Full-automatic production device and production process for middle-buried rubber waterstop

A technology of rubber waterstop and production equipment, which is applied in the direction of applications, household appliances, household components, etc., to achieve the effect of simplifying the preparation process and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

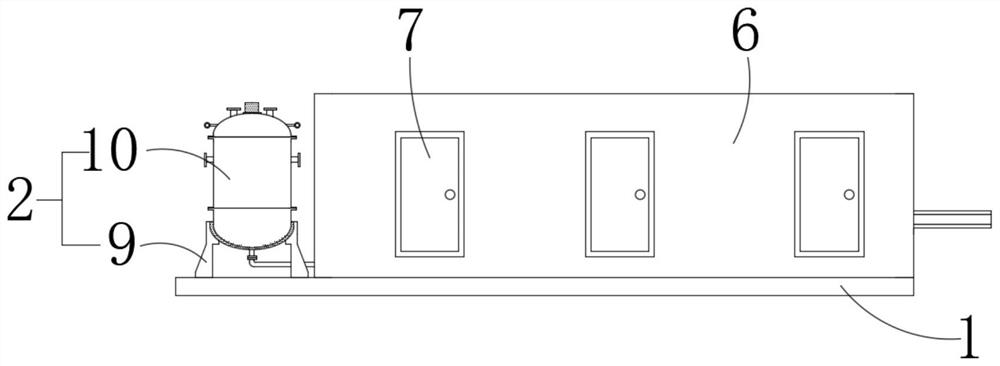

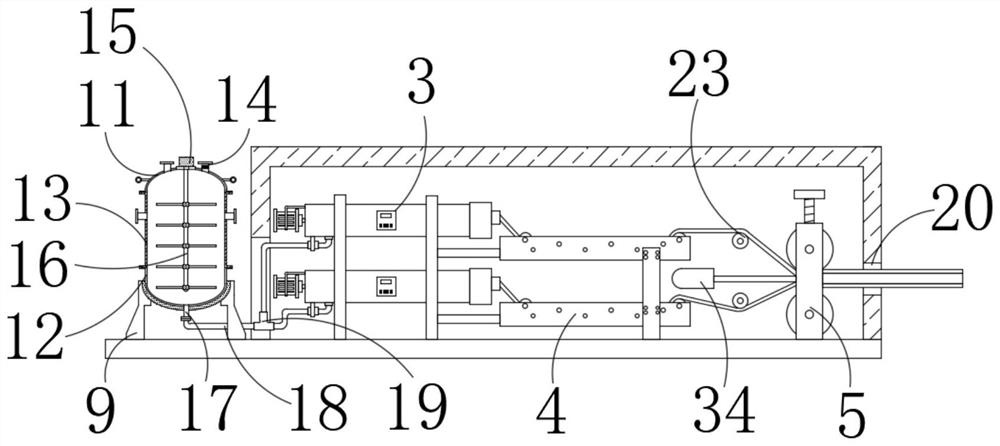

[0037] The present invention provides such as Figure 1-6 As shown, a fully automatic production device for a buried rubber waterstop includes a base 1 and a protective casing 6, and the upper end of the base 1 is respectively provided with a raw material mixing component 2, two sets of extruders 3, corresponding two The cooling water tank 4 and the forming and pressing component 5 of the group extruder 3, the raw material mixing component 2, the cooling water tank 4 and the forming and pressing component 5 of the extruder 3 are arranged in sequence;

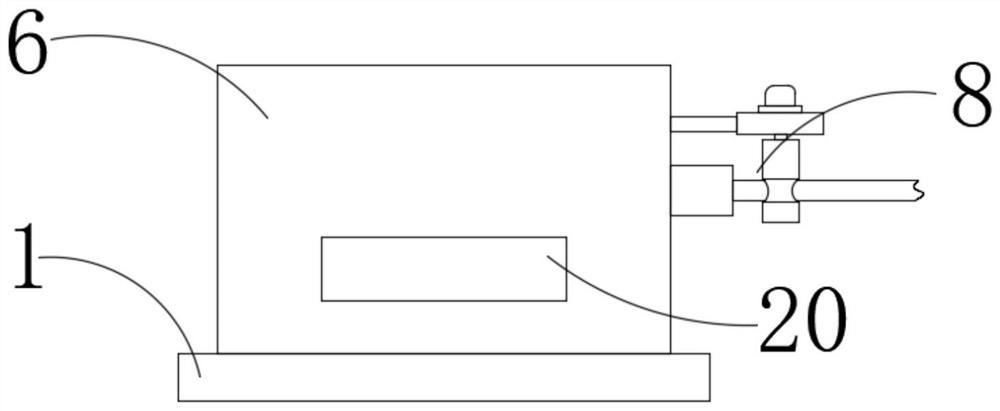

[0038] The protective casing 6 is installed on the base 1, the cooling water tank 4 of the extruder 3 and the forming and pressing assembly 5 are located inside the protective casing 6, an inspection door 7 is opened on the side wall of the protective casing 6, and the protective casing 6 and the inspection door 7 are provided. A hose feeding assembly 8 is arranged on the opposite side wall;

[0039] The raw material mixing ass...

Embodiment 2

[0044] On the basis of Embodiment 1, this embodiment is further refined, and the scheme is as follows:

[0045] Conveying rollers 21 are arranged inside the cooling water tank 4 and located at both ends respectively, and several groups of guide rollers 22 are arranged inside the cooling water tank 4. The installation levels of several groups of guide rollers 22 are staggered. The inner side of the protective casing 6 Two sets of feeding rollers 23 are respectively arranged on the wall. The two sets of feeding rollers 23 and the feeding rollers 21 of the two sets of cooling water tanks 4 are located at the same level, and the two sets of feeding rollers 23 are located in the cooling water tank 4 and the forming and pressing components. between 5;

[0046] The forming and pressing assembly 5 includes a first indented frame 24, an active pressing roller 25 and a moving pressing roller assembly 26. One side of the first indented frame 24 is fixedly mounted with a second driving mo...

Embodiment 3

[0051] On the basis of Embodiment 1 and Embodiment 2, the present embodiment provides a production process for a middle-buried rubber waterstop, comprising the following steps:

[0052] S1, mixing, adding the raw materials of the buried rubber waterstop in production into the raw material mixing component, and adding auxiliary materials, and heating, mixing and stirring through the raw material mixing component;

[0053] S2, conveying the material, the material in the raw material mixing component is drawn out through the extruder feed pump, and then added to the two groups of extruders respectively;

[0054] S3. Extrusion molding, extruding the prefabricated rubber sheet of the buried rubber waterstop through two groups of extruders respectively;

[0055] S4. Cooling at a constant temperature, respectively cooling the two groups of prefabricated rubber sheets through the cooling water tank. At this time, the cooled prefabricated rubber sheets are not completely cooled, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com