Rubbing and chopping device of greenfeed harvester

A technology of shredding device and harvester, which is applied to feed, cutting equipment, agricultural machinery and implements, etc., can solve the problems of reducing production efficiency, inconvenient use by farmers, and bulky, so as to reduce manufacturing workload and save space. The effect of reducing ground space and channel requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

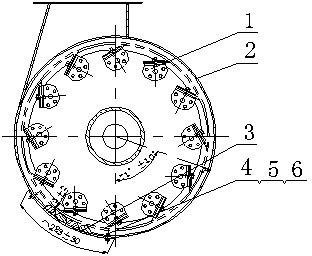

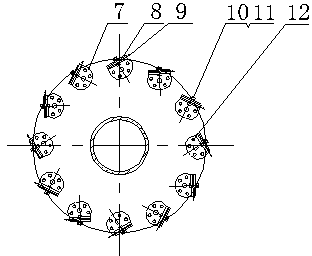

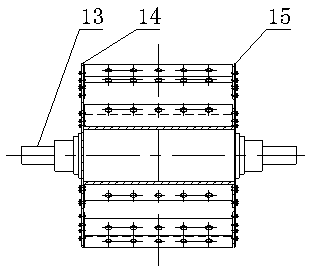

[0022] The kneading and chopping device of the green feed harvester comprises a chopping roller assembly 1, a chopping chamber assembly 2, a rubbing blocking plate device 3, bolts 4, nuts 5 and washers 6. The shredding chamber assembly 2 and the kneading blocking plate device 3 are connected to form a cylindrical chamber through bolts 4, nuts 5 and washers 6. The shredding roller assembly 1 is installed in the chamber, and the knife plate 9 in the shredding roller assembly 1 and The distance between the left-handed bar 26 and the right-handed bar 27 in the kneading blocking device 3 is 3 mm ± 2 mm, and the angle between the fixed knife assembly 18 in the chopping chamber assembly 2 and the edge of the kneading blocking device 3 is 71° ± 10 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com