Tilting tray type hydraulic plunger piston motor

A hydraulic plunger motor and swash plate type technology, applied in the field of plunger motors, can solve the problems of complex structure of MSF-46 motor, difficult connection and maintenance, complicated production process, etc., and achieve safe, stable and reliable operation, light weight and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

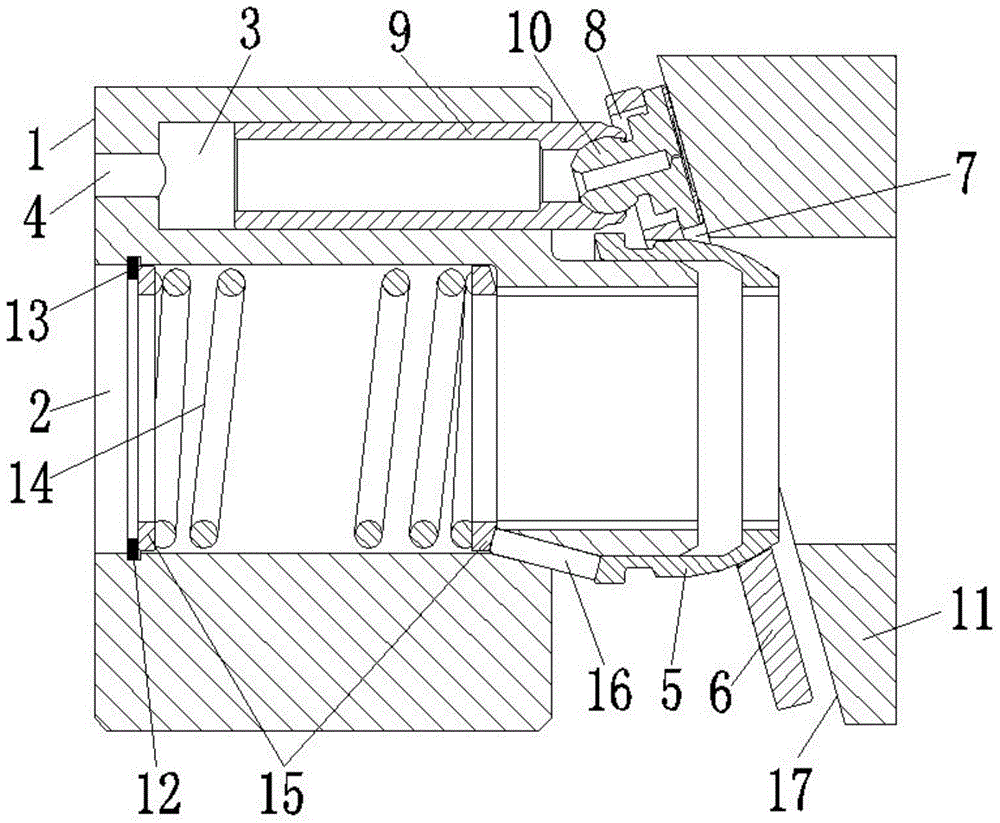

[0012] like figure 1 As shown, a swash plate hydraulic plunger motor according to the present invention includes a cylinder body 1, a through hole 2 penetrating both ends is provided in the middle of the cylinder body 1, and a side edge of one end of the through hole 2 is The through holes 2 are provided with plunger holes 3 at intervals, a flow channel 4 is provided at the bottom of the plunger holes 3, a ball joint 5 is provided at one end of the cylinder body 1, and a return plate is provided at the front of the ball joint 5. 6. The return plate 6 is a circular sheet structure, and a ball hinge support hole 7 is provided in the middle of the return plate 6, and at least five sliders are evenly arranged around the spherical hinge support hole 7 on the return plate 6. shoe guide hole 8, and on the same plane, the guide hole circle center of each slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com