Vertical assembling construction method for trussed arch bridge

A construction method and arch bridge technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., and can solve problems such as heavy construction workload, long construction period, and inability to realize rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions claimed in the present invention will be specifically described below in conjunction with the accompanying drawings.

[0019] A vertical assembly construction method for a truss-arch bridge, comprising:

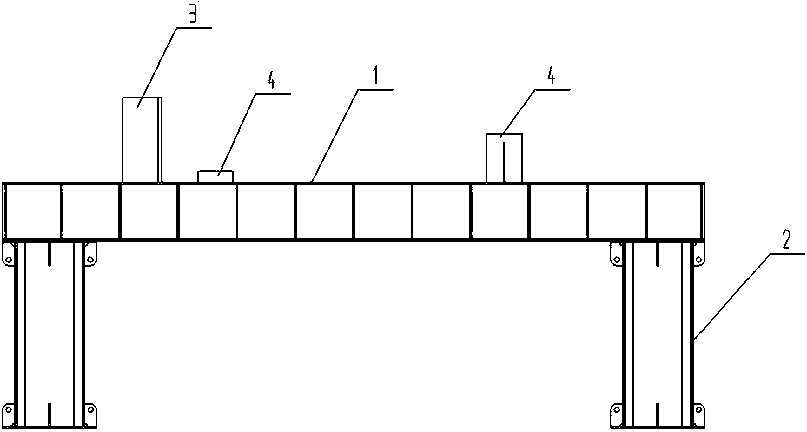

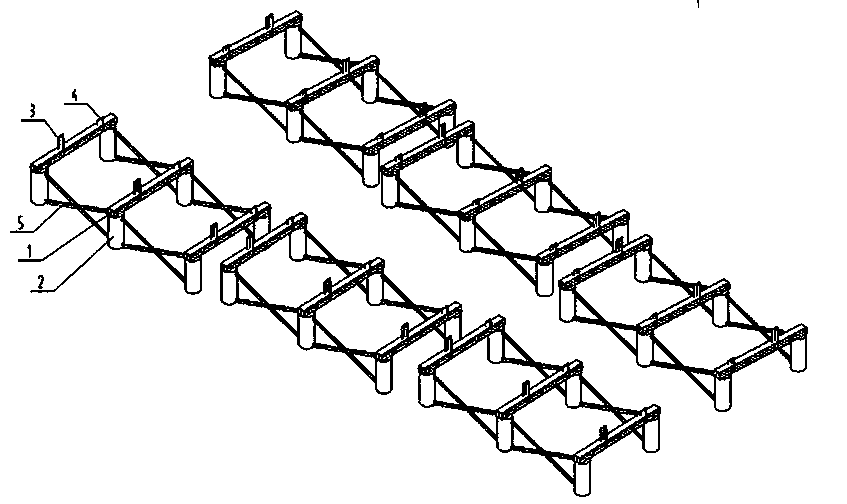

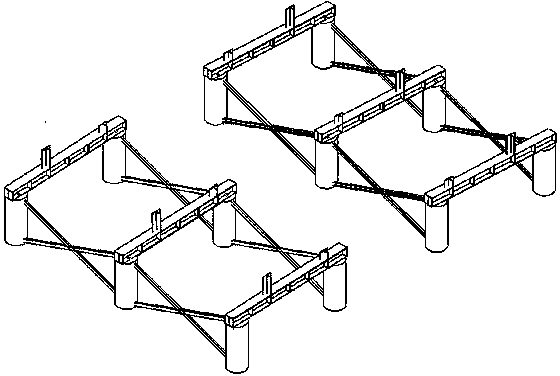

[0020] Step 1: Fabricate the tire frame. The tire frame includes a beam 1 and a column 2 fixed at both ends of the beam 1. A limiting plate 3 and a positioning plate 4 are installed on the upper surface of the beam 1; Cross support arm 5, through the cross support arm 5, the three frames are connected into tire frame groups, and the two tire frame groups placed in parallel are used as platforms for truss arch bridge vertical assembly;

[0021] Step 2: Assembling the arch rib segments of the truss arch bridge, hoisting and positioning the lower chord tube 6, the lower parallel tube 7, the web bar 8, the upper chord tube 9, the vertical support tube 10, Upper parallel pipe 11;

[0022] Step 3, place a hydraulic flatbed truck 12 on the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com