Method for producing and assembling micro-channel heat exchanger

A micro-channel heat exchanger, production and assembly technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of oxidation black residue attached to the guard plate, deformation of the core guard plate, complex process and other issues, to achieve the effect of reducing material cost, improving production efficiency, and smooth and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

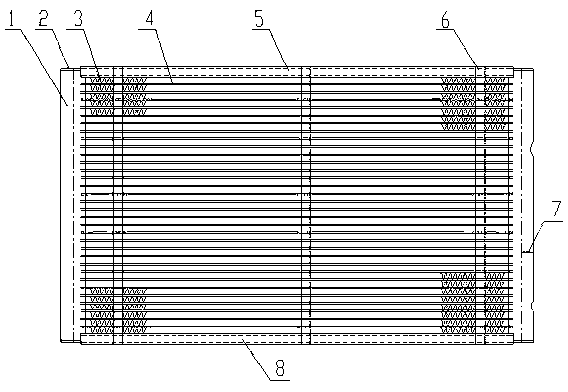

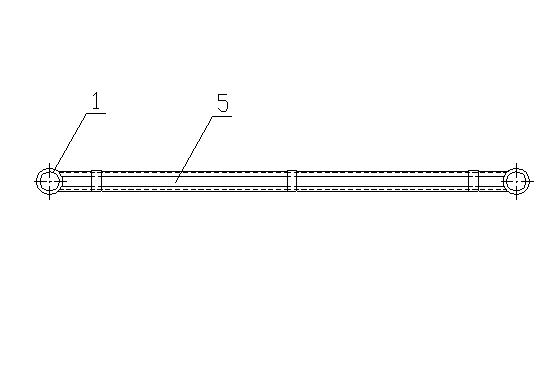

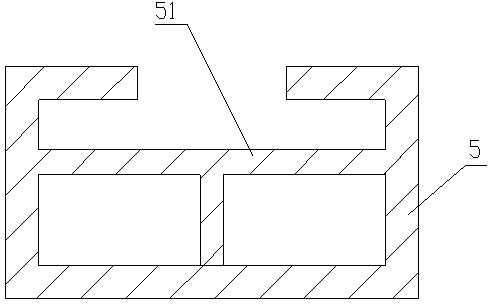

[0016] Such as figure 1 , figure 2 As shown, this embodiment is a production and assembly method of a microchannel heat exchanger, and the porous flat tubes 4 are evenly arranged between the headers 1 on both sides parallel to each other, and the porous flat tubes 4 are parallel to each other and perpendicular to the header 1 , All adjacent porous flat tubes 4 are provided with heat dissipation strips 3 . The ends of the collecting pipes 1 on both sides are blocked by end caps 2 , and the collecting pipe 1 is provided with a divider 7 for flow diversion. The inner side of the heat dissipation belt 3 located at the edge of the header 1 in the length direction is equipped with a porous flat tube 4, and the outer sides of the heat dissipation belt 3 are the upper guard plate 5 or the lower guard plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com