Solid and liquid hazardous waste plasma cracking and vitrification disposal equipment and solid and liquid hazardous waste plasma cracking and vitrification disposal method

A technology of plasma cracking and treatment equipment, which is applied in the field of ion cracking and vitrification treatment equipment, which can solve problems such as furnace blockage and lower work efficiency, and achieve the effects of prolonging service life, improving work efficiency and reducing waste weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

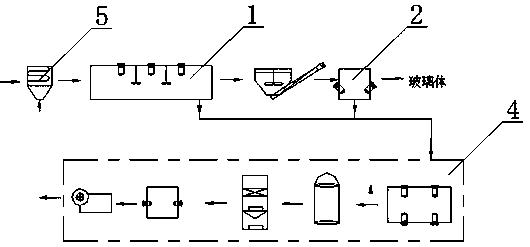

[0049] The following is an example of using the above-mentioned solid and liquid hazardous waste plasma cracking and vitrification treatment equipment and methods to treat common oilfield sludge in solid hazardous waste. The specific treatment process is as follows:

[0050] 1. First turn on the plasma incineration cracking furnace and vitrification melting furnace to preheat the inside of the furnace;

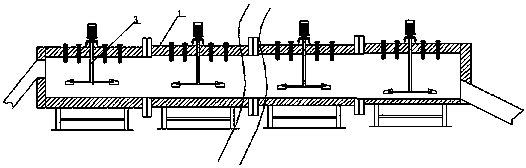

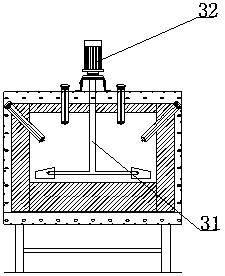

[0051] 2. 160 tons of oil sludge to be treated will be evenly transported to five groups of 120 plasma incineration and cracking furnaces for incineration and cracking within 20 hours after passing through the preheated hopper. The incineration temperature is controlled between 600-1000 degrees Celsius. The plasma generators and material propulsion components in each unit furnace body start to work, and the oil sludge is incinerated and cracked through each unit furnace body in turn, and the materials are stirred at the same time, so that the oil sludge can be continuously tran...

Embodiment 2

[0055] The following is an example of using the above-mentioned solid and liquid hazardous waste plasma cracking and vitrification treatment equipment and methods to treat common garbage concentrates in liquid hazardous waste. The specific treatment process is as follows:

[0056] 1. First turn on the plasma incineration cracking furnace and vitrification melting furnace to preheat the inside of the furnace;

[0057] 2. 120 tons of landfill leachate to be treated (with a moisture content of about 98%) will be uniformly transported to the hearth of three groups of 90-section plasma incineration and cracking furnaces for 1 hour of incineration after passing through the preheated hopper within 20 hours Cracking, incineration temperature is controlled between 600-800 degrees Celsius, the plasma generators and material propulsion components in each unit furnace start to work, fully stirred, so that the concentrated solution is continuously and fully cracked to form ash, and the weig...

Embodiment 3

[0061] The above-mentioned solid and liquid hazardous waste plasma cracking and vitrification treatment equipment and methods can be used to treat fly ash and can also achieve good results. The specific treatment process is as follows:

[0062] 1. First turn on the plasma incineration cracking furnace and vitrification melting furnace to preheat the inside of the furnace;

[0063] 2. 120 tons of fly ash to be processed will be evenly transported to the hearth of the 20-section plasma incineration cracking furnace within 20 hours after being preheated to the furnace for 10 minutes of incineration. The incineration temperature is controlled between 850-1000 degrees Celsius , remove the dioxins in the fly ash and heat the fly ash;

[0064] 3. The fly ash incinerated by the plasma incineration cracking furnace is transported by the screw conveyor to the vitrification melting furnace for 40 minutes of incineration. The incineration temperature is controlled between 1600-1800 ° C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com