TIG (Tungsten Inert Gas) automatic surfacing method for projectile copper alloy conduction band

An automatic surfacing and copper alloy technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of low dilution rate of surfacing layer, poor welding quality, low welding efficiency, etc., and achieve the repeatability of welding process. Good, reduce the processing process, improve the effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

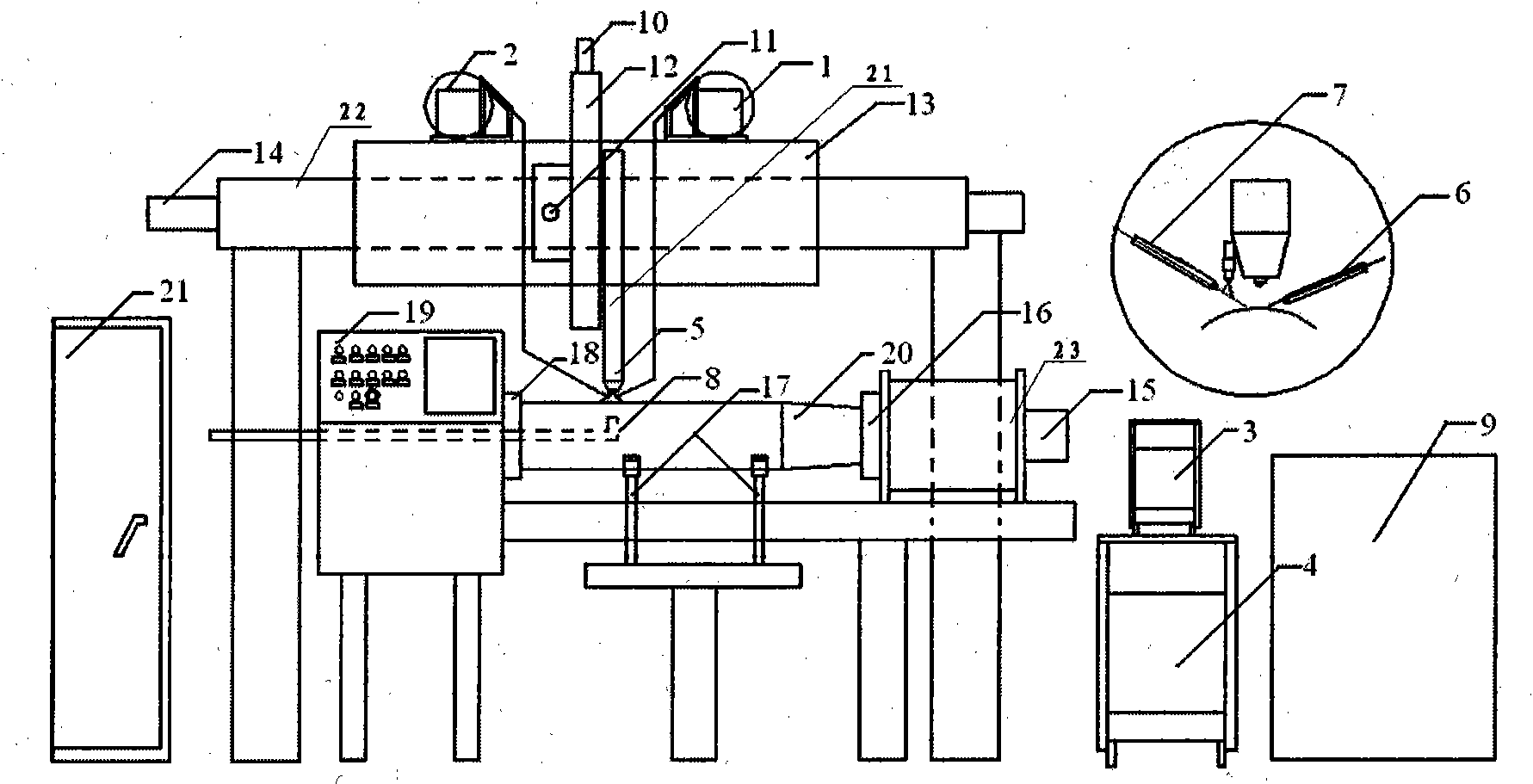

[0018] Embodiment 1, combining figure 1 , the TIG automatic surfacing welding method of shell copper alloy conduction band of the present invention is realized by the TIG automatic surfacing device of shell copper alloy conduction band, and it is made of welding system (21), welding system motion adjustment mechanism (22) and projectile body motion mechanism (23), the welding system (21) is connected to the welding system movement adjustment mechanism (22), and the welding system movement adjustment mechanism (22) is connected to the elastic body movement mechanism (23).

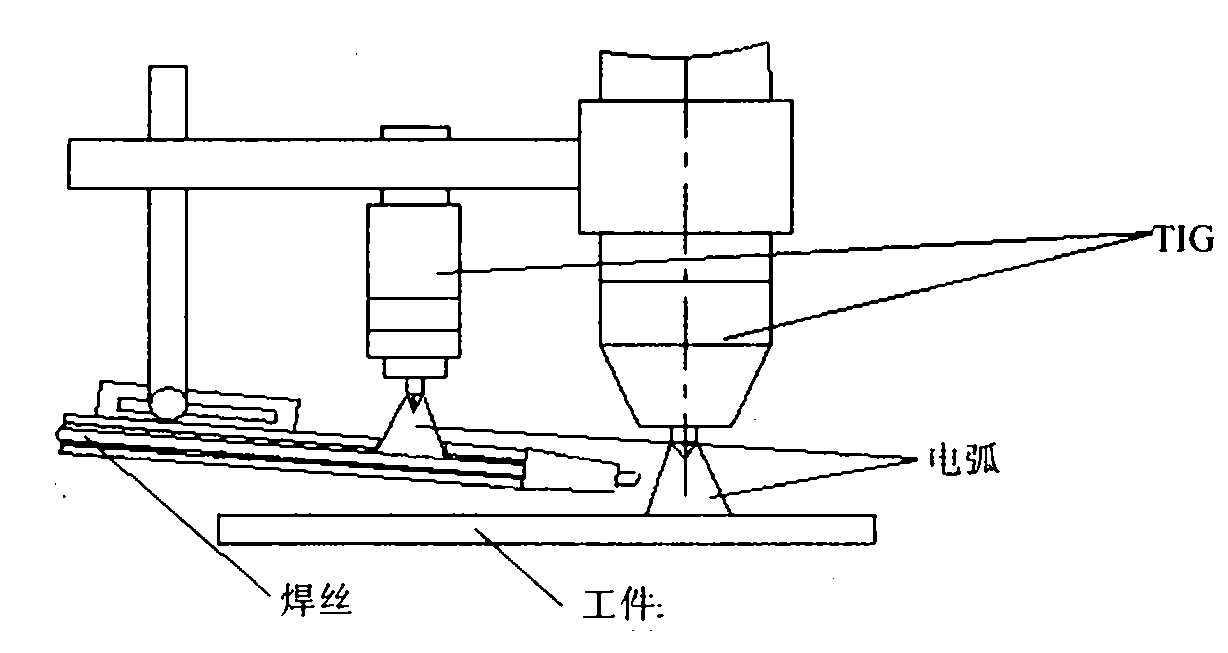

[0019] The welding system (21) includes a cold wire feeder (1), a hot wire feeder (2), a hot wire power supply (3), a TIG surfacing welding power supply (4), a welding torch (5), a cold wire Wire feeder (6), hot wire feeder (7), water shower pipe on the back of the body (8) and water tank (9), cold wire feeder (1) connected to hot wire feeder (2), hot wire The wire feeder (2) is connected to the hot wire po...

Embodiment 2

[0023] Example 2, combined with figure 1 , figure 2 , the present invention shell copper alloy guide band TIG automatic overlay welding method, welding process is as follows:

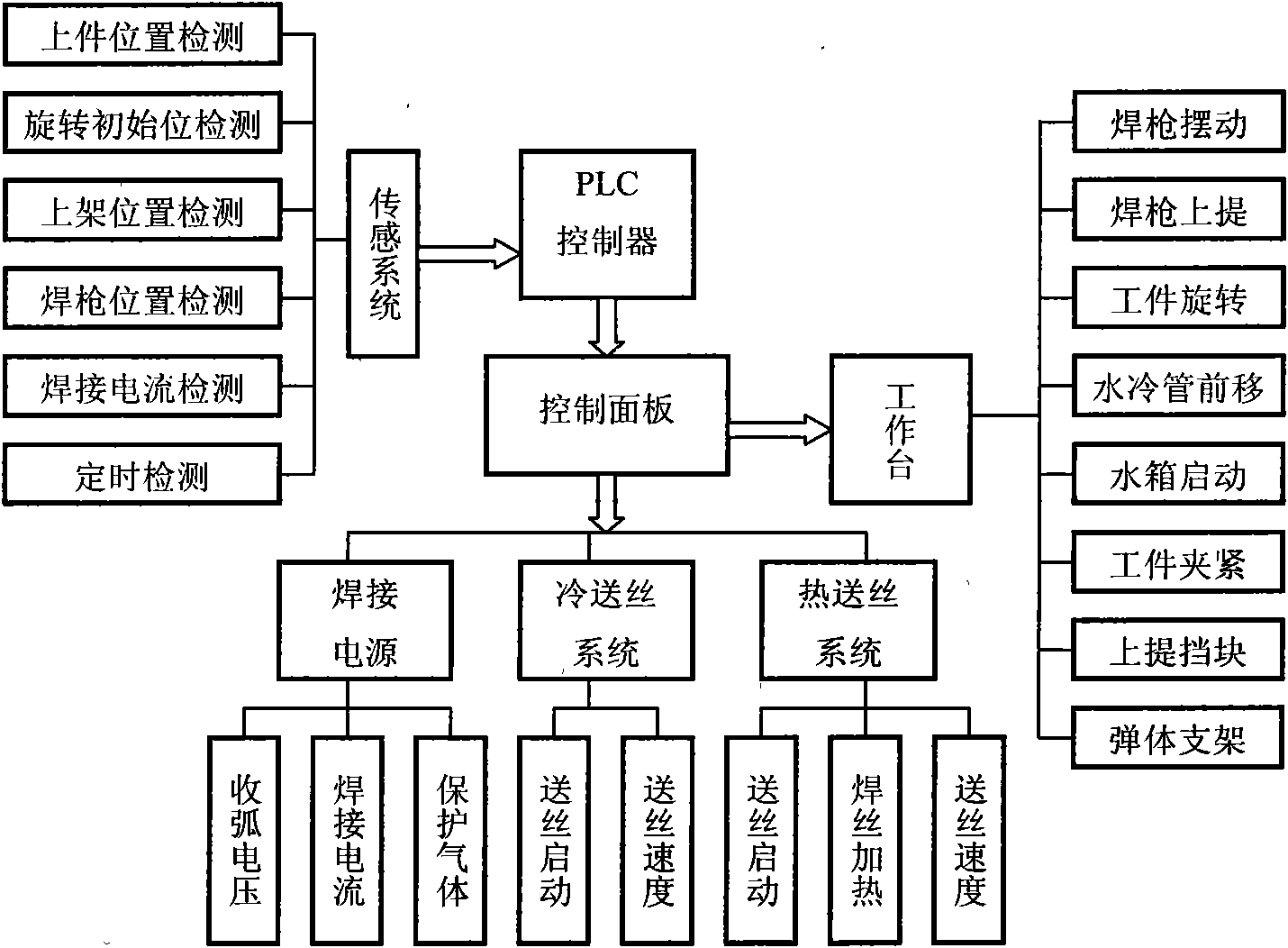

[0024] Step 1: Control the movement of the welding head and the welding workpiece through the PLC human-machine control interface. After centering the relative position of the welding torch and the workpiece, preset the welding current, projectile rotation speed and rotation mode through the PLC, and the uniform speed and stepping two One mode, the projectile body adopts the uniform rotation mode when the surfacing welding is relatively narrow, and the stepping rotation mode is used when the surfacing welding elastic belt is wider, the cold wire, hot wire feeding speed, welding head swing amplitude and speed, and arc lifting time and current parameters, real-time observation and adjustment;

[0025] Step 2: Before the welding arc is ignited, pass cooling water to cool the welding torch and projectile...

Embodiment 3

[0028] Example 3, combined with figure 1 , to realize the TIG automatic surfacing device for shell copper alloy guide belt of the present invention, with automatic feeding and clamping mechanism, the welding head can automatically swing according to the required belt width, and the welding head can realize free movement in the X-Y two-dimensional direction At the same time, it can realize the adjustment of the Z direction to realize the centering of the welding torch and the surfacing projectile; the projectile can carry out two rotation modes of uniform speed and step rotation under the action of the projectile rotation drive system, and the constant speed rotation is suitable for narrow elastic belts For welding, step rotation is suitable for welding with wider elastic bands. All welding parameters can be pre-set by the control panel and can be controlled and adjusted in real time. The movement mode of the workpiece is: the projectile to be surfacing is fixed by the pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com