Patents

Literature

79results about How to "Reduce production workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material for aluminum electrolysis crust-breaking hammer

The invention relates to a material for an aluminum electrolysis crust-breaking hammer, which is characterized by comprising the following components in percentage by weight: 0.5%-3.0% of carbon, 3.5%-10.0% of manganese, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulphur, 5.0%-20.0% of chromium, less than 0.05% of Ni and the balance of ferrum. The material for the aluminum electrolysis crust-breaking hammer is an iron alloy material and is prepared by using a lost foam casting or sand casting process. In the invention, The manganese content in the material for the crust-breaking hammer is increased and the chromium content is optimized, thereby the material effectively improves the strength and wear resistance of the aluminum electrolysis crust-breaking hammer, prolongs the service life of the hammer, extends the replacement period, reduces the production cost and effectively relieves the labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

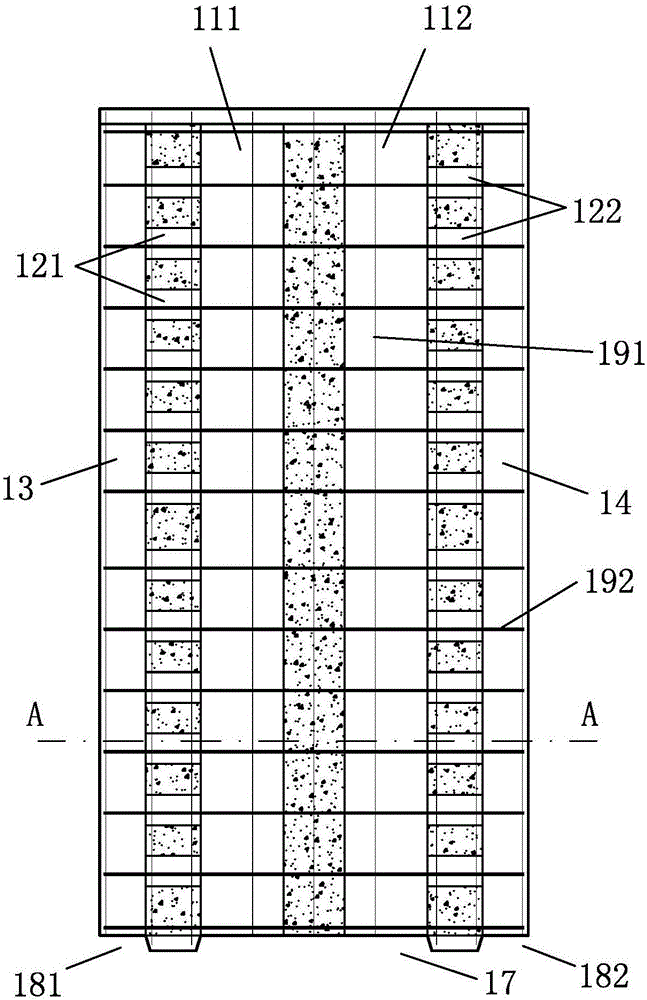

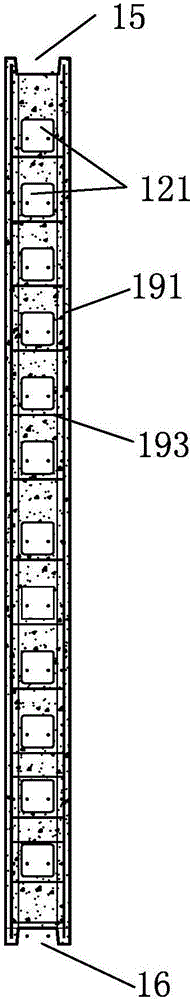

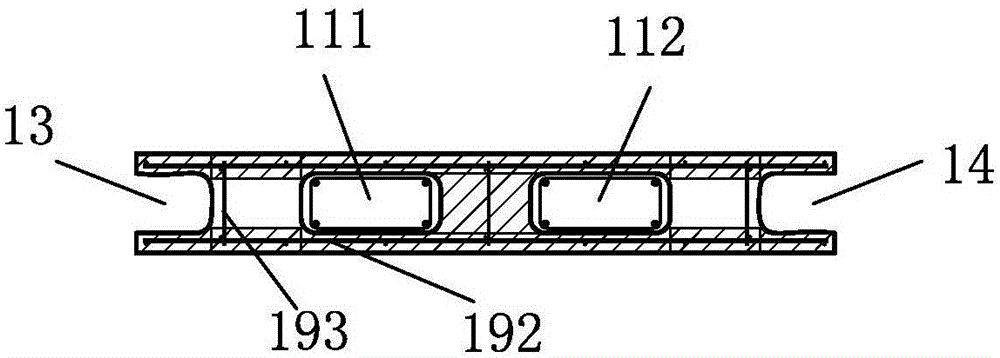

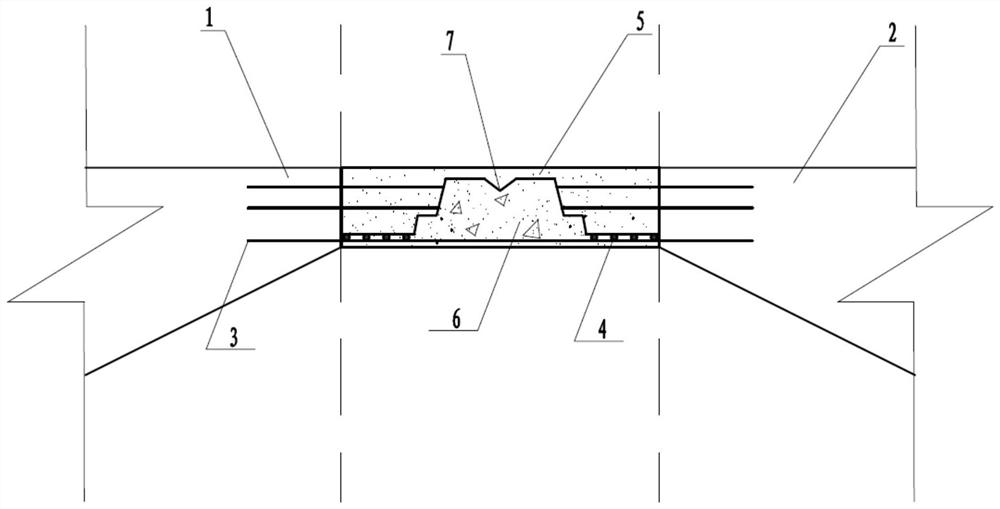

Concrete prefabricated panel, prefabricated building formed by same and construction method

PendingCN106499116AShorten the lengthReduce workloadDischarging arrangementWallsEngineeringBuilding design

The invention discloses a concrete prefabricated panel and a prefabricated building formed by the same. A nonpenetrating transverse hole is formed in the panel. The panel adopts a structure that the transverse hole is preserved in the edge rib of the panel, a horizontal steel bar meeting the splicing length required by codes for architectural and structural design is inserted into the hole, a transverse hole penetrating the whole panel is not required to be formed, the splicing of a horizontal steel bar between prefabricated panels can be achieved, the transverse transfer requirement is met, and the requirement of an earthquake resistant code of architectural design is met. The length of the inserted horizontal steel bar is greatly shortened, the cost is lowered, the workload and construction difficulty for penetrating the penetrating transverse steel bar are reduced, and the method is simple to implement, simple and effective, an excellent earthquake resistant effect can be achieved, and meanwhile the prefabricated panel is more convenient to produce and manufacture and higher in quality.

Owner:BEIJING EVEREST GREEN BUILDING TECH

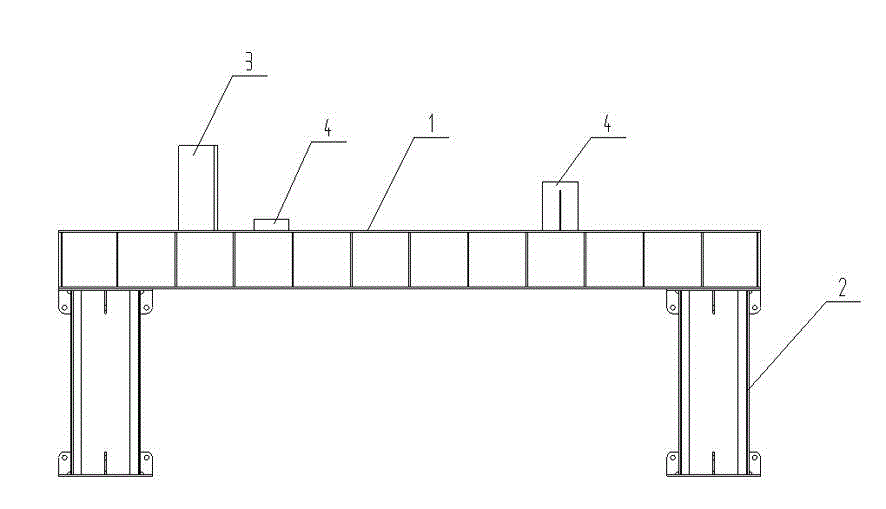

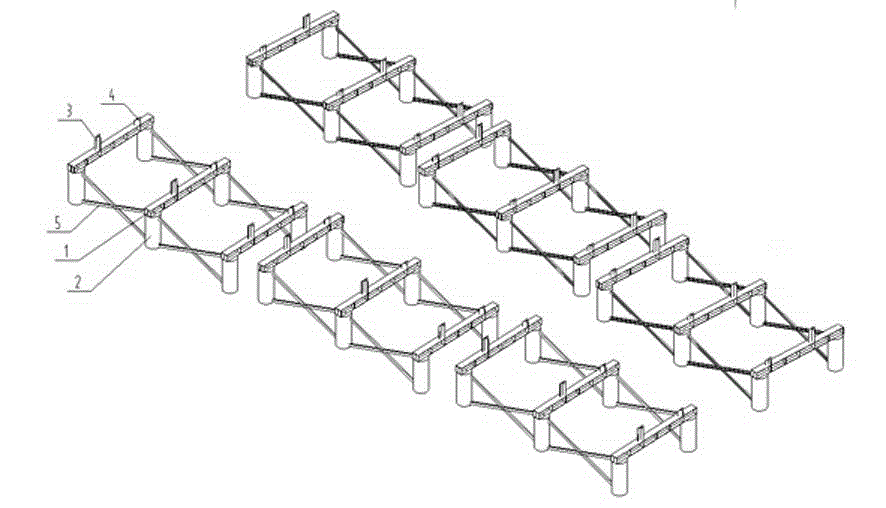

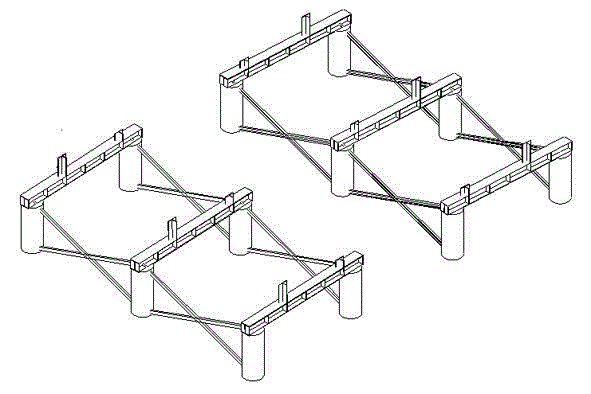

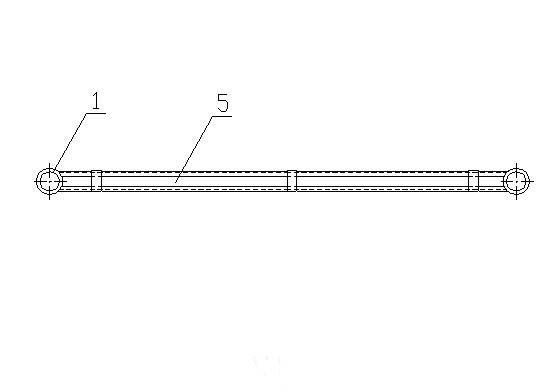

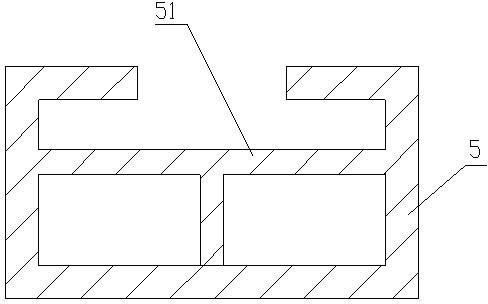

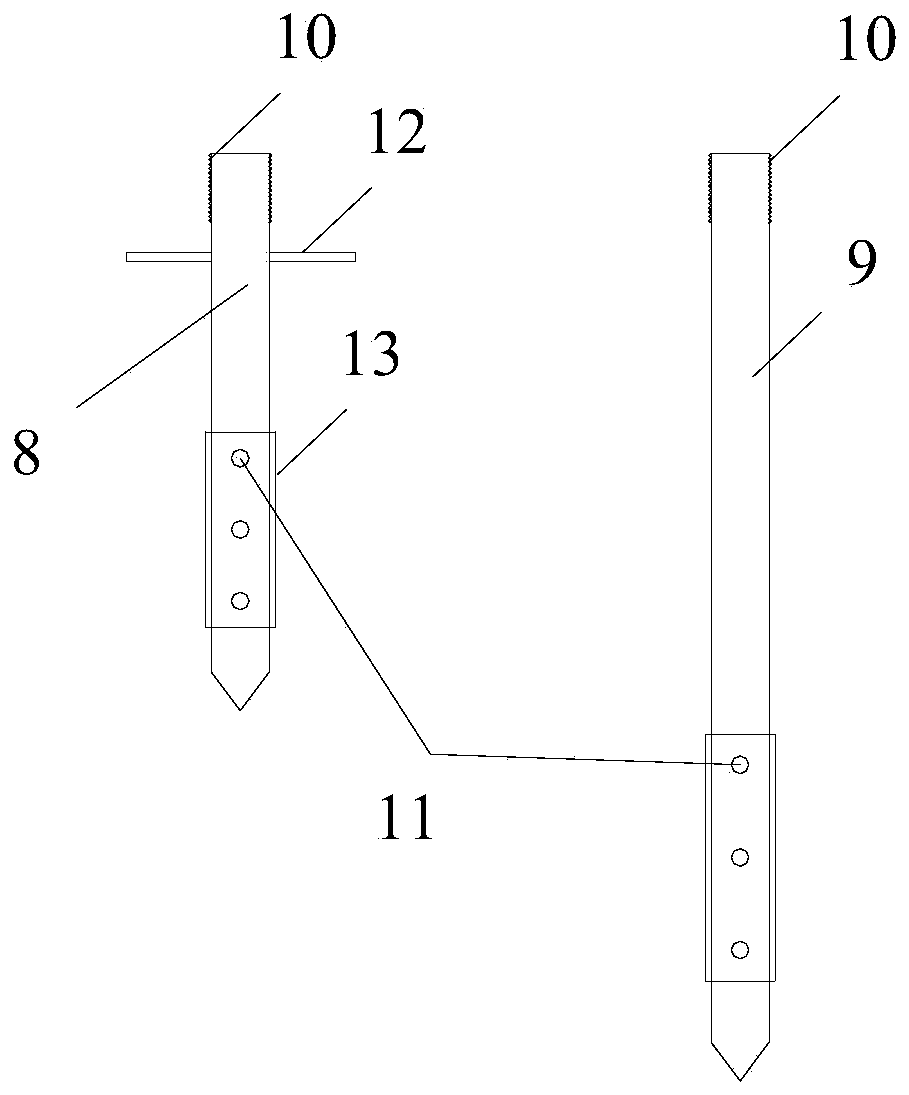

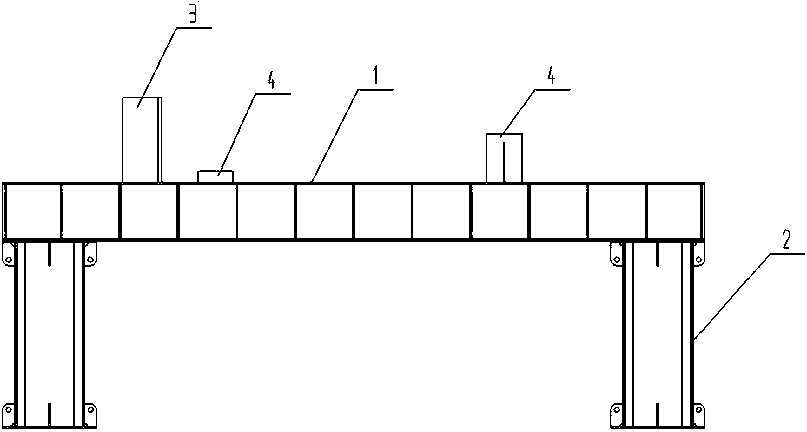

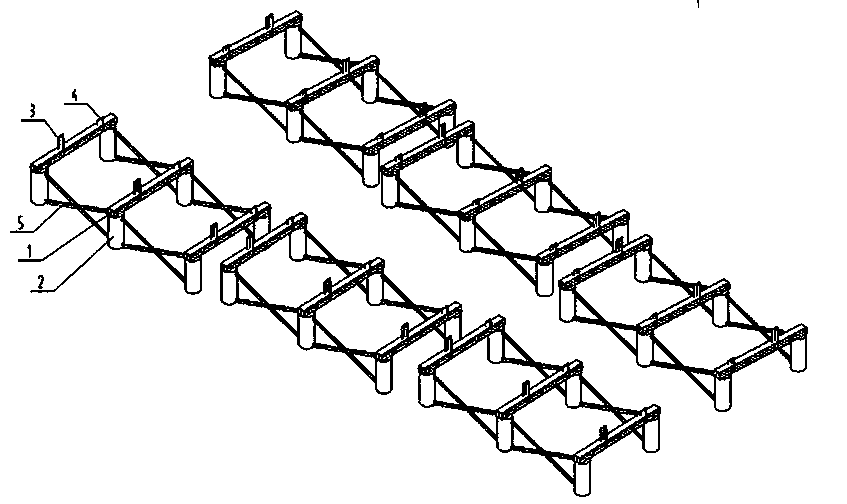

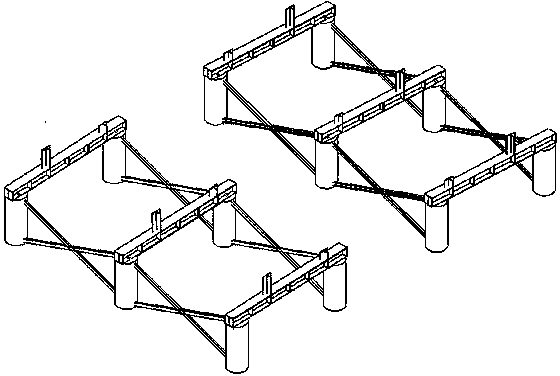

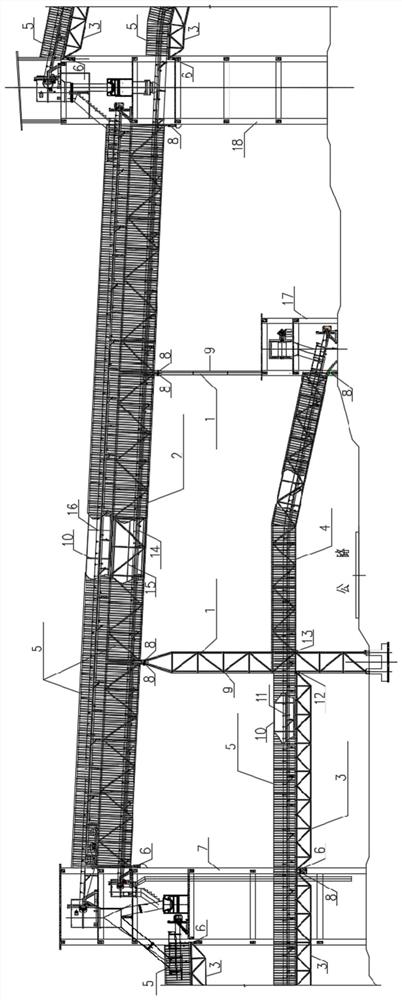

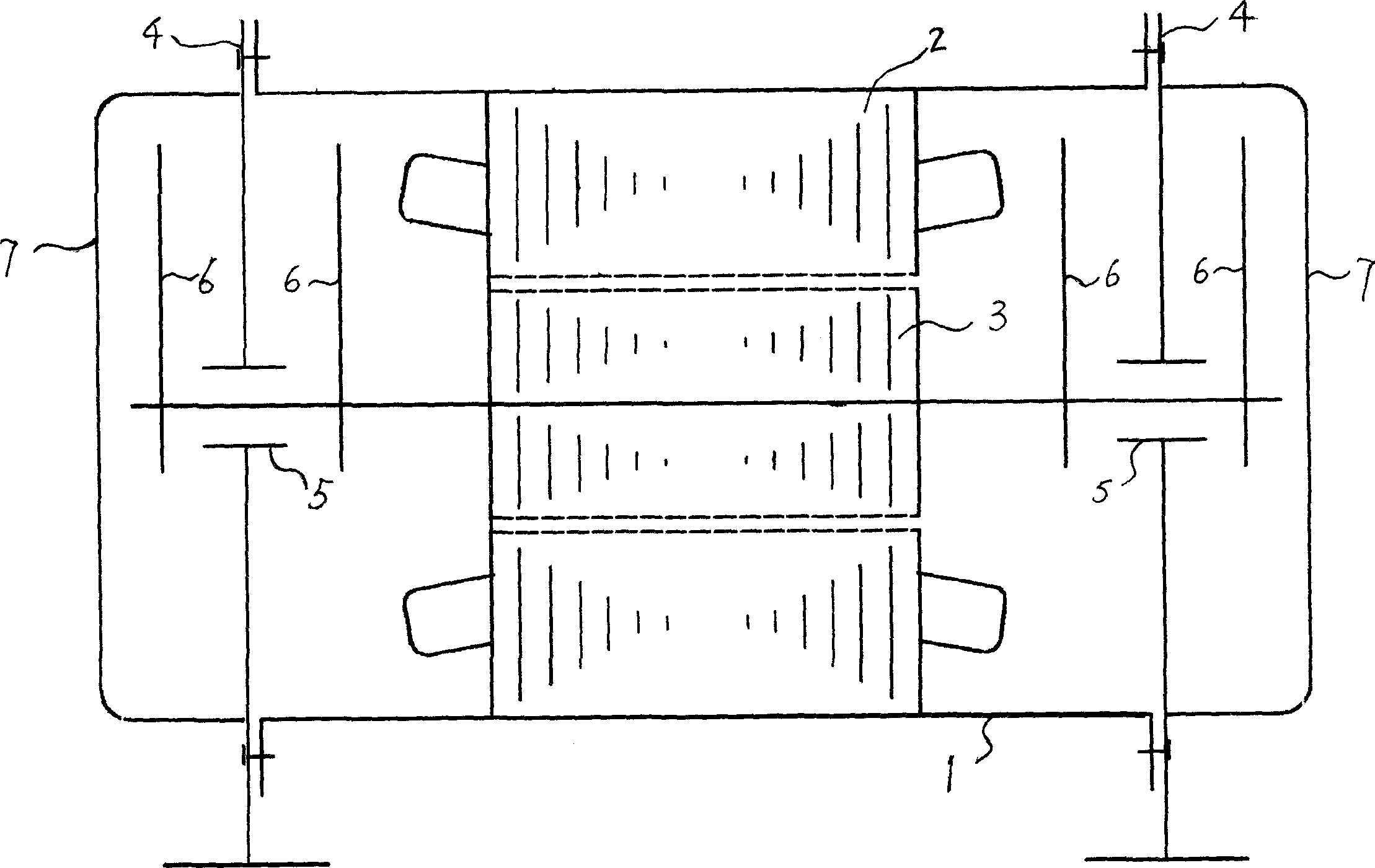

Vertical assembling construction method for trussed arch bridge

ActiveCN102912736AEasy to moveReduce production workloadBridge erection/assemblyEngineeringStructural engineering

The invention provides a vertical assembling construction method for a trussed arch bridge, and aims to overcome the shortcomings of large working amount and long working period of the conventional assembling method. The vertical assembling construction method comprises the following steps of: 1, manufacturing fixtures, wherein each fixture comprises a beam and vertical columns fixed at two ends of the beam; a limiting plate and a positioning plate are arranged on the upper end face of the beam; crossed supporting arms are arranged between the vertical columns of two fixtures; three fixtures are connected with one another by the crossed supporting arms to form a fixture group; and two parallel fixture groups serve as a platform for vertically assembling the trussed arch bridge; 2, assembling arch rib sections of the trussed arch bridge, and sequentially hoisting and positioning a lower chord pipe, a lower flat connection pipe, a web rod, an upper chord pipe, a vertical supporting pipe and an upper flat connection pipe on the two fixture groups; and 3, arranging a hydraulic flat plate trolley on the lower parts of the vertical columns of the fixtures, and conveying and transferring the assembled arch rib sections by the hydraulic flat plate trolley. According to the method, the fixture manufacturing working amount is reduced, the fixtures are convenient to move, and the working period can be shortened.

Owner:CHINA RAILWAYS CORPORATION +2

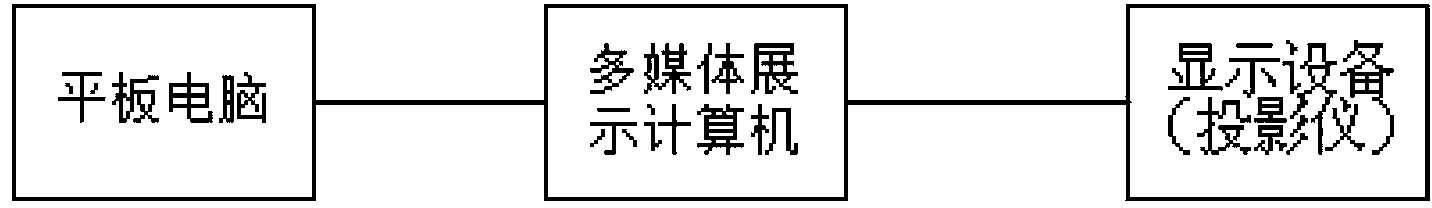

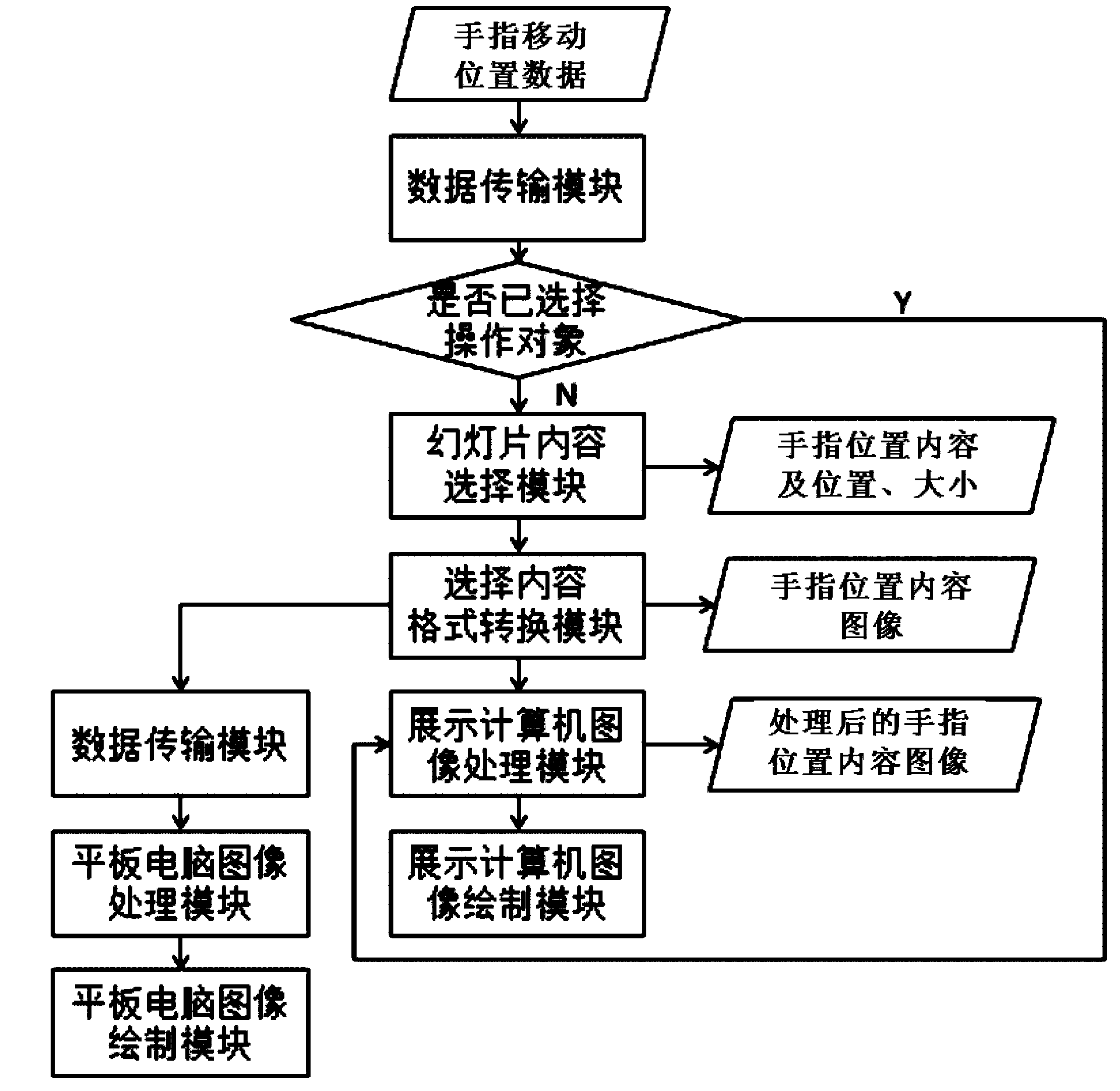

Slideshow-based dynamic content adjustment method

InactiveCN103365980AConvenient for dynamic adjustmentEasy to adjustSpecial data processing applicationsInput/output processes for data processingUser needsTablet computer

The invention relates to a slideshow-based dynamic content adjustment method which is characterized by comprising the following steps: 1, system connection is carried out; 2, the current operating state is judged and processed through an operating state control module after touch information is input to a panel computer; 3, a slide content selection module performs coordinate transformation to input position data and judges the content object that a user needs to operate; 4, a format conversion module converts the selected content object into image data in a bitmap format according to the type of the selected content object, and the image data are processed respectively by a computer and the panel computer; 5, the image drawing module of the multimedia display computer fulfill image drawing according to new position and size so as to replace the original display mode of the object in a slide. The method meets the requirement of dynamic adjustment of contents in a slideshow process, reduces the making difficulty and complexity of slides, enables the explanation process to be more flexible and convenient and is conductive to improving the explanation effect.

Owner:贾建仓

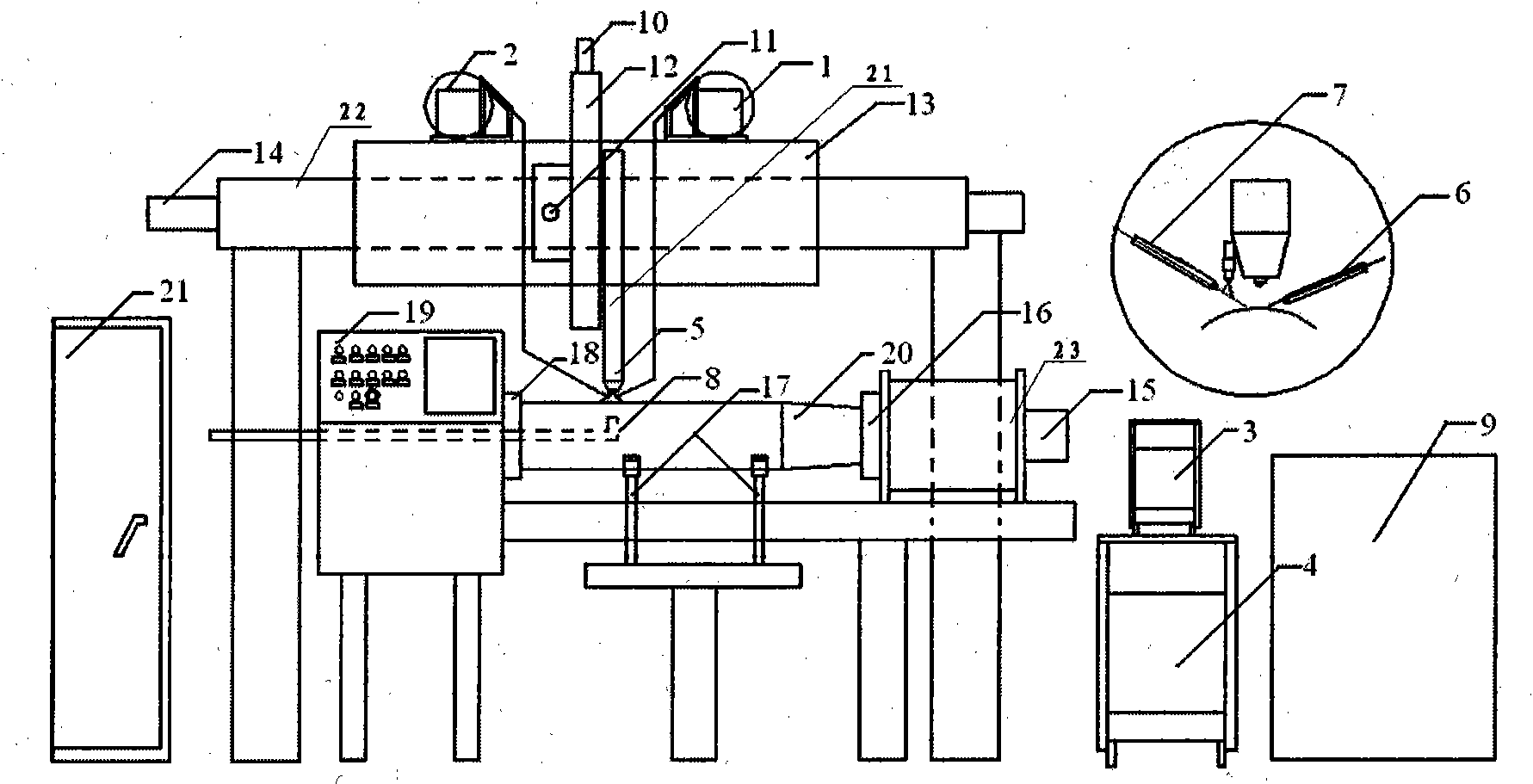

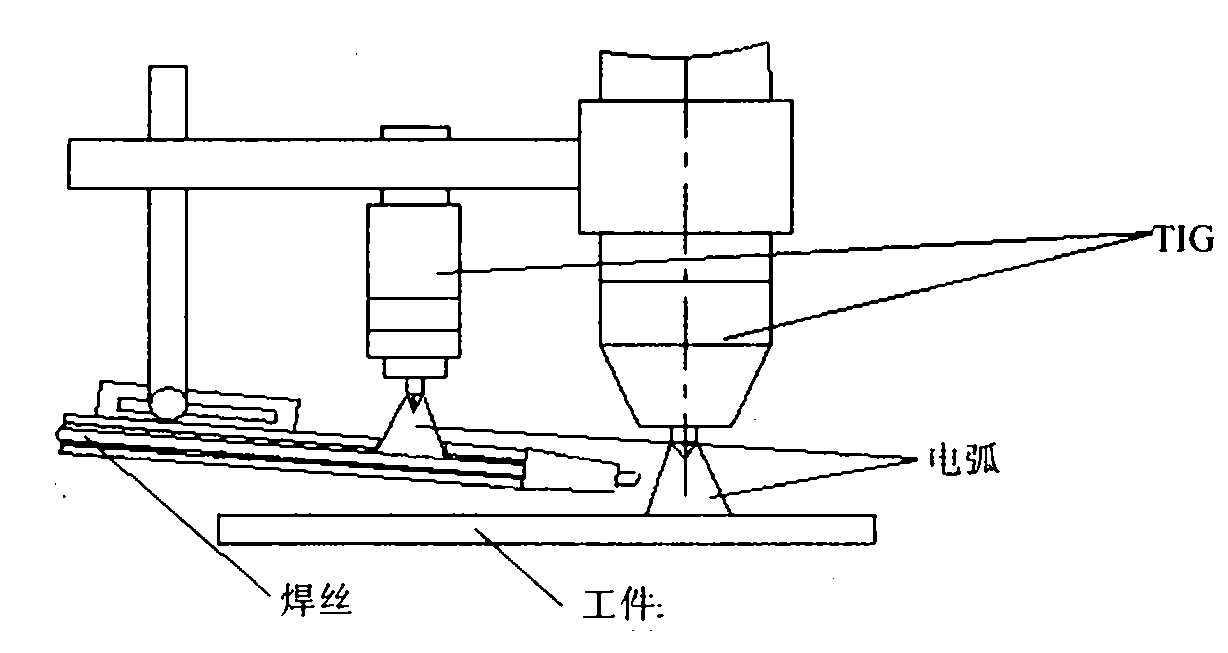

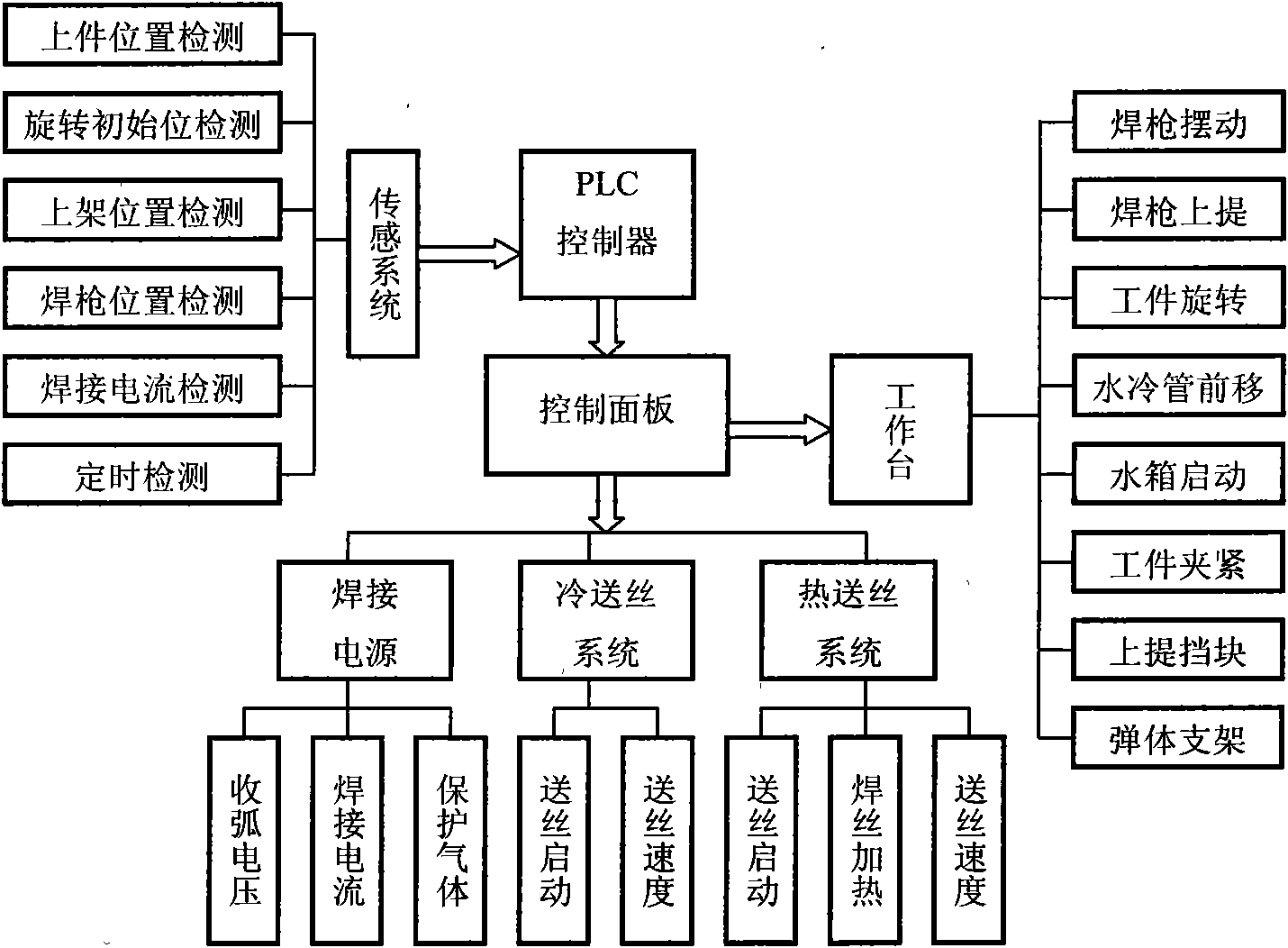

TIG (Tungsten Inert Gas) automatic surfacing method for projectile copper alloy conduction band

The invention aims to provide a TIG (Tungsten Inert Gas) automatic surfacing method for a projectile copper alloy conduction band by using a hot-cold wire double wire feeding system and a PLC (Programmable Logic Controller) control system. A welding process comprises the following steps of: presetting welding current, projectile body rotating speed and a rotating mode consisting of a uniform speed mode and a stepping mode by using the PLC, and introducing cooling water before ignition of welding electric arc to cool a welding gun and a projectile body, wherein the uniform-speed rotating mode is adopted during the surfacing of a narrow projectile band, and the stepping rotating mode is adopted during the surfacing of a wide projectile band; moving the welding gun to an appropriate position, igniting hot wire electric arc, welding main welding electric arc, and feeding a hot wire and a cold wire at the same time; and after surfacing and arc starting, surfacing for 5-10 millimeters at low current and low wire feeding speed. The method has the advantages of simplifying a machining process, lowering the production cost, reducing the machining procedures of the conventional process, shortening the production time, reducing the workload, increasing the production efficiency, lowering the material consumption and saving cost; and the welding process has high repeatability, and is easyto realize automatic production.

Owner:HARBIN INST OF TECH

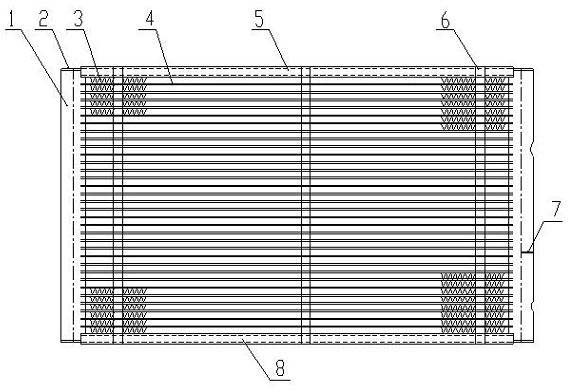

Method for producing and assembling micro-channel heat exchanger

ActiveCN102628654ALow costSolve the defect of deformationStationary conduit assembliesHeat exchanger casingsPlate heat exchangerNitrogen

The invention relates to a micro-channel heat exchanger technology, in particular to a method for producing and assembling a micro-channel heat exchanger. According to the method, the problems of deformation of a core body protective plate and oxidized black residues attached to the protective plate caused by that the core body of the micro-channel heat exchanger is reinforced by a stainless steel square pipe before braze welding are solved. The method is characterized in that porous flat pipes are arranged between collecting pipes on two sides uniformly in parallel; a radiating belt is arranged between the adjacent porous flat pipes; the end parts of the parallel and symmetrical collecting pipes are plugged by end covers; partition boards are arranged in the collecting pipe; the porous flat pipes are arranged on the inner sides of the radiating belts on the edge of the length direction of the collecting pipes; upper protective plates or lower protective plates are arranged on the outer sides of the radiating belts; the protective plates and the lower protective plates are bundled by a plurality of steel belts; the core body, bundled by the steel belts, of the micro-channel heat exchanger is conveyed to a nitrogen protection high-temperature brazing furnace to be welded; and after the core body of the micro-channel heat exchanger moves out of the nitrogen protection high-temperature brazing furnace, the steel belts are removed. According to the method, no deformation defect exists, the surface is smooth, clean and attractive, and production efficiency is high.

Owner:浙江康盛热交换器有限公司

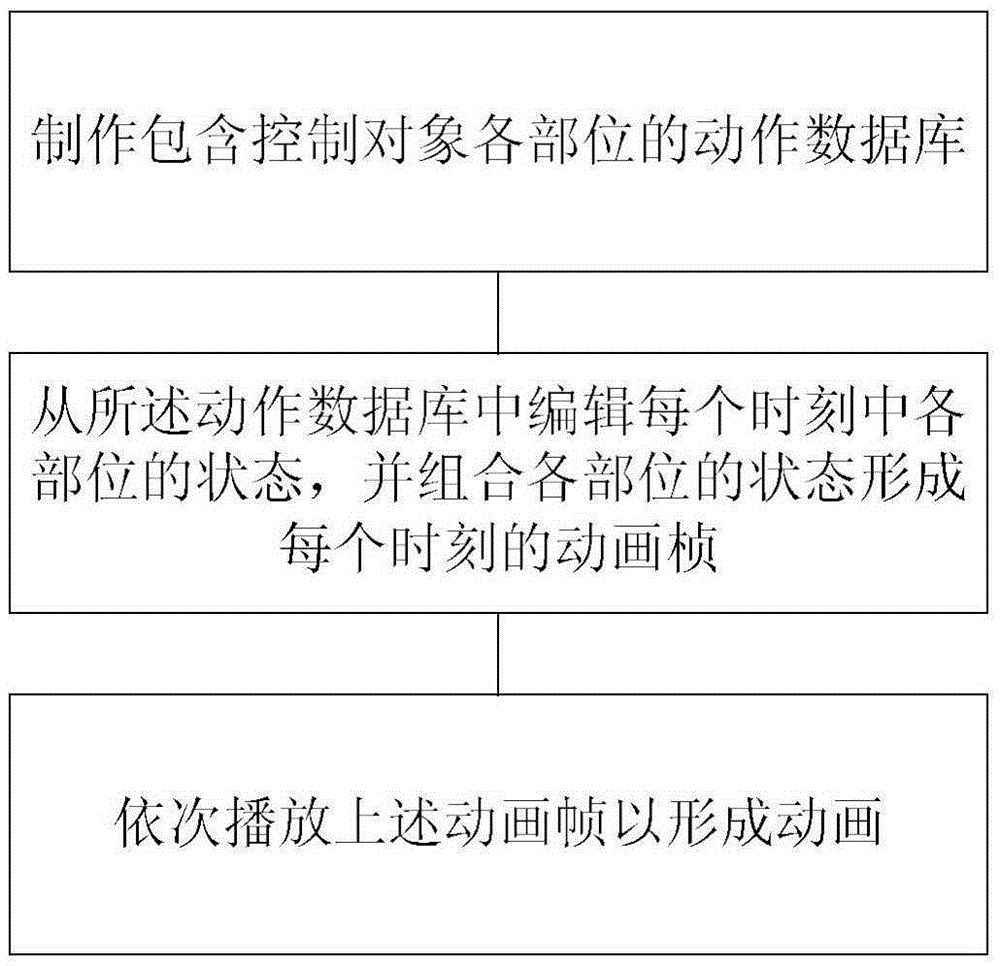

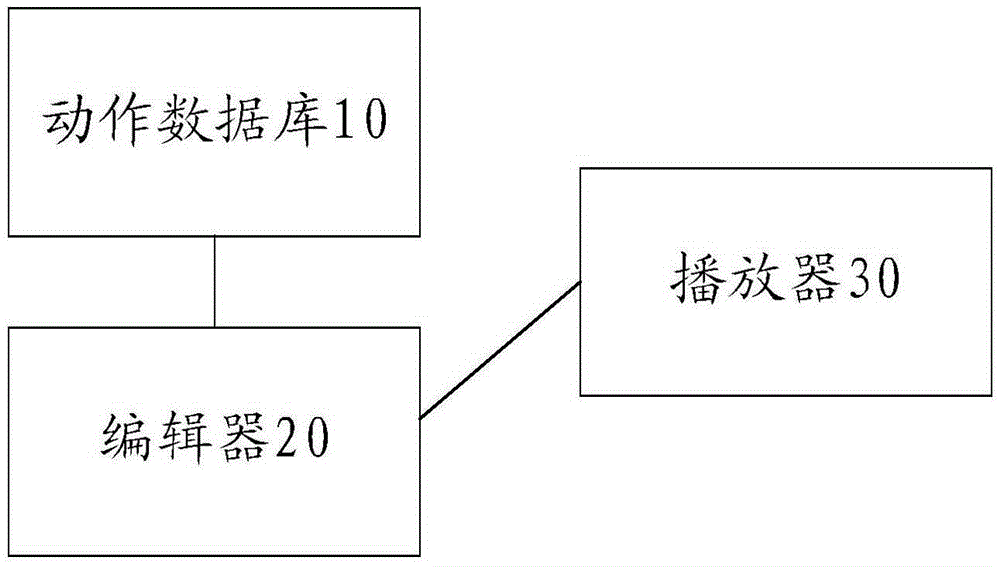

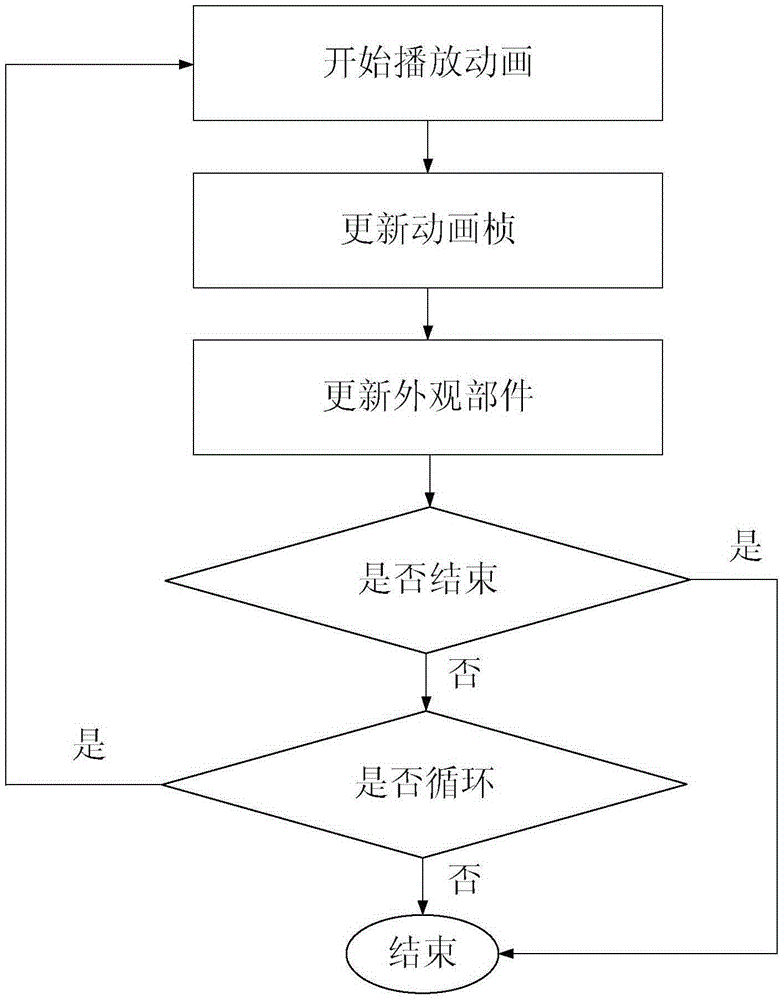

Animation implementation method, system and animation updating method

The invention provides an animation implementation method. The animation implementation method comprises the steps of making an action database including all parts of a control object, editing the state of each part at every moment in the action database, combining the state of each part to form an animation frame at every moment; and sequentially playing the animation frames to form an animation. The invention also provides an animation implementation system corresponding to the above animation implementation method. The animation implementation system comprises the action database, an editor and a player. The animation technology comprises a whole set of technical solution, specific animation editing tools, rich body parts and application of a key frame technology, the specific way of combining key frames and bone animation is adopted, the rich clothes-changing effect can be realized, meanwhile the animation data volume is greatly decreased and the making workload is greatly reduced, thus the comprehensive effect of flexibility, resource saving and friendliness to art is achieved. Based on the above system, the invention also provides an animation updating method so that clothes and equipment are convenient to change.

Owner:SHENGQU INFORMATION TECH SHANGHAI

Tap hole integral pouring mud sleeve for blast furnace and manufacturing method thereof

ActiveCN101781693AReduce production workloadSave consumption and costBlast furnace componentsBlast furnace detailsSlagRefractory

The invention relates to a tap hole integral pouring mud sleeve, which belongs to fittings for an ironmaking blast furnace tap hole and particularly relates to a mud sleeve for opening or blocking a tap hole. The mud sleeve is made of a refractory material arranged in a mud sleeve frame, and is characterized in that the refractory material is a pouring material and is compactly filled in the mud sleeve frame. The mud sleeve frame is a box-shaped body, and a consolidated hanger is arranged at the inner side of a frame plate; the rear end of the mud sleeve frame is connected with a blast furnace shell, a door frame is arranged at the front end of the mud sleeve frame, and a template is embedded in the door frame; a pouring hole is arranged at the upper side of the template, a module is fixed on the template and is opposite to the center of the tap hole, and an iron pipe provided with a tapping channel is arranged between the module and the tap hole; and compared with the prior art, the invention has the advantages that the tap hole mud sleeve is durable, the service life is markedly prolonged, the manufacturing workload of the mud sleeve is reduced, the usage quantity and the expense of the refractory material are saved, the gas leakage is reduced, and the casthouse operation is safe; the operation under pressure can be carried out, thereby avoiding damping down due to the manufacture of the tap hole mud sleeve, ensuring the timely slag iron tapping of the blast furnace and ensuring blast furnace successful operation, energy saving, consumption reduction and yield increase.

Owner:MAANSHAN IRON & STEEL CO LTD

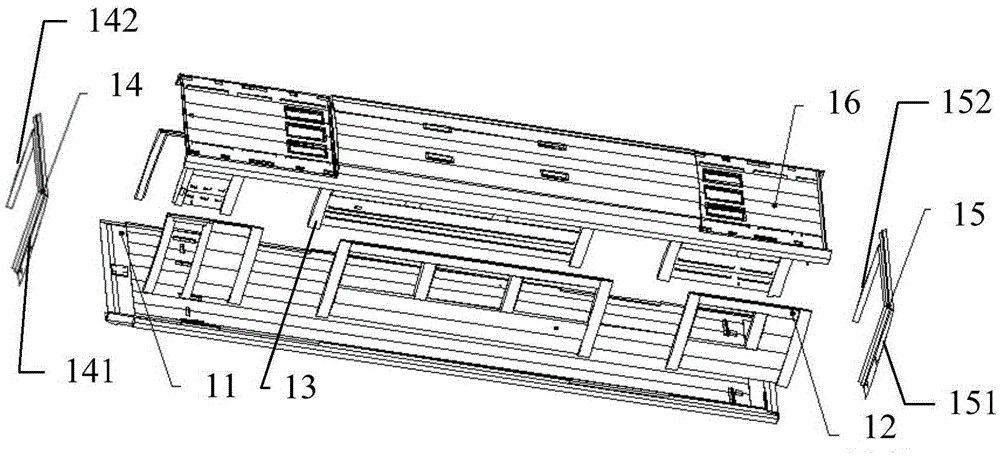

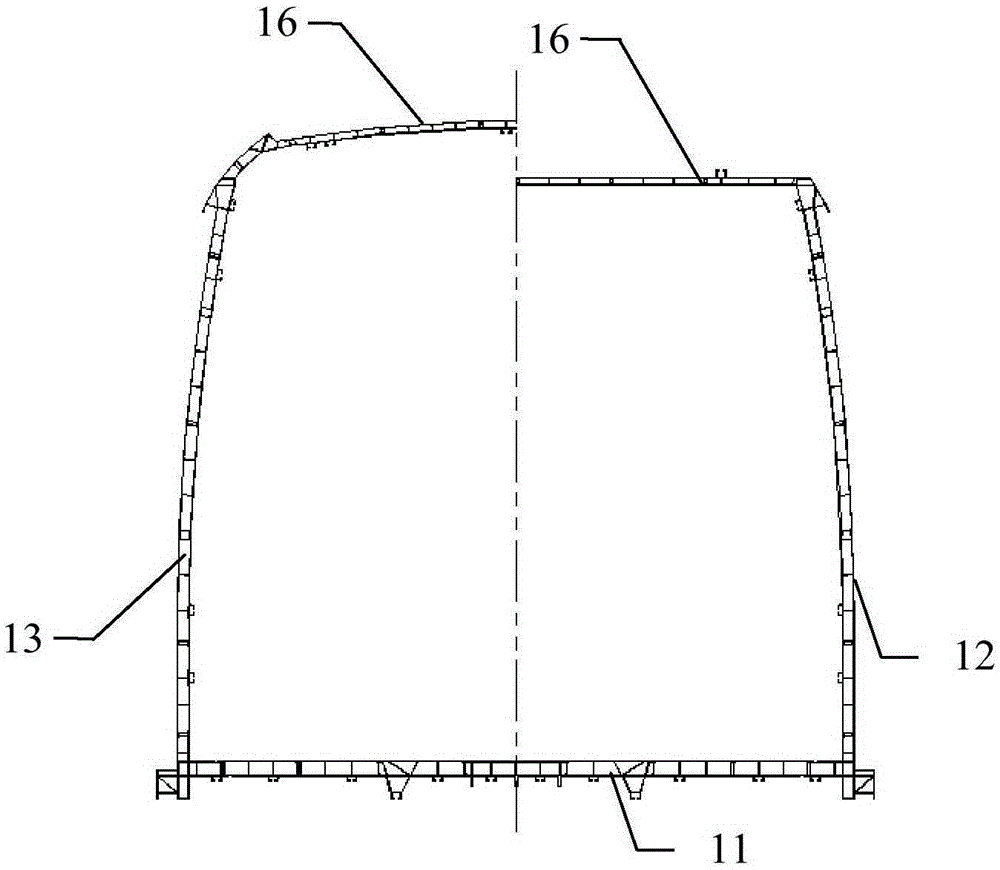

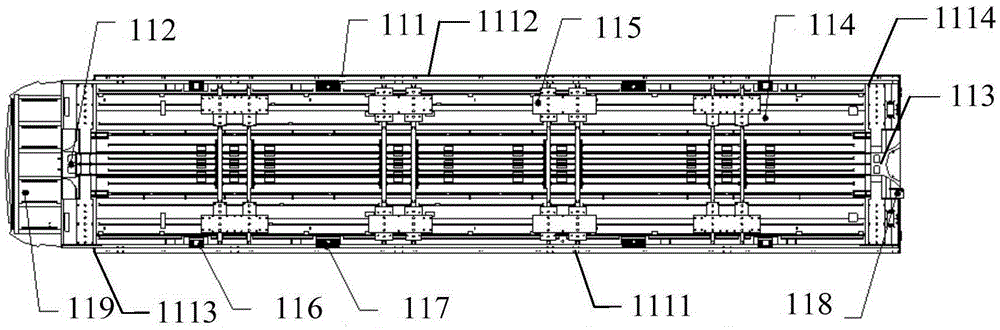

Train body structure of magnetic suspension train

InactiveCN105235697ASimple manufacturing processImprove product qualityRailway transportAxle-box lubricationEngineeringMaglev

The invention provides a train body structure of a magnetic suspension train. The train body structure of the magnetic suspension train comprises a chassis, a first side wall, a second side wall, a first end wall, a second end wall and a train roof, wherein the chassis is in welded connection with the train roof through the first side wall, the second side wall, the first end wall and the second end wall; the first side wall is in welded connection with the first end of the first end wall and the first end of the second end wall; the second end wall is in welded connection with the second end of the first end wall and the second end of the second end wall; the structure of the chassis, the structure of the first side wall, the structure of the second side wall, the structure of the first end wall, the structure of the second end wall and the structure of the train roof are each of an all-welded structure. Through the train body structure of the magnetic suspension train, the manufacturing quality of the train body of the magnetic suspension train can be improved, the manufacturing workload can be reduced, the manufacturing period can be shortened, and batch production can be accelerated.

Owner:CRRC TANGSHAN CO LTD

Cross-platform courseware intelligent synthesis method

ActiveCN107016631ASolve the problem of making online coursesSolve the problem of data interactionData processing applicationsFile access structuresThird partySynthesis methods

The invention discloses a cross-platform courseware intelligent synthesis method, which comprises the steps of performing resource preprocessing, that is, scanning an original course catalog structure to acquire an audio / video file, and transcoding or slicing the audio / video file through a transcoding tool or a slicing tool; generating course metadata, that is, scanning the course catalog structure, and generating a complete piece of metadata information when a current catalog name is scanned to be a predetermined resource type; building a new course chapter catalog, that is, building a chapter catalog corresponding to a new course according to the course metadata, and copying a corresponding template file. The cross-platform courseware intelligent synthesis method solves a problem that existing courseware materials need to be made into a network course in the reality, and supports offline and online courseware playing and cross-platform resource reading and data transmission. As long as resources of a teacher need not to be played by a third-party plug-in, the generated courseware can be played without a third-party plug-in.

Owner:弘成科技发展有限公司

Material for aluminium electrolysis crust breaking chip

The invention relates to a material for an aluminium electrolysis crust breaking chip. The invention is characterized in that the material comprises the following components by weight percent: 50%-70% of tungsten carbide, 5%-10% of titanium carbide, 0.01%-1.0% of carbon, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulfur, less than 0.05% of nickel and the balance iron. The invention discloses the high hardness crust breaking material; and the material for the crust breaking chip is designed again and uses tungsten carbide as the basic material, thus the service life of the crust breaking chip can be increased, the replacement cycle can be prolonged, the production cost can be reduced and the labor intensity is lowered.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

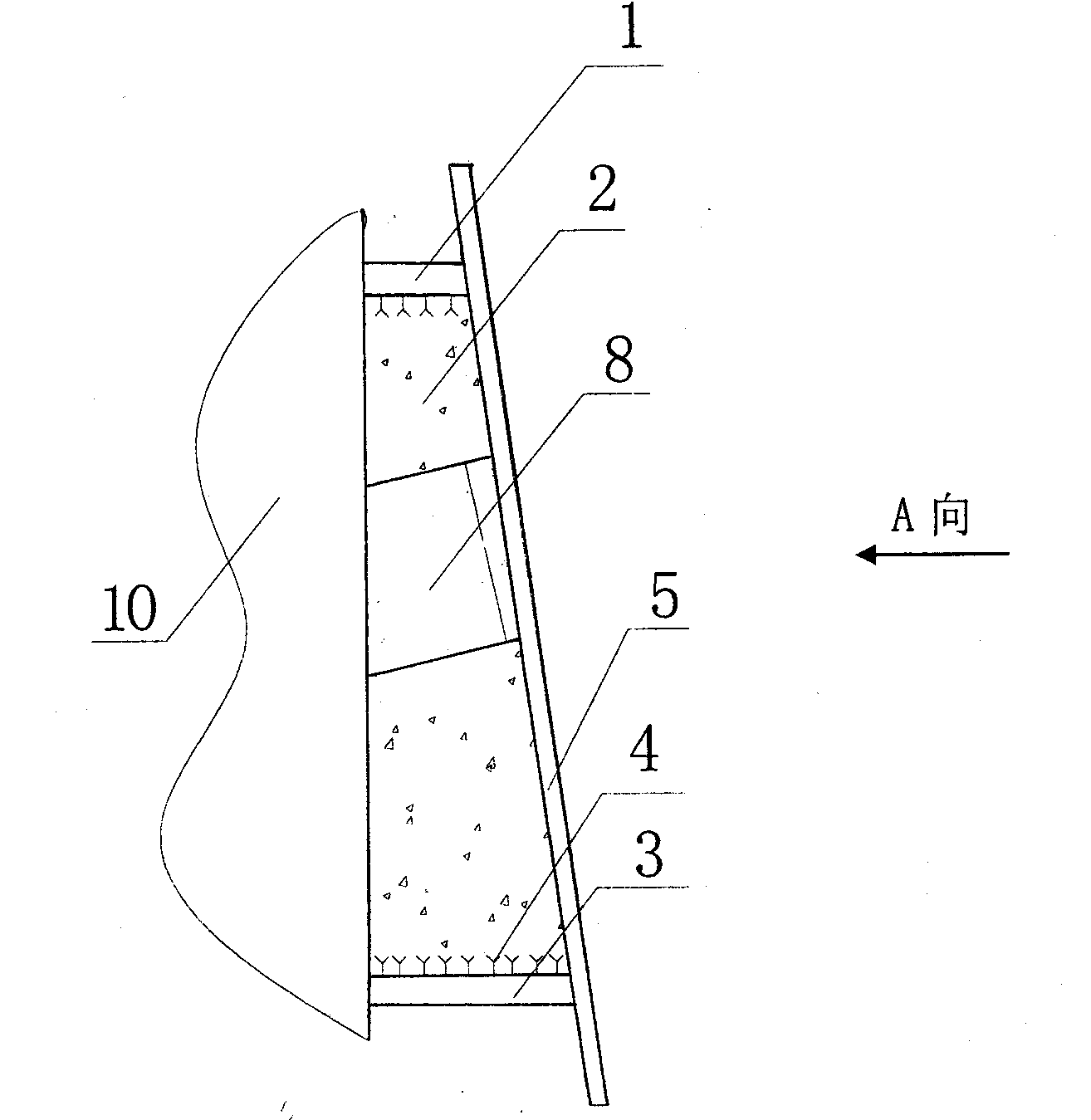

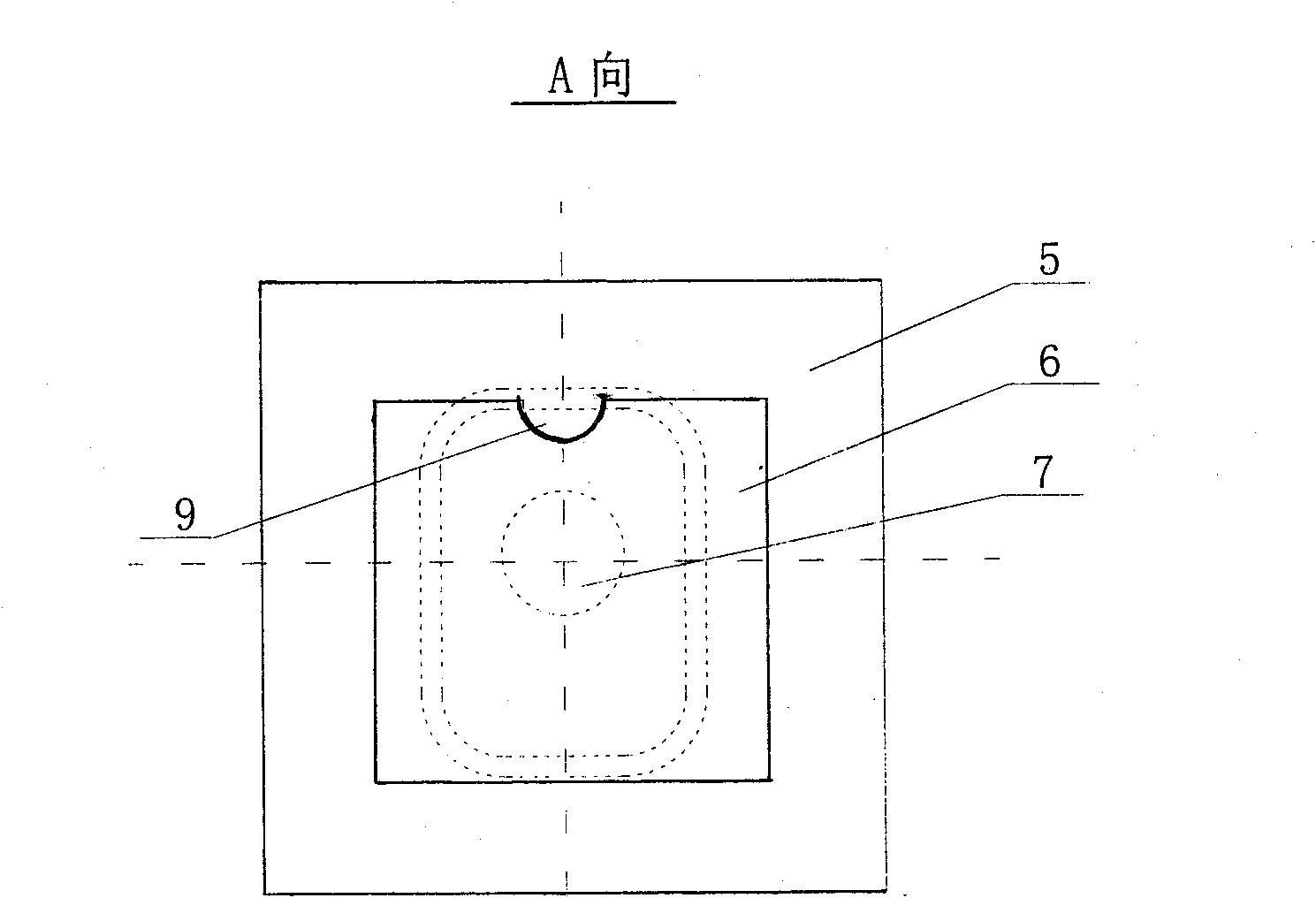

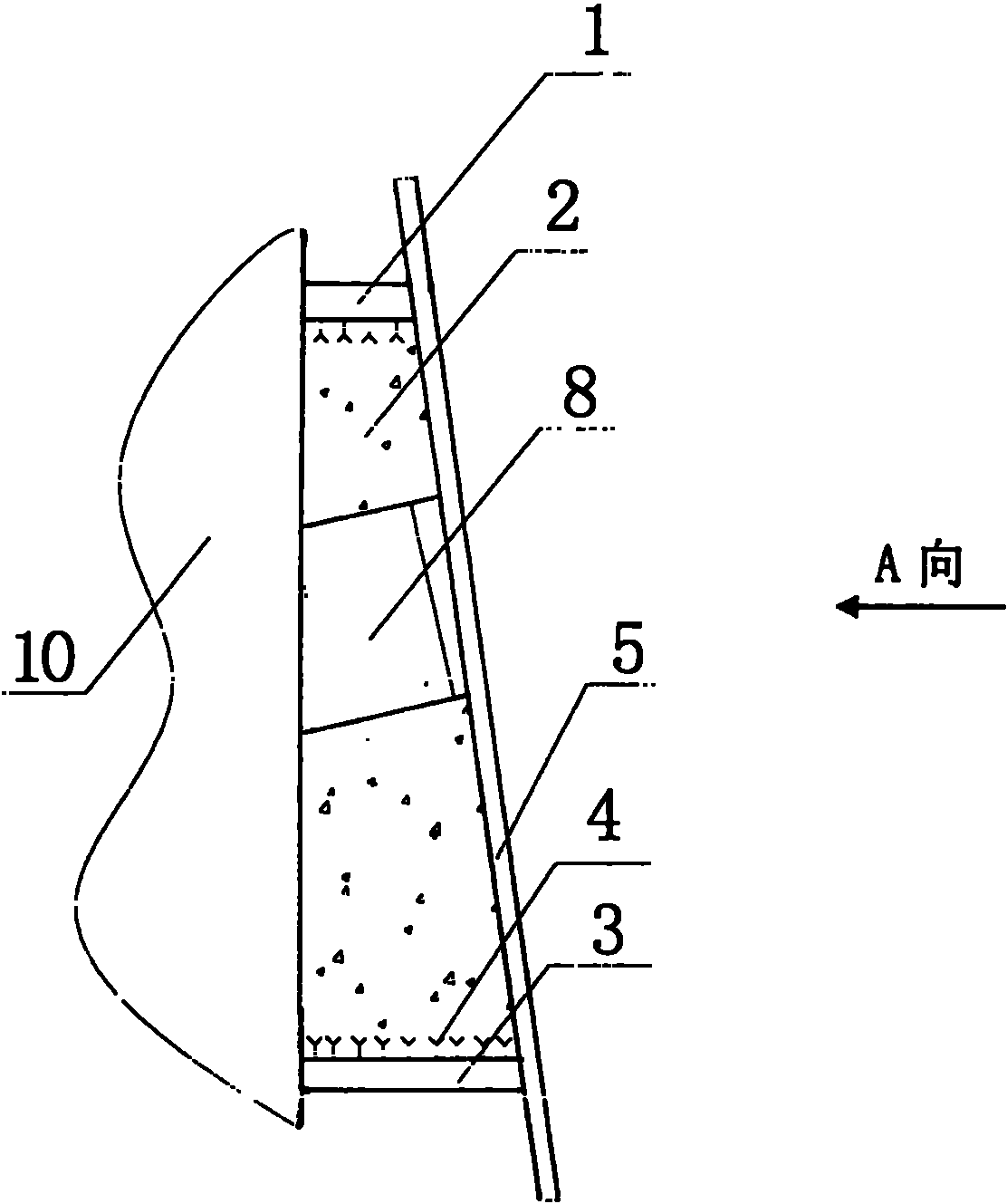

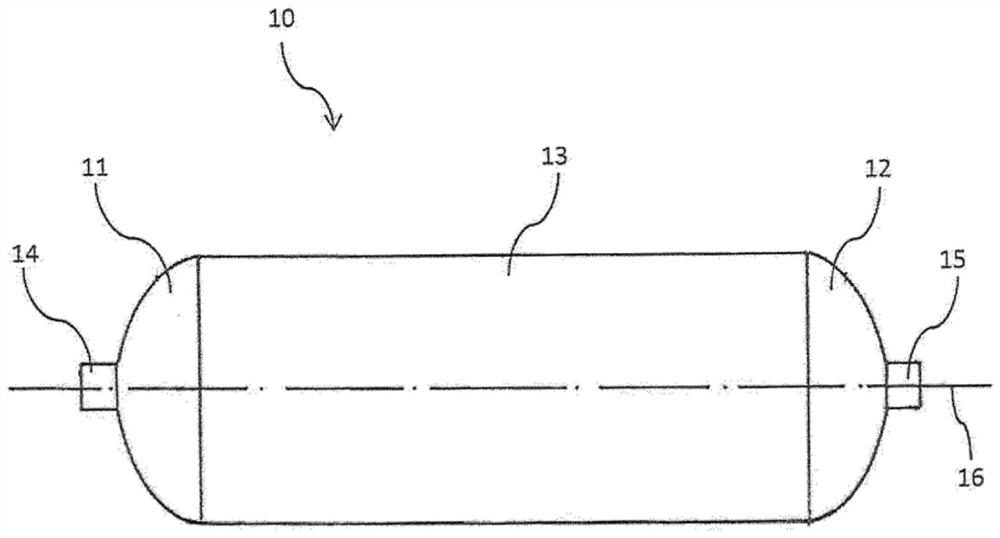

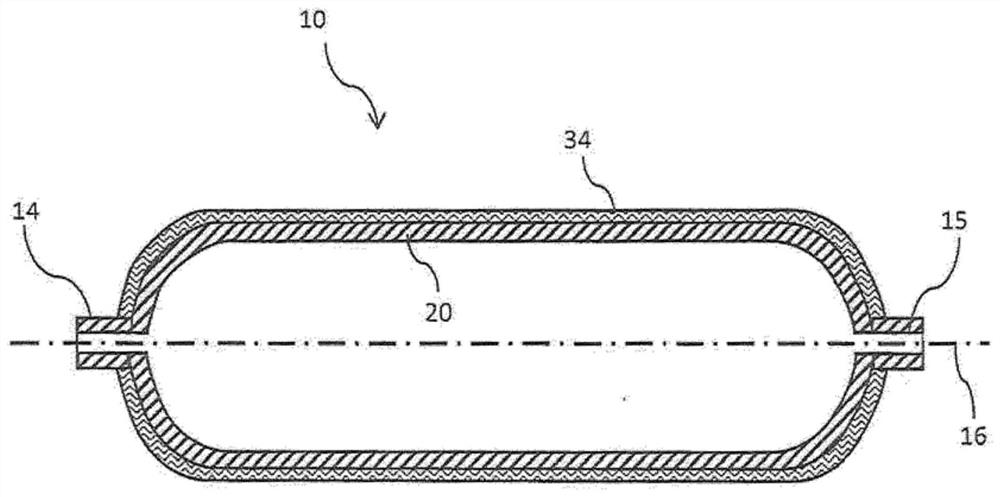

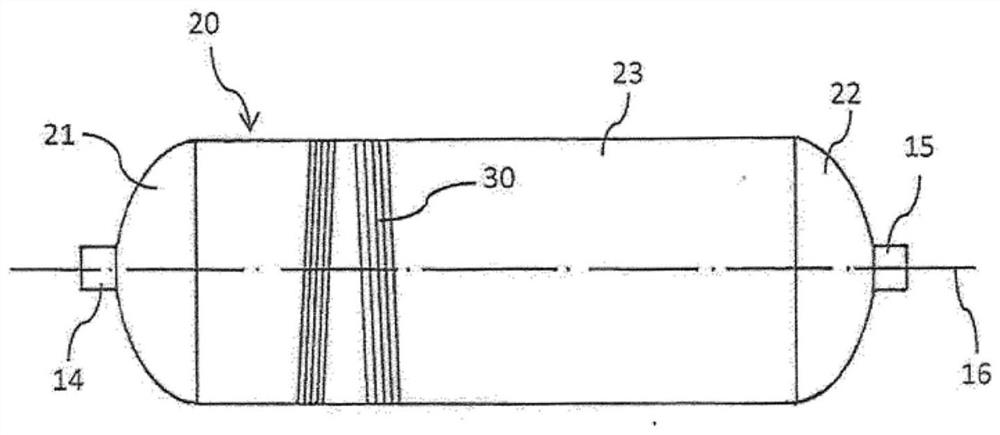

Method for producing a fibre-reinforced pressure vessel with pole cap reinforcement

ActiveCN112219058ALess quantityReduce production workloadVessel manufacturingVessel geometry/arrangement/sizeFiberEngineering

The invention relates to a method for producing a pressure vessel (10), comprising an inner vessel (20) and an outer layer (34) wound onto the inner vessel (20) and consisting of a fibre material. Inthe method, a holding device having multiple holding elements protruding therefrom is attached to an inner vessel (20) in order to wind a local pole cap reinforcement in a dome-shaped pole cap region(21;22) of the inner vessel. The holding device is then removed and an outer layer (340 is produced by winding fibre material, the outer layer (34) enclosing the central region (23) and the pole cap regions (21;22) of the inner vessel (20).

Owner:奈普奥私营有限公司

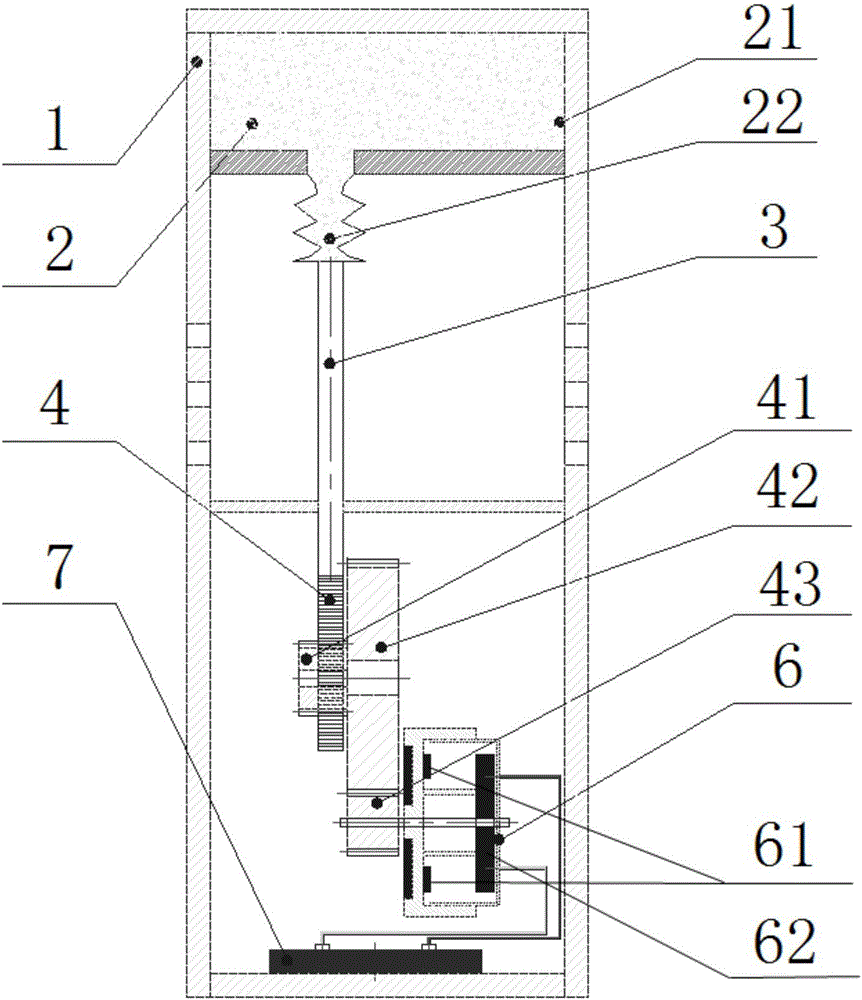

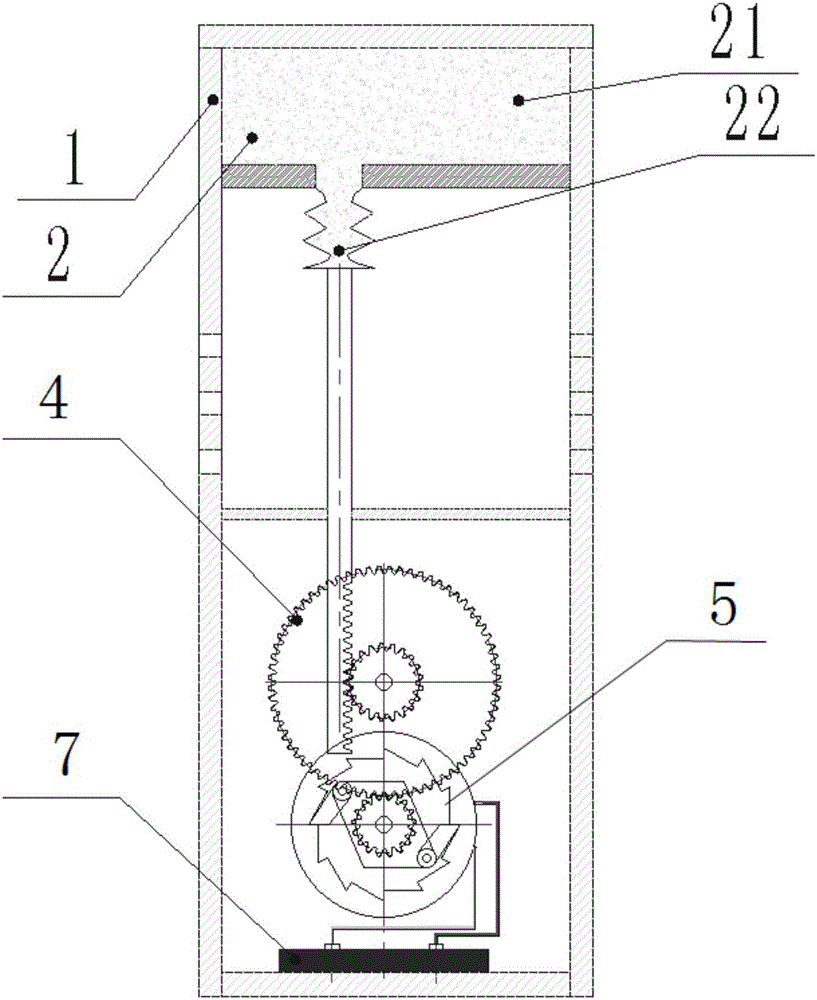

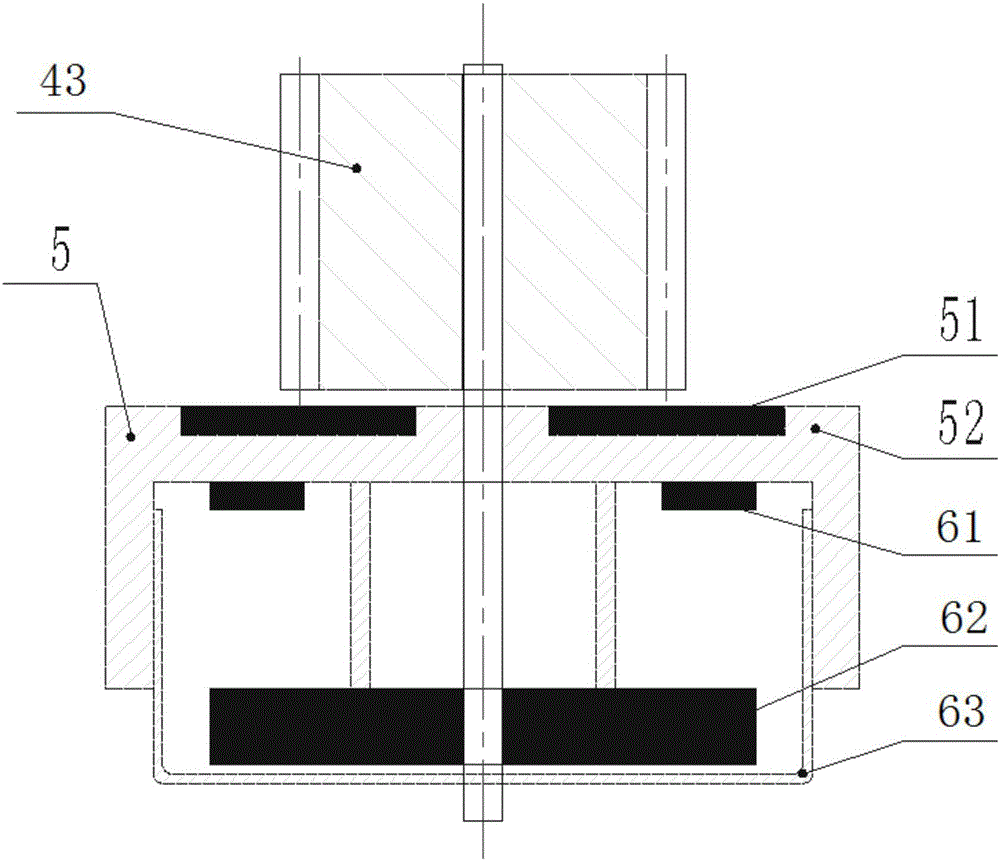

Oil well downhole power supply device and method

ActiveCN106761567AImprove battery lifeReduce manufacturing costMechanical energy handlingBorehole/well accessoriesEngineeringElectromagnetic induction

The invention provides an oil well downhole power supply device and method. The device comprises a shell body, an air bag, a transmission piece, a transmission mechanism, a ratchet mechanism and magnetic pieces. The interior and the exterior of the shell body communicate. The air bag is arranged in the shell body. When the air bag expands or shrinks, the air bag drives the transmission piece to move. When the transmission piece moves, the transmission mechanism is driven to move. When an active piece rotates, a ratchet wheel of the ratchet mechanism is driven to rotate. The magnetic pieces are arranged on the ratchet wheel, and when the ratchet wheel rotates, the magnetic pieces are driven to rotate. The magnetic pieces generate an electromagnetic induction with a coil in the rotating process, and generate an induced current in the coil. According to the oil well downhole power supply device provided by the embodiments of the invention, the cruising ability of the downhole power supply device is effectively improved, and the production cost and operation work load are reduced.

Owner:PETROCHINA CO LTD

Material for aluminium electrolysis crust breaking chip

The invention relates to a material for an aluminium electrolysis crust breaking chip. The invention is characterized in that the material comprises the following components by weight percent: 50%-70% of tungsten carbide, 5%-10% of titanium carbide, 0.01%-1.0% of carbon, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulfur, less than 0.05% of nickel and the balance iron. The invention discloses the high hardness crust breaking material; and the material for the crust breaking chip is designed again and uses tungsten carbide as the basic material, thus the service life of the crust breaking chip can be increased, the replacement cycle can be prolonged, the production cost can be reduced and the labor intensity is lowered.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

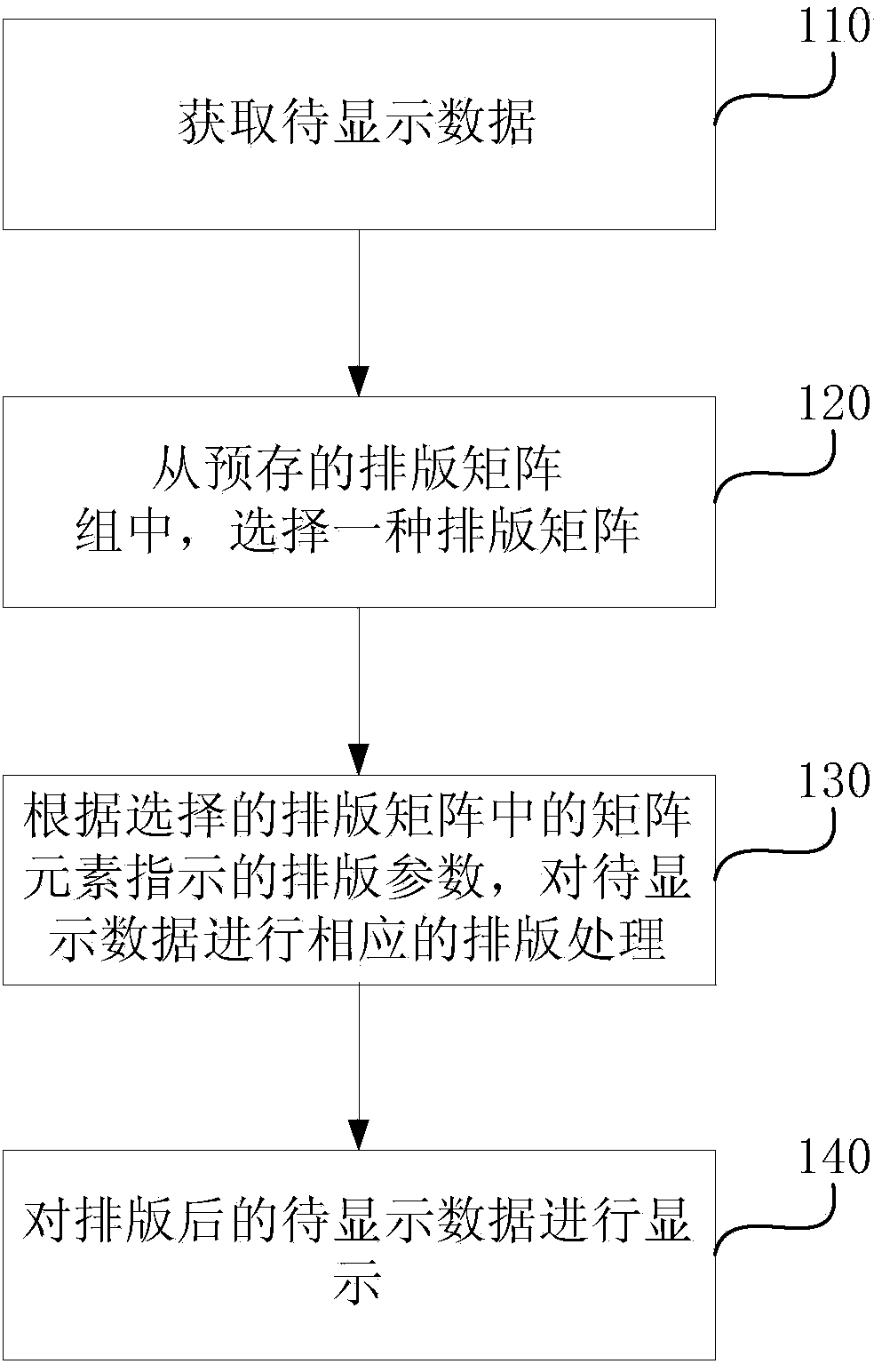

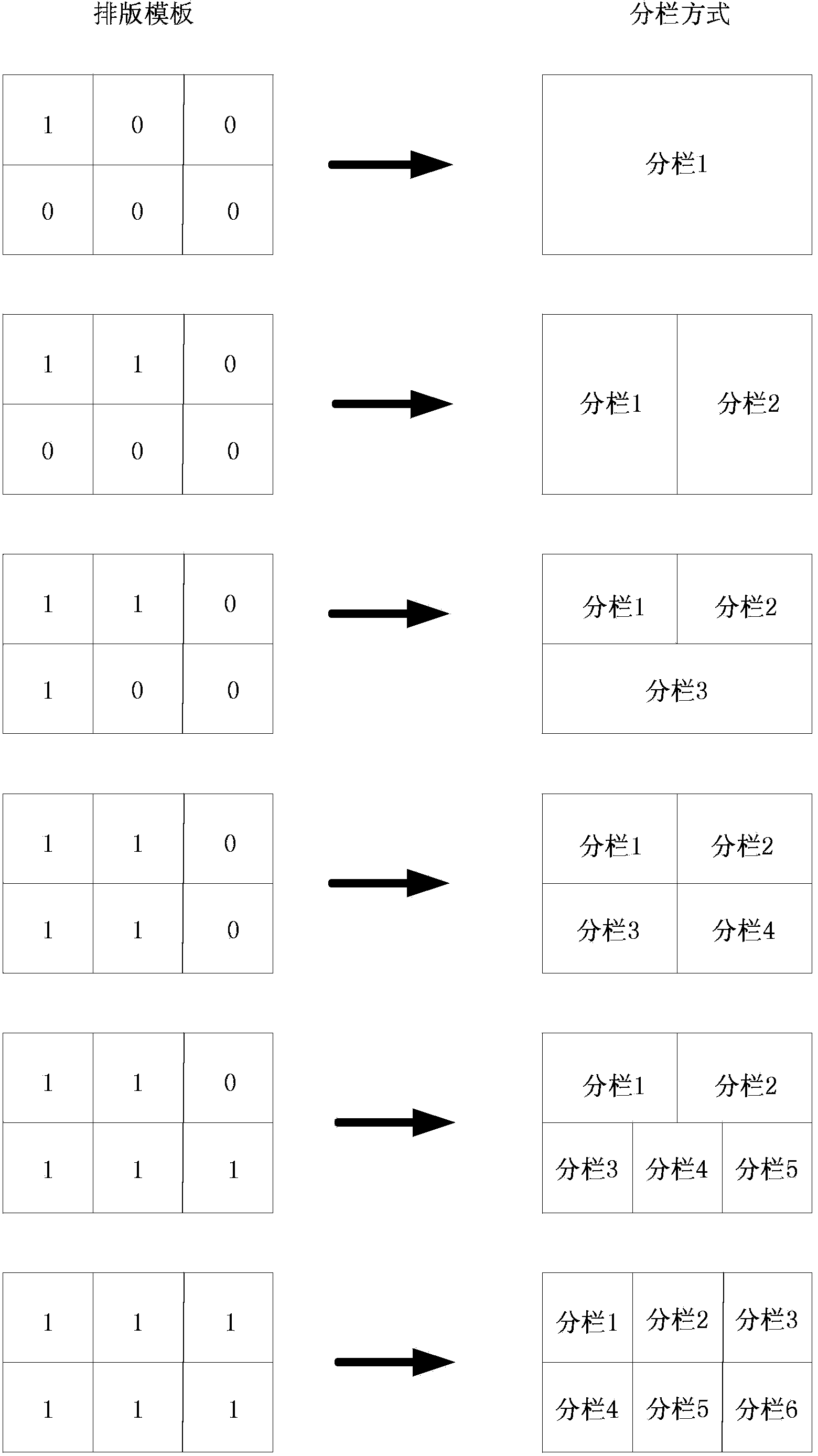

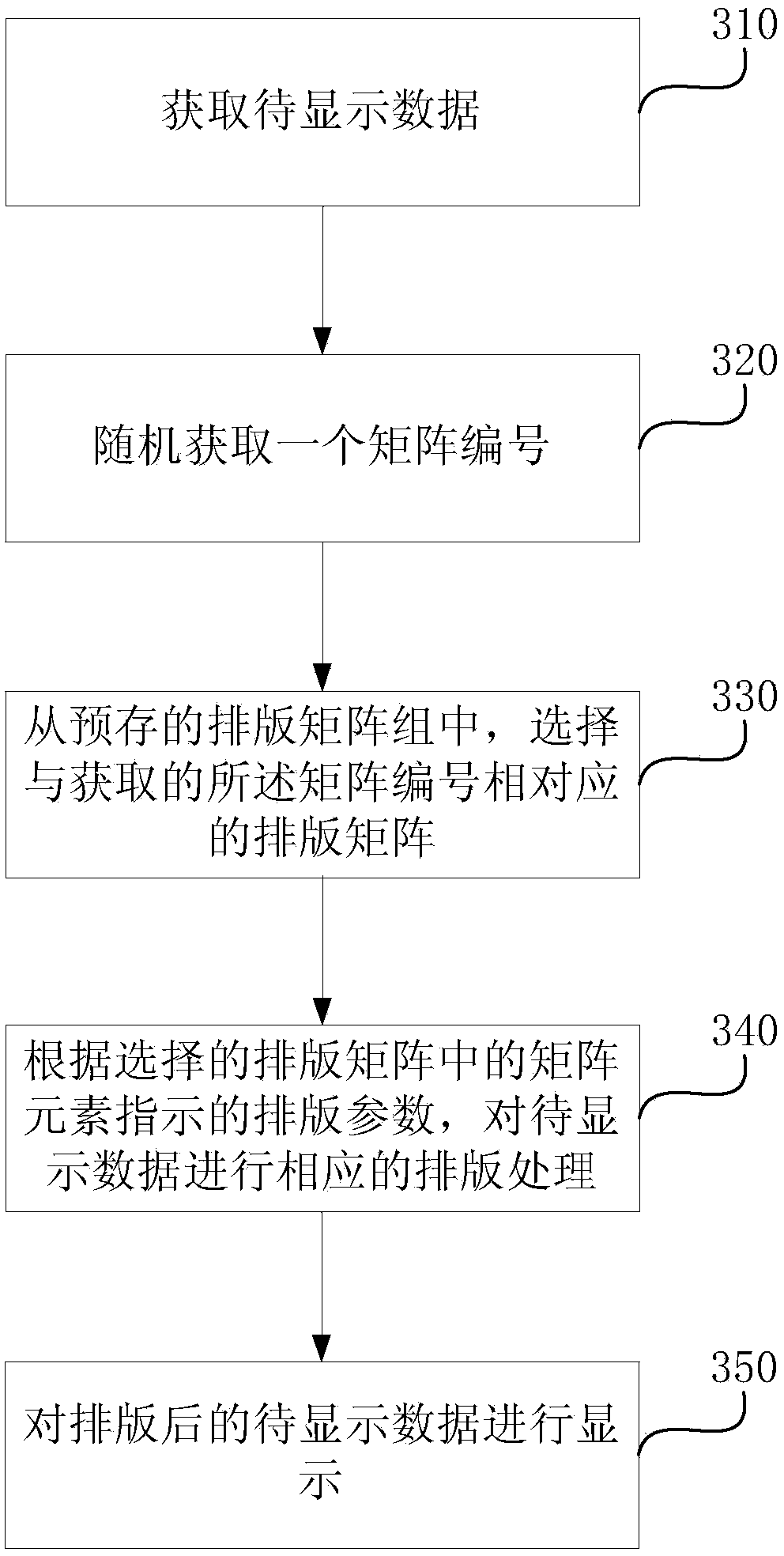

Electronic typesetting method and electronic typesetting device

ActiveCN103838708AReduce production workloadImprove experienceNatural language data processingSpecial data processing applicationsMatrix groupComputer terminal

Owner:TIANWEN DIGITAL MEDIA TECH BEIJING

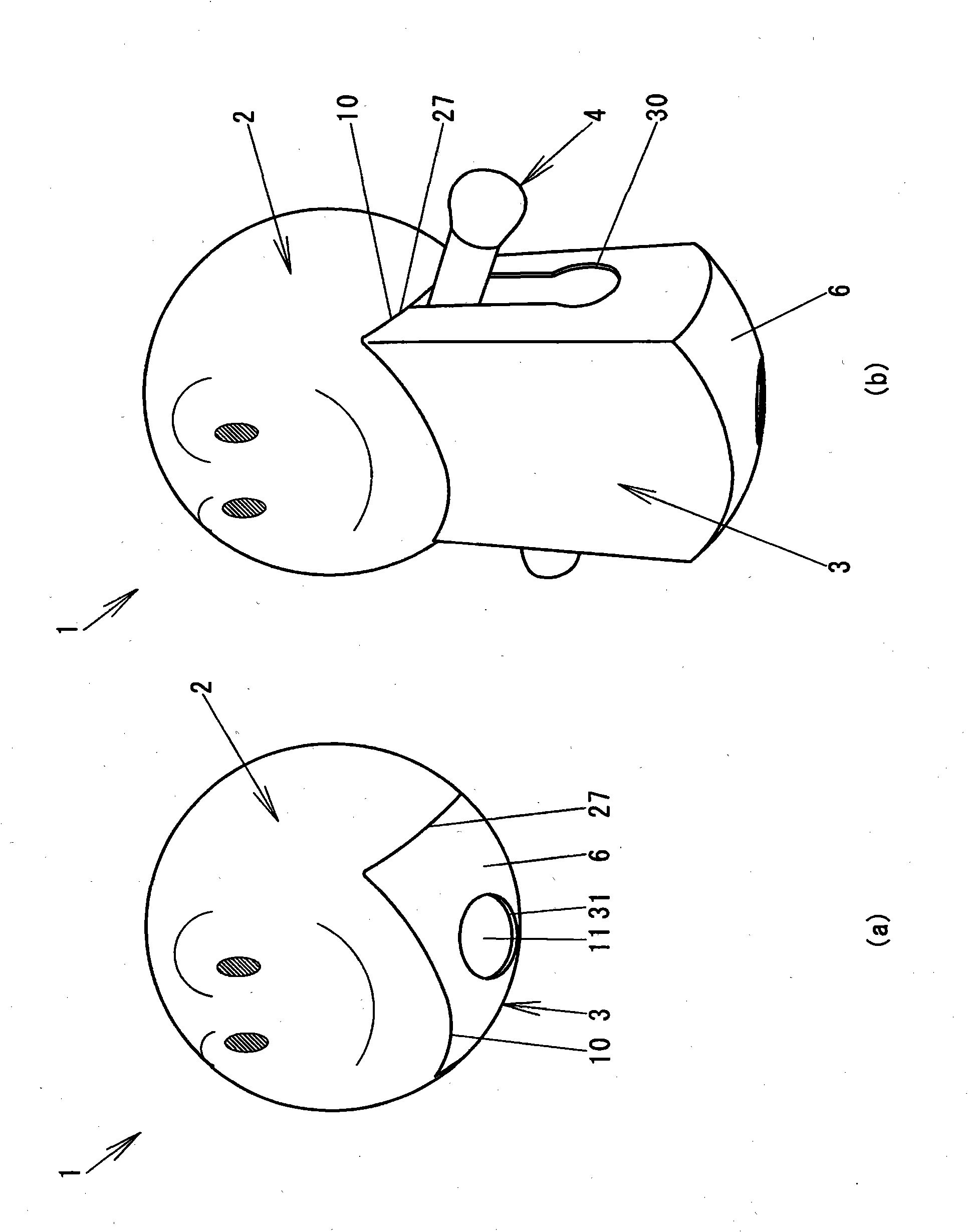

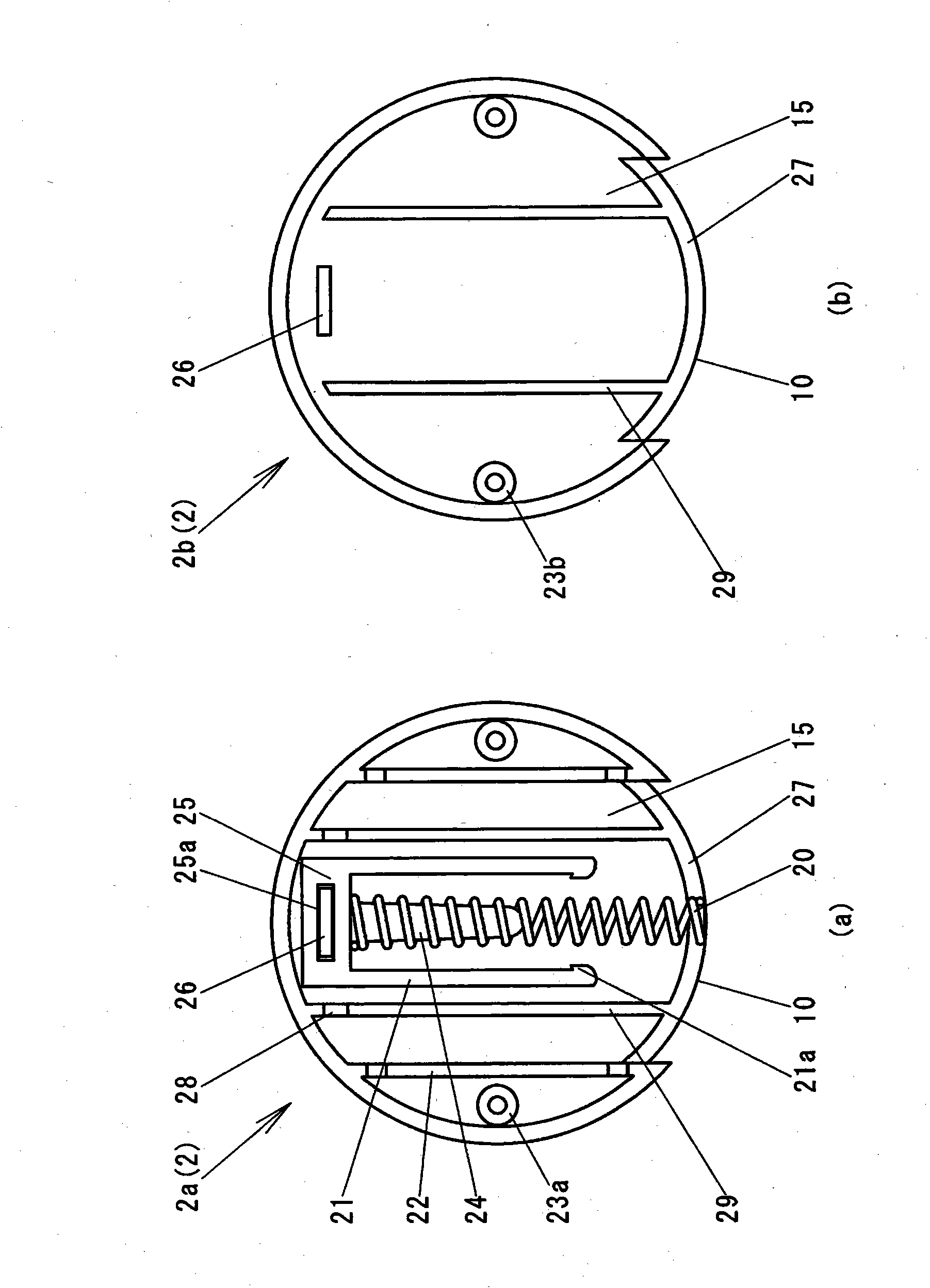

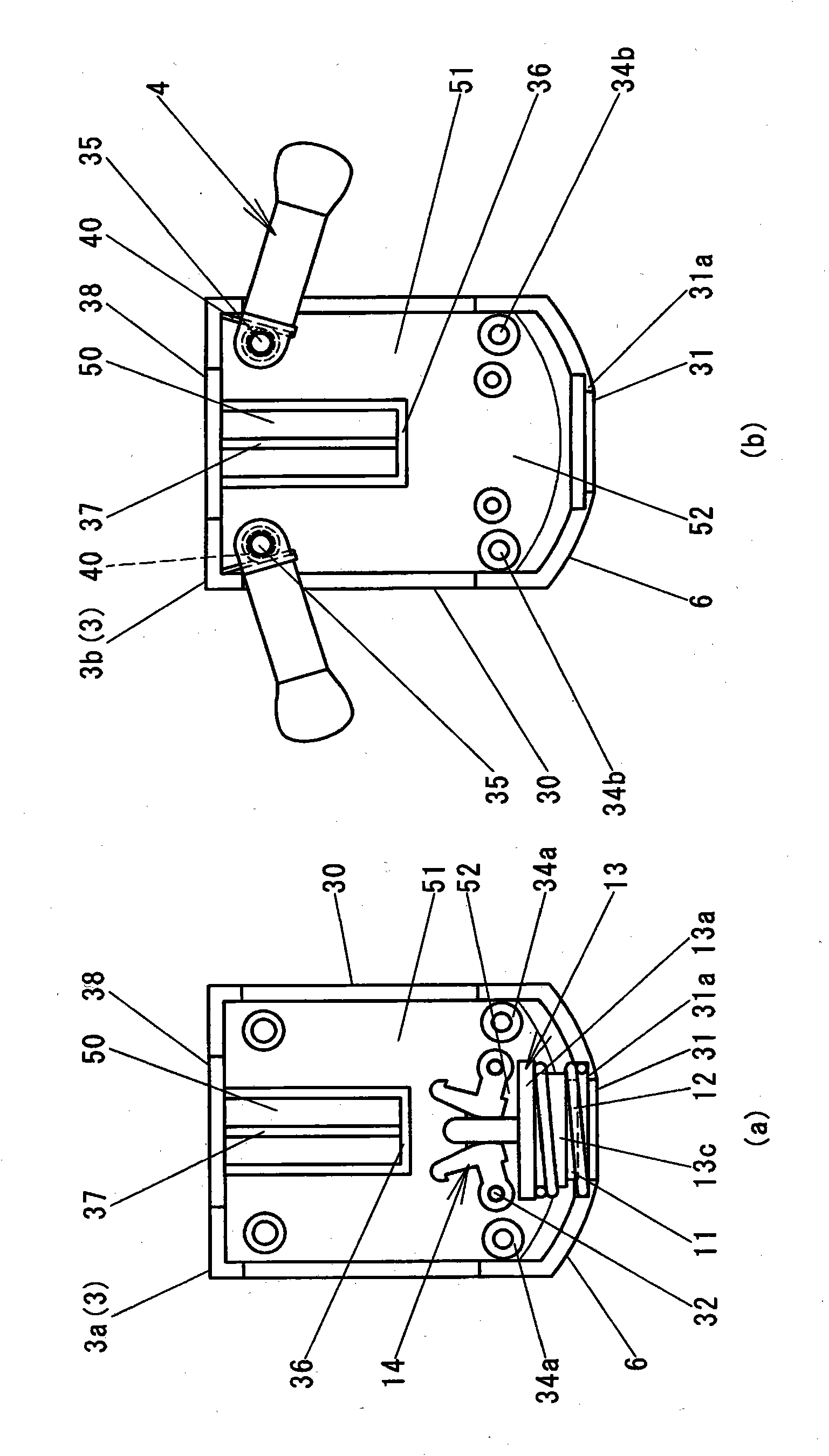

Toy

ActiveCN101970069AImprove product valueReduce production workloadDollsSelf-moving toy figuresMagnetic tension forceSpherical shaped

Owner:SEGA TOYS

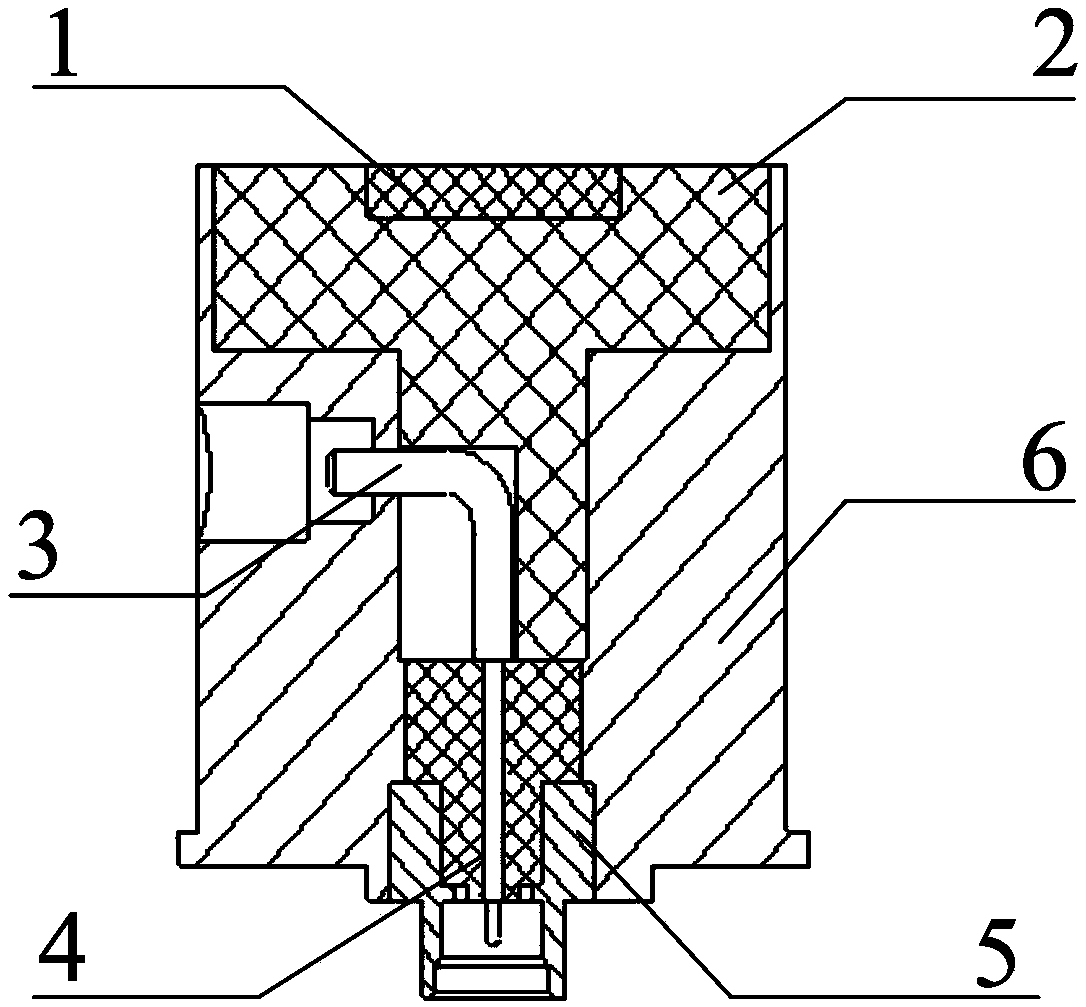

X-waveband dielectric horn antenna

InactiveCN108134205AWorking bandwidthThe processing technology has little influenceWaveguide hornsAntennas earthing switches associationDielectricHorn antenna

The invention provides an X-waveband dielectric horn antenna. The X-waveband dielectric horn antenna comprises a polarized sheet, filling dielectric, an inverted L-shaped probe, a core sleeve, a feedstructure and a metal shell; the polarized sheet is fixed in a groove in the top of the filling dielectric, and the top of the polarized sheet is flush with the top of the filling dielectric; a ''horizontal-line''-shaped slit is dig in a rectangular structure at the lower end of the filling dielectric, and the inverted L-shaped probe is placed in the slit; the core sleeve is hollow cylindrical dielectric and arranged on the exterior of the inverted L-shaped probe in a sleeving manner, wherein the top end of the core sleeve is flush with the bottom of the filling dielectric; the feed structureis a cylindrical metal shell and has a hollow stage-shaped interior, wherein the upper end of the feed structure and the relatively thin part at the lower end of the core sleeve are tightly matched while the bottom of the feed structure and the thinnest part of the inverted L-shaped probe jointly form a feed port; the polarized sheet, the filling dielectric, the inverted L-shaped probe, the core sleeve and the feed structure are all placed in the metal shell; the filling dielectric, the core sleeve and the interior of the metal shell are tightly matched; and the inverted L-shaped probe and themetal shell are concentric, and the probe can perform feed through the bottom.

Owner:SHANGHAI AEROSPACE ELECTRONICS CO LTD +1

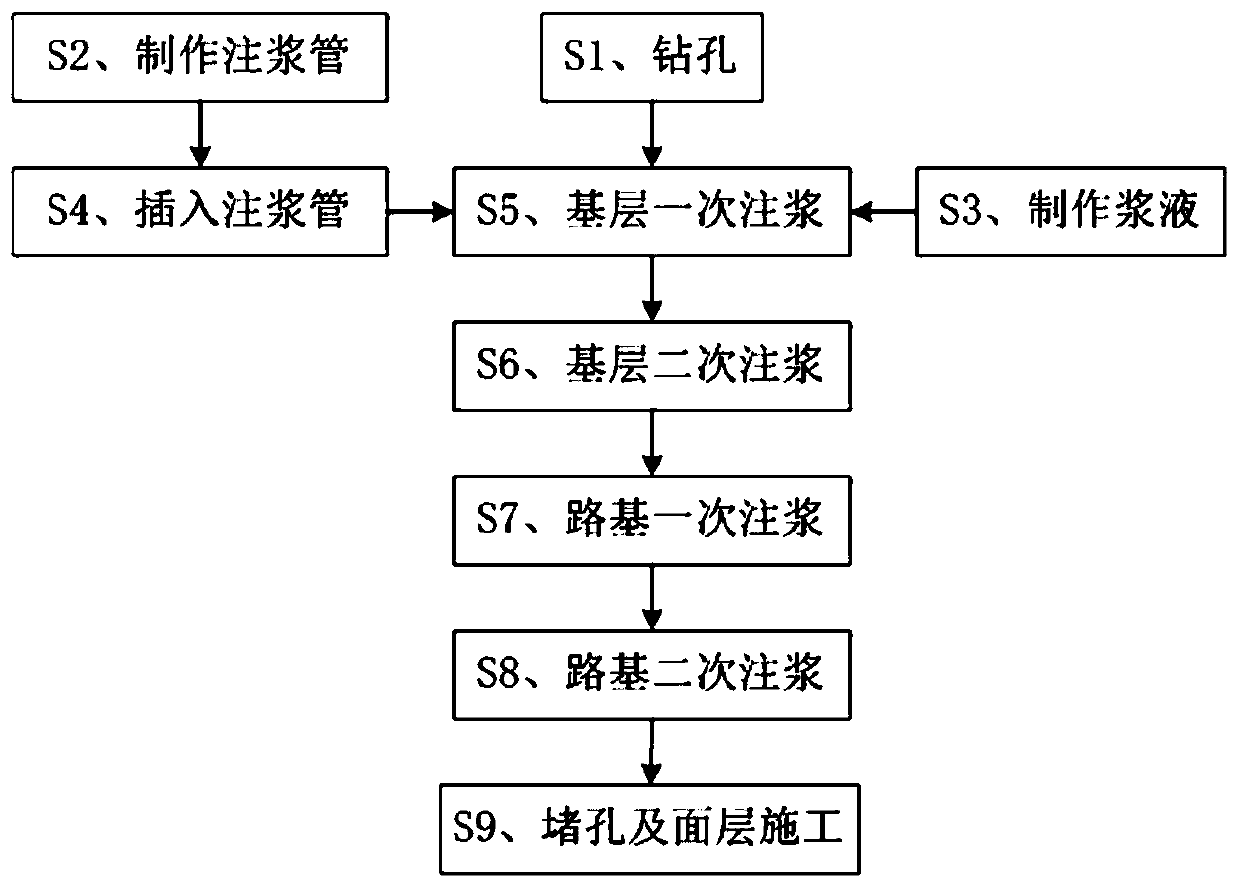

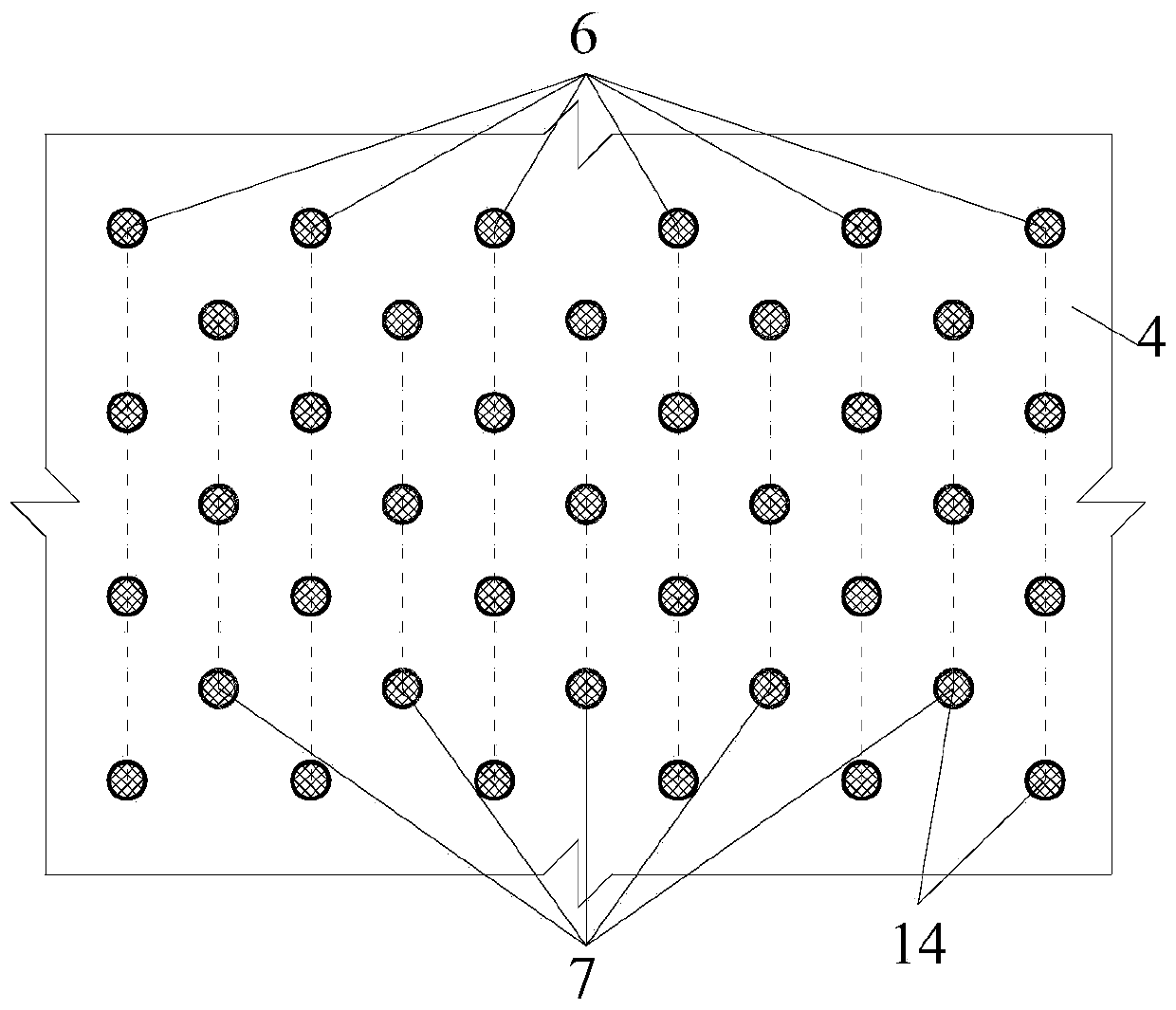

Construction method for reinforcing base course and roadbed of disease road through single-hole compound grouting

ActiveCN109763391AReduce the amount of drillingImprove construction efficiencyRoadwaysDiseaseSurface layer

The invention discloses a construction method for reinforcing base course and roadbed of disease road through single-hole compound grouting. A base course grouting pipe and a roadbed grouting pipe areused for realizing the successive grouting on the base course and the roadbed under different pressures in single borehole; when performing the grouting, the grouting is firstly performed on groutingholes all around, and the grouting is performed on middle release holes after final setting, thereby realizing secondary grouting supplementary. The construction method comprises the following construction steps: drilling the holes, manufacturing grouting pipes, manufacturing ground polymer grout, inserting the base course grouting pipes, performing base course primary grouting, performing base course primary grouting, performing roadbed primary grouting, performing roadbed secondary grouting, blocking holes and constructing on a surface layer. By adopting the single-hole compound grouting technology, the grouting is performed on the base course and the roadbed in single borehole, the boring quantity is reduced; the low-pressure grouting is firstly performed at the base course, and then the high-pressure grouting reinforcement is performed on the roadbed; the grouting is firstly performed on the grouting holes all around, and then the grouting is performed on the center release holes,the grouting reinforcement quality and effect can be improved, and the grout oozing out loss can be reduced.

Owner:浩祥(福建)建设有限公司

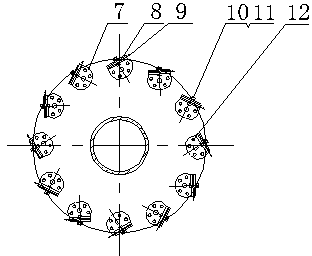

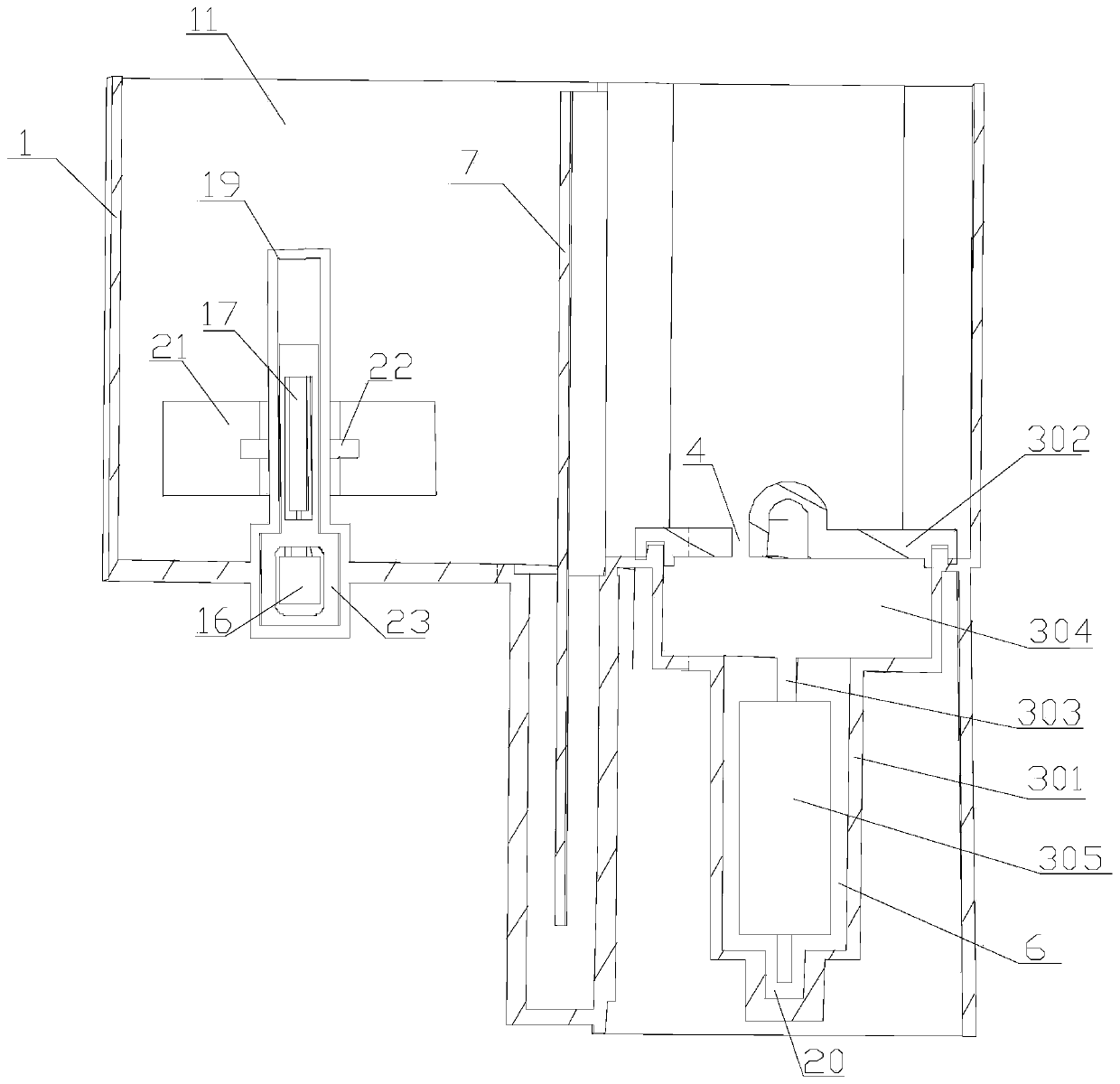

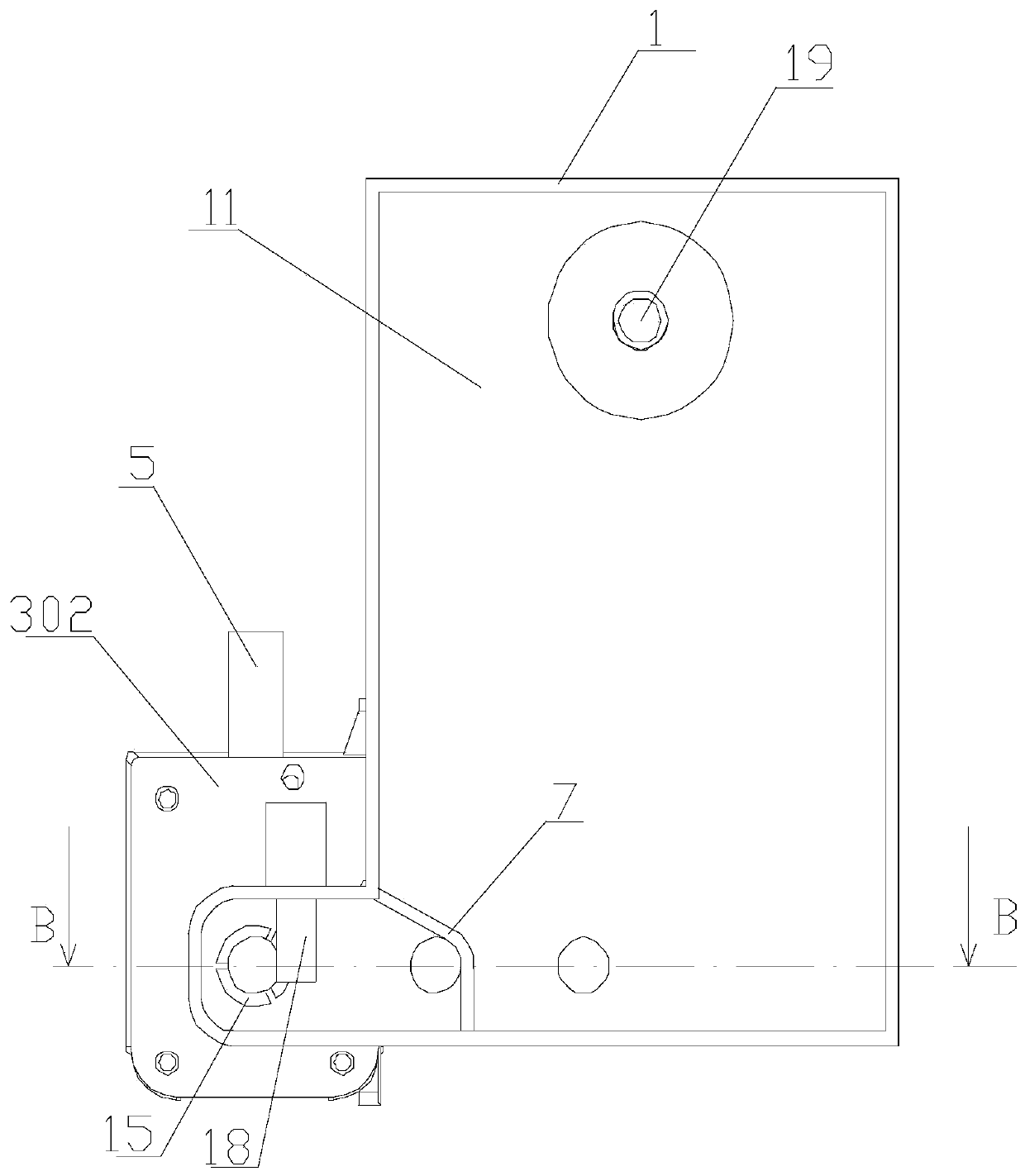

Rubbing and chopping device of greenfeed harvester

InactiveCN106258251ACompact structureSmall footprintFeeding-stuffCuttersEconomic benefitsEngineering

The invention relates to a rubbing and chopping device of a greenfeed harvester. The rubbing and chopping device comprises a chopping roller assembly, a chopping chamber assembly, a rubbing block board device, bolts, nuts and gaskets. The rubbing block board device is installed on the lower portion of the chopping chamber assembly. The bolts, the nuts and the gaskets are fixed to an arc plate in the chopping chamber assembly, a cylindrical cavity is formed, and the chopping roller assembly is installed in the cavity. Due to the fact that the chopping roller assembly and the rubbing block board device are installed in the same chopping chamber assembly, the greenfeed harvester is compact in structure, the occupied space is saved, the requirements for a traveling channel of the harvester are lowered, the procedure of manufacturing a conveying mechanism is removed, raw materials are saved, the manufacturing workload is reduced, the production efficiency is improved, the manufacturing cost is saved, and economic benefits are created. Moreover, the rubbing block board device is connected with the chopping chamber assembly through the bolts, the nuts and the gaskets, a farmer can carry out maintaining and dredge block crops conveniently, convenience is provided for the farmer using the device, and the working efficiency of the farmer is improved.

Owner:YONGMENG MACHINERY CO LTD

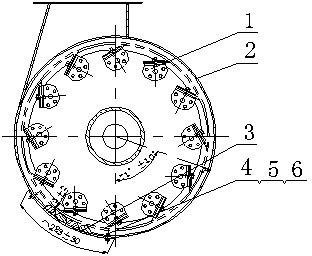

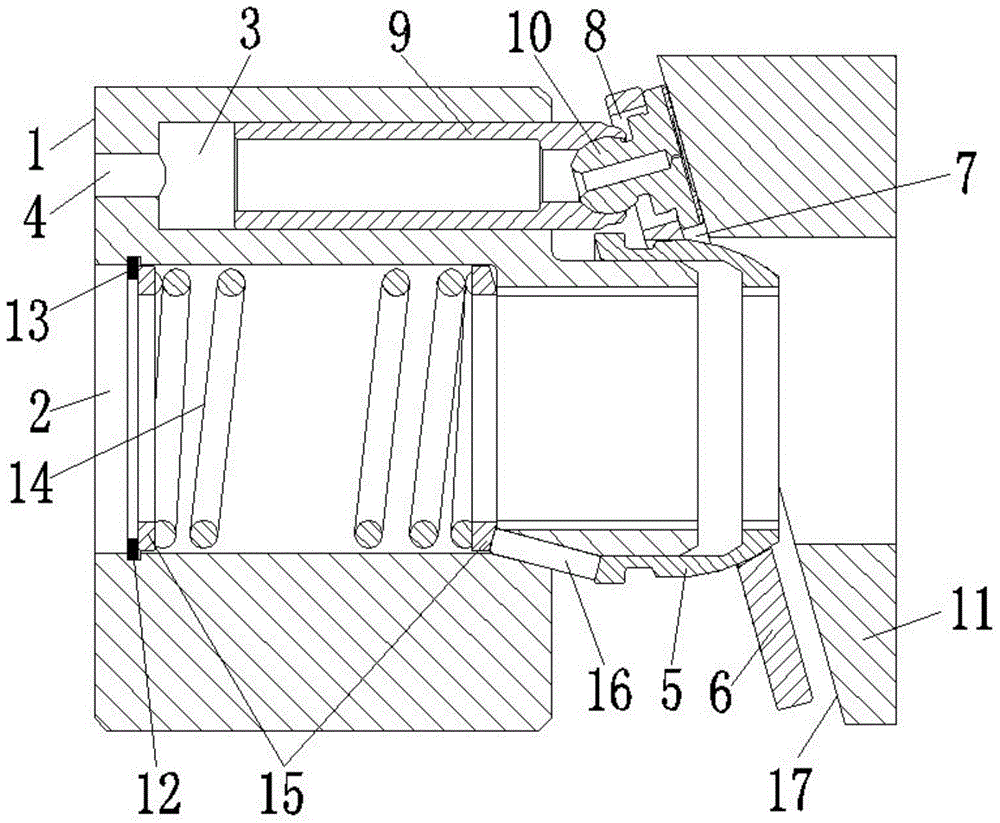

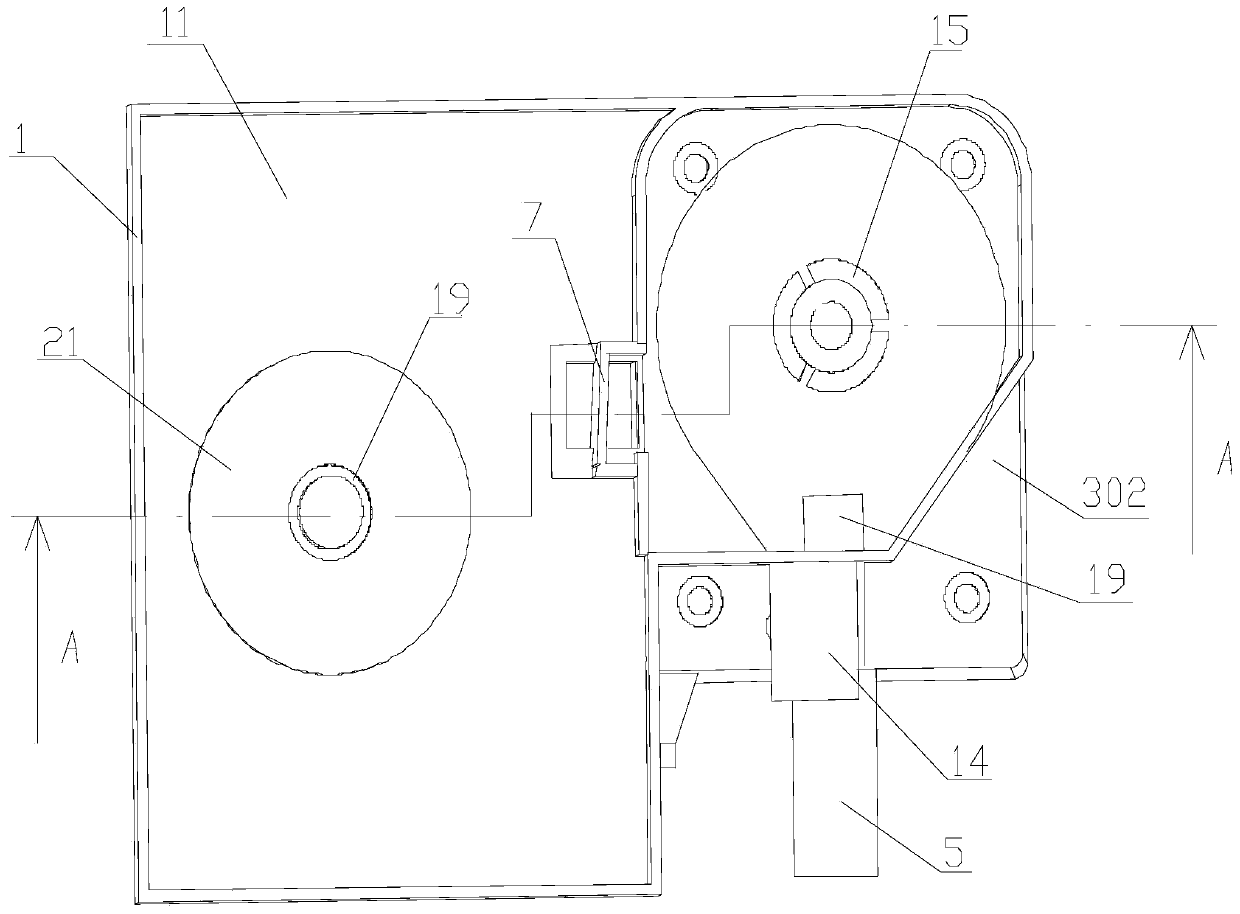

Tilting tray type hydraulic plunger piston motor

InactiveCN106545462AReduce volumeReduce weightReciprocating piston enginesMechanical engineeringPiston

The invention relates to a tilting tray type piston motor which comprises a cylinder body, wherein a spherical hinge is arranged at one end of the cylinder body; a return plate is arranged on the front part of the spherical hinge; a spherical hinge supporting hole is formed in the middle of the return plate; at least five slide boot guide holes are uniformly distributed around the spherical hinge supporting hole in the return plate in an equal-radian mode; a plunger piston-slide boot assembly is arranged between the plunger piston hole of the cylinder body and the slide boot guide hole of the return plate; a tilting tray is arranged on the front part of the return plate; the tilting tray is connected with a cylindrical slide boot; and a gap is reserved between the return plate and the tilting tray. According to the tilting tray type piston motor, the return plate is not in contact with the tilting tray, so that production and maintenance workload is reduced.

Owner:WUXI DEMEIJIA MACHINERY TECH CO LTD

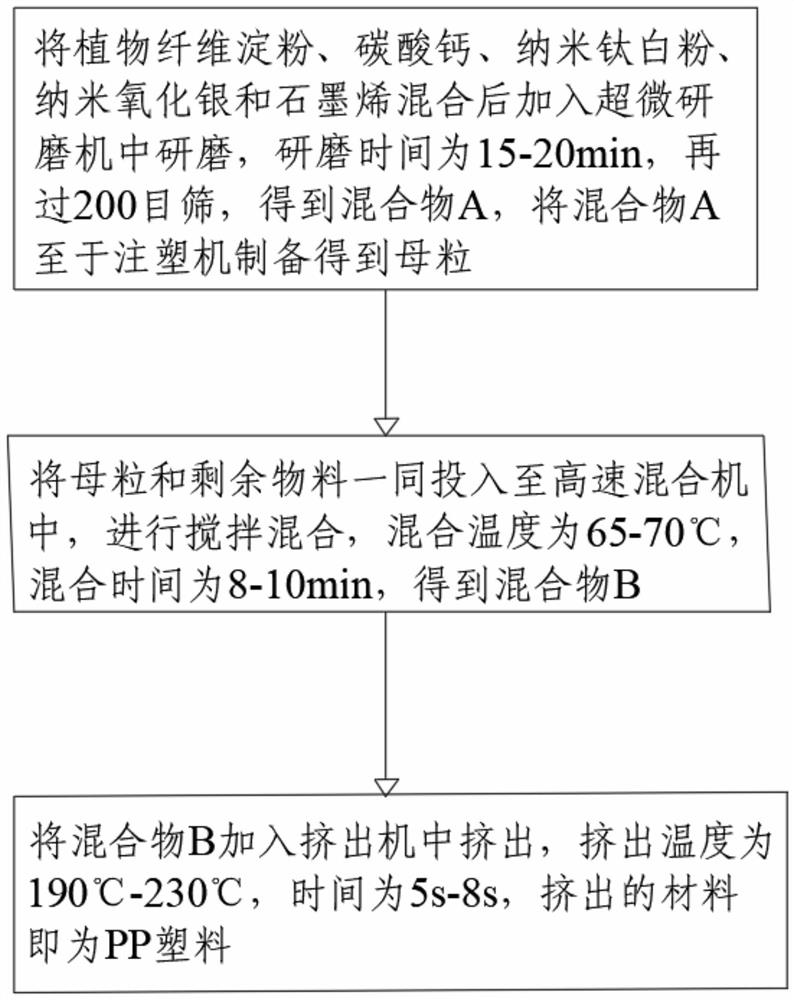

Preparation method of environment-friendly PP plastic

The invention discloses a preparation method of environment-friendly PP plastic. The environment-friendly PP plastic is prepared from the following components in parts by weight: 58 to 88 parts of PP resin, 5 to 19 parts of plant fiber starch, 8 to 16 parts of calcium carbonate, 1.3 to 3 parts of nano titanium dioxide, 6.8 to 9.8 parts of silane coupling agent, 1 to 2 parts of nano silver oxide, 8 to 12 parts of graphene, 1 to 3 parts of nano zinc oxide, 8 to 18 parts of ethylene-vinyl acetate copolymer, 8 to 12 parts of 3-aminopropyltriethoxysilane and 10 to 15 parts of ethyl acetate. The PP resin, the plant fiber starch, the calcium carbonate, the nano titanium dioxide, the silane coupling agent, the nano silver oxide, the graphene, the nano zinc oxide, the ethylene-vinyl acetate copolymer, the 3-aminopropyltriethoxysilane and the ethyl acetate are used as raw materials for preparing the environment-friendly PP plastic, and the prepared environment-friendly PP plastic has the advantages of being high in toughness, low in low-temperature brittleness, high in impact resistance, short in degradation period, and beneficial to environmental protection.

Owner:孙兰

Vertical assembling construction method for trussed arch bridge

InactiveCN102912736BEasy to moveReduce production workloadBridge erection/assemblyStructural engineeringCross bracing

The invention provides a vertical assembling construction method for a trussed arch bridge, and aims to overcome the shortcomings of large working amount and long working period of the conventional assembling method. The vertical assembling construction method comprises the following steps of: 1, manufacturing fixtures, wherein each fixture comprises a beam and vertical columns fixed at two ends of the beam; a limiting plate and a positioning plate are arranged on the upper end face of the beam; crossed supporting arms are arranged between the vertical columns of two fixtures; three fixtures are connected with one another by the crossed supporting arms to form a fixture group; and two parallel fixture groups serve as a platform for vertically assembling the trussed arch bridge; 2, assembling arch rib sections of the trussed arch bridge, and sequentially hoisting and positioning a lower chord pipe, a lower flat connection pipe, a web rod, an upper chord pipe, a vertical supporting pipe and an upper flat connection pipe on the two fixture groups; and 3, arranging a hydraulic flat plate trolley on the lower parts of the vertical columns of the fixtures, and conveying and transferring the assembled arch rib sections by the hydraulic flat plate trolley. According to the method, the fixture manufacturing working amount is reduced, the fixtures are convenient to move, and the working period can be shortened.

Owner:CHINA RAILWAYS CORPORATION +2

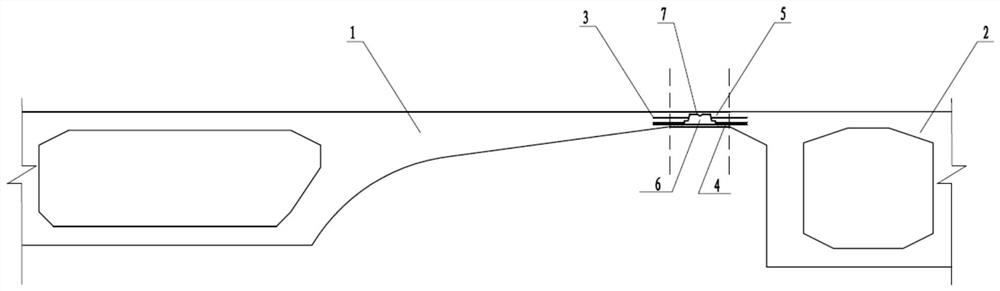

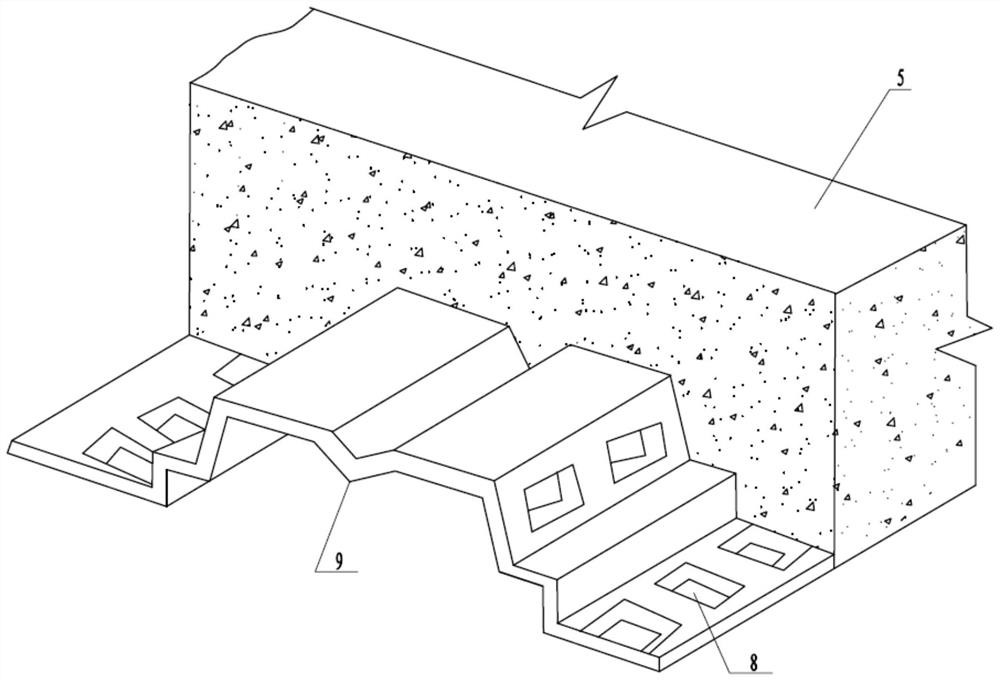

Prestressed Concrete Continuous Box Girder Bridge Transverse Width Structure

ActiveCN110258289BAvoid wastingImprove adhesionBridge structural detailsPre stressArchitectural engineering

The invention discloses a prestressed concrete continuous box girder bridge transverse width-splicing structure, which comprises a profiled steel plate, a plurality of longitudinally distributed steel bars connected to the bottom of the profiled steel plate, horizontal connecting steel bars connected to the bottom of the longitudinally distributed steel bars, and Both sides of the upper flange of the profiled steel plate are connected with horizontal connecting steel bars, the profiled steel plate is provided with indentation holes, fiber-reinforced cement-based materials are poured above the profiled steel plate, and concrete materials are sprayed below the profiled steel plate. The invention can effectively improve the additional stress of the structural splicing section due to the uneven settlement of the foundation and the shrinkage and creep of the concrete, shorten the construction period and save the cost.

Owner:SOUTHEAST UNIV

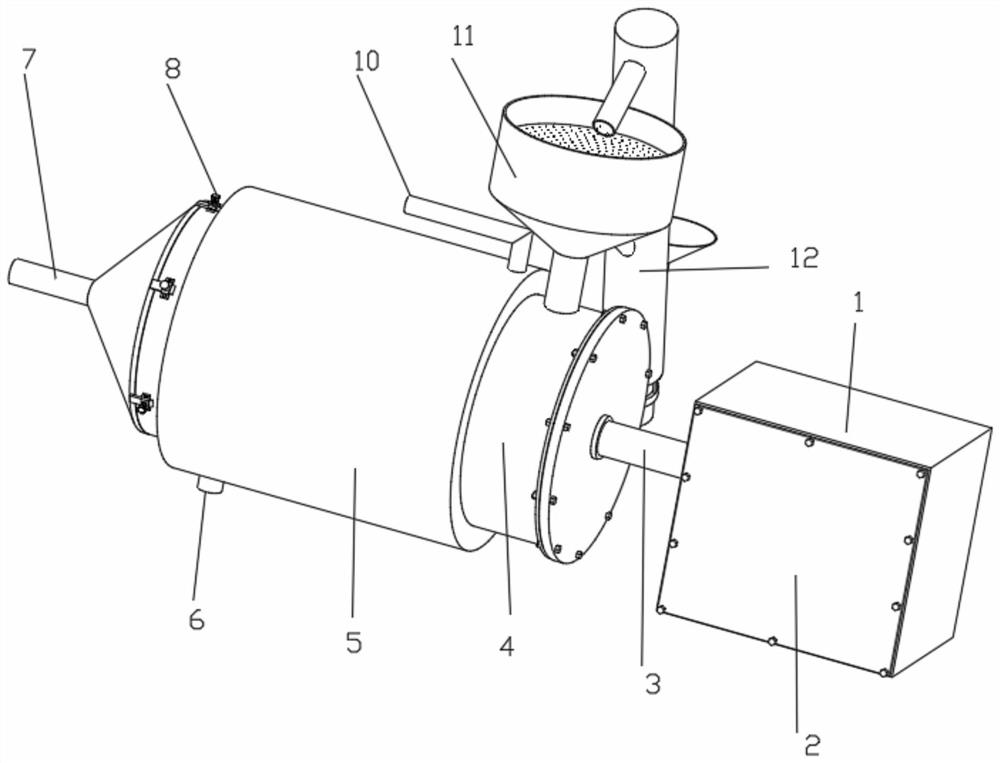

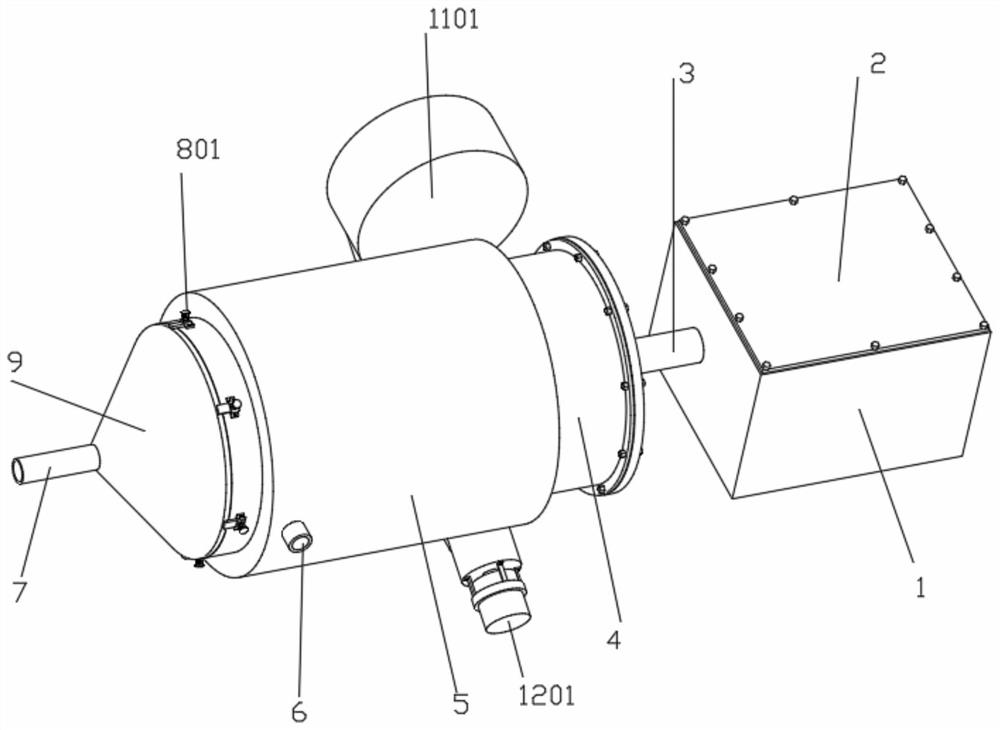

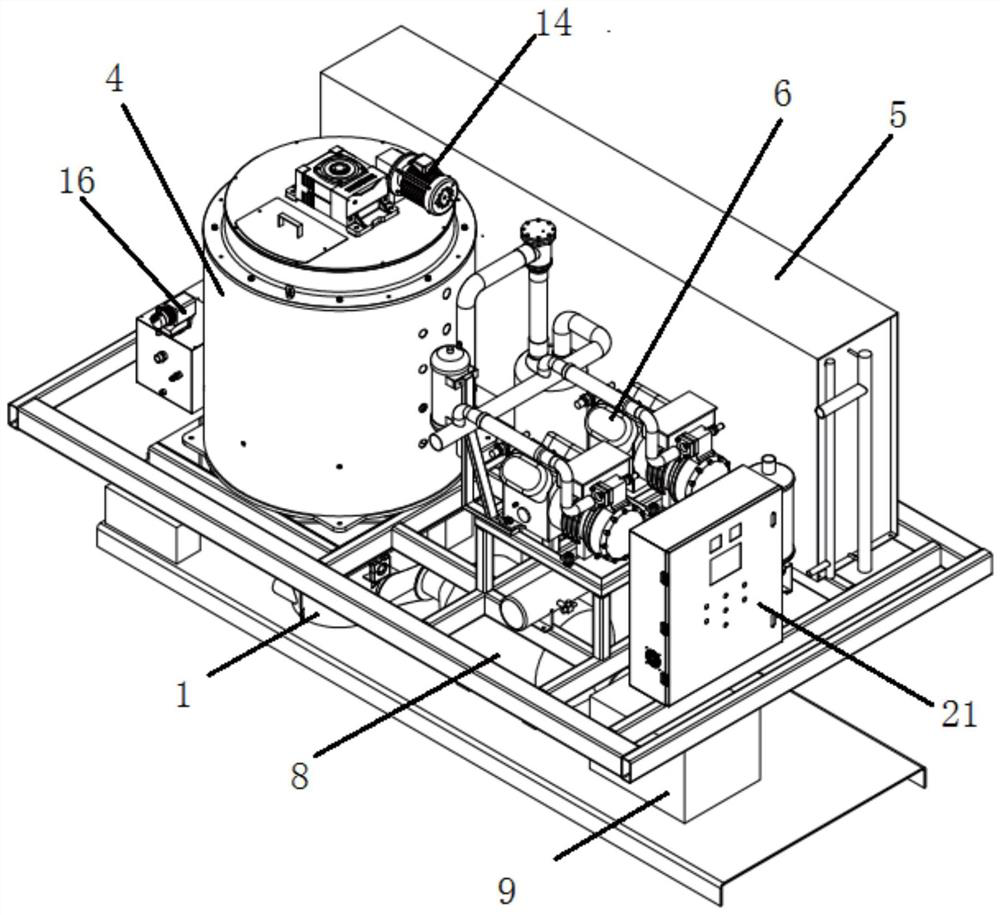

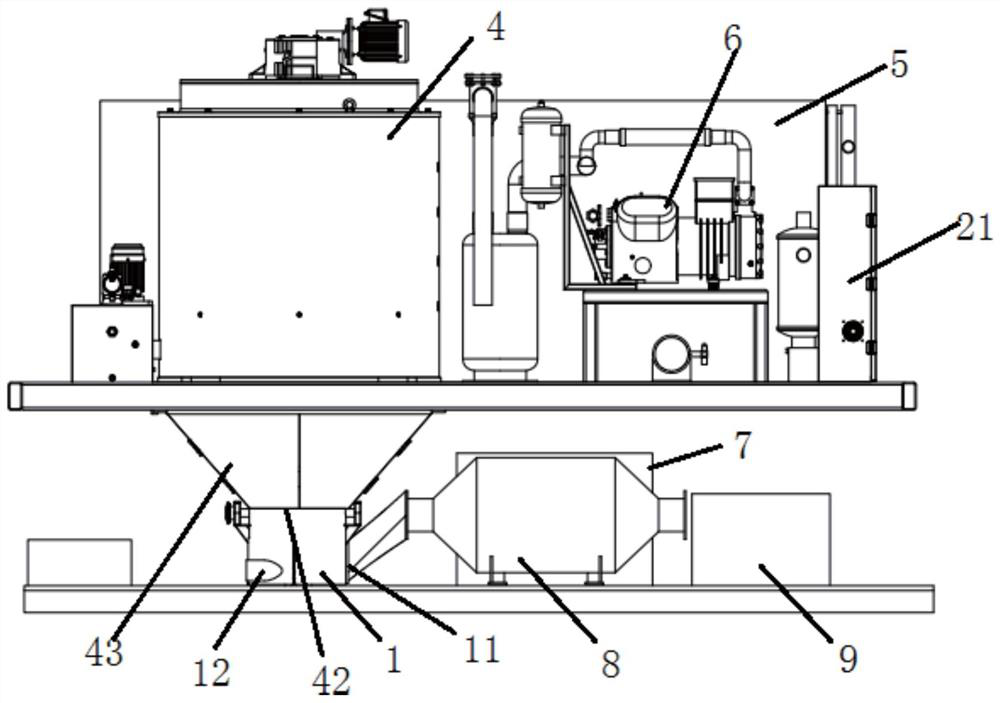

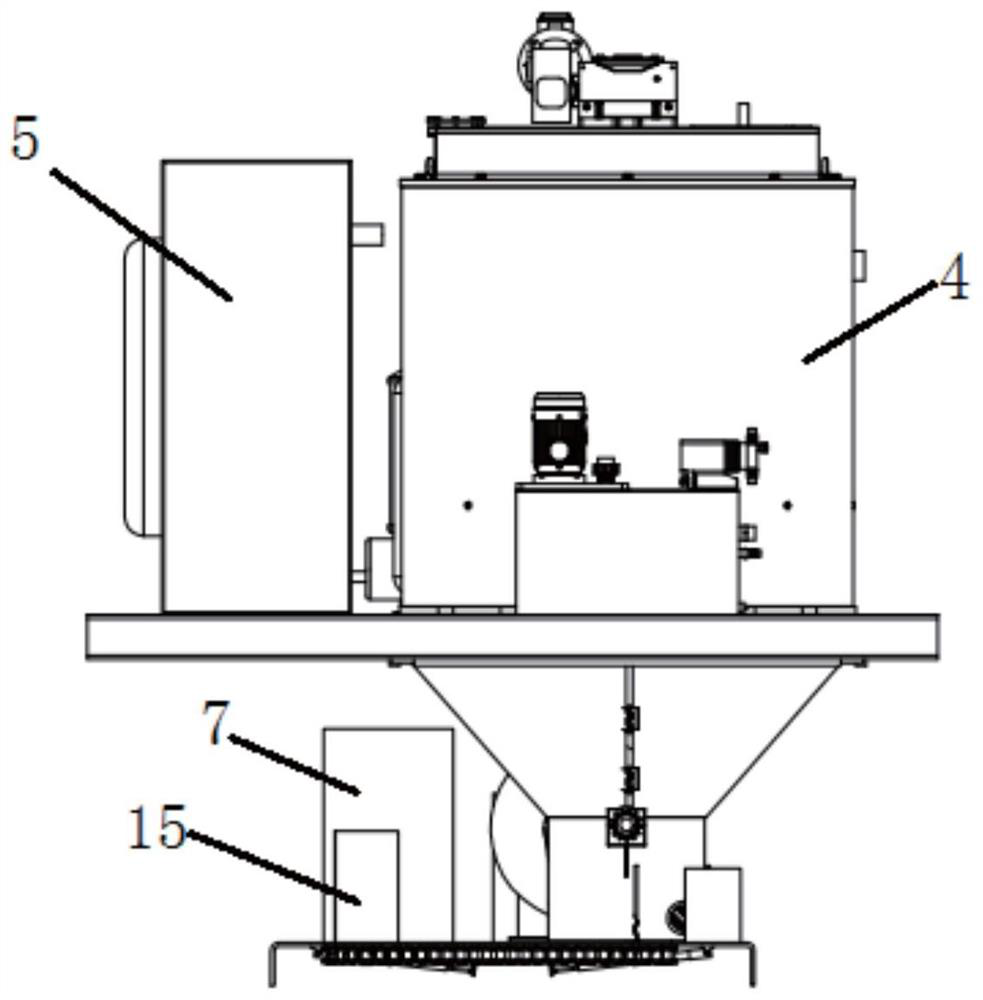

Artificial snow making device

PendingCN112815588AReduce weightReduce consumptionRecreational ice productionEvaporators/condensersImpellerDrive shaft

The invention discloses an artificial snow making device. The artificial snow making device comprises an ice making machine and a smashing snow making machine, wherein the ice making machine comprises an ice bucket, a condenser and a compressor, one end of the compressor is connected with an evaporator in the ice bucket, and the other end of the compressor is connected with the condenser; the smashing snow making machine comprises a cylinder body, a closed impeller, a smashing impeller, a smashing motor, an air conditioner outdoor unit, a cooler and a fan, the upper end of the cylinder body is connected with a flake ice output port at the lower end of the ice bucket, the closed impeller is pivoted at the upper end of the cylinder body in a mode of being capable of closing the flake ice output port, the smashing impeller is pivoted in the cylinder body and comprises a smashing driving shaft and smashing blades fixedly connected to the smashing driving shaft. According to the artificial snow making device, the evaporator is integrally cast and formed, and deformation in the welding process is completely avoided, so that the product consistency and the product quality are greatly improved, the production workload is reduced, and the working efficiency is improved.

Owner:株洲天桥奥悦冰雪科技有限公司

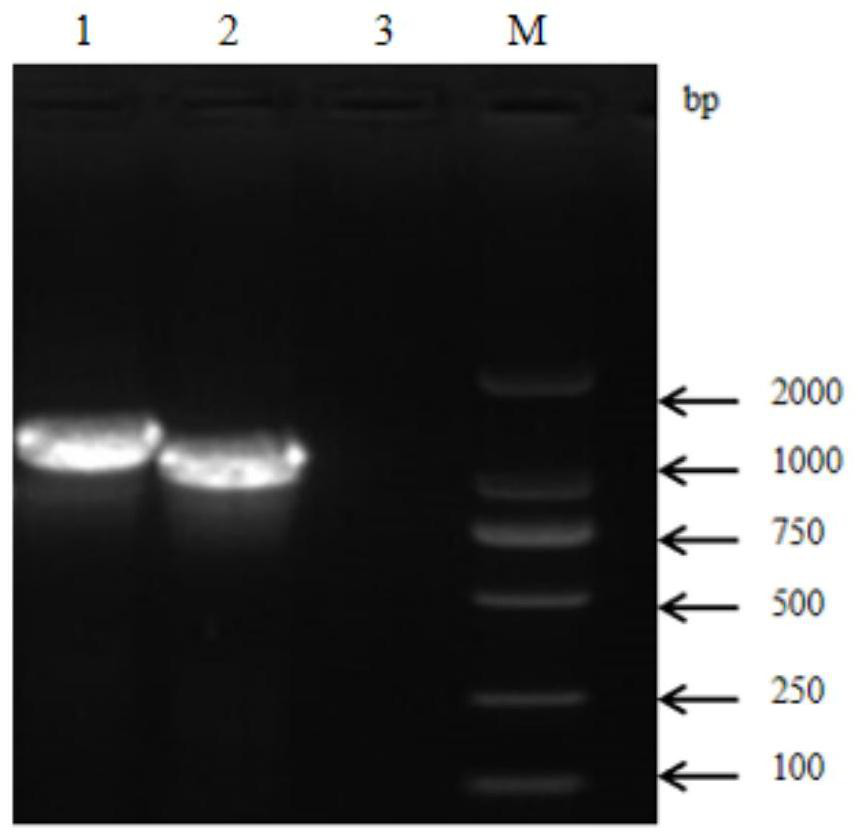

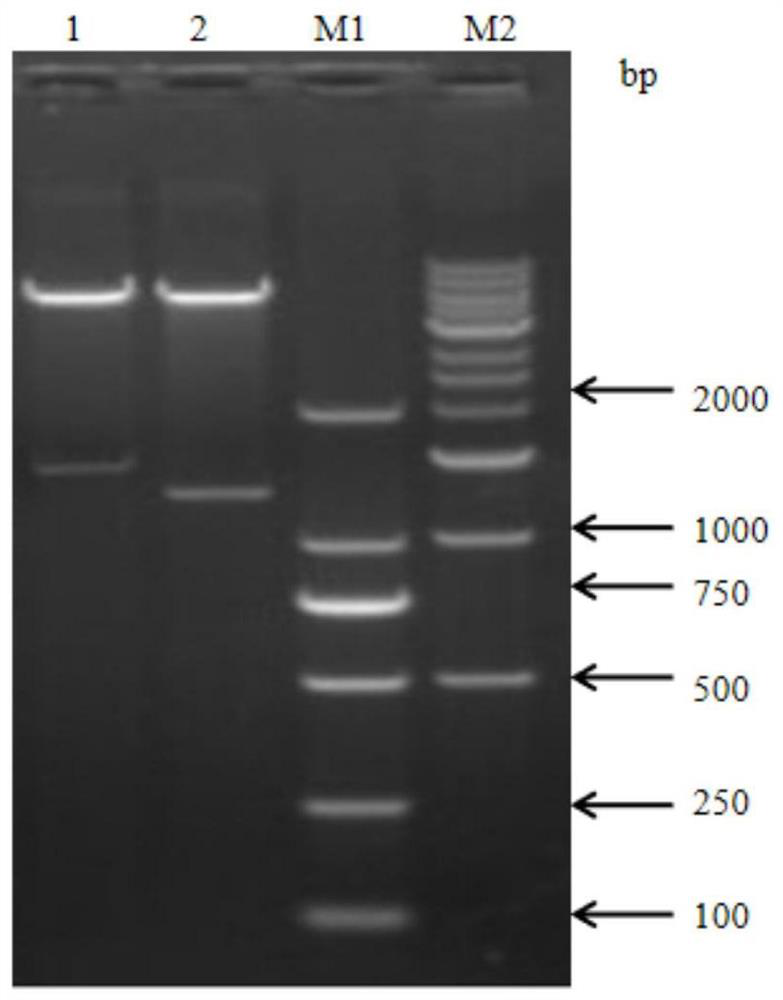

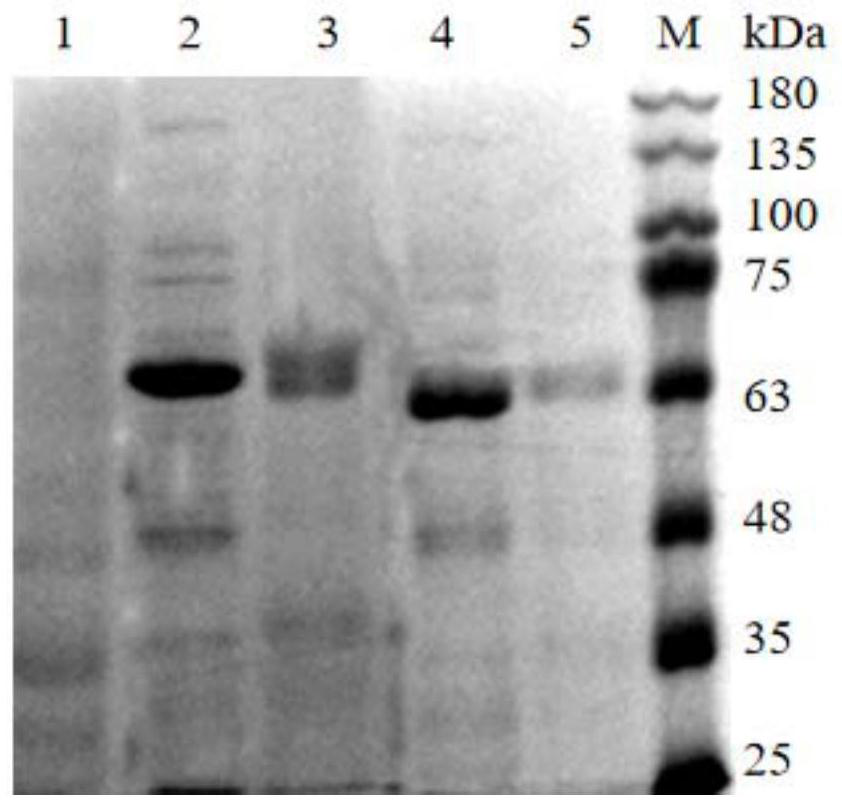

Swine streptococcosis vaccine

ActiveCN113332421AImprove versatilityReduce stress responseAntibacterial agentsBacterial antigen ingredientsAdjuvantAluminum Stearate

The invention provides a swine streptococcosis vaccine, and relates to the field of veterinary vaccines. According to the swine streptococcosis vaccine, an antigen is a protein with an amino acid sequence as shown in SEQ ID NO: 2. The invention also provides a preparation method of the swine streptococcosis vaccine. The preparation method comprises the following steps: mixing white oil and aluminum stearate to obtain a white oil adjuvant; adding Tween-80 into an aqueous solution of the protein with the amino acid sequence as shown in SEQ ID NO: 2, and performing uniform mixing to obtain an antigen solution; and mixing the antigen solution with the white oil adjuvant according to a volume ratio of (0.5-1.5): 2, and performing emulsifying to obtain the vaccine. Animals immunized by the swine streptococcosis vaccine can effectively resist attack of streptococcus suis type 2, type 3 and type 31, the vaccine protection rate reaches 100%, the swine streptococcosis vaccine is good in universality, the production cost and the inoculation workload are remarkably reduced, and besides, stress of the immunized animals can be reduced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

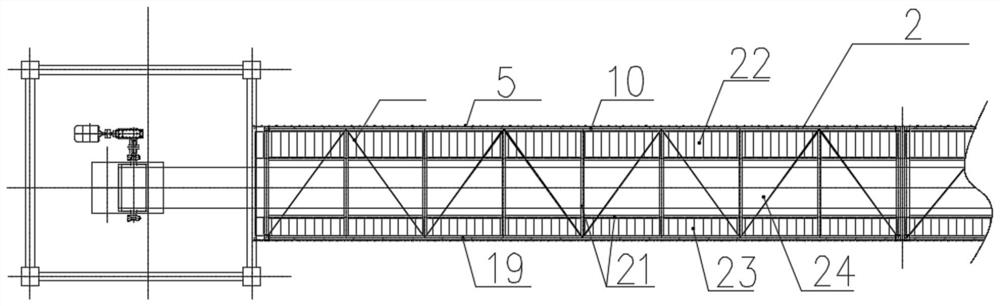

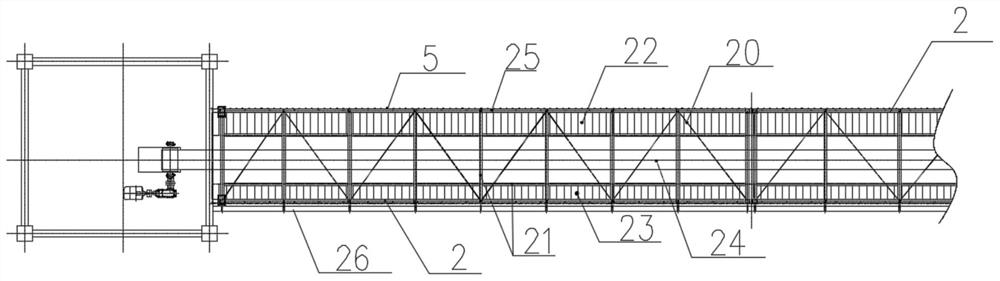

Multi-layer overhead closed conveying gallery steel pipe truss combination system

ActiveCN113636361AReduce occupancyReduce in quantityConveyorsSupporting framesEngineeringIntegrated design

The invention discloses a multi-layer overhead closed conveying gallery steel pipe truss combination system, and belongs to the technical field of assembly type steel structures. The multi-layer overhead closed conveying gallery steel pipe truss combination system involves a plurality of transfer stations and a plurality of conveying galleries, wherein the conveying galleries are arranged between the transfer stations, and the conveying galleries running in the same transportation direction are arranged in the same vertical surface direction, and are formed into a three-dimensional overall structure in spatial arrangement; the conveying galleries on the same vertical surface share a common stand column support, the stand column support is provided with a penetrating channel, the two ends of the penetrating channel are connected with the corresponding conveying galleries into a whole, and the stand column support can be supported on the roof or the ground of the transfer stations; and the conveying galleries located on the same vertical surface are arranged to be any one or two or more combinations of single-layer conveying galleries and double-layer conveying galleries. A plurality of belts running in the same direction are arranged on the same vertical surface in a conveying mode, and meanwhile a conveying structure is subjected to three-dimensional integrated design, so that multiple purposes of a structural unit are achieved, and the effect that the single structural unit can support a plurality of belt conveyor conveying devices is achieved.

Owner:成都建筑材料工业设计研究院有限公司

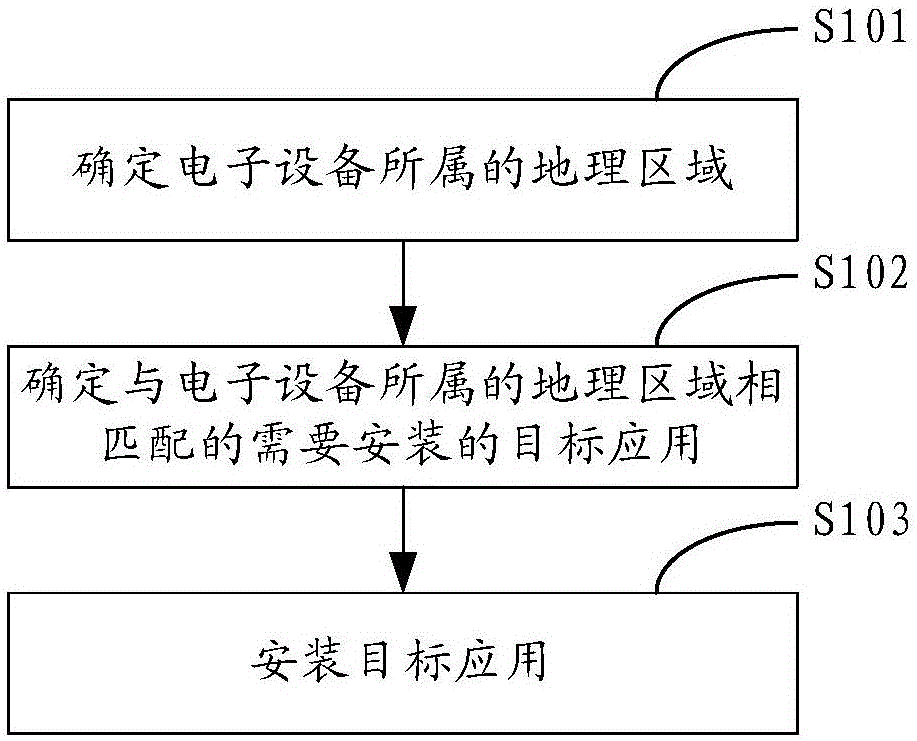

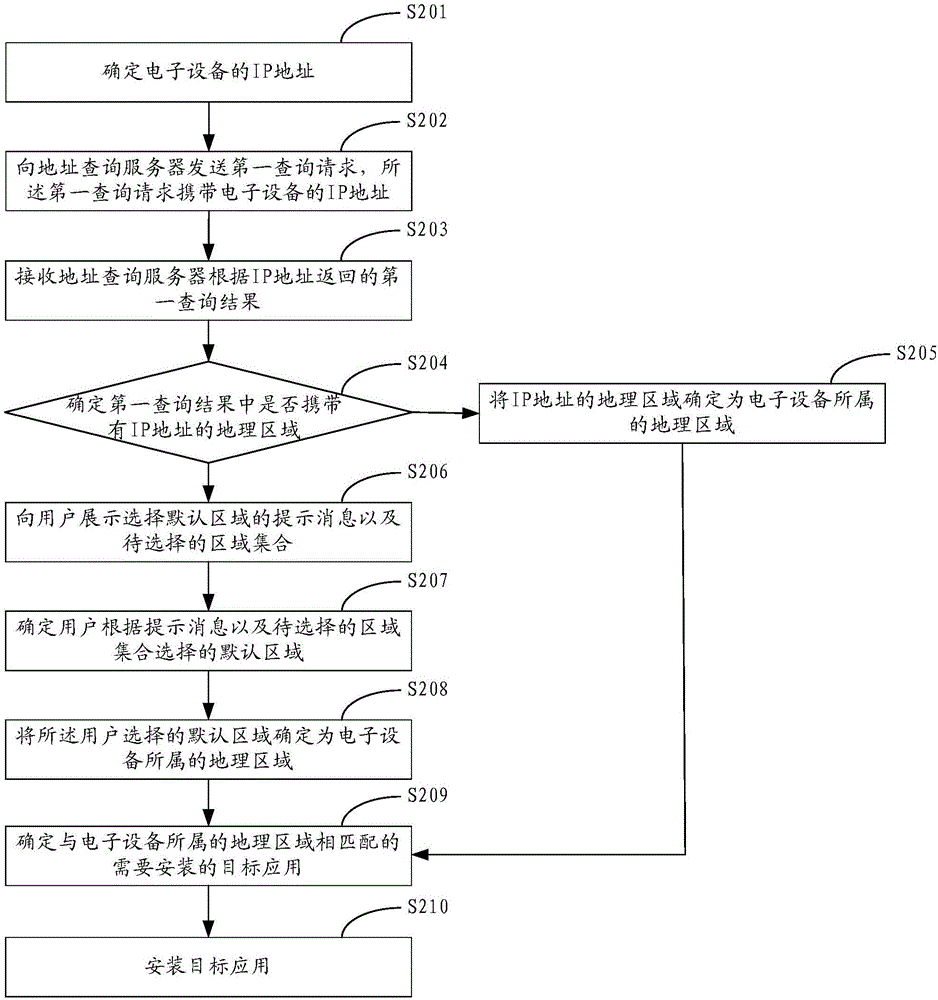

Application installation method, application installation device and electronic equipment

The invention relates to an application installation method, an application installation device and electronic equipment. The application installation method comprises the steps of determining a geographic region to which the electronic equipment belongs; determining a target application which is required to be installed and matched with the geographic region to which the electronic equipment belongs; and installing the target application. The technical scheme provided by the invention can be used for reducing the production workload and the test and maintenance workload of system software of the electronic equipment.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

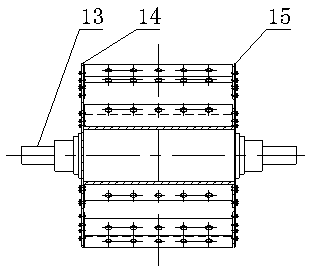

Motor vibration exciter

InactiveCN1736619AExtended service lifeAvoid breakingMechanical vibrations separationMotor vibrationEngineering

The invention discloses a motor exciting device, which comprises a shell, a stator and rotor equipped with said shell; the two ends of said shell being separately equipped with bearing block; the two ends of said rotor shaft passing separately across the bearing hole of said bearing block; the rotor shafts locating on the two sides of said bearing being separately equipped with eccentric mass block; the two ports of said shell being separately equipped with guard which is linked with said bearing block. Compared with the domestic prior vibration electromotor, the invented has a simple structure and a low cost as the same, and it prolongs the life time of the bearing and the foundation bolt with said structure; compared with the foreign inertial vibration source of fluid-pressure driving eccentric block, the invented has a much simpler structure.

Owner:樊振江

Material for cast aluminum water distributor

InactiveCN102234733AExtended service lifeExtended replacement cycleMelt-holding vesselsElectrolysisAlloy

The invention provides a material for a cast aluminum water distributor for aluminum electrolysis and relates to an alloy material for the aluminum water distributor used in a casting process of an aluminum liquid generated by electrolysis during an electrolytic aluminum production process. The material is characterized by comprising the following components in percentage by weight: 5%-15% of tungsten carbide, 2%-15% of titanium carbide, 1%-15% of titanium boride, 0-5% of zirconium carbide, 5%-10% of nickel, 1%-5% of chromium, 0.01%-1.0% of carbon, 0.5%-1.0% of silicon, 0.5%-2% of vanadium, less than 0.05% of phosphorus, less than 0.05% of sulfur and the balance of iron and inevitable impurities. In the material for the cast aluminum water distributor for aluminum electrolysis, the material of the aluminum water distributor is designed again, and compounds with high melting points and strong corrosion resistance, such as tungsten carbide, titanium carbide, titanium boride and the like, are added, thus prolonging the service life of the distributor, prolonging the exchange period, reducing production cost and alleviating labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Water heating blanket main unit and water heating blanket

PendingCN111156687AReduce in quantityEasy to produceSleeping rugTravelling rugPhysicsElectric heating

The invention discloses a water heating blanket main unit and a water heating blanket, and relates to the technical field of water heating electric appliance electric heating. The water heating blanket main unit comprises a shell, a water tank, a combination switch, a heating structure and a water pump, wherein the combination switch, the heating structure and the water pump are mounted in the water tank, a water returning opening of the water tank communicates with a water returning joint of a cooling body, the combination switch comprises a pipe body, a water level switch and an anti-tippingswitch, the end of the pipe body is connected with the inner wall of the water tank, the water level switch and the anti-tipping switch are arranged in the pipe body and are in communication connection with a control device, the water pump comprises a pump shell connected with the outer wall of the water tank, a rotating assembly is mounted in the pump shell, a pumping-in water opening communicating with a water outlet and a pumping-out water opening communicating with a water inlet joint of the cooling body are arranged on the pump shell, and the pipe body, the water tank and the pump shellare of an integrally-formed structure. Accordingly, the production process of the water heating blanket main unit is simple, the number of production parts is small, workloads are small, product quality of one part is easily controlled, and water is not prone to leaking.

Owner:高雪娇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com