Shot peening strengthening deformation regulation method for large-curvature double-convex exterior ribbed integral panel

An integral wallboard and shot-peening strengthening technology, which is applied in the direction of used abrasive processing devices, abrasive materials, metal processing equipment, etc., can solve problems such as deformation, achieve the effect of eliminating local out-of-tolerance items and avoiding the risk of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

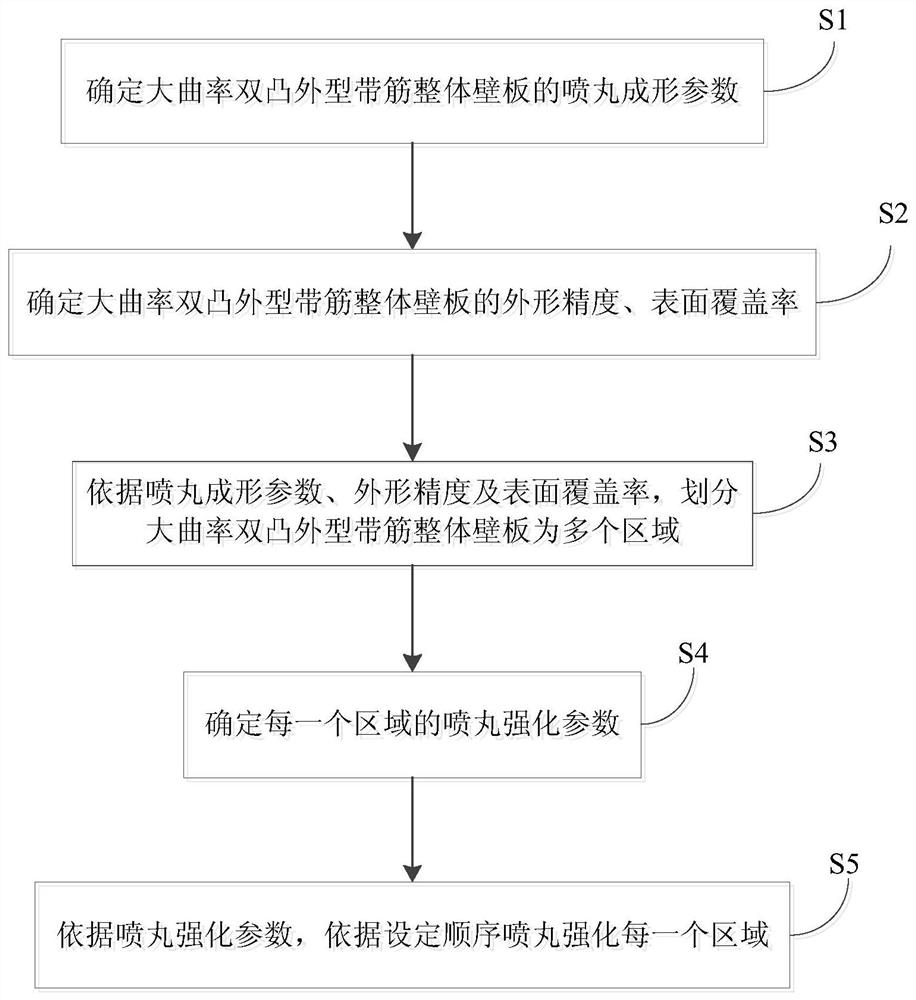

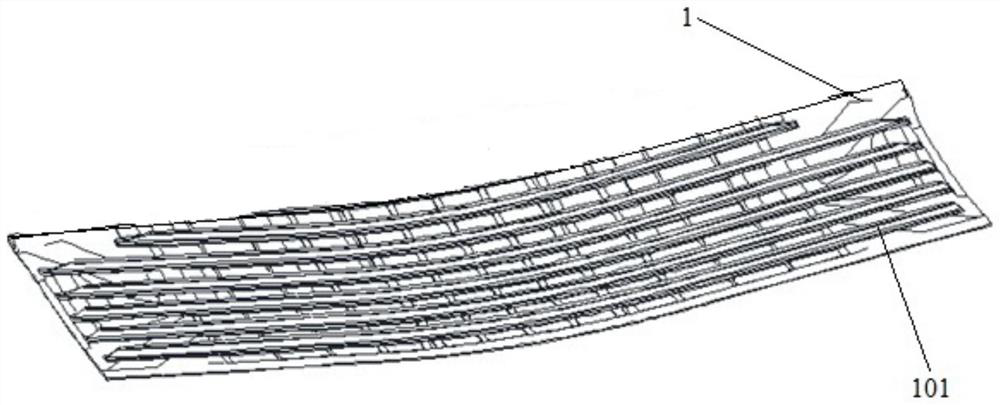

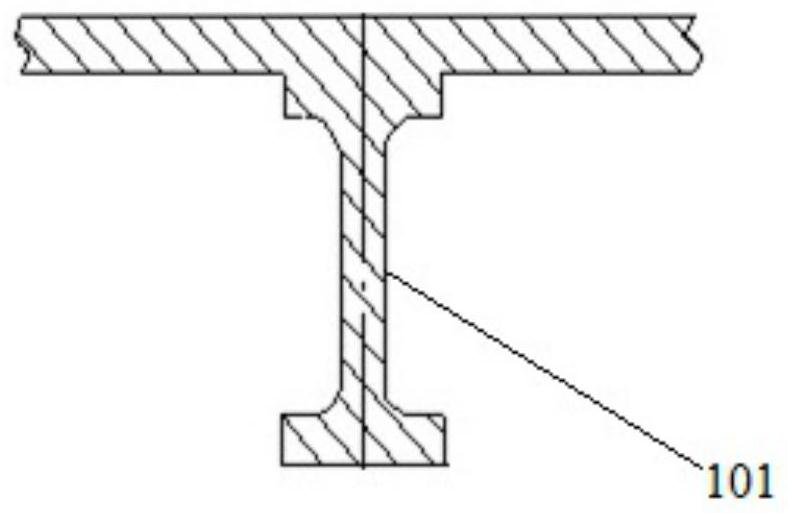

[0065] Taking a certain type of large-curvature double-convex complex ribbed integral wall panel shot peening as an example, the slab shape structure of the large-curvature double-convex complex ribbed integral wall plate 1 is as follows: figure 2 As shown, the material is 2024-T351 aluminum alloy, the yield limit of the material is σys=370Mpa, the length is 8500mm, and the width is 1400mm. The number of ribs 101 distributed along the width of the panel is 8, and the profile of the ribs 101 is as follows: image 3 As shown, the large-curvature double-convex shape area in the middle of the wall plate has a length of about 2500mm and a width of 1400mm.

[0066] Shot peening implementation steps:

[0067] (1) Determination of panel forming parameters

[0068] Clear the shot peening area and process parameters of the wallboard, and record them, as shown in Table 1.

[0069] Table 1 Wall panel shot peening parameters

[0070] Projectile grade barometric pressure f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com