Method for producing a fibre-reinforced pressure vessel with pole cap reinforcement

A technology of pressure tanks and reinforcements, which is applied in the manufacture of pressure vessels, vessel structures, and outer walls of vessel structures, and can solve problems such as increasing production workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

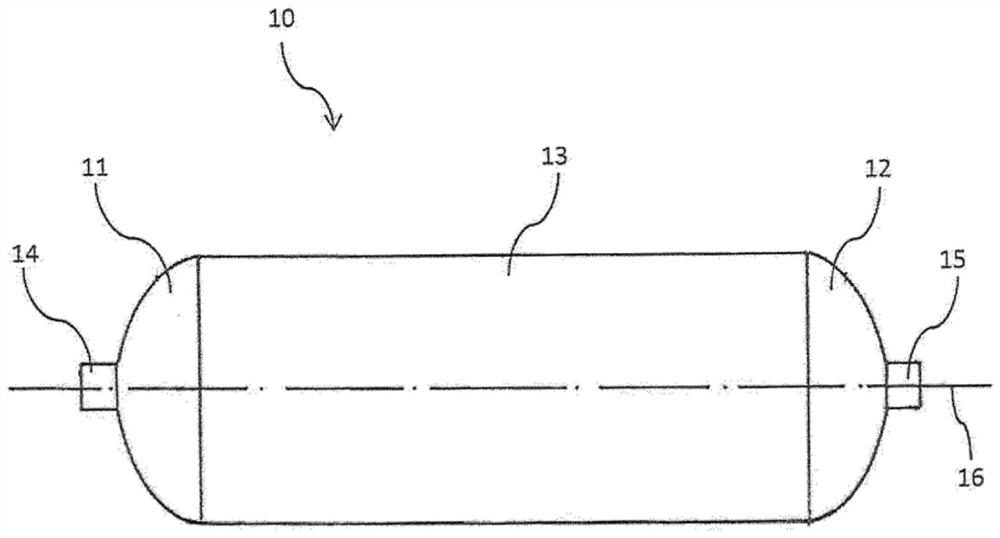

[0046] figure 1 A pressure tank or a composite pressure tank, respectively, produced by the method according to the invention is shown in . The pressure vessel 10 has a cylindrical central part 13 and two protruding pole caps 11 and 12 for closing the opening of the cylindrical central part 13 . Protruding connecting flanges 14 and 15 may be provided on these pole caps 11 , 12 , the shape and arrangement of these flanges 14 , 15 being shown by way of example only. The cylindrical central part 13 has ends adjoining the protruding pole caps 11 , 12 .

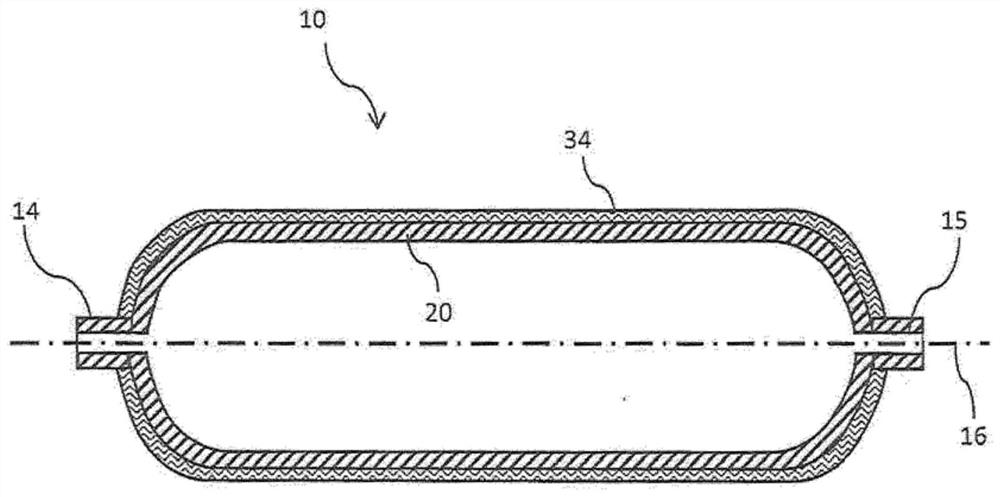

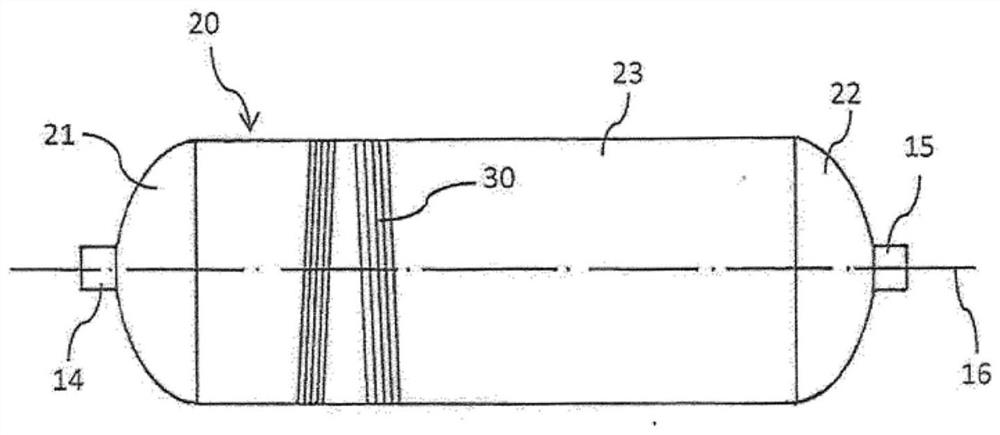

[0047] Such a pressure tank 10 is produced by reinforcing the inner vessel with an outer layer made of fiber reinforcement. figure 2 This structure of the pressure tank 10 is shown in a schematic longitudinal section. An outer layer 34 made of reinforcing fibers is wrapped around the inner container 20 . The shape of the inner container 20 substantially corresponds to the shape of the pressure tank 10 to be produced, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com