Novel press gate adjustment device and adjustment method

A technology of an adjusting device and an adjusting method, which is applied in the manufacturing of laminated printed circuit boards, electrical components, printed circuits, etc., can solve problems such as deformation of the door of the press, and achieve the effects of reducing work intensity, simple alignment, and solving deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

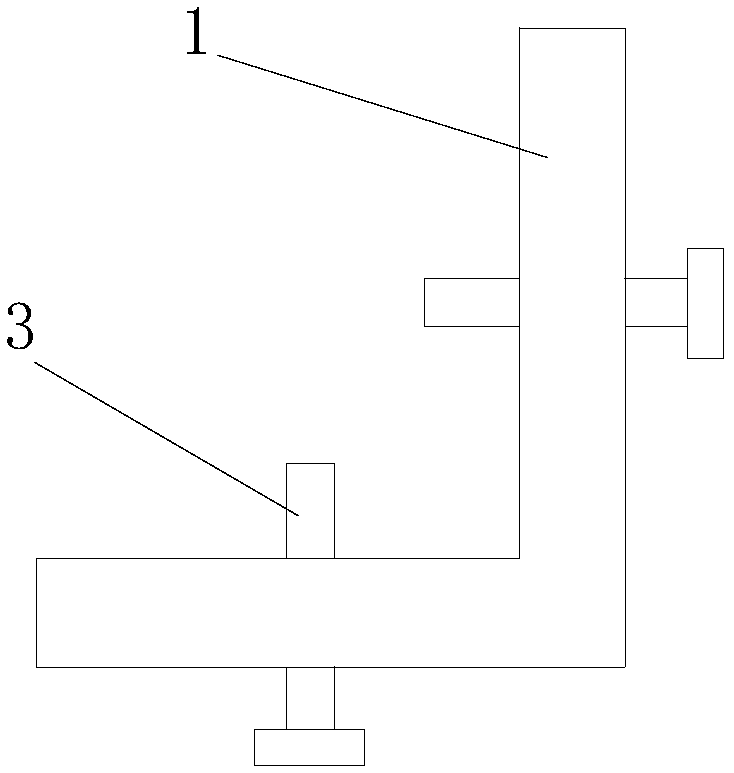

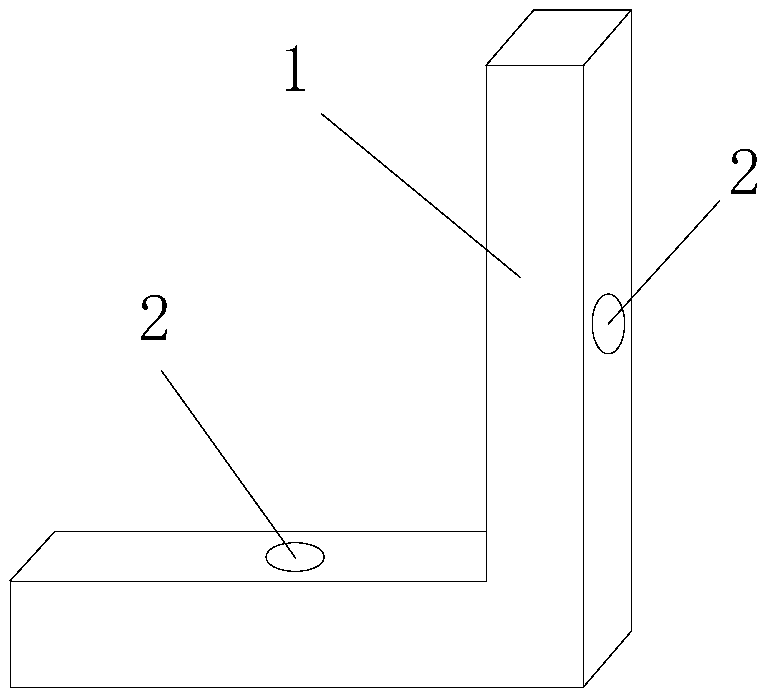

[0027] Such as figure 1 and figure 2 As shown, a novel press gate adjustment device shown in this embodiment includes an L-shaped frame 1, a threaded hole 2 is provided on both sides of the L-shaped frame 1, and matching bolts are set on the threaded hole 2. 3.

[0028] Specifically, the diameter of the threaded hole 2 is 10mm, and the bolt 3 is an M10 bolt with a length of 10cm.

[0029] Specifically, the thickness of the L-shaped frame 1 is greater than 1.5 cm to ensure the strength of the L-shaped frame.

[0030] Such as figure 2 As shown, in another embodiment of the present invention, the two sides of the L-shaped frame have the same length, and the distance between the threaded holes on the two sides and the intersection of the right angles on the L-shaped frame is the same; Relative position, the length of any side can be used as bottom or side.

[0031] Specifically, the threaded holes are respectively arranged in the middle of the two sides of the L-shaped fram...

Embodiment 2

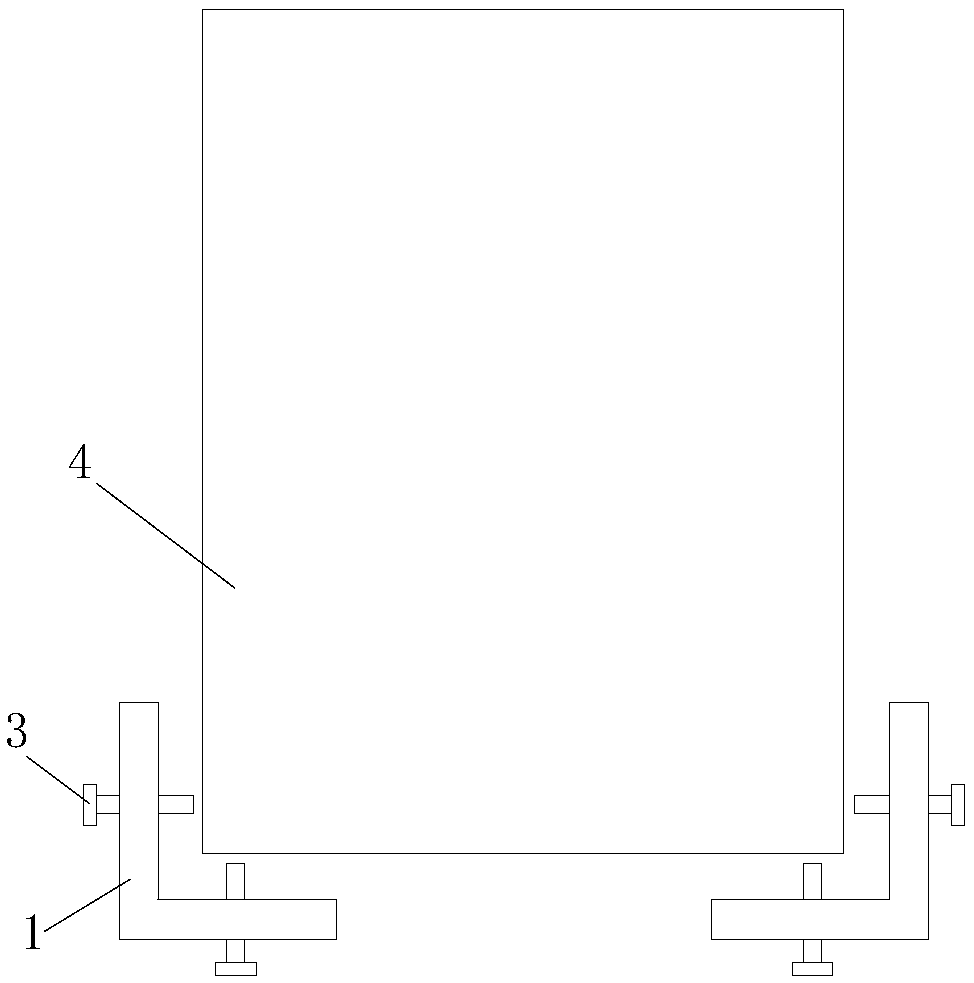

[0033] Such as image 3 As shown, there is also provided an adjustment method for adjusting the press gate using the novel press gate adjusting device of the above embodiment, including the following steps:

[0034] (1), two L-shaped frames 1 are respectively fixed on the outside of the two corners below the press door 4, and the two threaded holes on the L-shaped frame 1 correspond to the bottom and the side of the press door 4 respectively;

[0035] (2), install the matching bolt 3 on the threaded hole;

[0036] (3) Adjust the position of the press door 4 up, down, left, and right through the four bolts 3 on the two L-shaped frames 1, so that the screw holes on the press door and the press body are aligned;

[0037] (4) Install screws on the screw holes to fix the press door and the press body together.

[0038] Specifically, in step S1, the two L-shaped frames 1 are respectively fixed on the outside of the two corners below the press door and away from the press door by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com