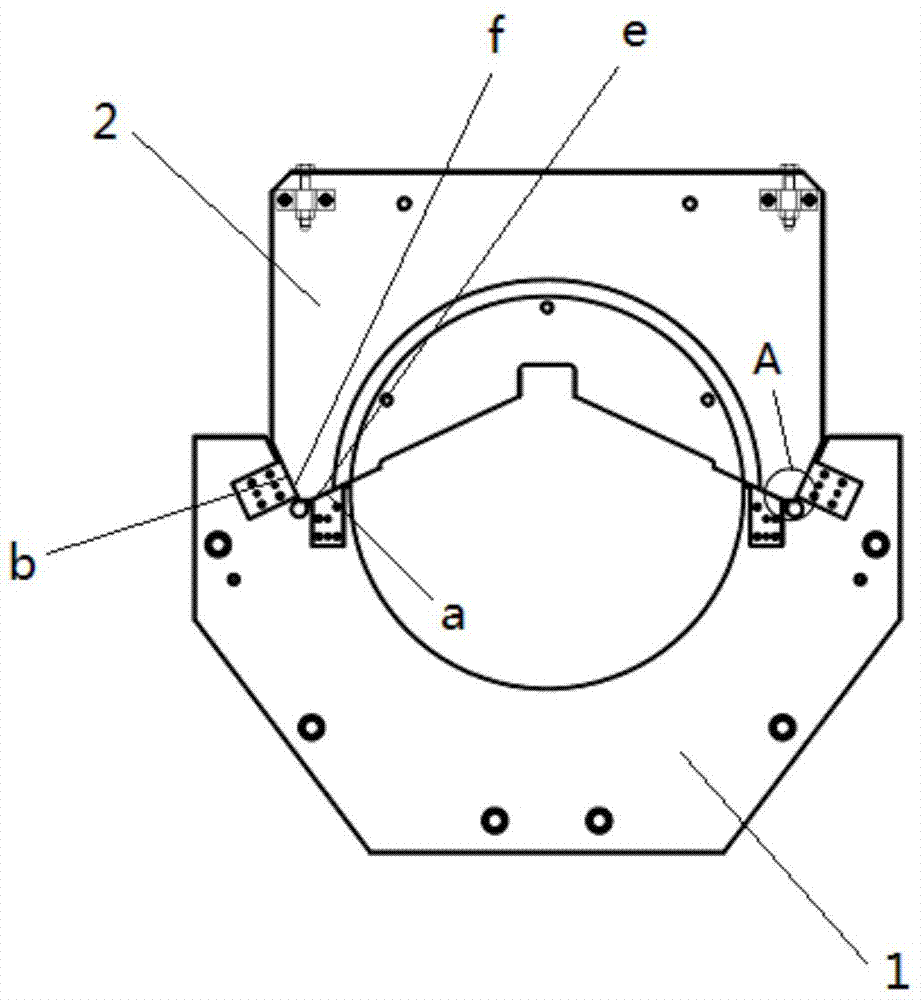

Adjustable flow blade rotation angle detection device and detection method

ActiveCN111272132AImprove detection efficiencyAvoid the risk of obsolescenceMeasurement devicesStructural engineeringMechanical engineering

The invention discloses an adjustable flow blade rotation angle detection device and detection method. A digital display angle detector is fixedly connected with a detected adjustable flow blade, so that the rotation angle of the adjustable flow blade can be detected by rotating the adjustable flow blade; a self-locking nut buckle thread is exposed on the long shaft of the adjustable flow blade, asupport is connected through the thread, the digital display angle detector is fixed on the support, and the rotation angle of the adjustable flow blade can be measured only by one-time disassembly and assembly during detection. The adjustable flow blade rotation angle detection device can be installed on N adjustable flow blades at the same time for one-time detection, and the detection efficiency can be greatly improved. After the adjustable flow blade rotation angle detection device and method are adopted, the risk of scrapping caused by repeated disassembly and assembly of the self-locking nut is effectively avoided, more importantly, the detection device is convenient to disassemble and easy to operate, the detection time is greatly shortened, the detection efficiency is effectivelyimproved, and meanwhile, the labor intensity of operators is greatly reduced.

Owner:AECC AVIATION POWER CO LTD

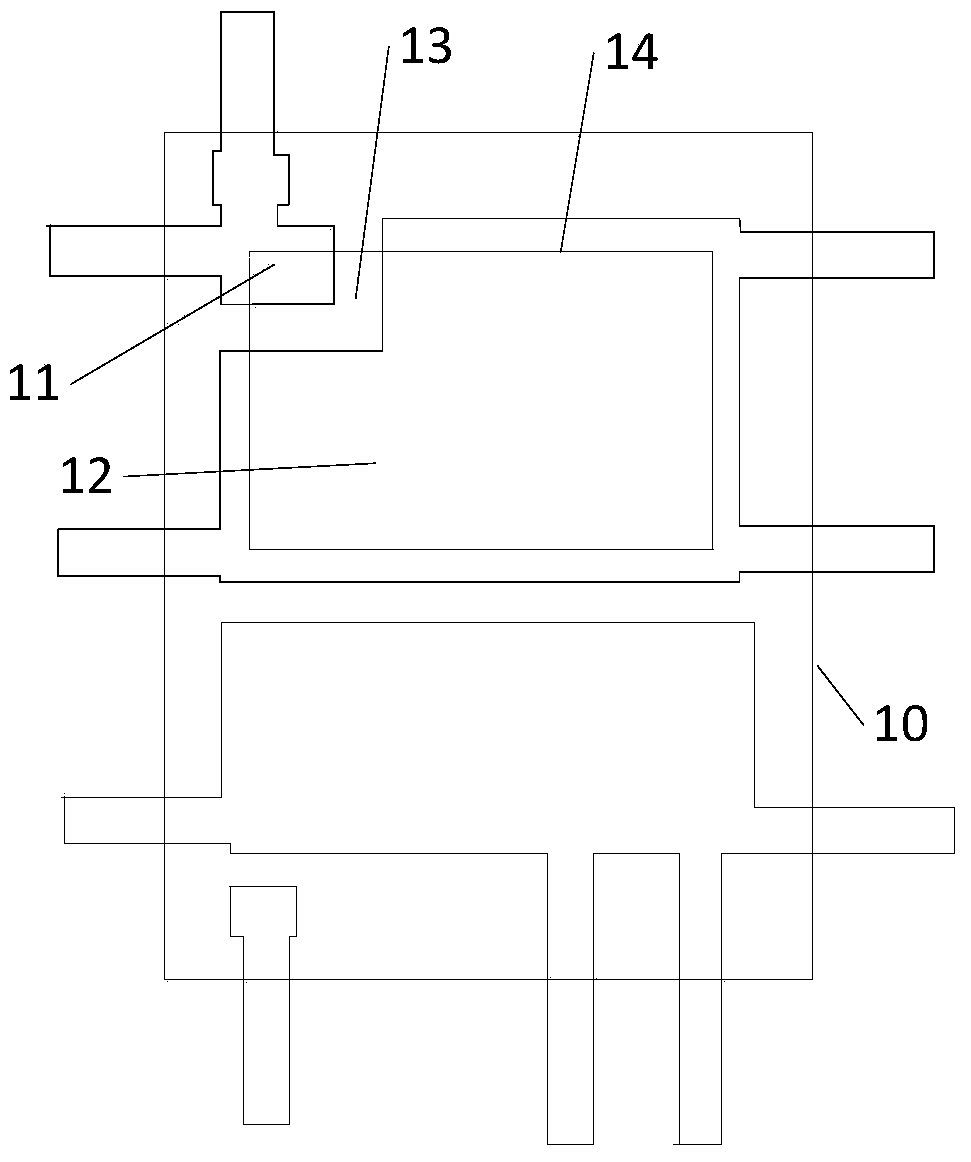

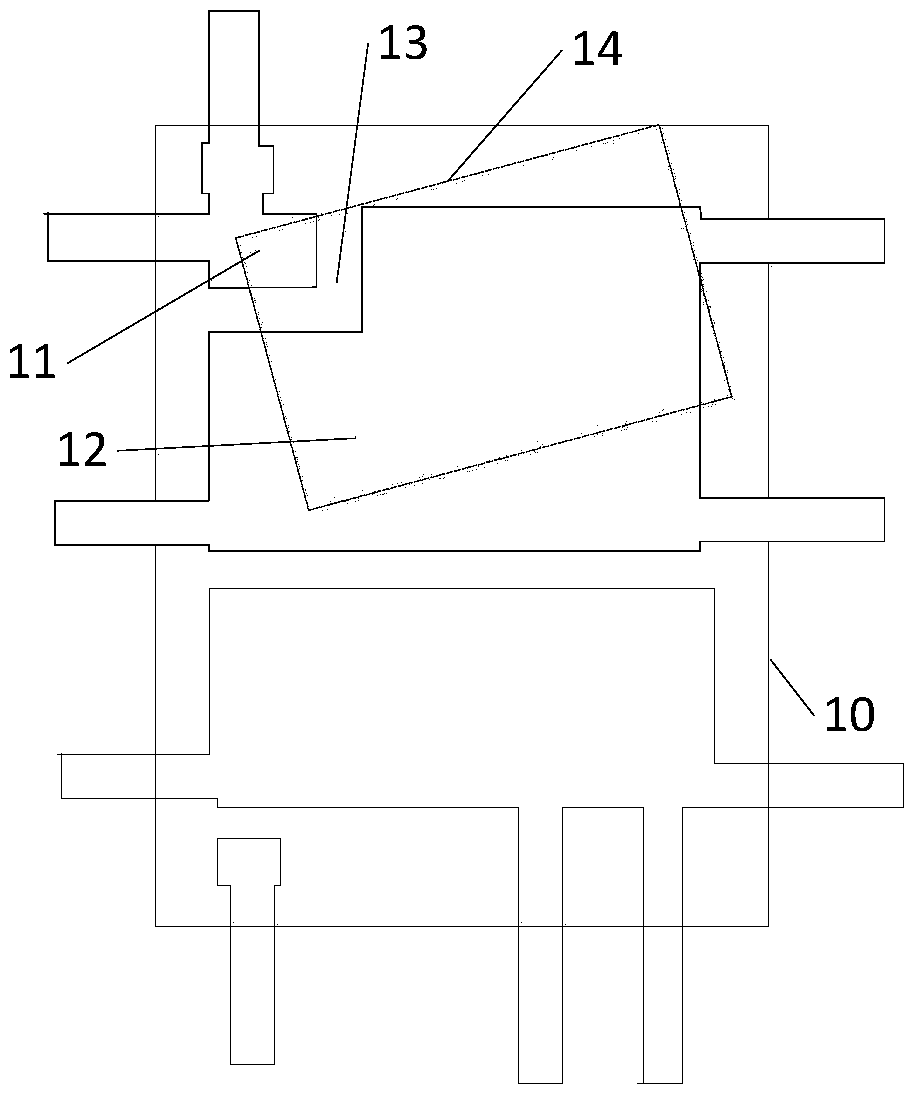

New type solid insulation vacuum switch three-position isolation grounding switch module

ActiveCN103915282BOptimizing the appearance profileUniform electric fieldEarthing arrangementsAir-break switch detailsEpoxyManufacturing technology

A novel solid insulation vacuum switch three-position isolation earthing switch module is composed of a three-position isolation earthing switch operation end, a three-position isolation earthing switch, a bus interface, an outgoing line terminal, a vacuum switch, an isolation static contact, an earthing contact, an epoxy resin shell and an end cover. The novel solid insulation vacuum switch three-position isolation earthing switch module is characterized in that the three-position isolation earthing switch and the vacuum switch are cast in the epoxy resin shell in parallel and connected with a conductive contact finger base through a movable contact support, the earthing contact is installed on the end cover or the epoxy resin shell in a rear-assembly mode, and the isolation static contact is fixedly sealed inside the epoxy resin shell. According to the novel solid insulation vacuum switch three-position isolation earthing switch module, the outer contours of high-voltage parts at the working position are optimized, no additional shielding nets need to be cast inside the epoxy resin shell, product miniaturization is easily achieved, and the manufacturing technology is simplified; local electric field concentration does not exist, and the product local discharge capacity is low even if the requirement that portions which the human body can touch are earthed is met; the whole product scrapped risk is reduced.

Owner:I SEE R&D INT CO LTD

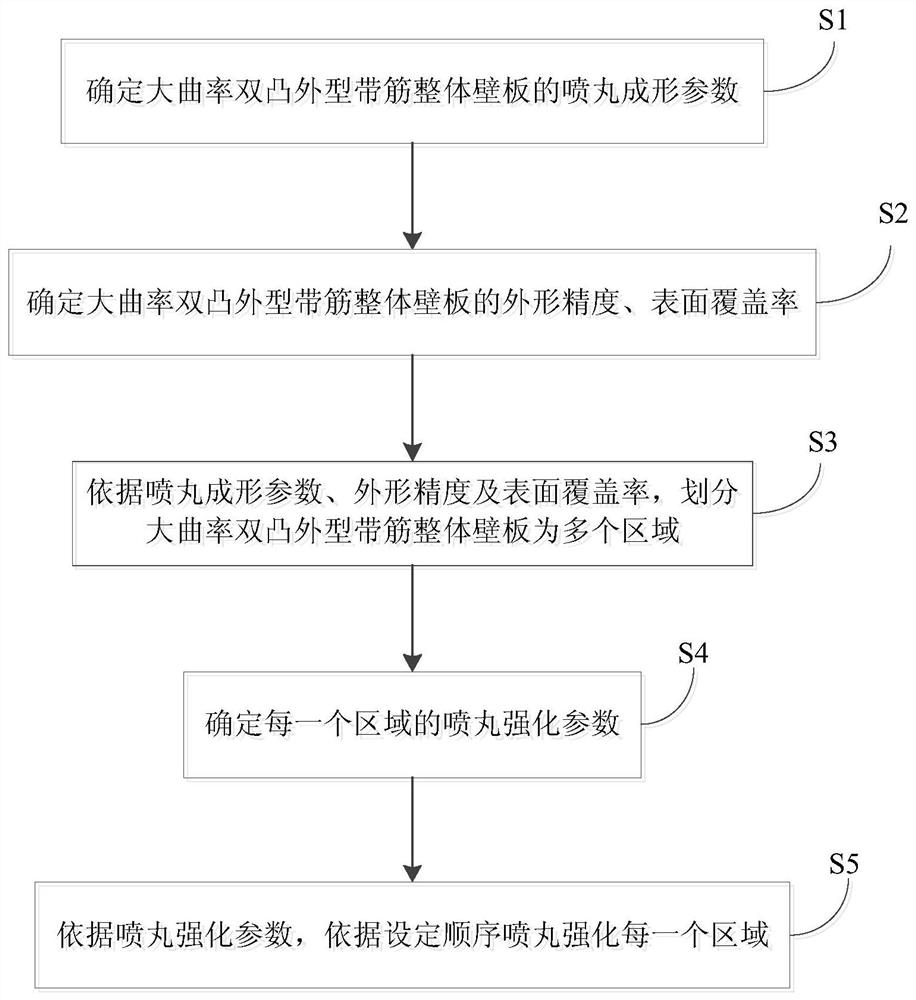

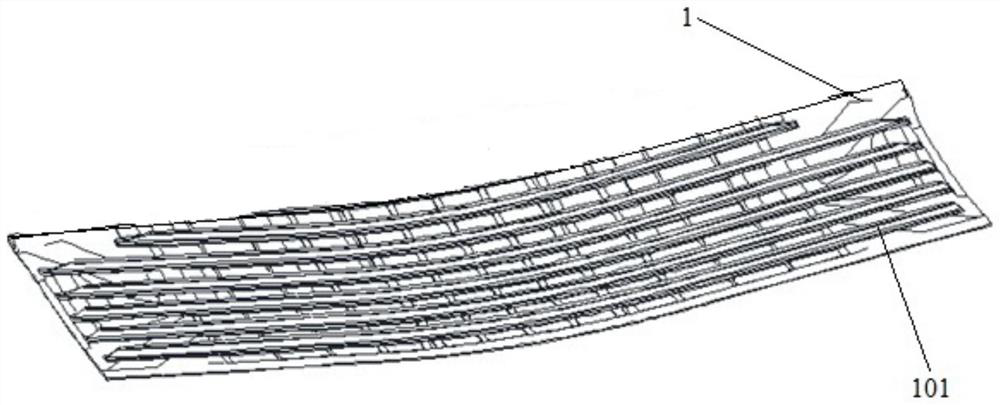

Shot peening strengthening deformation regulation method for large-curvature double-convex exterior ribbed integral panel

PendingCN111922922AAvoid the risk of obsolescenceHigh precisionAbrasive feedersAbrasive machine appurtenancesClassical mechanicsStructural engineering

The invention relates to a shot peening strengthening deformation regulation method for a large-curvature double-convex exterior ribbed integral panel. The method comprises the following steps of determining shot peening forming parameters of the large-curvature double-convex exterior ribbed integral panel; determining the shape accuracy and the surface coverage rate of the large-curvature double-convex exterior ribbed integral panel; dividing the large-curvature double-convex exterior ribbed integral panel into multiple areas according to the shot peening forming parameters, the shape accuracy and the surface coverage rate; determining shot peening strengthening parameters of each area; and shot peening strengthening each area according to a set order according to the shot peening strengthening parameters. The shot peening strengthening deformation regulation method for the large-curvature double-convex exterior ribbed integral panel provided by the invention aims to solve the problemthat the large-curvature double-convex exterior ribbed integral panel is very easy to generate relatively large deformation after being subjected to full-surface shot peening strengthening.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

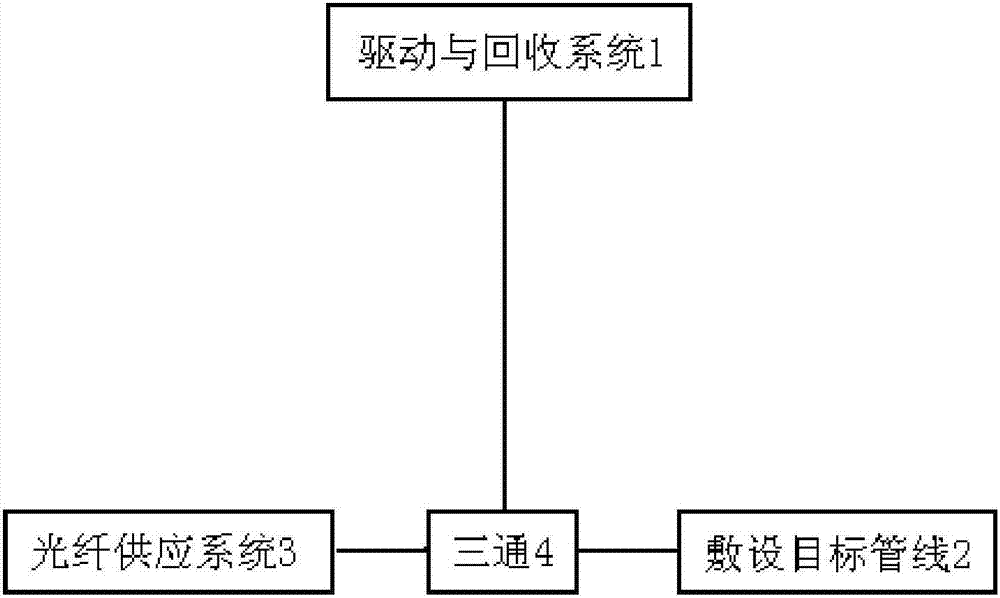

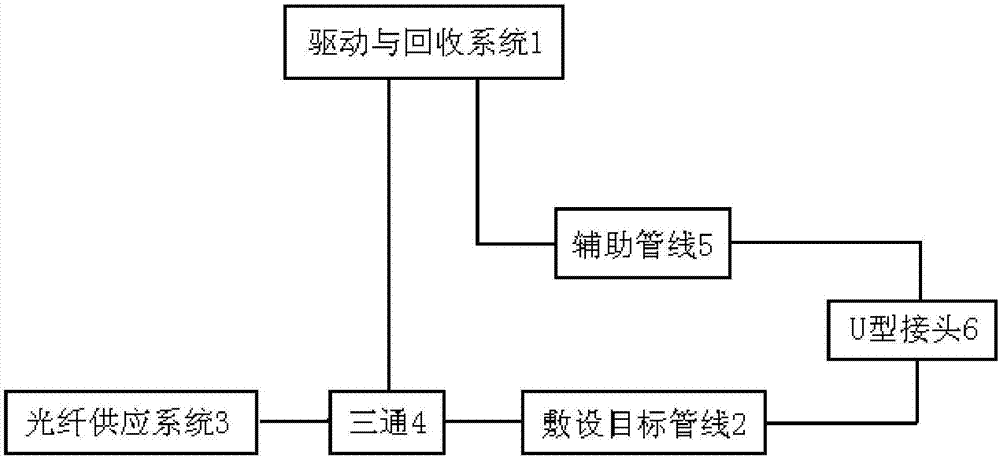

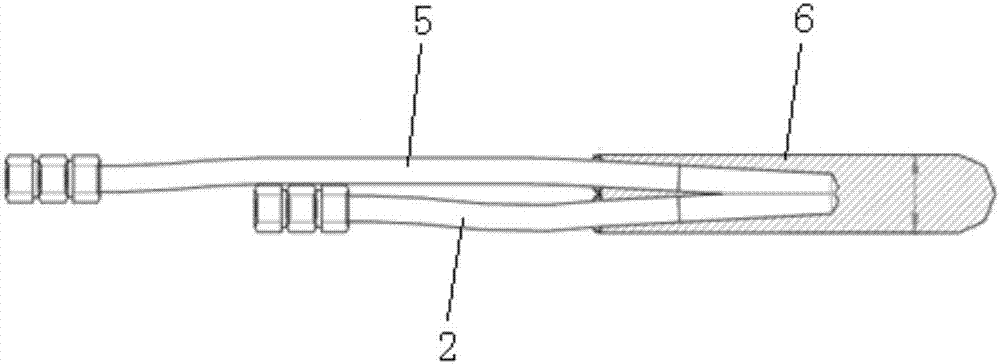

Method for performing optical fiber laying in pipeline through liquid working medium

InactiveCN107065110AUniform stress distribution within the fiberFiber protectionOptical fibre/cable installationPetroleumEngineering

The invention relates to a method for performing optical fiber laying in a pipeline through a liquid working medium. The method is characterized in that the friction force between the liquid working medium and optical fibers is used as dragging force to bring the optical fibers into the target laying pipeline. When the method is applied to optical cable processing, the stainless steel pipe is formed firstly and then the optical fibers enter the pipe so that the risk of scrapping of the whole section of optical cable caused by heat damage of the internally filled optical fibers in welding the stainless steel band by using the conventional optical cable processing technology can be effectively avoided, the cabling reliability of the optical fibers can be enhanced, the cabling distance of the optical fibers can be effectively enhanced, the cabling speed of the optical fiber cable is fast and the cabling process is simple and reliable. Underground optical fiber laying can be successfully completed or the damaged optical fibers in the original pipe column can be replaced without using the downward entering optical cable pipe column so that the work risk and cost can be greatly reduced, and the reliability of optical fiber sensing in oil field application can be substantially enhanced. The method can be widely applied to the technical field of petroleum engineering, photoelectric sensing, optical fiber testing and signal transmission.

Owner:中清盈创(北京)科技有限公司

Solar cell encapsulation sheet and solar cell module

ActiveCN104506131BAvoid the risk of obsolescenceEnable connectivityPhotovoltaicsPhotovoltaic energy generationElectrical batterySolar cell

The invention discloses a solar battery packaging sheet. The solar battery packaging sheet comprises a packaging bottom plate, a first series battery stack, a second series battery stack and magnets, wherein the first series battery stack and the second series battery stack are independently packaged on the packaging bottom plate; the positive electrode of the first series battery stack and the negative electrode of the second series battery stack are positioned on the identical side of the packaging sheet; the magnets are respectively embedded to the two sides of the packaging sheet; the edges of the magnets are positioned at the outer parts of the edges of the packaging sheet; the output electrodes of the first series battery stack and the second series battery stack are respectively connected with the magnets beside the series battery stacks according to different requirements. The invention further provides another three solar battery packaging sheets and solar battery components comprising the solar battery packaging sheets. The packaging sheets and the battery components provided by the invention can meet different requirements on power of users, and are small in size, convenient to carry and low in cost.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

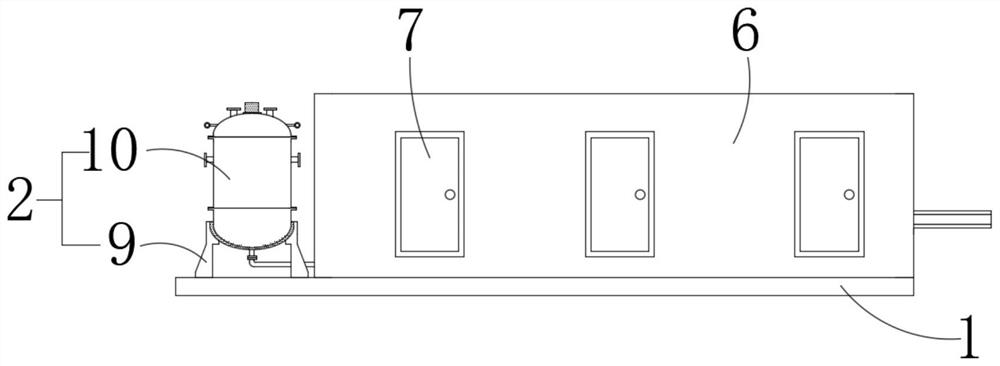

Full-automatic production device and production process for middle-buried rubber waterstop

PendingCN114834018AAvoid wasting resourcesAvoid the risk of obsolescenceDomestic articlesCoatingsMechanical engineeringIndustrial engineering

The full-automatic production device comprises a base and a protective shell, a raw material mixing assembly, two sets of plastic extruding machines, cooling water tanks corresponding to the two sets of plastic extruding machines, and a forming pressing assembly are arranged at the upper end of the base; the raw material mixing assembly, the plastic extruding machine cooling water tank and the forming and pressing assembly are sequentially arranged. The raw material mixing assembly, the two plastic extruding machines, the cooling water tank corresponding to the two plastic extruding machines and the forming and pressing assembly are arranged at the upper end of the base, the hose feeding assembly is arranged on the side wall, opposite to the access door, of the protective shell, and production equipment for different working procedures of the middle-buried type rubber water stop belt is integrated; raw materials and finished products are finished at a time, and resource waste and potential scrapping risks caused by the fact that transfer equipment is needed to assist transfer between aisle procedures in the prior art are avoided.

Owner:江苏中瑞铁路器材有限公司

Solid insulation vacuum switch three-position isolation earth switch module

ActiveCN103928274AUniform electric fieldShort insulation distanceEmergency protective devicesGround contactEpoxy

A solid insulation vacuum switch three-position isolation earth switch module is composed of a three-position isolation earth switch operation side, a three-position isolation earth switch, a bus interface, a wire outlet terminal, a vacuum switch, an isolation fixed contact, a grounding contact, an epoxy resin shell and an end cover. The solid insulation vacuum switch three-position isolation earth switch module is characterized in that the three-position isolation earth switch and the vacuum switch are cast inside the epoxy resin shell in parallel and connected with a conductive button contact base through a moving contact support; the grounding contact and the moving contact support are fixedly packaged to the end cover and the epoxy resin shell respectively; the isolation fixed contact is cast in the bus interface and connected with a conductor in the bus interface. The appearance profiles of all high-voltage components of the module are optimized, a shielding screen does not need to be additionally cast to the inner portion of the epoxy resin shell, miniaturization of the product is easily achieved, and the manufacturing process is simplified. Under the condition that portions capable of being touched by the human body are all grounded, magnitude of partial discharge of the product is still low; the requirement for the appearance profile of the moving contact support is low, part allowable errors are higher, the manufacturing process is simpler, cost is low, and the service life of the product is prolonged.

Owner:I SEE R&D INT CO LTD

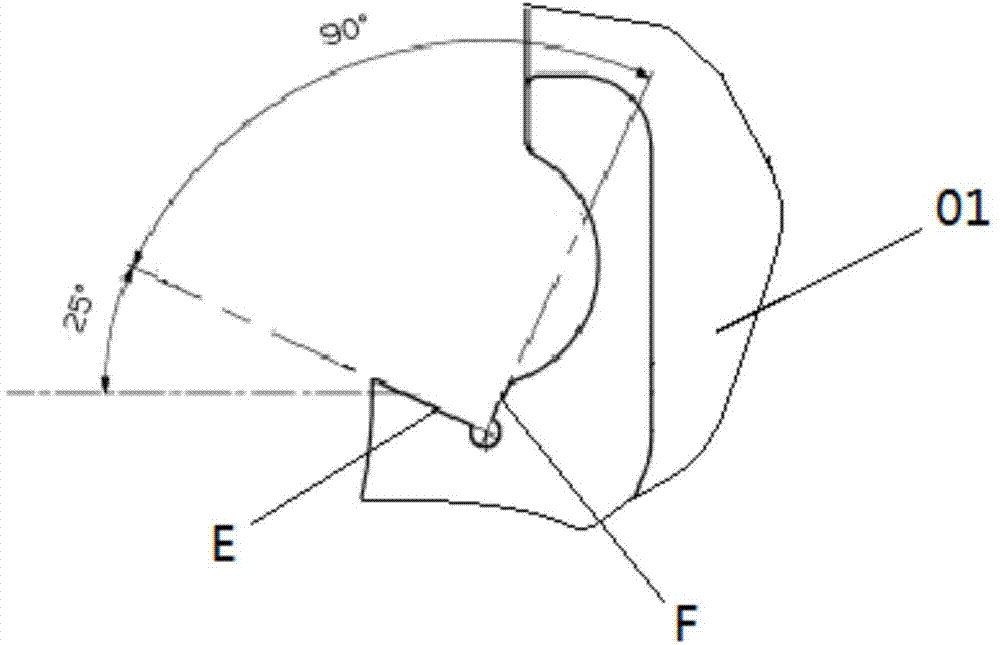

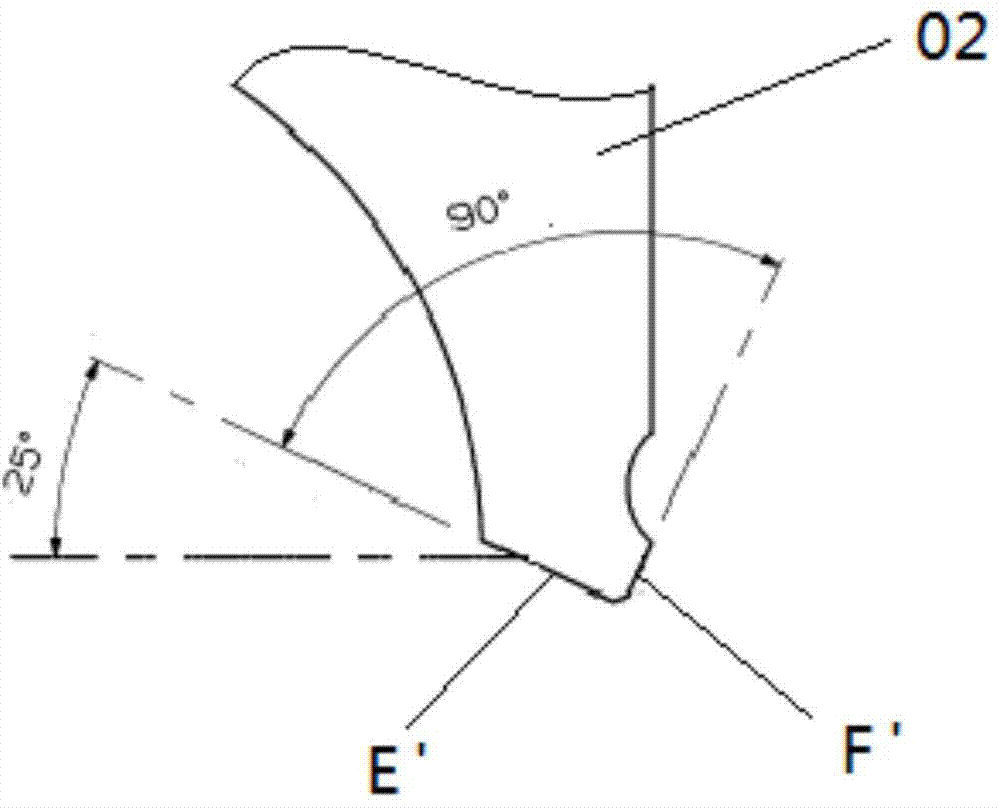

Diesel engine main bearing block and main bearing cap joint face machining method and presetting die plates therefor

ActiveCN103921156AImprove efficiency and accuracyAvoid machine time lossAutomatic control devicesPositioning apparatusMain bearingDiesel engine

Disclosed are a diesel engine main bearing block and main bearing cap joint face machining method and presetting die plates therefor. Two presetting die plates in conformity to features of main bearing block and main bearing cap joint faces are adopted. The presetting die plates are provided with two 25-degree presetting slants and two 115-degree presetting slants which are symmetric; the slants of the presetting die plates are in conformity to 25-degree slants and 115-degree slants of a main bearing block and a main bearing cap in terms of position, shape and size; the position, shape and size of the slants of the presetting die plates meet the corresponding requirements for tolerance in shape and size. The presetting die plates are paired, finished and machined, so that the requirement for a fitting gap between the main bearing block and main bearing cap joint faces is met, the requirement for the gap between the joint faces during assembly is also met, accuracy and effectiveness in machining are greatly improved, waste on machine-hour and labor and risk of workpiece scrapping are avoided.

Owner:CSSC MES DIESEL

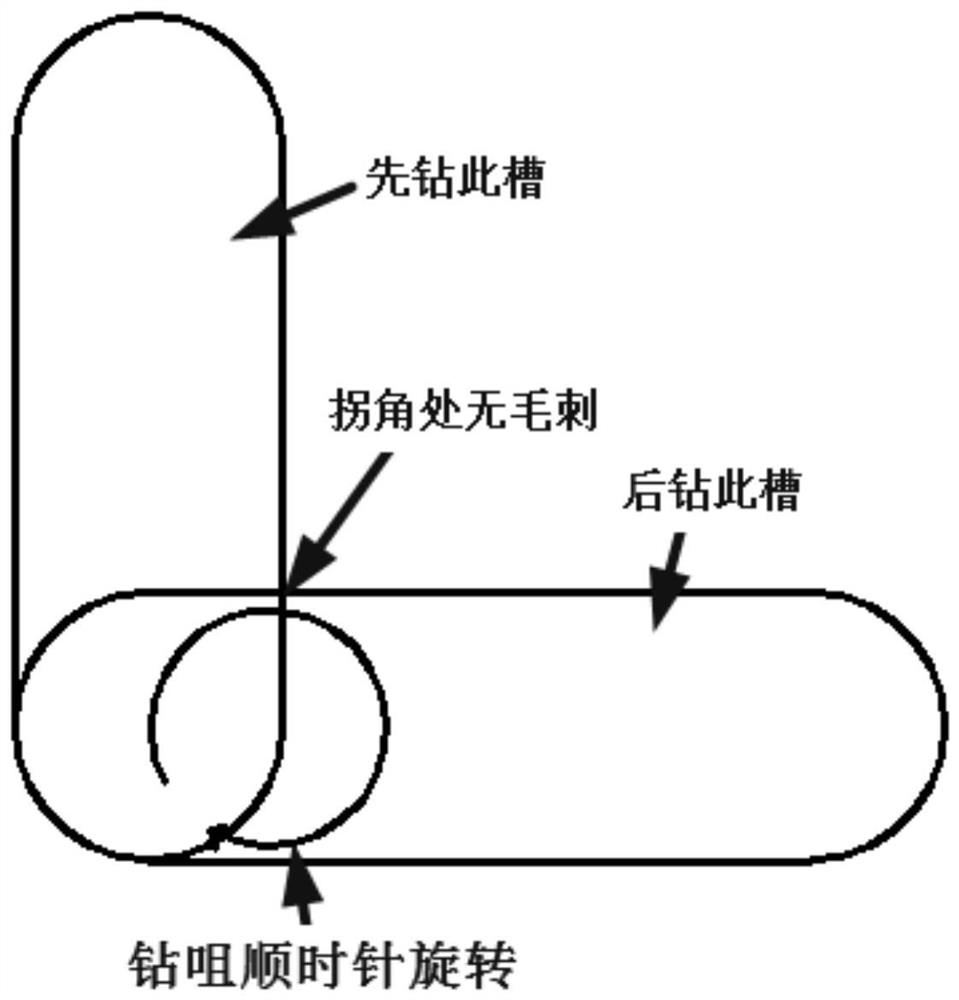

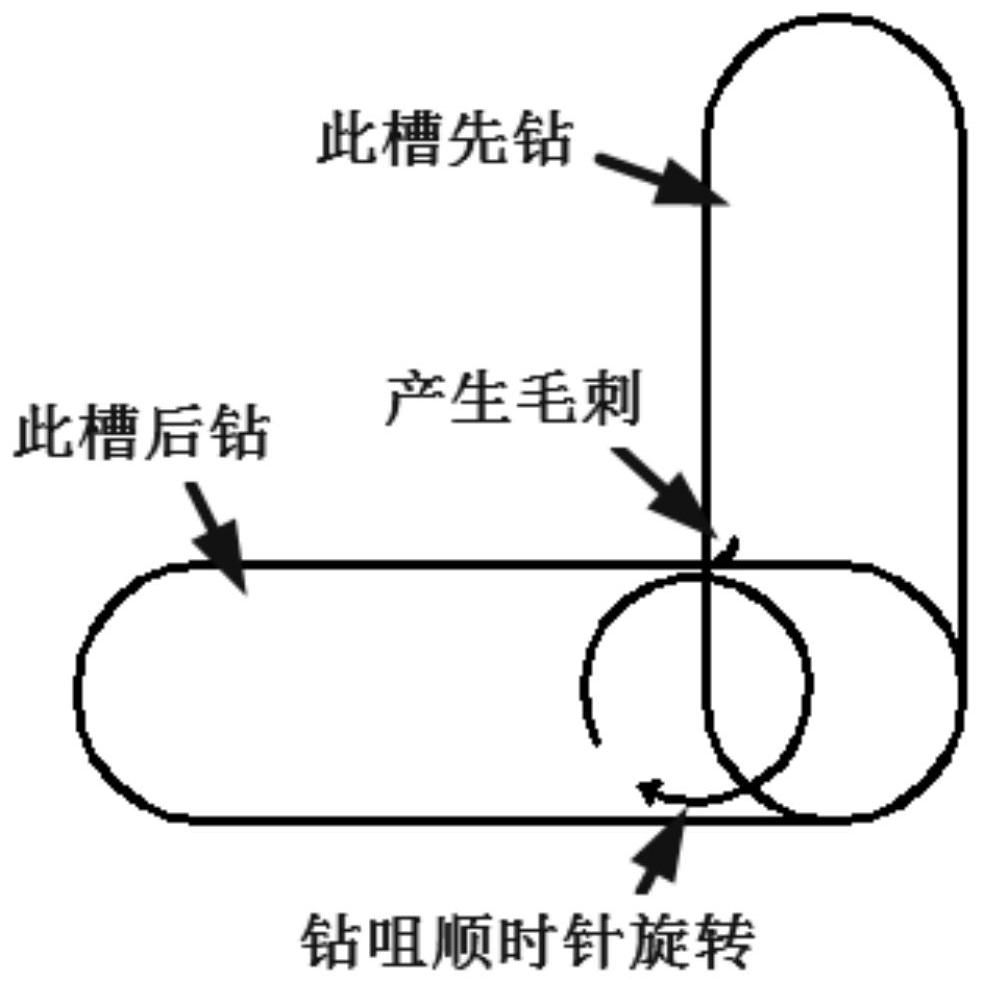

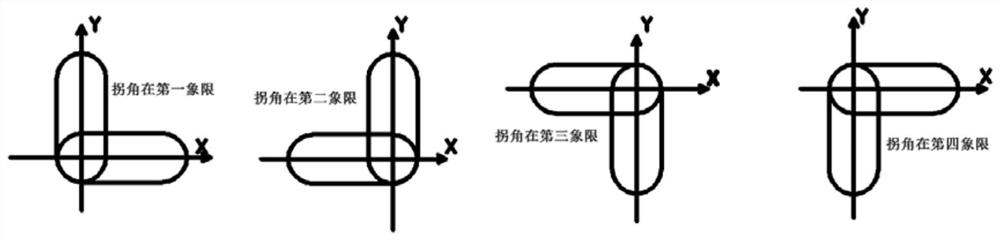

Method for eliminating burrs at corners of L-shaped special-shaped slotted hole

InactiveCN112976144AEliminate generationReduce labor costsMetal working apparatusStructural engineeringAbnormal shaped

The invention provides a method for eliminating burrs at corners of an L-shaped special-shaped slotted hole. The method for eliminating the burrs at the corners of the L-shaped special-shaped slotted hole comprises the following steps that S1, the intersection circle center of two slots serves as an original point, and a plane coordinate system is established; S2, the position of a corner of the L slot is judged; and S3, slot drilling is carried out, specifically, when the corner of the L-shaped slot is in the first quadrant and the third quadrant, a vertical slot is drilled firstly and then a transverse slot is drilled, and when the corner of the L-shaped slot is in the second quadrant and the fourth quadrant, the transverse slot is drilled firstly, and then the vertical slot is drilled. According to the method for eliminating the burrs at the corners of the L-shaped special-shaped slotted hole, the burrs are eliminated from the mechanism, the link of manually brushing the burrs does not need to be added, the labor cost is saved, and therefore the risk of scrapping is avoided.

Owner:AOSHIKANG TECH CO LTD

Ceramic matrix composite material fixing guider blade structure of aircraft engine and molding thereof

ActiveCN110985134AAvoid the defects of insufficient strengthAvoid the risk of obsolescenceStatorsMachines/enginesAviationStructural engineering

The invention relates to a fixing guider blade structure and molding thereof, in particular to a ceramic matrix composite material fixing guider blade structure of an aircraft engine and molding thereof, and belongs to the technical field of preparation of fixing guiders of aircraft engines. According to the fixing guider blade structure and the molding thereof, the structural defects of unreasonable design and poor root strength of an existing CMC guider blade prefabricated body are overcome, a turbine guider blade is prepared by adopting an integrated assembly mode, parts are integrally assembled by adopting a riveting mode, the assembly structure adopts a SiC ceramic matrix to realize welding, and then the defect of insufficient root strength caused by conventional sewing the molded prefabricated body is avoided; and multi-part backup and assembly optimization can be realized, the risk of whole component scrapping caused by single part scrapping can be avoided, the preparation riskis reduced, the cost is reduced, and the component quality is improved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

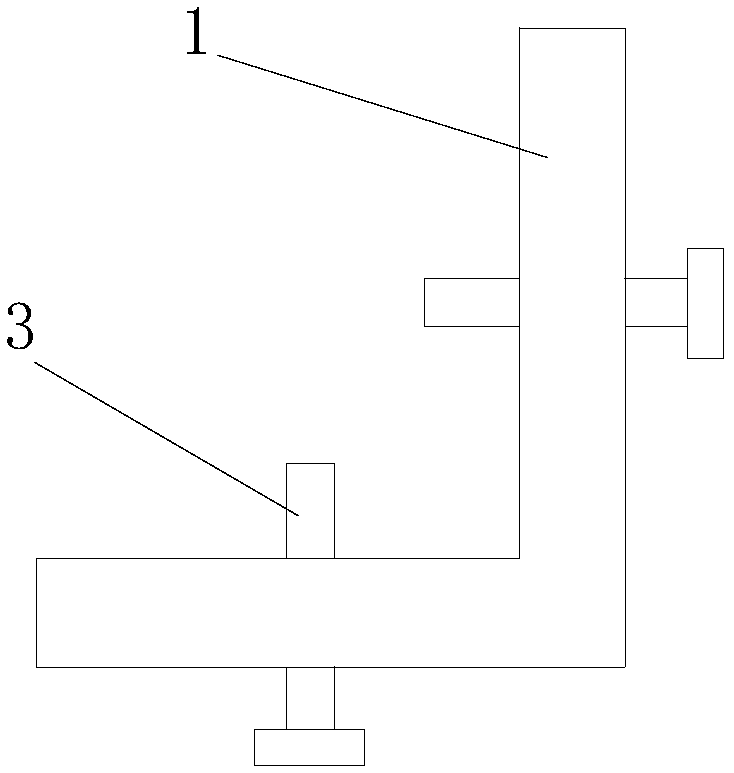

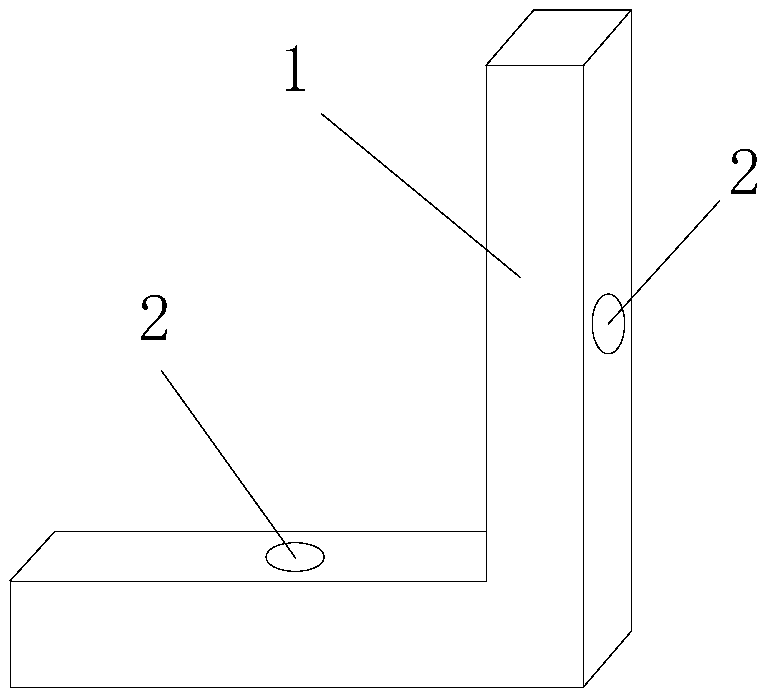

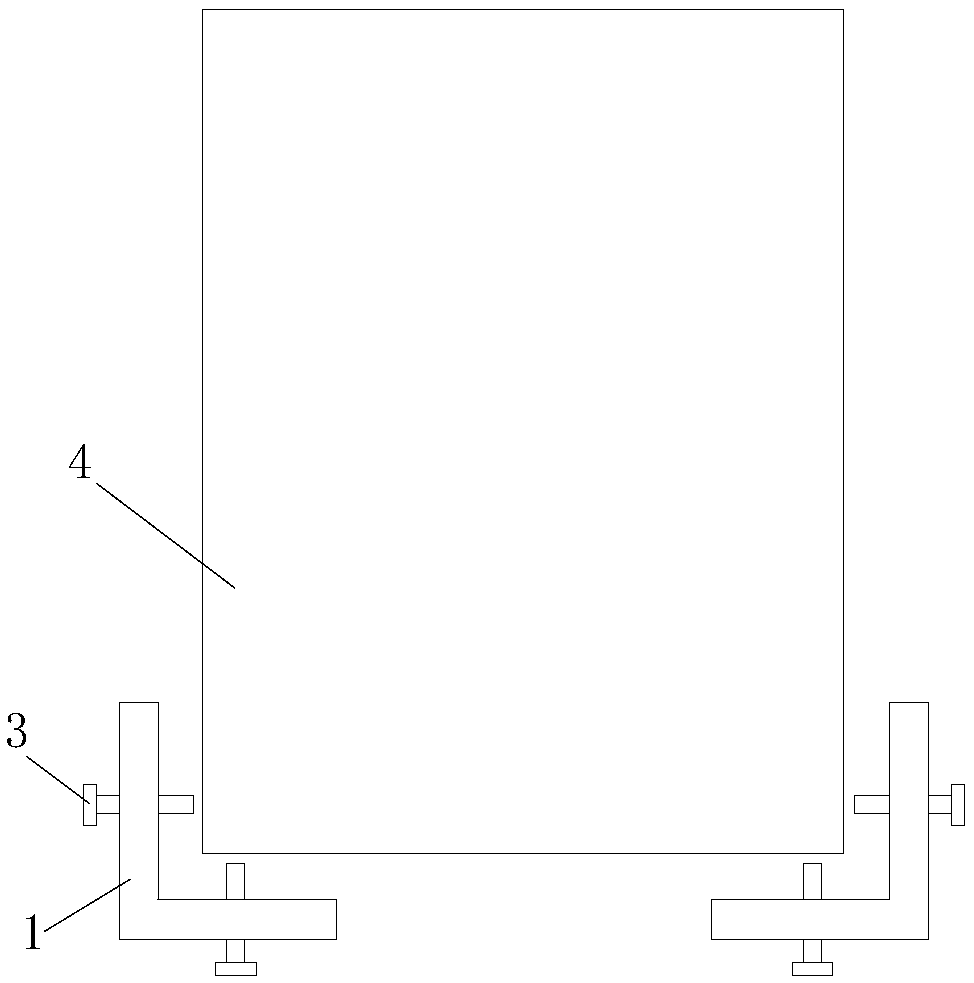

Novel press gate adjustment device and adjustment method

InactiveCN108601224ASolve the defect of deformationSimple counterpointLaminating printed circuit boardsUltimate tensile strengthComputer engineering

The invention discloses a novel press gate adjustment device and an adjustment method. The adjustment device comprises an L-shaped frame, wherein a threaded hole is formed in each of two edges of theL-shaped frame; and an assorted bolt is arranged on each threaded hole in a sleeving manner. By adoption of the adjustment device disclosed by the invention, a press gate is simply aligned with screwholes of a machine body, so that time and labor are saved; the working intensity of a worker can be substantially relieved; the press gate can be further protected; and the defect that the press gatedeforms easily in the original method is overcome.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

a lead frame

ActiveCN105006464BSolve the phenomenon of deviating from the original chip flipping areaAvoid the risk of obsolescenceSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The embodiment of the invention discloses a leading wire frame. The leading wire frame comprises a grid electrode welding area, a source electrode welding area, and a grid electrode isolation zone, the grid electrode isolation zone is used for electrical insulation of the grid electrode welding area and the source electrode welding area, the leading wire frame is also provided with a balance groove opposite to the grid electrode isolation zone, and the balance groove is used for balancing uneven bearing caused by the grid electrode isolation zone during inverted installation of a chip. The leading wire frame is provided with the balance groove so that the problem that the chip deviates from a predetermined chip inverted-installation area during inverted installation of the chip is solved, the risk of product scrap due to the rotation of the chip is avoided, and subsequent manufacture is facilitated.

Owner:GREAT TEAM BACKEND FOUNDRY (DONGGUAN) LTD

Aeroengine ceramic matrix composite fixed guide vane structure and its molding

ActiveCN111102017BAvoid the defects of insufficient strengthGood workmanshipEfficient propulsion technologiesStatorsEngineeringTurbojet engine

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Novel fastening structure for through belt of low-speed diesel engine

InactiveCN110552945AAvoid the risk of obsolescenceReduce the time required for installationNutsScrewsPulp and paper industryDiesel engine

The invention discloses a novel fastening structure for a through belt of a low-speed diesel engine. The novel fastening structure penetrates through and is in fastening connection to a machine base,a rack and a gas cylinder body, and comprises the through bolt, a positioning sleeve, a positioning screw, a positioning block, a hydraulic nut and a positioning nut, wherein an upper fixed through hole and a middle fixed through hole are formed in the gas cylinder body; a through hole is formed in the rack; the machine base is equipped with a lower fixed through hole and a transverse mounting hole; the transverse mounting hole and the lower fixed through hole define inverted-T-shaped penetration; the upper fixed through hole is embedded into the positioning block, the positioning nut is arranged in the transverse mounting hole, the through bolt and the positioning sleeve which are integrally welded pass through the positioning block, the middle fixed through hole, the through hole and thelower fixed through hole; the positioning sleeve is in matched positioning with the lower fixed through hole; the positioning screw jacks the positioning sleeve; the hydraulic nut and the positioningnut are separately connected to the upper end and the lower end of the through bolt; and a hydraulic elongator is used for fastening the hydraulic nut, the positioning nut and a through bolt pump forconnecting the machine base, the rack and the gas cylinder based in a fastening mode. The novel fastening structure is simple, is good in performance, is high in reliability, is convenient in mounting and dismounting, and avoids the risk that machine base scrap is caused by damages on a threaded hole.

Owner:CSSC MES DIESEL

Structure and Forming of Aeroengine Ceramic Matrix Composite Fixed Guide Vane

ActiveCN110966049BAvoid the defects of insufficient strengthGood workmanshipStatorsMachines/enginesAviationTurbine

The invention belongs to the technical field of preparation of fixed guides of aero-engines, and relates to a blade structure of a fixed guide made of a ceramic matrix composite material of an aero-engine and its forming. To overcome the structural defects of unreasonable design of the existing CMC guide vane prefabrication and poor blade root strength, the turbine guide vane including multi-stage guide vanes is prepared by integrated assembly method, and the parts are integrated and assembled by riveting, and the assembly structure is realized by SiC ceramic matrix "Welding"; and make full use of the effective space between the upper edge plate and the outer casing, install and position the blade body and the upper edge plate through limit rivets and limit platforms, and use CVI technology to deposit SiC ceramic substrates on the entire product , to complete the integrated preparation. This structure makes the complex SiC / SiC multi-connected high-pressure guide vane have good manufacturability, the preparation of the edge plate and the vane is simpler, the installation is more reliable, and the dimensional accuracy of the final product is easier to guarantee. This structure can be fully applied to medium and large engines and fifth-generation aircraft.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com