Prestressed Concrete Continuous Box Girder Bridge Transverse Width Structure

A concrete and prestressed technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as uneven settlement, shrinkage and creep deformation, complex construction, etc., achieve easy transportation and installation, reduce earthquake response, and simplify construction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

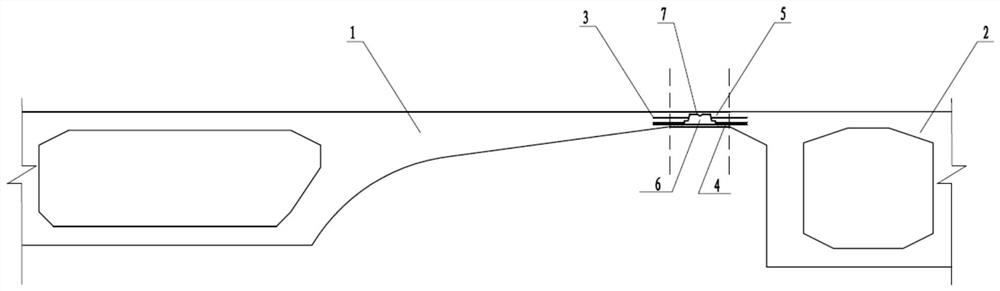

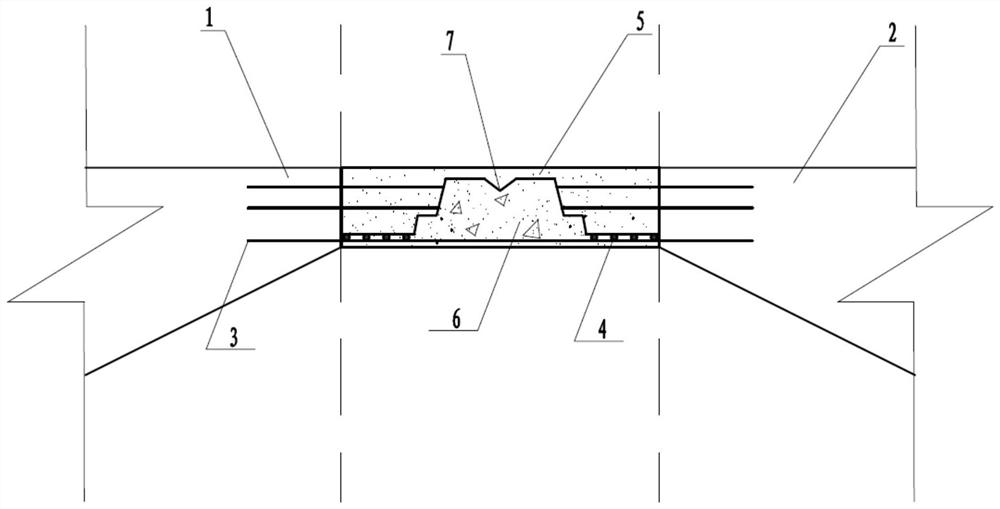

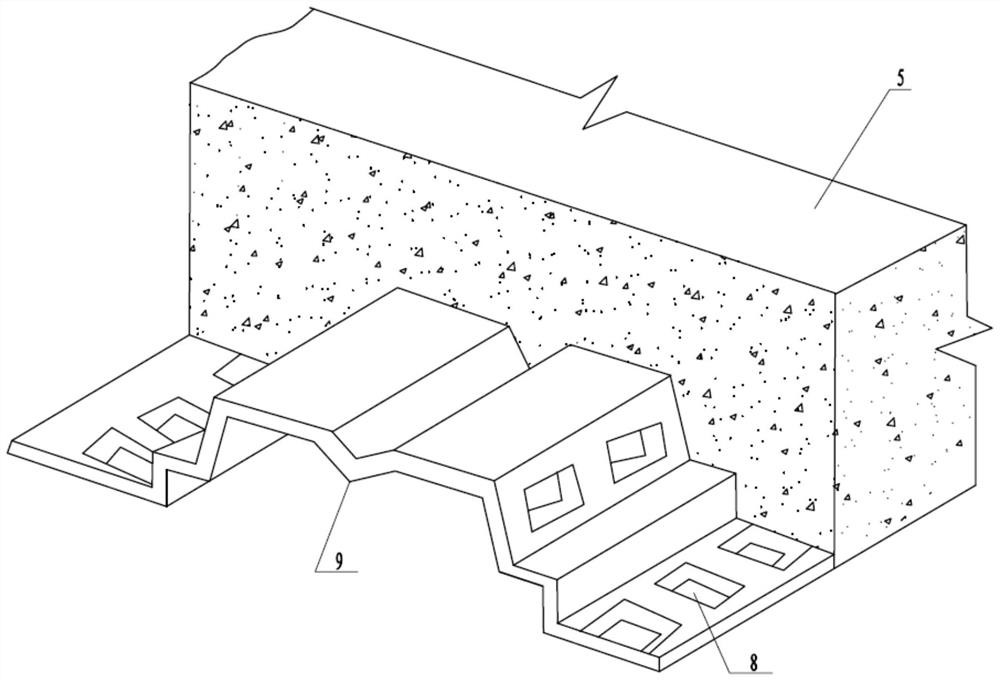

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-4 As shown, the prestressed concrete continuous box girder bridge horizontally widening structure includes profiled steel plates 7, a number of longitudinally distributed steel bars 4 are welded below the profiled steel plates 7, and the bottom of the longitudinally distributed steel bars 4 is welded to the connecting steel bars 3, and the profiled steel plates 7 are welded Both sides of the flange are welded with transverse connecting steel bars 3, and the profiled steel plate 7 is provided with indentation holes 8, and the top of the profiled steel plate 7 is poured with ECC high-toughness fiber-reinforced cement-based composite material 5, and the profiled steel plate 7 and ECC high-toughness fiber The reinforced cement-based composite materials 5 can work well together as a whole, and the superimposed surface between the two can withstand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com