Drilling and sealing method for gas drainage from coal seam

A technology for extracting gas and coal seam, which is applied in the field of drilling and sealing for gas extraction in coal seams, can solve the problems of complicated sealing process, gas leakage in drilling, shallow sealing depth, etc., achieves good sealing and isolation effect, and avoids waste of resources. , The effect of large sealing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

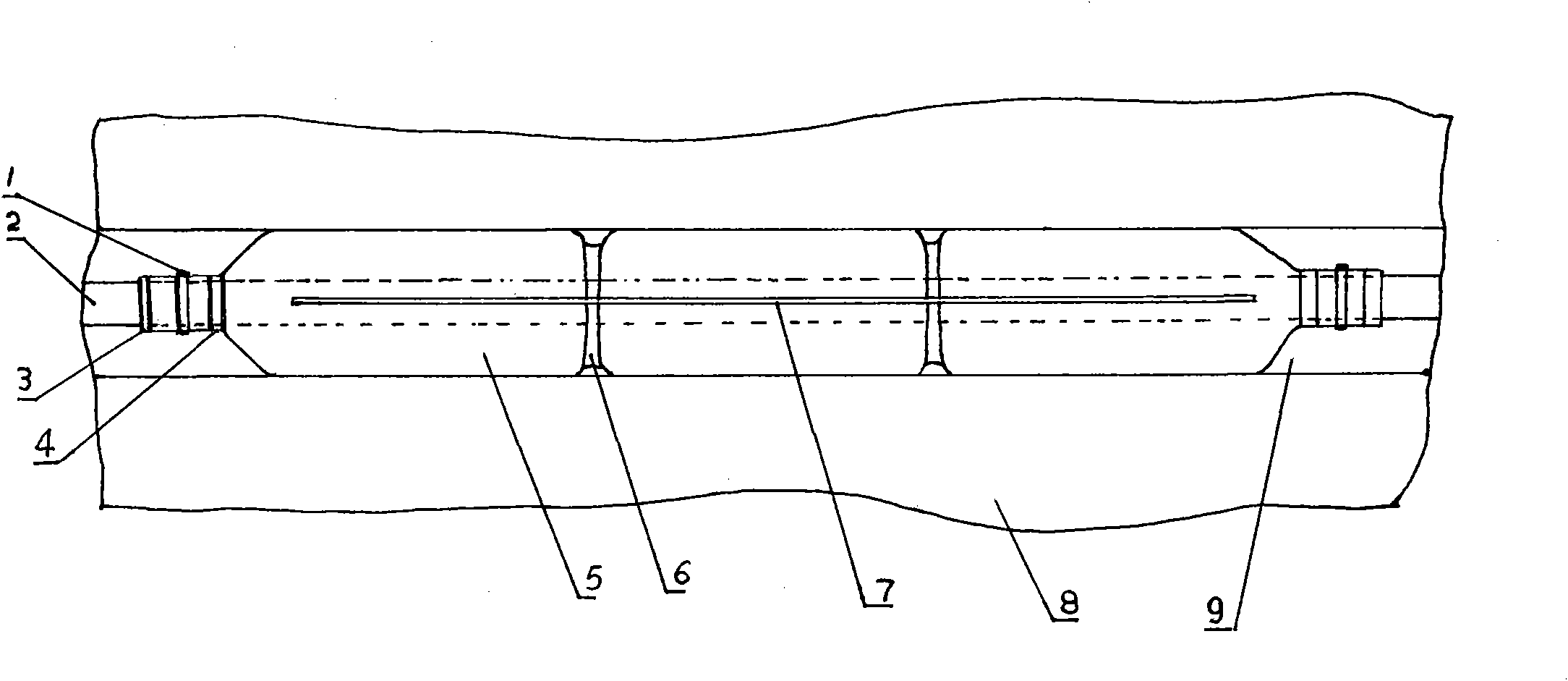

[0014] Both ends of the tubular cloth bag 5 have two adhesive buttons 3, 4 and a snap ring 1 respectively, and the two adhesive buttons 3, 4 are located on both sides of the snap ring 1 respectively. The clasp 1 is made of a thin steel plate with a thickness of 0.3-0.5 mm and a width of 10 mm, and its size matches the outer circumference of the gas extraction pipe 2 .

[0015] The gas extraction pipe 2 penetrates through one end of the tubular cloth bag 5 and exits from the other end; fasten the adhesive buttons 3 and 4 at both ends of the tubular cloth bag 5 and fasten the snap ring 1 so that the tubular cloth bag 5 and the gas extraction The sampling pipes 2 are tightly connected together. The tubular cloth bag 5 is provided with two tightening belts 6 to prevent the cloth bag from falling down along three equal parts of the length direction. Open the zipper 7, quickly put the filling material with expansion properties into the tubular cloth bag 5, close the zipper 7, and q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com