Novel fastening structure for through belt of low-speed diesel engine

A technology that penetrates through bolts and fastens structures. It is applied in the field of diesel engines. It can solve problems such as thread rot in threaded holes, inconvenient repairs, thread scratches, etc., and achieves the effects of reducing manufacturing costs, reducing installation and disassembly time, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments, in order to understand the structure and installation process of the present invention more clearly, but this should not limit the protection scope of the present invention.

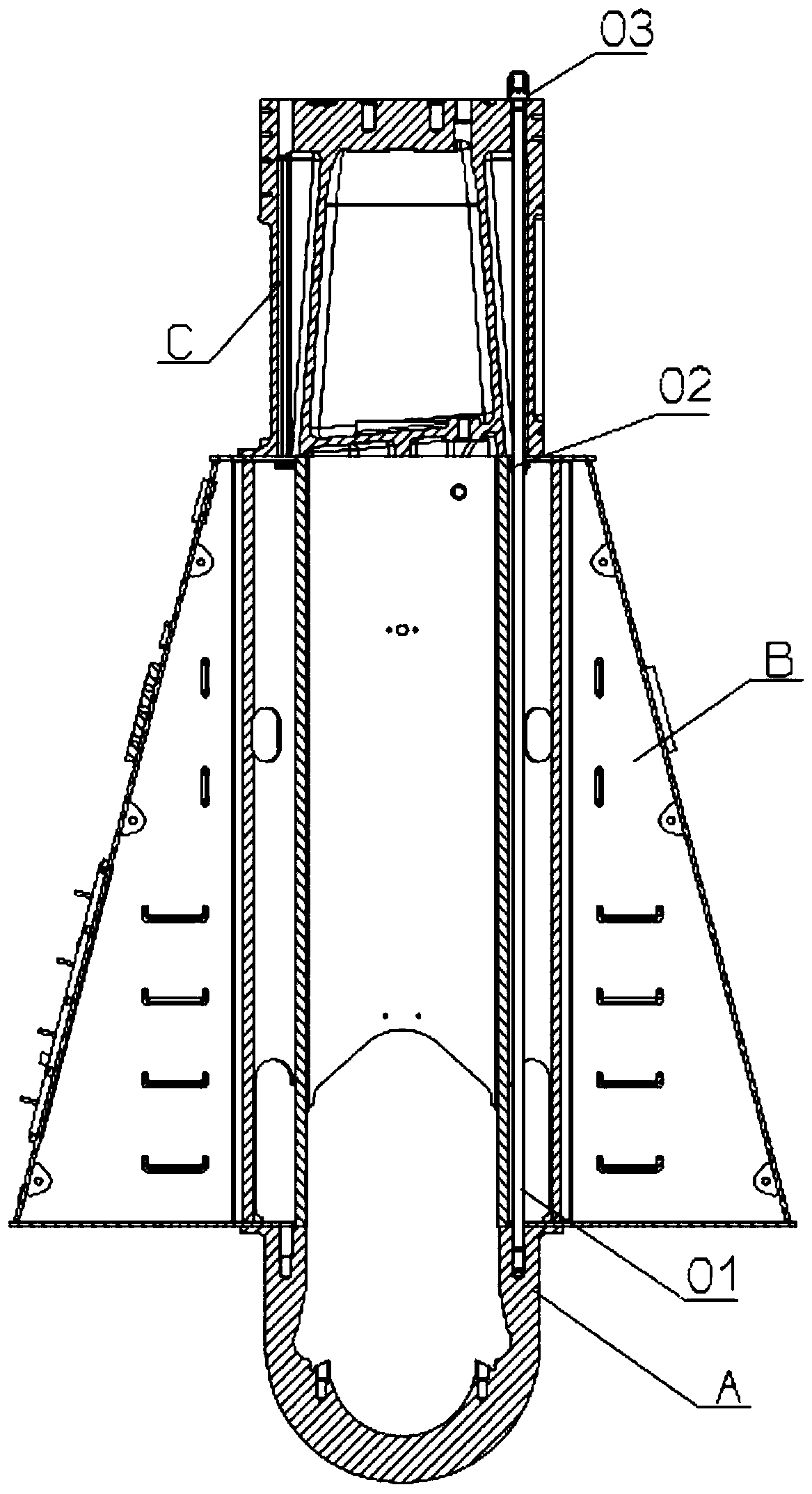

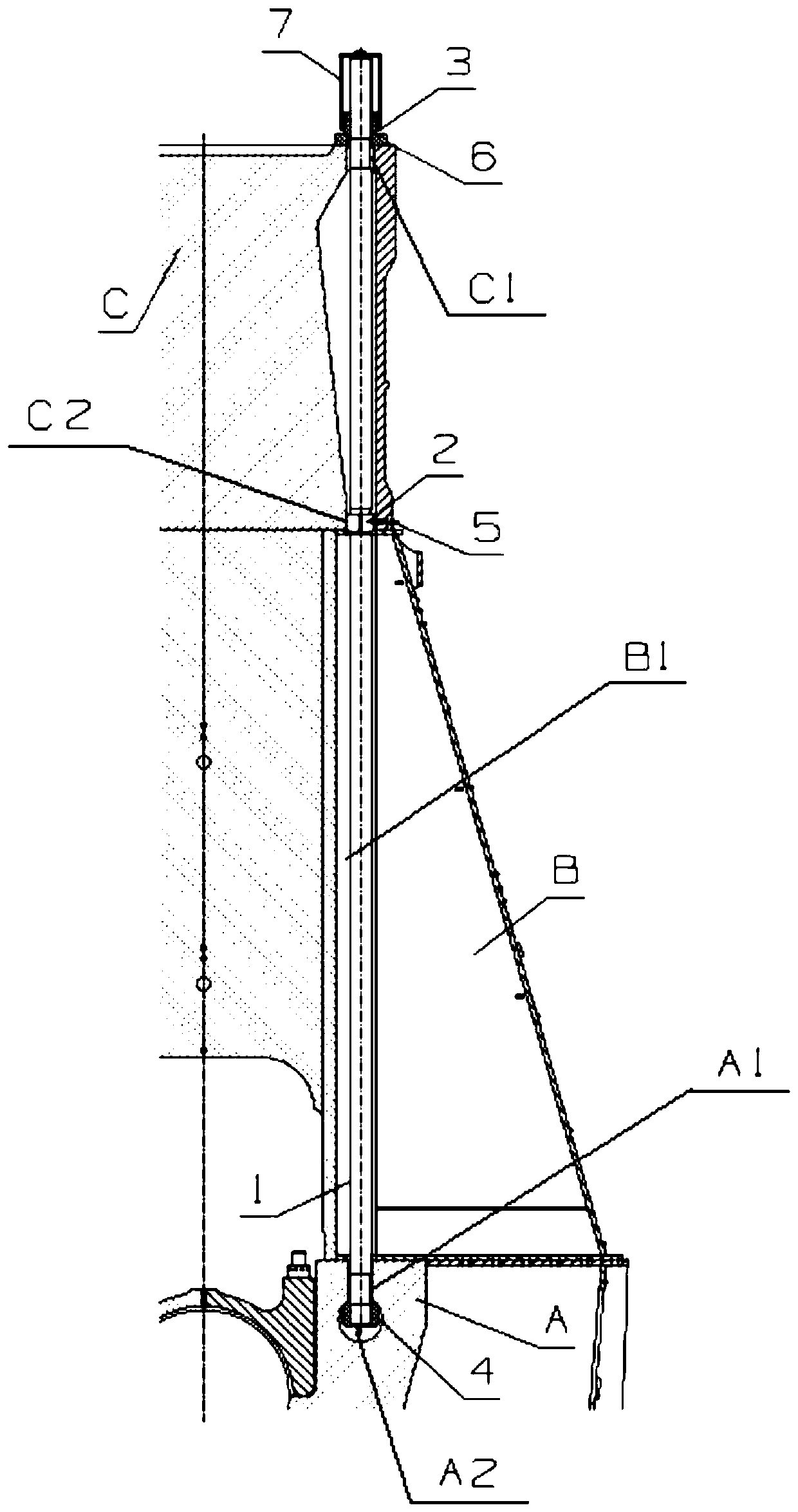

[0032] see figure 2 , the new fastening structure of the through bolt of the low-speed diesel engine runs through and fastens the base A, frame B and cylinder block C of the marine low-speed diesel engine, and the upper part of the cylinder block C is provided with a vertical upper fixing channel hole C1, the lower part is provided with a middle fixing through hole C2, the frame B is provided with a vertical through hole B1, and the base A is provided with a vertical lower fixing through hole A1 and a horizontal horizontal mounting hole A2 The horizontal mounting hole A2 is located at the lower end of the lower fixing through hole A1 and forms an inverted "T" through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com